In the modern world, a car is not only a means of transportation, but also an indicator of the social status and respectability of its owner.

Pleasant to the eye color, impeccable shape, shiny, perfectly smooth surface - all these characteristics serve as a source of pride in your “iron horse”.

However, a car is not a decorative product that is stored only in exceptionally favorable conditions, where it is not in danger of rapidly deteriorating in all its qualities.

The environment for using a vehicle is open space with all its negative impacts, including both weather changes and a large number of anthropogenic and other factors.

Traces of frequent washing, stains, chips, scratches caused by branches or careless loading can easily ruin a motorist’s mood.

But you can correct the situation by resorting to polishing - a process the result of which is the reconstruction or restoration of the paintwork.

But not every vehicle owner decides to carry out this process on their own; they only trust specialists from auto repair shops and assume that only they know how to polish a car correctly.

In fact, any car owner can do this with his own hands; you just need to follow the main rules, and also listen to recommendations and advice.

Composition of alkyd paint for a car, its properties

Each car painting involves applying special enamels to the surface.

All types of car paints have both disadvantages and advantages. Alkyd car paint is a derivative of oil-based alkyd resin. The peculiarity of this type of enamels is rapid polymerization without creating any additional conditions. This means at normal temperature under the influence of atmospheric oxygen. To paint a car completely, such enamel is used very rarely, since it requires additional varnish and polishing. Fully matte enamel is also available; it is used for local repairs before varnishing or as an independent decoration of parts. It was the advent of synthetic paints that contributed to the dramatic improvement in the car painting process. Thus, alkyd paints are one-component paints that dry well in the open air. This type of car paint has high elasticity, shine, and high performance. But with prolonged exposure to atmospheric phenomena such as frost, heat, precipitation, such paint begins to lose its qualities. There are also some disadvantages: it takes a long time to dry and is difficult to polish. Special additives are used to speed up drying. Thanks to this, the evaporation of solvents is faster.

Today, alkyd enamels occupy a large market volume. Almost half of all car paints produced are made from them. Here are some brands: Vika, Helios, Sadolin, Mipa and others.

Why do you need to polish your car?

Polishing is carried out not only for cosmetic purposes, it is also a technical procedure that protects against damage to the enamel, which leads to the formation of rust. In addition, if there is such a need, you can polish headlights and even car windows.

The paint coating of most of the entire surface of the body prevents corrosion, but the paint is quite easily covered with small cracks.

It is into such minor defects that all sorts of substances seep in, which trigger a seemingly imperceptible, but rather rapidly progressing corrosion process.

The reason for this is dust and dirt, which have abrasive qualities, which in the absence of proper care renders the coating unusable.

In addition, direct exposure to sunlight for a long time can improve the shine of the car's surface.

Conventionally, polishing work can be divided into four stages:

- Preparatory stage

- Grinding

- Polishing

- Final stage

Technology of painting cars with alkyd paint

If the question arises about which enamel is best suited for protecting a car without taking into account time costs, then alkyd-based car paint is one of the most reliable means of protecting metal. The resulting coating resists all exposure to the sun, atmosphere, and chemicals. The shine of such a film can be compared to the shine of an acrylic coating, only at a lower cost and without a hardener in the paint (the material is applied to the car in 2 layers).

The durable film that is formed by synthetic resins is also considered a disadvantage of enamel: the surface forms quickly, and alkyd enamel takes longer to dry. Professional use of an alkyd helmet requires a special drying mode with increased heating and good ventilation. Since alkyd enamel for cars forms thick layers, you need to apply 1-2 layers. But, despite their good protective properties against atmospheric influences, alkyd paints do not inhibit the formation of corrosion, so such paint should be applied to a primed surface.

If we are talking about painting a car in the garage, then it is rarely talked about a major update of the paintwork. But even with minor repairs, it is necessary to prepare the car body or its parts no less carefully. Professional application of alkyd paint occurs in three layers:

The backing is a thin layer that is needed only for adhesion to the surface (it sprays quickly, so it is difficult to maintain uniformity).

