- Automatic transmission automatic transmission repair

- Manual transmission repair

REPAIR of gearboxes of any models of MANUAL GEARBOXES of passenger cars and trucks

sale | replacement | buy gearbox repair and restoration of shafts | argon welding of manual transmission housing, Moscow

Artem 8 965 126 13 83 Vadim 8 925 675 78 75

Complete vehicle diagnostics during repairs – free of charge!

Having a high level of professionalism, extensive experience in repairing gearboxes, and our own warehouse of spare parts, we carry out diagnostics, sale, replacement and repair of all types of manual transmissions for cars of Domestic, European, American, Asian (including China) production, passenger cars, trucks and special vehicles. . Box repair begins with an initial, mandatory free diagnosis.

Cost of work for gearbox repair:

| car entry diagnostics | for free |

| removal and installation /independent of the vehicle drive/ | 5,000 rub. |

| disassembly and assembly | 5,000 rub. |

| Replacing the clutch at the request of the car owner | 2,000 rub. |

| filling the gearbox with transmission oil | for free |

A range of services for repairing a manual gearbox:

- consultation with a repairman /by phone free of charge/

- delivery of the car for repair /within Moscow RUB 3,000. From the Moscow region and other regions of the Russian Federation - by agreement/

- comprehensive vehicle diagnostics / determination of the presence of a malfunction in the engine, gearbox, ABS, brake system; checking the vehicle's electrical circuits for corrosion, checking the kinematic damage of the unit, checking the transmission oil level, checking the functionality of the clutch hydraulic system/ - free of charge during repairs

- visual inspection, body integrity check

- checking the transmission oil content for the presence of steel, aluminum or bronze chips

- opening the pallet /if necessary/

- removal from the car

- disassembly, washing of parts and assemblies

- defect detection /presence of the car owner is mandatory/

- agreement with the car owner on the cost of complete repairs and the completion date of the repairs

- receipt from the spare parts/repairs warehouse. kit, consumables, components/

- repair / argon welding / gearbox housing if necessary

- assembly

- clutch replacement /at the request of the car owner/

- car installation

- refilling with transmission oil

- output diagnostics and test drive of the car

Warranty from 3 to 24 months or 60,000 km. mileage

| Phone number of the repairman: | Artem 8 /965/ 126 13 83 Vadim 8 /925/ 675 78 75 |

| Tow truck assistance /24/7/, dispatcher: | 8 /926/ 167 15 40 8 /985/ 888 68 14 |

We have a stock of restored manual transmissions /see article replacement/. If the car owner wishes, we can replace the faulty one with one taken from the exchange stock, which is often more economically feasible.

Prices for additional work

| № | Job title | Sum |

| 1 | Comprehensive troubleshooting of manual transmission (disassembly - assembly) without repair | 4000 |

| 2 | Oil change and manual transmission diagnostics | 2000 |

| 3 | Removal and installation (without repair) | 8000 |

| 4 | Replacing the clutch with the box removed | 2000 |

Spare parts for manual transmission repair:

- economy - from 3,000 to 8,000 rubles. /use, at the request of the car owner, only used parts to reduce the cost of repairs/

- business - from 8,000 to 18,000 rubles. /replacement of only directly damaged parts in the unit/

- executive - from 18,000 to 40,000 rub. /replacement, regardless of damage, as a set: oil seals, carrier bearings, needle bearings, synchronizers, stoppers, coupling hub locks - plus directly damaged parts/

- SUVs, minibuses - from 12,000 to 40,000 rubles.

Our own warehouse of spare parts necessary for repairing gearboxes. Bearings, seals, gears, synchronizers, gear couplings, shafts, differentials are in stock and on order for all makes of cars.

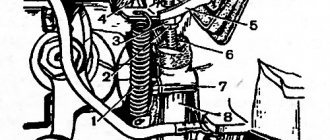

An example of disassembling and assembling a manual transmission:

See the manual transmission diagram below the text...

Manual transmission repair (part 1)

Manual transmission repair

has become one of the popular services of our workshop in Moscow. Although modern automatic and robotic transmissions have become widespread, manual transmissions continue to be in demand. We repair transmissions of domestic and foreign cars; experienced mechanics will be able to quickly restore the gear shift mechanism and guarantee its long-term trouble-free use. Order qualified repairs with free diagnostics, as well as a warranty card.

