In case of various damages, as well as if you want to change the exterior of the car, you need paint repair. It can be partial or complete. There are several techniques for applying it:

- brush (manual);

- pneumatic sprayer.

Most of the work is carried out with pneumatic guns, which spray paint particles onto the body more efficiently. Similar equipment is used both in car services and at home (spray guns).

Like any type of work, car painting has its own difficulties and nuances.

Applying paint with a brush is carried out for local repairs, and in areas where the spray gun cannot reach.

Types of car varnishes

The most common types of varnish are:

Glypthal

Outside a special car painting chamber, the application of glypthal coating must be carried out in compliance with safety precautions in a sufficiently ventilated, dust-free room. After application, glypthal varnish takes longer to dry than, for example, cellulose varnish. But it surpasses the latter in terms of gloss intensity without additional polishing.

Apply the varnish at a temperature of 20°C and dry at 60°C. Modification with the addition of a hardening activator makes the coating more resistant to mechanical stress. Heat curing materials and epoxy backing are more suitable for use with this type of varnish than thermoplastic material. This is due to poor tolerance to temperature changes.

If you add a light thinner to the varnish composition, then even in conditions of poor ventilation and room temperature you can achieve rapid drying and film formation. Hot painting, when varnish heated to 70°C is sprayed with a spray gun onto a part heated in a compressor at 10°C, eliminates the need for a thinner.

Cellulose

One of the first varnishes that began to be used for car painting. Its use in the automotive industry has almost disappeared today. The reason for this was the low gloss, rapid loss of color intensity and the flammability of cellulose compared to more modern products.

Matt varnish with hardener

Acrylic

This is one of the best options offered today by the car paint and varnish market. Polyacrylates are divided into two subtypes:

- Thermoplastic, hardening of which occurs as a result of evaporation of solvents;

- Thermosetting, which hardens at high temperatures and cannot be applied at home;

Polyurethane

A two-component varnish that requires the use of a hardener. Due to the latter, the hardening reaction immediately begins. During this process, the varnish applied to the surface of the car dries. The hardener is added to the varnish 10 minutes before painting. Spray at room temperature in 3 passes. The first is needed as a link, the second is the main one and the finishing third. In the intervals between their application, drying takes place for 15 minutes. After the third layer, the period of final drying of the car surface is increased to an hour.

How to store it correctly?

Price is not always the determining factor in choosing materials for painting work. Moreover, branded and expensive enamel or aerosol, carefully selected for your favorite car, may in fact turn out to be counterfeit. This is especially common if you buy the spray at the first car market stall you come across. However, it is not always possible to blame the seller, since the counterfeit aerosol could have arrived from the supplier, or it could simply have been spoiled by improper storage.

The shelf life of the vast majority of paint materials used on cars is in the range of 2–4 years. However, this is only true if storage conditions are met. The packaging of almost any automotive varnish or paint contains a description of the conditions under which the indicated expiration date is valid.

One of the main parameters is the permissible temperature difference at which the material should be stored. This information will help you make the right decision about whether it is wise to buy this product.

For example, consider the ordinary automobile market. Almost all goods are stored here at ambient temperatures, which in winter are sometimes minus 20–25 °C. For car cosmetics and paint materials, this often becomes the reason that after 2-3 weeks the highest quality varnish may turn out to be spoiled. The characteristics that the aerosol originally possessed may be irretrievably lost. If such a material is nevertheless used to paint a car, then the consequences in the form of clouding of the surface or peeling of the coating can spoil the mood for a long time and also cause financial losses.

Some materials are no better affected by high temperatures. In the summer heat, when the air temperature reaches 28–30 °C, the hardener, for example, thickens. This condition transforms the composition into an absolutely useless “porridge” over the course of several months. This also applies to many material options, such as paints, primers or varnish. As a result, what may be more important is not what brand and price range the aerosol is used, but whether it was stored under suitable conditions and for how long. It is clear that a budget product can give better results if it is fresh and its properties are well suited for car varnishing.