The base is a layer of normal thickness (it is possible to combine with the first).

The outer film is a layer on which the appearance of the surface depends (it is diluted a little more, and is more likely to be poured than applied).

The first and last layers are very important, since the first is able to provide adhesion, and the second is responsible for the appearance. Since the thickness of an individual layer is small, errors that were made when applying the first layer can also appear in the last. This effect is called “first layer memory”.

The distance of the gun to the car surface depends on the pressure, viscosity of the enamel and the nozzle.

The optimal distance is 15-20 cm, but since the last layer is liquid, it is better to increase the distance to 30-35 cm. You should move the gun quickly, you should carefully monitor the drying of the paint, since at high temperatures or with a solid solvent the paint can dry on the fly and form shagreen.

The opposite of this danger is smudges that appear due to too active use of solvent. In case of deviation from the norm, and especially with regard to humidity, it is quite possible to choose another solvent or change its amount.

Preparatory stage

Sanding and polishing is carried out no earlier than on the 20th day after painting. This is the optimal period when even a thick layer of paintwork dries out. In addition, in the third week all possible surface defects become noticeable.

The preparatory stage before polishing after painting takes a short time. You need to wash your car using car shampoo. The surface of the body is treated with a degreaser, all rubber bushings and car parts are sealed with masking tape.

Physical and chemical properties of alkyd auto enamel

Alkyd paints are a common type of paint and varnish material suitable for painting vehicle body surfaces. Thanks to its use, the maximum effect of painting the car body will be achieved.

Alkyd paints – avtomaler-plus.com.ua

Advantages of the paint:

With regard to chemical and physical influences, alkyd auto enamel is distinguished by its resistance. It forms thick layers, which helps reduce the number of painting stages. Also, it contains polyhydric alcohols and orthophthalic acid. Auto enamel penetrates deeply into metal planes. This is a guarantee of its durability on the body surface. Compared to acrylic paints, the film of alkyd paints is more durable.

Specifics of using alkyd types of paints

When working with alkyd paints and varnishes, the prescribed rules of use must be followed. In particular, it must be diluted with certain types of solvents recommended by the manufacturer. Thanks to this, the declared color brightness will be achieved.

To decorate car body parts without a shiny effect, you can use matte alkyd auto enamel. Since it contains a number of chemical components, it has a specific odor. Also, the disadvantages of this paint include its long drying time, and there is a risk of smudges. Taking this into account, painting a car with this substance should be done in special chambers (convection chambers) where there is good ventilation.

Paint is applied to the pre-primed car body in 1 or 2 layers. It takes several hours for the painted body surface to dry completely. As a result, a high level of protective properties is achieved. When applying alkyd car paint to a body, it is advisable to use a spray gun, the operation of which requires certain skills.

Thus, car paint should not only give the vehicle an attractive appearance, but also protect the body from corrosion. Alkyd types of paints have these characteristics. They contain persistent pigments. It will not change its color for a long time.

Source

Final chord: coloring

When starting to apply the enamel coating, you should carefully choose the color. When purchasing a can, use a computer-based shade selection that takes into account not only the code designation of the factory enamel, but also the degree of its fading. The new coating should differ minimally from the existing one.

Before spraying, it is recommended to clean the surface of any remaining water using blowing equipment. During painting, the can is held firmly at a right angle at a distance of no more than 15 cm from the surface. The paint will be applied evenly only if the can moves evenly along the surface. If you use acrylic enamel, then you can apply the next layer in ten minutes. If any defects form, you can sand the surface again with abrasive. Before spraying the next coat of paint, clean the painted area from small dust particles using an antistatic cloth.

After completing the procedure, a new layer of varnish and enamel is applied to the surface for additional protection and shine. When choosing varnishing products, you can choose quick-drying mixtures. The final stage of painting is thoroughly drying the car and polishing, due to which certain coating defects are removed. Polishing can be done with your own hands by applying a special product to the surface.