Why do manual transmission malfunctions occur?

The mechanics work on a simple and effective principle: torque is transmitted from the engine through the clutch mechanism to the wheels through the primary and secondary shafts, it is changed using pairs of gears - stages. Gears vary in size and number of teeth, which determines whether the torque is reduced or increased. This design does not have complex electronics; the unit operates independently of the battery. Mechanics make it possible to control the speed limit of the car and independently engage the gear at the right time.

Due to the simplicity of the design and the absence of electronics, such a unit can last up to 250 thousand kilometers and even more. However, some factors significantly shorten its use:

- Late oil change

or poor quality. The recommended service interval is about 60 thousand kilometers traveled, during which time the lubricant becomes contaminated with metal shavings and loses its effectiveness. Its contamination leads to damage to the surfaces of parts and overheating of the unit. - Aggressive management style. Sharp jerks from a stop, quick starts, instant braking, sharp turns - all this puts an increased load on the gearbox and provokes accelerated wear of parts.

- Driving on broken roads, mud, snowdrifts. When parts slip, they suffer from increased load, which provokes premature failures.

- Incorrect gear shifting. Each of them has its own speed range, violation of which leads to rapid destruction of parts.

Most premature breakdowns occur precisely because of operational violations. After the repair, the technician will tell you how to avoid repeated malfunctions.

description and instructions with video

Generator "Kalina": disassembly, diagram, device and description

This is not a particularly breakable gearbox part and rarely requires replacement. But it happens periodically. In this article we will show you how to remove the gear shift lever on a VAZ 2107.

Where is

It is located in the car interior, below the dashboard, to the right of the driver (or to the left if the car is right-hand drive). It is used to change gears in the gearbox.

The shift lever is a reliable and stable part. But due to careless and careless use, it also breaks. If you suddenly begin to grab the control lever or press on it, then repairs cannot be avoided. Before you start replacing the VAZ 2107, you need to understand how to remove it from the box.

Common illnesses include rattling and loose handles. Let's call this the first stage. If you do not fix the problem immediately, you will have to completely replace the element in the future. This part, like others in the car, must be treated with care and calm. Don’t pull it, hurry up and press it into the “feeder”. If the gears do not shift smoothly and comfortably, then you probably did not press the clutch all the way, or there are problems with the gearbox. And you need to repair it, not the handle.

They will help us:

- wrench;

- screwdriver.

Instructions

- Place the VAZ 2107 car on stands.

- Eliminate the exhaust system and remove the thermal protection valve.

- First remove the cover from the handle.

Removing the cover - Remove the retaining clip and washer. And take out the shift rod, it is located on the side.

- Place a wrench at the bottom and turn it 90 degrees. Press out the spherical liner.

- Pull out the handle.

- Lubricate the liner with lubricant.

- Install the handle with the insert (the arrows should indicate the direction of the longitudinal axis).

- Press down on the liner from above. Secure it.

- Attach the cover so that the arrow points forward.

- Place the washers and insert the rod. Screw on the bracket.

- Replace the thermal protection valve, as well as the exhaust system.

- Secure the cover and put on the handle. Record the state.

Now you know how to make this replacement on a VAZ 2107. We hope that our article was useful. Let your car work long and well.

Video “Replacing the gearshift lever”

We offer you to watch a video that shows how to change the lever.

How to recognize gearbox problems?

Problems with manual transmissions often develop gradually, many of them can be detected in the early stages so that repairs can be carried out inexpensively

. The following symptoms often indicate problems:

- Noisy operation of the gearbox. As friction increases, various extraneous sounds arise, which are important to pay attention to in time. After diagnostics, the technician will replace worn gears, shafts or other components, and also fill in new transmission fluid.

- Humming due to faulty input shaft bearing. If it is damaged, an increasingly noticeable sound will occur; it is important to contact a workshop in time for a replacement.

- Oil leaks on the housing resulting from a leak. This malfunction must be corrected urgently, as a lack of lubrication will lead to unpleasant consequences.

- Difficulty shifting gears, lever play. Problems with the switching mechanism can be quickly resolved if you immediately contact professionals for help.