Possible defect: varnish smudges

No matter how modern the means used are, this does not guarantee the absence of defects after painting the car. The most common of these are varnish smudges. What causes them to appear? How to remove them? Let's look at these questions in more detail.

Possible causes of varnish leakage

So, smudges appeared on the car. Before we try to remove them, let’s find out the reasons for their appearance:

Paint leak on the front bumper of a car

- Excessive coat of paint.

- Slow evaporation of the solvent contained in the coating.

- The sprayer is located too close to the surface of the car during application.

- Insufficient drying time after applying one coat of varnish and before applying the next one.

- Spraying too quickly can also cause drips.

- Excessive air pressure.

Ways to eliminate smudges

There are two most effective ways to eliminate smudges and restore a perfectly smooth car surface. Let's take a closer look at each of them:

- A prerequisite for the effectiveness of this method is that the varnish is completely dry after application. Minimum – within 12 hours. However, this time can be reduced by drying with infrared lamps or an industrial hair dryer. Then apply acrylic one-component putty with a rubber spatula to the area of the car with the leak. After that, we clean the layer of putty soaked in water with P2500 sandpaper, thereby removing the smudge. Excessive pressure and going beyond the defective area should be avoided.

- Smudges of varnish after painting can also be removed with the blade of a construction knife. To do this, place the knife perpendicular to the surface of the car and scrape off any stains from the coating (do not cut under any circumstances!) The force with which we press the knife should be small.

Thus, even if there are painting defects, it is quite possible to achieve a high-quality varnish coating of the car with your own hands. There are effective ways to remove smudges, after which the surface of the car will look like new.

For one reason or another, the number of cars painted with metallic paints is growing, but for some reason they suffer in accidents just like the rest. Repair painting of such cars places serious demands on the painter’s qualifications. The main reason is that, whatever one may say, the metal particles contained in these paints are still insoluble foreign bodies, which in a layer of paint can behave absolutely unpredictably and capriciously.

Therefore, to successfully work with metallic enamels, the painter must not only practice applying paint, but also study theory - understand the most important properties of “metallics” and the principles of “behavior” of these paints.

Today you will find out

What is autovarnish and how is it used?

Varnish for painting cars appeared in the 19th century. Back then it was a quick-drying paint product. Today it has a two-component composition. Interacting with metal, it creates a durable and attractive coating that protects the car body from the effects of negative natural conditions.

The advantages of using are:

- gives an aesthetic effect. The car owner can choose a gloss or matte finish on the car;

- durability. Thanks to the special substances included in the solution, the varnish lasts a long time and does not wear off;

- provides additional hardness to the metal;

- provides the opportunity to polish the body, since after applying regular paint it is not allowed to polish the car. This can lead to negative consequences for appearance;

- ease of application.

Varnish is used to paint a car

Car varnish is applied last as a topcoat. Recently, a large number of varieties of varnish coatings have appeared.

Before…

Considering that each person has a certain degree of figurative representation of a particular process being described, and also in order to give our “technical” narrative a little artistic style, we will clarify what, how and with what we plan to paint.

Let's say we were damaged in an accident, and then a beautiful, modern, new, expensive, elegant (I think there are enough adjectives to scare you a little) car, painted a light silver metallic, was restored and prepared for painting.

Without delving into the initial nuances of damage, repair or replacement of this or that part, we will dwell on the fact that the restored body elements are primed over the entire plane, thoroughly sanded (for metallic this is done with abrasive material P400-P500 “dry” or P800-P1000 “ wet") and are designed for complete repainting. This is important, since in this case there is a serious question about the accuracy of selecting the shade of enamel, or the need to make a smooth transition to adjacent elements.

His Majesty - varnish

Modern varnishes face quite varied requirements. The varnish must have high strength, but at the same time be elastic. It must have high transparency and be resistant to various chemicals, precipitation and sunlight. And most importantly - shine perfectly!

By the way, about shine. What is glitter anyway? In R. Pohl's book “Optics and Atomic Physics” this phenomenon is explained using one interesting experiment.