Often, it may also be necessary to clean the surface from minor defects. In this case, soft abrasive sandpaper is used to carefully remove the top layer of the coating. At the same time, it is important not to damage the enamel and not disturb the even color of the car. If there are a large number of defects, you can use a stronger abrasive, carefully rubbing out the unevenness and regularly wetting nearby surfaces to protect them from dust particles. One way or another, with strict adherence to all the rules and stages, the application of paint to the car fender should proceed without any defects or errors.

General characteristics of alkyd coating for cars and difference from acrylic

When choosing a paint coating, you must first pay attention to how long the enamel will meet the required characteristics.

Important! Acrylic paints, glyphthalic, cellulose and other enamels retain their properties for approximately three years, while alkyd-styrene and urethane paints have a service life of approximately 5-6 years.

This allows you to expand the scope of its use in different climatic conditions without fear of premature wear. Resistance to minor mechanical damage will help avoid minor scratches of both the coating itself and the metal it protects.

When applied, urethane paint forms a thick layer of coating, which reduces the number of applied layers and material consumption. It is not recommended to mix this paint and solvent. It is possible to dilute alkyd enamel with a compatible paint solvent, for example Vika 60. Alkyd urethane paint has the following negative aspects of use:

Information! To achieve the maximum required effect, it is necessary to properly prepare the surface to be treated.

It is recommended to use products of the same chemical composition, so it is best to use alkyd primer. This additional layer of protective coating reduces the possibility of moisture penetration onto the car body to zero, and also compensates for the deficiencies in the corrosion protection of the main paint coating.

How to properly care for a polished surface?

Finishing wood using polish makes it mirror-smooth. Dust and other contaminants are less likely to be retained on such a surface. It becomes more resistant to moisture present in the air. However, this type of finishing is not able to completely protect the product from external influences. For example, when touching a sharp or rough object, scratches appear on polished wood. Under the influence of high temperature, the polish may lose its original strength and “float”.

All these points should be taken into account when choosing a finishing method and subsequent operation of this product. You should not polish objects that will be subject to active use, for example, the horizontal surface of a tabletop. Any hard object left on it, such as keys, can damage it and leave scratches. High temperatures damage polished wood, so items made from it should not be left in the sun or near heating devices for a long time. Contact with water and water vapor should be avoided.

In order for the item to remain beautiful and serve for a long time, it is protected from getting wet, overheating, and contact with sharp objects. For care, it is recommended to use special compounds for polished furniture, which are sold in household chemicals departments. A small amount of this composition is applied to a napkin and the wood is wiped with it. Heavy stains can be removed with warm water and a small amount of dishwashing gel. The washed surface is immediately wiped with a dry cloth and treated with polish.

The process of preliminary preparation of a car body before painting

The preliminary area of the surface to be painted is thoroughly cleaned of old enamel, dust, and dirt. To carry out this procedure, you need to prepare a weak solution of ordinary water and detergent. The surface is degreased using white spirit, although any other solvent can be used.

Next, all unnecessary parts are disconnected - we leave only the surface of the “bare” metal, which, if necessary, is defective (mechanical damage is eliminated). To do this, you will need a sharpened screwdriver or chisel, coarse and fine sandpaper.

Important! Old paint and primer are removed, and scratches need to be removed using grout paper. After carrying out the damage removal procedure, you need to once again remove traces of abrasive from the surface of the car and degrease it using an alcohol solvent.

Next, if necessary, the required areas should be treated with a special putty for metal. This action is carried out in order to eliminate unevenness or deep dents on the body. After all the manipulations, you need to let the putty dry.

The final stage of preparing the car body for painting will be the final sanding of the required areas.

What is required for polishing?

During the varnishing process and under its influence, slight deformation of wood fibers occurs. As a result, they begin to protrude above the previously sanded surface. The main task of polishing is to smooth out as much as possible all protruding areas of the wood relief until a perfectly smooth surface is formed. Dense wood species lend themselves best to polishing to a shine. These include beech, oak, birch, and acacia. Loose woods, such as cedar, larch, aspen or linden, are less polished.

Polishing on varnish is performed using special tools and materials. The main ones are the polishing composition and the equipment with which the polish is distributed over the surface of the wood. In addition, you will need means to protect your skin and respiratory tract from the smallest particles of dust that will fly away during work.