If there are any deviations from the norm in the operation of the gearbox, please contact our specialists for help. Qualified repair technicians will conduct a free diagnosis and then replace all damaged parts with new ones.

How to dismantle the gearbox lever of a VAZ 2107

If you had problems with play in the bushings, then you need to purchase a repair kit for the VAZ 2107 gearbox handle in advance and after dismantling it.

Before starting work, prepare a screwdriver.

- Set the box to neutral.

- Slide the cover.

- Push the damper locking sleeve down with a screwdriver.

- Remove the rod with the knob.

- Remove the remaining bushings from it.

- Replace them in reverse order as shown in the picture.

Before reinstalling, fully assemble the rod and bushings, slide it onto the lever, and push down sharply to seat it in place.

If you need to completely replace the rocker, then add a 10mm wrench to the screwdriver (preferably a socket or socket):

- remove the decorative panel;

- unscrew the boot;

- use a 10mm key to unscrew the mechanism;

- remove it from the box.

After repair or replacement, assembly is performed in the reverse order.

The quality of bushing repair kits leaves much to be desired and the backlash of the rod remains quite large, so some, instead of plastic and rubber bushings, simply select a simple hose according to size and attach it to it.

Advantages of our auto repair shop

A specialized workshop works specifically with gearboxes of any type: thanks to many years of experience, we successfully carry out repairs of any complexity and guarantee reliable results. Mster will dismantle and disassemble the gearbox, in the presence of the client, check the condition of the parts and prepare a list of components for exchange. Choose everything you need for repairs from us: on sale

You can find new and

used

parts.

It is also proposed to buy a manual transmission

for a complete replacement. You can choose a new or remanufactured unit to install the complete transmission and ensure that problems do not reoccur. This work takes a minimum of time, and a warranty card is provided for the longest possible period. Choose a time for diagnostics and take advantage of convenient ordering conditions.

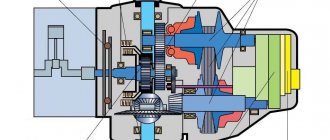

Manual transmission diagram (example) housing

input shaft

output shaft

gear selection

differential

Transmission repair: transmission repair

Order professional gearbox repair

in our workshop in

Moscow

at low

prices

.

Despite its high reliability, a manual transmission periodically fails: any problems can only be repaired by a specialist. Timely contacting a car repair shop will minimize costs; many faults inexpensively

eliminated in the early stages. Take advantage of the convenient conditions to get your machine back to work in the shortest possible time and receive a quality guarantee. We work with Russian cars and foreign cars; many years of experience allow us to quickly deal with any transmission breakdowns?

How does a manual transmission work: principle and advantages

Manual transmission: a simple design and reliable unit that can last as long as the engine itself. Unlike the automatic

or a robot, its operation does not depend on the battery, which will allow you to start the car even if there is a problem with the car’s electrical system. The mechanics are controlled only by the mechanical force of the driver, which allows you to fully control the car and independently choose the moment to engage the gear.

A manual transmission operates on the following principle: torque is transmitted from the engine through the clutch mechanism to the input shaft, and from there to the wheels with a change in gear ratio. For this purpose, pairs of gears are used - degrees having different numbers and sizes of teeth. An increase in torque results in a decrease in speed and vice versa, in the first case the gear will be called a reduction gear, in the second – a reduction gear.

Depending on the design, a manual transmission can be two-shaft or three-shaft: the first type is used primarily for front-wheel drive passenger cars, the second - for rear-wheel drive cars and trucks. Mechanics have several advantages over other types of gearboxes:

- Low cost compared to automatic and robot.

- High efficiency, which ensures fuel savings.

- Reliability due to the simplicity of the design and the absence of complex system components.

How to install the gearshift lever

All work is done in reverse order. Depending on the model, some nuances may vary. For example, Passat cars often have problems getting the lever into place. The reason lies in the fact that the lock button, which needs to be fixed, returns to its original position. You have to unclip the latch from inside the handle to put it in place.

Replacing an automatic transmission lever by an unqualified technician is fraught with incorrect installation, which leads to incorrect operation of the system and failure of the sensor readings. Contacting a specialized service will eliminate such consequences and eliminate the risk of repeated repairs.

