As a result of new developments in the automotive industry, modern cars equipped with original gearboxes called Powershift appeared on the roads. Unlike robots created earlier, the new Powershift box has a double clutch instead of a single one. The word Powershift is literally translated from English as “changed power”. This design concentrates the main advantages borrowed from manual and automatic transmissions.

Powershift - What kind of box is this?

The modern gearbox is a mechanical robot with a double clutch. Here the speeds are switched via an automatic drive. The scope of use of this mechanism extends to cars equipped with powerful diesel engines, which are designed to provide increased torsional torque. Most often, Powershift automatic transmissions are installed on vehicles of well-known companies Volvo and Ford.

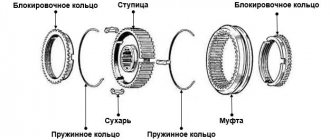

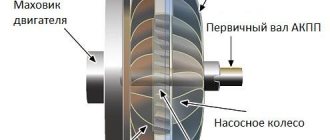

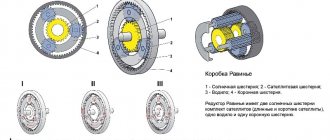

The transmission Powershift includes two drive gears. Each of them rotates thanks to an individual clutch system. The central place of the robotic box is occupied by the input shaft, consisting of two elements. One is placed inside the other. Both shafts are primary. Even-numbered gears and reverse are engaged from the outer hollow shaft. The odd ones operate from the central axis, respectively.

Losses of internal combustion engine power and rotational torque in the robotic gearbox are minimized. The design does not include a torque converter, friction clutches, or planetary gear. The TCM electronic control unit is installed on the transmission housing. The ECU performs the following functions:

- Processing data from numerous sensors.

- Transmission of control signals to actuators.

- Monitoring the operation of the automatic transmission.

- Clutch control.

- Changing gears.

- When performing the last two functions, special DC motors are used, as well as built-in sensors.

Advantages and disadvantages of the robot

If it were possible to achieve perfection in any field of technology, then humanity would not have such a variety of instruments and devices. The robotic gearbox was born as a result of the desire of car manufacturers to make driving more comfortable, but at the same time without increasing the cost of such improvements too much.

The main advantages of using manual transmission:

- Compared to an automatic transmission, the use of a robotic gearbox can significantly reduce the cost of the car;

- Low cost of maintenance;

- Fuel savings up to 8%;

- High efficiency.

Disadvantages of manual transmission:

- Significant “time gap” when changing gears;

- Shocks are possible during the start;

- It is difficult to drive a car in off-road conditions.

Considering the constant rise in energy prices, an important advantage of the robot is its cost-effectiveness compared to automatic and manual ones. Smart electronics accurately determine when the gear is engaged, preventing excessive fuel consumption and at the same time increasing engine life by reducing excessive load on its main parts.

Operating principle of Powershift automatic transmission

To ensure instant transition from one gear to another, the robot gears in the gearbox are in constant mesh. The original principle of an electronically controlled double clutch is at work here:

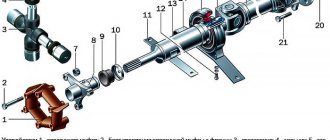

impact on the automatic transmission selector inside the car; opening the clutch of the current transmission; engaging the clutch elements of the next gear. The selector is connected to the gearbox through a special cable.

What's the result?

As you can see, the Powershift gearbox is a modern version of robotic preselective gearboxes. Thanks to this transmission, gear shifting is smooth (as opposed to jerks and delays typical of single-disc robots). The box also allows you to shift without a noticeable interruption in the power flow; a car with this transmission has high acceleration dynamics.

With each new generation, the manufacturer also takes into account and eliminates shortcomings, the software is constantly being improved, and changes are made to the operating algorithms. For example, in addition to the standard D mode, there is also a sport mode S. In this case, the box is adaptive, that is, the electronics flexibly adapt to the driving style of a particular driver.

As a result, I would like to note that in comparison with other similar robots (DSG from Volkswagen), the PowerShift gearbox, according to reviews from some owners, shows itself to be more reliable. However, the general statistics of breakdowns still does not allow us to say with complete confidence that this gearbox is a leader on the market.

How does a double clutch work?

What is Powershift? To clearly describe the Powershift device, we can say that it is presented in the form of two transmissions that operate using each their own clutch system. The first clutch is designed to transmit power to I, III, V gears; the second - on II, IV, VI, respectively.

To increase the service life of the clutch elements and the reliability of Powershift, the system provides automatic wear adjustment. The working stroke of the actuator parts is strictly limited.

There are two versions of Ford Powershift transmissions:

- European;

- American

The Powershift Ford Focus of the European version is characterized by a dry clutch, all elements of the system are immersed in transmission fluid.