The wood polisher is recommended to cover his hair with a scarf or bandana, since a hair falling on the surface of the wood can lead to scratches and impair the quality of the work. You should stock up on cleaning equipment in advance, which is carried out before and after each polishing stage.

Maintaining cleanliness helps prevent dust, grains of sand or small insects from getting on the product. The workplace is carefully protected from flies, mosquitoes and midges by using nets on the windows and hanging traps made of adhesive tape nearby.

Tools and materials

For this type of finishing you will need:

- abrasive materials - sandpaper or discs of varying degrees of grain;

- polishing machine (it is not advisable to replace it with a grinder, since it operates at a high speed, which can lead to overheating of the varnish and its sticking);

- tampons and lint-free wipes for cleaning dust (they cannot be replaced with cotton cloth);

- ready-made or self-made polishing liquid;

- solvent: alcohol, white spirit;

- polishing oil, such as linseed oil;

- vacuum cleaner (you can do without it, but in this case the work will be less productive);

- protective equipment: gloves, respirator, hat.

Ready-made polishes for varnished wood

Depending on the density, polishing compounds can be divided into several groups:

The first ones are intended for machine polishing; it is physically difficult to work with them manually. Semi-liquid and liquid compositions are suitable for both machine and hand polishing.

Examples of ready-made polishes and polishing compounds:

- liquid wax “Mirka Polarshine”;

- antistatic paste “Polarshine” with carnauba wax;

- 3M Imperial polish;

- nitro polish;

- nitroshell polish;

- birch bark polish;

- alcohol-shellac polish.

Alcohol-shellac compositions are marked with numbers depending on the color: No. 13 - light brown, No. 14 - dark brown, No. 15 - red-crimson, No. 16 - black and blue. This type of polishing fluid can be prepared at home.

Homemade polishing compounds

One of the most popular polishes is shellac. It has a simple composition, so you can prepare such a polish yourself. To do this, 650 ml of ethyl alcohol with a concentration of 90% to 95% is mixed with 115 g of ground shellac. Ethyl alcohol can be replaced with wine alcohol, but it is more correct to use highly purified medical alcohol.

The mixture of shellac and alcohol is placed in a hermetically sealed glass or ceramic container and left until the shellac is completely dissolved. To speed up the process, the solution must be shaken periodically. When the shellac has dissolved, the resulting liquid is filtered and poured into a dark glass bottle with a tightly screwed cap. Store the composition in a dark place, because shellac may precipitate when exposed to light.

The polish according to this recipe has a concentration of 15%. When a less concentrated solution is required for work, alcohol is added to the original composition. If you add one part of alcohol to 2 parts of a 15% polish, you get a 10% solution. A 5% polish is prepared by mixing 1 part of a 15% solution with 2 parts of alcohol.

Composition of alkyd paint for a car, its properties

Each car painting involves applying special enamels to the surface. All types of car paints have both disadvantages and advantages.

Alkyd car paint is a derivative of oil-based alkyd resin. The peculiarity of this type of enamels is rapid polymerization without creating any additional conditions. This means at normal temperature under the influence of atmospheric oxygen. To paint a car completely, such enamel is used very rarely, since it requires additional varnish and polishing. Fully matte enamel is also available; it is used for local repairs before varnishing or as an independent decoration of parts. It was the advent of synthetic paints that contributed to the dramatic improvement in the car painting process. Thus, alkyd paints are one-component paints that dry well in the open air. This type of car paint has high elasticity, shine, and high performance. But with prolonged exposure to atmospheric phenomena such as frost, heat, precipitation, such paint begins to lose its qualities. There are also some disadvantages: it takes a long time to dry and is difficult to polish. Special additives are used to speed up drying. Thanks to this, the evaporation of solvents is faster.

Today, alkyd enamels occupy a large market volume. Almost half of all car paints produced are made from them. Here are some brands: Vika, Helios, Sadolin, Mipa and others.