Sometimes car owners are faced with the problem of removing the gear shift lever. This procedure must be carried out when replacing the silent blocks of the lever or extension, as well as when replacing the lever itself. The extension is removed to replace the silent blocks on it or to completely disassemble the front suspension. Since these repair procedures are not very difficult, you can remove the lever yourself rather than contact a service station for help.

Advice:

It is advisable to carry out the work in the presence of an inspection hole or a lift.

Common problems with gearbox operation

Although such a unit can last up to 250 thousand kilometers, breakdowns often occur much earlier than planned. Malfunctions may be associated with accelerated wear due to untimely oil changes

, aggressive driving style, incorrect gear shifting, and other factors. Manual transmission does not like driving with slipping, increased mechanical loads on parts when driving on broken and dirty roads.

Transmission repair

may be required for the following common reasons:

- Bearing wear. Most often, the input shaft bearing fails; its problems can be detected by a characteristic hum.

- Wear of shafts, gears and other components. Part surfaces are damaged more quickly when contaminated or low-quality oil is used. The problem in the initial stages is often manifested by extraneous sounds in the gearbox.

- Worn seals, which leads to oil leakage.

- Damage to the linkage, resulting in problems with gear shifting.

- Knockout of gear due to wear of gear teeth and other reasons. In case of such malfunctions, it is necessary to seek professional help as soon as possible in order to prevent a decrease in the car’s controllability.

Order from our workshop in Moscow

free diagnostics to accurately identify the causes of gearbox malfunctions. After inspection, the repair will be completed as soon as possible.

Removing and installing the gearshift lever on a VAZ 2107

The VAZ 2107 gear shift lever is used to enable the driver to control the car, which is possible using a gearbox. The gearbox, in turn, is a mechanism inside which there are gears of different diameters. This device is the link between the engine and the drive wheels of the car. For rear-wheel drive cars, which is the VAZ 2107, the manual transmission is typically located under the lever itself. To connect the lever to the gearbox, no additional link is required, as is typical for front-wheel drive car models. The VAZ 2107 rocker is presented in the form of a small half-bent tube onto which the gearshift lever itself is placed. In the material we will pay attention to the question of how to replace it, as well as the features of dismantling.

Device location and characteristics

The gearshift lever of the VAZ 2107 is located directly in the car's interior. It is used to be able to change gears while moving. The gear lever fails only in rare cases, and the reason for this is negligence towards the product. If the product fails, it must be replaced. But before replacing, it is necessary to remove the product in question. We’ll find out in more detail how to remove it, as well as replace it on the “seven”.

On the “seven” the gear shift knob has a common problem - rattling and chattering. If you fix such a malfunction using improvised means, then replacing the device will not be necessary. Before you begin replacing the device, you will need to find out the exact causes of the malfunction. After all, sometimes not only the part in question can “fail,” but also the gearbox or clutch.

If you are convinced that it is the gearshift lever that is faulty, then only then should you start replacing it.

Replacement features

Before you begin the replacement, you need to stock up on tools such as wrenches and a screwdriver. We start with the following steps:

- Set the lever to neutral position.

- After this, you need to slide the top cover up. There is no need to completely remove the cover.

- The next step is to move the cover, which is located below, to the top. This cover is also called a thermal protection valve. In the photo below it is shown with a red arrow.

- Now you need to press the device, pushing it to the bottom. After this, you need to insert a screwdriver into the lower part of the product, where the plastic sleeve is located. The bushing is located at the very bottom of the device, as shown in the photo below.

- It is necessary to move the locking sleeve to the lower part, and then remove the product from the box.

- If the device emits strong vibrations, it needs to be replaced with a new one. In this case, you can exchange the part for a product of shorter length, as on foreign cars. A short device is much more comfortable to operate than a standard product.

Many motorists replace the standard gear shift levers with more modern ones, which allows them to uniquely customize the interior of the Seven.

After the standard product is dismantled, we install a new handle in its place. Let's look at what the installation is.

Installing the device on a VAZ 2107

After the standard mechanism has been removed, you will need to remove the rubber bushing from it, if it remains inside. To remove the bushing, you need to use a screwdriver or hook. By prying the sleeve, we remove it from the device, as shown in the photo above.