The dry clutch version is more often found on vehicles of the American car market. An oil-free clutch overcomes drag forces better. It does not require the installation of special hydraulic systems in the form of pipelines, cooling devices (fans), pumps, etc.

manual transmission control PowerShift

One of the features of the box is a fully electronic control system. The equipment is equipped with automatic systems that constantly monitor basic operating parameters, such as:

- clutch rotation indicators,

- rotation of internal shafts, etc.

— • —

The main control element is mechatronics. It analyzes parameters (for example, driving speed and engine speed). Based on the results of the information received, a suitable gear is selected, and the automatic system operates faster and more accurately than a human. The gear change is carried out in a fraction of a second, so “softly” that neither the driver nor the passengers have time to catch the moment of switching.

It is possible to switch the box to manual mode - in this case, the driver changes gears himself. It is recommended to select this mode in cases where it is necessary to perform high-speed maneuvers (for example, overtaking). No power interruptions improve safety of complex movements at high speed. In some modifications of the gearbox it is possible to install steering column switches. In this case, manual gear changes are carried out without a lever, with a simple movement of the fingers.

Box operating modes

The box can operate in the following modes.

- In Drive, gear shifts occur at approximately 3000 rpm.

- In “Sport” mode, the gearbox shifts gears at 5000-6000 rpm.

— • —

Even if you switch the equipment to manual mode, a system is activated that will prevent damage to the motor during prolonged operation at high speeds. In this case, the driver will not be able to shift to a low gear to prevent excessive wear on the power unit. The result is an increase in the service life and operational reliability of the main components of the machine.

— • —

An important component of the technology is the temperature sensor. It measures the degree of heating of the oil. If problems arise, the driver will receive a warning signal.

Common Powershift problems

This gearbox is reliable, but if used incorrectly, malfunctions may occur.

It is important to operate equipment carefully in winter.

If it's cold outside, warm up the transmission before driving. Thanks to this, the properties of the oil will be preserved for a long time, which will have a positive effect on the service life of the components. It is not recommended to choose a car with such a box if you drive in an aggressive style.

If there is a problem with this gearbox or you suspect that it will soon break, do not delay - come to us for diagnostics and repair of the Powershift gearbox +375 (29) 608-27-52

And finally - reviews of Powershift

Feedback from car owners about the box is generally positive, but it is necessary to take into account the fact that this robot has a much more complex design than classic automatic and manual ones.

Positive reviews about powershift

Negative reviews about powershift

- Next Oil change in Powershift Ford Mondeo

- Previous Car brands: Fiat, Lancia, Alfa-Romeo | Questions, answers and discussions about manual transmission

Possible problems with the Powershift box

Owners of cars equipped with a robotic gearbox are faced with the following serious defects:

- Jerking of the car while driving (these defects are eliminated in specialized workshops during the process of Powershift adaptation).

- Leaking seals and seals.

- Relatively short lifespan of the clutch mechanism (often lasts only one period before the first maintenance).

- The appearance of extraneous sounds when moving from 1st to 2nd and 3rd gears.

If serious defects occur, the Powershift gearbox cannot be repaired. If the machine is under warranty, service companies adapt or replace the expensive robot.

Explanation: Adaptation of the Powershift gearbox is the so-called “training” of the mechanism using a program called FORScan. This service updates the software and identifies the causes of box malfunctions. If defects are detected in the design of the robot, the official Ford dealer is obliged to replace the clutch.

Tips and tricks

The robotic gearbox can significantly increase the comfort of driving a car, but compared to a manual transmission, the built-in automatic requires more attention and more careful handling

Particular attention should be paid to the condition of this unit when operating the vehicle in difficult road conditions; It is recommended to carry out independent repairs of manual transmissions only if you have the appropriate technical skills, and also if problems in the operation of the robot arose after the expiration of the warranty period; The use of low-quality lubricants can lead to premature failure of the robotic gearbox. An indirect sign of purchasing low-quality gear oil is an easily peelable label on the packaging, as well as the lack of information about the manufacturer of this product on the packaging

After low-quality oil is poured into the robotic automatic, the box will definitely let you know about this by increased transmission noise in all operating modes, as well as by more rigid gear shifting.

Problems in the operation of the powershift transmission may arise not through the driver’s fault, but as a result of a manufacturing defect, so during the entire warranty period you should not carry out any repair operations with the manual transmission yourself or seek help from garage technicians. If these recommendations are not followed, warranty repairs will be denied, and replacement or repair of the robotic gearbox will fall entirely on the shoulders of the car owner.

Main advantages

This box has several advantages. The first of them is the absence of a break in the flow of torque that goes from the engine to the wheels. This characteristic is achieved thanks to a dual-mass flywheel. The second plus is the acceleration dynamics. The automatic transmission loses a lot of time switching from first to second gear when accelerating. Here this operation takes place in a matter of moments. Thanks to this, maximum acceleration dynamics are realized. Also with this box the car consumes less fuel. If we take into account a conventional six-speed gearbox, the savings will be about one and a half liters per hundred kilometers.