The right combinations of materials

The right combinations of materials. The difference between acrylic and alkyd enamels and general recommendations for use.

Properties of one-component acrylic enamels

Unlike acrylic emulsions in jars, aerosol acrylic enamels have an organic rather than aqueous base.

Advantages (compared to alkyd aerosol enamels):

- high drying speed;

- rich colors;

- high elasticity and high adhesion to plastics (due to these properties, acrylic enamels are preferable for application to plastic surfaces).

Disadvantages (compared to alkyd aerosol enamels):

- moderate weather resistance;

- moderate adhesion to metals (preliminary priming is required);

- moderate resistance to solvents.

Properties of one-component alkyd enamels

The peculiarity of alkyd enamels compared to acrylic enamels is that after drying the chemical processes in them do not end. After the solvent has evaporated, the polymerization process continues in the alkyd enamel under the influence of atmospheric oxygen. The molecules are “stitched” together and, figuratively speaking, form one large molecule, making the coating more durable and resistant to various influences, but at the same time less elastic and more fragile. However, alkyds have been discovered for a very long time and are very well studied. Modern KUDO formulations take this fact into account, and even after complete polymerization, the paint film remains quite elastic. The polymerization process can last from several days to two weeks. During polymerization, the coating must not be subjected to mechanical stress. For example, a car body element painted with alkyd enamel cannot be washed or polished for two weeks. Also, during polymerization, alkyd enamel cannot be coated on top with other paints and varnishes, even those based on alkyd - the coating may be damaged. You need to coat either “wet on wet”, that is, apply the next coating immediately after drying “touch to touch”, or after waiting for complete polymerization. When applied “wet on wet”, the adhesion of the applied layer will be higher than when applied after complete polymerization.

Advantages (compared to acrylic aerosol enamels):

- high adhesion to metals;

- higher hardness;

- higher weather resistance;

- higher light fastness (less fading);

- higher resistance to solvents.

Disadvantages (compared to acrylic aerosol enamels):

- longer drying time;

- long polymerization process.

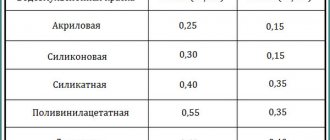

Table of correct combinations

The alkyd base cannot be coated with paints and varnishes during its polymerization - the alkyd base may swell! The alkyd coating must be applied to the alkyd base either “wet on wet” **, that is, immediately after the base has dried “touch” (no later than 1.5 hours after applying the base), or after waiting for complete polymerization. *

When applied “wet on wet”, the adhesion of the applied layer will be higher than when applied after complete polymerization.

Alkyd coating can be applied to an acrylic base ** by waiting until the base is touch dry. *

You can also apply the coating after the base has completely dried.

Attention!

Do not apply aclide-urethane coatings, in particular yacht varnish, to one-component acrylic primer - the base may swell.

The alkyd base cannot be coated with paints and varnishes during its polymerization—the alkyd base may swell. An acrylic coating on an alkyd base must be applied either “wet on wet”, that is, immediately after the base has dried “touch” (no later than 1.5 hours after applying the base), or after waiting for complete polymerization. *

When applied “wet on wet”, the adhesion of the applied layer will be higher than when applied after complete polymerization.

Acrylic coating can be applied to an acrylic base by waiting until the base is touch dry. *

You can also apply the coating after the base has completely dried.

* Intermediate drying time between layers, touch-drying time, complete drying time and the time for the base to gain full mechanical strength are indicated in the instructions for use of each specific product.

** We recommend using a primer color as close as possible to the enamel color.

If the acrylic base is brightly colored, then when a thick layer of alkyd coating is applied to it (especially light colors), the bright pigment of the base may “rise.” The same is possible when applying an alkyd coating to an alkyd base “wet on wet”. For example, if a brown-red acrylic primer is painted with white alkyd enamel, then there is a high chance of getting a pink finish.

How to apply acrylic coating to acrylic base.

Acrylic coating can be applied to an acrylic base by waiting until the base is touch dry.

You can also apply the coating after the base has completely dried.

How to apply alkyd coating to acrylic base.