If you plan to install a standard product in place, then it is advisable to replace the bushing by purchasing a repair kit in advance. When choosing a repair kit, preference should be given to products manufactured by VAZ. The installation process is similar to removing the device. Initially, a rubber bushing is installed, recessing it into the device. Following the bushing, it is necessary to install a rubber band in the form of a washer, which softens the control of the mechanism. Next, you need to install a plastic lock inside the mechanism, due to which the device is fixed to the gearbox “scene”. The assembly is completed by installing the locking sleeve, which had to be moved down at the initial stage in order to dismantle the gearbox lever.

Once the product is ready for installation, you will need to insert it into the drawstring. To do this, you should initially lubricate the slide, and then hit the mechanism handle well with your hand until you feel that the lever has settled into place. This is how the installation of both new and old mechanisms, which were dismantled to replace component parts, is carried out.

Self-tuning of the handle

Some drivers are not satisfied with the quality of repair kits for installation, and they came up with a kind of tuning of the gearbox handle itself: to reduce rattling and vibration going to the shift handle, instead of standard plastic bushings and rubber bands, they insert a piece of hose that fits the outer and inner diameters. This upgrade also allows for easier future installation of the handle.

Additionally, you can make the gear shifting process more convenient by slightly reducing the length of the standard handle. To do this, you need to remove the lever, cut it with a hacksaw to 5-6 cm in length and cut a thread at the end, the same as it was on the cut piece (if you wish, you don’t have to cut the thread). These upgrades are advisory in nature and have their pros and cons. Each driver decides for himself whether to produce them or not.

When choosing products for foreign cars, you should make sure that it can be reliably installed on the VAZ-2107. Otherwise, an incorrectly secured mechanism will lead to an emergency situation while driving.

provaz07.ru

How is the repair carried out?

Free diagnostics at a car repair shop will allow you to identify all existing problems and find the best way to eliminate them. Our specialists will dismantle and disassemble the gearbox, and parts will be defective in the presence of the client. The technician will make a list of components that require urgent exchange for new parts.

Sometimes you need to buy a gearbox

to completely replace a worn-out unit.

In case of serious damage, the bulkhead will take a lot of time, but will not guarantee a positive result. A complete replacement of the gearbox assembly will allow you to eliminate all problems at a low cost

; in the future, repeated repairs of the unit will not be required very soon.

On sale

you will find new and

used

gearboxes, you can choose a reconditioned unit at a low

price

, which will be guaranteed long-term operation.

Gearbox repairs are carried out in our workshop in Moscow

mechanical type.

Manual transmissions are widely used for passenger cars, despite the widespread use of modern multi-speed automatic transmissions

and robotic transmissions. The mechanics are easy to use and reliable; this gearbox rarely fails. If a breakdown does occur, use the services of our workshop: we quickly and inexpensively carry out any type of repair. Diagnostics before troubleshooting will be performed free of charge, the check is carried out in the presence of the customer.

Operating principle and main advantages of manual transmission

Mechanics ensure the transmission of torque from the engine to the wheels of the car using the clutch mechanism. It is transmitted to the input shaft and then converted: for this, pairs of gears with different gear ratios are used. The increase or decrease in torque depends on the number and size of the teeth: in the first case, the speed decreases, in the second, it increases. Accordingly, the transmission can be up or down.

Although a number of other types of torque varying devices have emerged, the mechanics continue to be popular. This type of gearbox is in demand due to several advantages:

- Simplicity of design, which ensures long service life. Mechanics can last up to 250 thousand kilometers or more with regular oil changes

and other service work. - The ability to save fuel due to high efficiency when driving a vehicle.

- Light weight, which helps improve the dynamic characteristics of the car.

- Fast acceleration. It is the mechanics that allow you to sequentially change gears in the shortest possible time and accelerate the car to high speeds.

- The ability to start a car without a battery if the car's electrical system malfunctions. The mechanics work autonomously, while the automatic will be completely disabled if the battery is not working.

If necessary, a car with a manual transmission can be towed, push out rocks and mud, it will be as reliable as possible. Because of this, mechanics are often chosen by SUV lovers who are often forced to drive on broken and dirty roads.

Main faults of manual transmission

Mechanics rarely fail, but it is necessary to monitor their condition in order to identify signs of problems in time. All parts have a limited lifespan, but they often come out much earlier than planned. Damage occurs due to aggressive driving style with sudden jerks and untimely gear changes, rare oil changes

, the use of low-quality lubricants and consumables, as well as some other factors.

Gearbox repair will be required if the following symptoms of problems are detected:

- Noise appears when driving or in neutral gear. This may indicate wear of the bearings or gears; in any case, the machine will require quick diagnostics.

- Change in oil color, appearance of a burning smell. This indicates that the gearbox is suffering from overheating. It is necessary to replace the transmission fluid and eliminate the cause of the problem.

- Gears are difficult to shift. This may be a sign of a faulty shift linkage or other components of the shift mechanism. The car must be sent for diagnostics.

- A noise indicating a problem with the input shaft bearing. Bearings often fail and require replacement.

- The appearance of play in the lever, in the future the transmission may be knocked out. In case of such problems, the car must be sent for repairs as quickly as possible.

If any changes occur in the operation of the manual transmission, you must immediately seek professional help. The specialists of our workshop repair foreign and domestic cars, quickly troubleshoot problems and provide a warranty card.

Box removal process

To carry out the removal procedure, the car must be placed on an overpass, lift or inspection pit, since the process is labor-intensive and difficult. Removing the box is impossible without help, so you should call a couple of people, preferably with experience in car repair.

Tools

To carry out the gearbox removal procedure, you will need the following tools:

- a set of wrenches, which should contain keys for “10”, “13” and “19”;

- you can use union joints with heads of the same sizes, cardan joints with an extension on which the heads will be put;

- pliers;

- flat and Phillips screwdrivers;

- tweezers;

- funnel;

- oil container;

- gearbox support;

- clean rags.

Gearbox replacement

In some cases, a complete overhaul of a worn-out gearbox will require too much expense; it is more profitable to buy a gearbox

and replace it completely. You can purchase a new or refurbished gearbox from us to eliminate all problems and guarantee trouble-free further operation.

On sale at a bargain price

New and

used

gearboxes are presented: purchasing remanufactured parts will reduce

the cost

of repairs. To discuss repair conditions and find out upcoming costs, call the numbers provided.

A specialized service workshop repairs a manual transmission

. Despite the widespread use of other types of transmission, manual transmission continues to be popular: it is a reliable and easy-to-use unit that allows the car owner to control the car in any driving situation and independently switch the speed mode. Mechanical breakdowns occur as a result of natural wear and tear of parts or due to incorrect actions by the driver: in any case, the unit requires the help of specialists. Book your car for a free diagnostic in our workshop and order qualified repairs.

Features of the device and main types of mechanics

Any manual transmission works on the following principle: through the clutch mechanism, torque is transmitted from the engine to the input shaft, after which it is converted using a pair of gears and supplied to the wheels. Each gearbox has a certain number of pairs of gears - stages: most modern cars have 5 or 6 forward gears. If the torque increases during transmission, the speed decreases, and vice versa.

The gear can be reduced or increased, it depends on the ratio of the number of gear teeth, as well as on their size. Changing gears requires fully pressing the clutch pedal to interrupt the flow of power from the engine. Each gear is designed to operate in a certain speed range: the driver relies on the speedometer readings and selects the moment to shift the lever.

There are two types of manual transmissions used in modern cars:

- Twin-shaft gearboxes with primary and secondary shafts. This device is used primarily for front-wheel drive passenger cars.

- Three-shaft gearboxes. They are widely used on rear-wheel drive cars, as well as on trucks.

Mechanics remain in demand due to their simple design and inexpensive maintenance. Such a gearbox rarely fails because it does not have a complex system of electronic components.

How to get rid of the rattling gear shift knob of a VAZ 2110

Almost the entire domestic auto industry has one very surprising feature. While driving, something is constantly ringing, rattling, or clicking inside the car. And what’s interesting is that it’s not possible to completely get rid of extraneous sounds. For example, the VAZ 2110 suffers from imperfect design of the gear shift lever, which during driving affects its monotonous rattling, which irritates many motorists. how to get rid of the rattling gear shift knob on a VAZ 2110 in today’s publication.