Alkyd coating can be applied to an acrylic base by waiting until the base is touch dry.

You can also apply the coating after the base has completely dried. Attention! Do not apply aclide-urethane coatings, in particular yacht varnish, to one-component acrylic primer - the base may swell.

How to apply acrylic coating to an alkyd base.

The alkyd base cannot be coated with paints and varnishes during its polymerization—the alkyd base may swell. An acrylic coating on an alkyd base must be applied either “wet on wet”, that is, immediately after the base has dried “touch” (no later than 1.5 hours after applying the base), or after waiting for complete polymerization, when the coating has gained full strength.

When applied “wet on wet”, the adhesion of the applied layer will be higher than when applied after complete polymerization.

How to apply an alkyd coating to an alkyd base.

The alkyd base cannot be coated with paints and varnishes during its polymerization - the alkyd base can swell even if the same composition is applied as the base. An alkyd coating on an alkyd base must be applied either “wet on wet”, that is, immediately after the base has dried “touch” (no later than 1.5 hours after applying the base), or after waiting for complete polymerization, when the coating has gained full strength.

When applied “wet on wet”, the adhesion of the applied layer will be higher than when applied after complete polymerization.

The intermediate drying time between layers, touch-drying time, complete drying time and the time during which the base will gain full mechanical strength are indicated in the instructions for use of each specific product.

Technology of painting cars with alkyd paint

If the question arises about which enamel is best suited for protecting a car without taking into account time costs, then alkyd-based car paint is one of the most reliable means of protecting metal. The resulting coating resists all exposure to the sun, atmosphere, and chemicals. The shine of such a film can be compared to the shine of an acrylic coating, only at a lower cost and without a hardener in the paint (the material is applied to the car in 2 layers).

The durable film that is formed by synthetic resins is also considered a disadvantage of enamel: the surface forms quickly, and alkyd enamel takes longer to dry. Professional use of an alkyd helmet requires a special drying mode with increased heating and good ventilation. Since alkyd enamel for cars forms thick layers, you need to apply 1-2 layers. But, despite their good protective properties against atmospheric influences, alkyd paints do not inhibit the formation of corrosion, so such paint should be applied to a primed surface.

How long after applying the last coat of varnish can I polish it?

After applying the last coat of varnish, there is no rush to polish. You can begin work only after making sure that the varnish has completely hardened. Otherwise, stripes or lines may form on its surface. How long should you wait? When calculating the holding time, you need to take into account the drying period indicated on the packaging for a particular paintwork material.

However, the actual polymerization period may be longer than indicated if, for example, the room is cool or the varnish is applied in a thick layer. Experienced craftsmen recommend adding an additional 36–72 hours to the exposure period specified in the instructions, and only after that begin finishing treatment.

Painting parts

The technological process of painting individual parts directly depends on their size. It is recommended to apply enamel to the roof, starting from the center, painting the vertical part from above. The distance from the gun and the viscosity of the enamel are greatly influenced. It is necessary to take into account that very diluted material will leak a little, and using a dry hardener and a small amount of solvent, the paint dries faster.

Sometimes the thickness of the layer can give a different shade, but in relation to materials based on alkyds, this is not so effective. Thus, the technology of painting parts with alkyd paint consists in their identical location in relation to the positions they occupy in the car. In this case, all changes that are associated with pressure and conditions are the same for all parts.

Source

Popular questions

How to polish small parts?

Polishing on small parts is best done by hand. The first thing you need to do is wash it and completely clean it of dust particles, and then start working with the machine. Be very careful on the edges while polishing, rubbing very gently. It is quite easy to wipe off the varnish on protruding elements and edges.

Is it possible to polish paint without varnish?

As for VIKO paint specifically, you can polish it. However, when purchasing, make sure that it comes with a hardener. This paint is polished in the same way, only in this case you need to try not to wipe the varnish, but the paint itself to the primer.

How do you know when you can polish a smudge?

You can touch the stain with the edge of your nail. If paint leaves marks, then it’s too early to polish. If it is already difficult to push through the smudge, then you can already polish it.