How to disconnect the gear shift lever from the rocker on a VAZ 2110

Before you begin to eliminate the rattling, the gear shift knob must be disconnected from the gearbox rocker. To do this, remove the lever casing; it is secured using four latches, one on each side. Then, on the left side of the air duct opposite the locking screw, drill a small hole with an approximate diameter of 8 mm. This hole will help you easily unscrew the locking screw. Then we unscrew the axle nut and remove the bushing, with which we will carry out the modernization, which will help get rid of the rattling of the gear knob while the car is moving.

Common manual transmission problems: causes and symptoms

Most malfunctions occur as a result of premature wear of parts due to incorrect driver actions. The service life of a manual transmission is reduced if the oil is not changed

or its poor quality, aggressive driving style with frequent sharp jerks, slipping on dirty and broken roads and other extreme operating conditions. Most often, gears, shafts, bearings, seals are damaged; seals may lose their tightness, link malfunctions, and other problems.

Repair of a manual transmission is required when the following signs of malfunction appear:

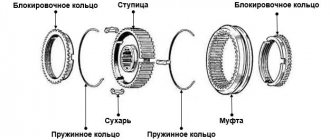

- Knocking out a pass. This may indicate wear on the gears or a malfunction of the synchronizer clutch.

- The appearance of noise at idle speed. They often talk about a faulty input shaft bearing that needs urgent replacement.

- The appearance of play in the lever when changing gears. This indicates the need for urgent diagnosis and repair.

- Oil leakage, which indicates a faulty seal or differential.

- The appearance of all kinds of noise when moving. The occurrence of extraneous sounds is a reason to urgently carry out diagnostics in order to identify and eliminate the problem.

If there are any signs of problems, use the services of our workshop. We offer qualified repairs of any complexity; experienced employees will quickly cope with the task.

Signs and causes of failure of the VAZ 2107 gearbox handle

Gearbox lever diagram

A manual transmission allows you to exercise complete control over the vehicle's handling. Using a special lever, speed modes are changed. You should find out what problems may arise with this mechanism on the box, what are the ways to eliminate them.

Among the signs of a broken gearshift lever on a VAZ 2107 are:

- impossibility or difficulty of changing speeds;

- excessively free movement of the handle;

- the lever rotates freely;

- another transmission is activated.

https://youtube.com/watch?v=jOg7g84XbN8

The lever may be loose due to a worn bushing. When this component is deformed, vibration is often observed from the handle. The consumable must be replaced.

If there is noise from the gearbox when the lever is in neutral with the engine running, it is advisable for the car owner to check the condition of the oil and bearings. It is worth changing the oil in accordance with the established regulations.

Repair services in a specialized workshop

We repair the mechanics of cars of all models and brands; experienced workshop staff have been working with this type of gearbox for many years. Diagnostics and troubleshooting are carried out with the preparation of a list of parts for exchange, after which high-quality spare parts will be installed on the machine. Getting help from professionals is the best way to ensure that problems do not reoccur.

If the transmission is very worn, the most effective solution is to completely replace it. To do this, we suggest purchasing a manual transmission.

assembled: on sale you will find new and used refurbished units after overhaul. Their installation will make it possible to eliminate any repeated breakdowns and reliably prepare the car for further long-term use. Take advantage of free diagnostics in our workshop to quickly identify and fix all breakdowns.

How to remove the gear shift lever on a VAZ 2110

To remove the lever, you only need a set of open-end wrenches, as well as a Phillips and slotted screwdriver. Remove the protective cover and lift it up to secure it to the lever handle. If possible, unscrew the lever handle and completely remove the cover. Using a “13” key, unscrew the nut of the bolt securing the lever to the rocker (it goes inside the tunnel). Then, using a “10” key, unscrew the nuts securing the plastic guide plate (it is screwed to the tunnel wall). Remove the guide plate, then insert a Phillips screwdriver between the top and bottom of the tunnel to the right of the lever and remove the screw that secures the plastic guide to the lever. Then press the lever in the neutral position all the way to the right and pull out the bolt and guide. Remove the retaining ring from the ball joint and pull out the lever. Do not pull it when the ring is installed, this may cause the bowl to collapse.