The experiment boiled down to the following. A smoked fine wire mesh was installed at a distance of a few millimeters from a sheet of matte orange-red paper, and the resulting structure was illuminated with bright white light and observed.

At the same time, interesting things were observed: in a certain position, through the loops of the mesh, one could see the shadows of its wires (the brightness of which is low) and because of this, one got the impression that it was not the mesh that was visible, but a warped, shiny copper plate. In another position, the unshaded part of the paper could be seen through the hinges, which made the surface appear to the observer to be brightly shiny.

From this we can conclude that gloss is not a physical property of the surface at all, as we are accustomed to believe, but just “appearance”!

The described experiment once again proves to us how strong the influence of subjective factors can be when assessing the work of a car painter. The same subjective biases can also explain the fact that different painters give different ratings to the same varnish. Moreover, opinions about the same product can be diametrically opposed.

For example, one painter likes to work with liquid varnishes, praising their unpretentiousness to conditions and good spreadability. Others like thick ones, which can be applied in thicker layers and gain the required coating thickness in fewer layers. Everyone here is right in their own way, there is no point in arguing about this.

Well, manufacturers of modern paints and varnishes have no choice but to try to offer consumers more different varnishes for all occasions, which, as a result of their use, would give equally good results.

Indeed, the choice of transparent varnishes today is very rich. This makes it possible to adapt any type of repair not only to the conditions of a particular workshop, but even to the individual habits and skills of different painters.

For example, quick-drying varnishes are effective for performing local repairs and painting small surfaces when time is short. Long-drying ones are used to cover large areas or repaint the entire machine, as well as when working in the hot season. High-hardness varnishes are best suited for painting those parts of the car that are highly susceptible to mechanical stress - front fenders, bumpers, hoods. Ceramic varnishes - for painting expensive luxury cars. And so on.

You need to understand that each of these varnishes has its own specific characteristics, which can give a good effect only if the material is used correctly.

Let's finish the introduction here and get down to business.

In the last article we found out that one of the most important parameters of varnishes is the dry residue content. On this basis, all varnishes are divided into several classes:

- LS - low solid (low solids content);

- MS - medium solid (average solids content);

- HS - high solid (high solids content);

- UHS/VHS - ultra high solid/very high solid (ultra-high solids content).

LS materials have not been used for a long time due to their low productivity and high toxicity, so we will omit them and start with MS materials.

Silversmith's tool

Modern base enamels require the use of spray guns with low air outlet pressure. Cheap conventional sprayers, available in a wide variety on the market, are not good helpers here. Their high pressure sometimes makes it possible to obtain a wide spray, but during application it “knocks out” a large amount of solvent from the material, and the paint is laid on the surface virtually without it. On metallics this inevitably leads to the appearance of streaks and “clouds”, especially on silver colors. Here, enjoy...

If you use spray guns of more advanced systems (HVLP or LVLP) instead of conventional guns, the risk of such defects will be significantly reduced. The low outlet pressure of such sprayers allows a sufficient amount of solvent to be delivered to the surface so that the metallic grains lie on the surface in the correct form.

Before painting, do not forget to make sure that the spray gun provides a sufficiently wide and uniform spray pattern over the entire width, and that the pattern of the spray pattern has the correct outline.

To apply base enamels, it is recommended to use a gun with a nozzle diameter of 1.3-1.4 mm. The air pressure must be accurately set directly on the gun (usually 2-2.2 bar) and not fluctuate during operation. The air must be cleaned of oil and moisture.

“Can you paint metallic?” This question was asked in the early 90s to any painter who decided to get a job at a car service. Now, when painters can easily cope with ordinary “metallic”, new requirements are placed on their qualifications: in particular, skills in working with light “metallic”

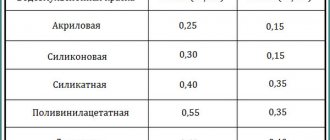

Comparison of the presented funds

For a more clear comparison of the presented models, we use a comparison table.

| Model | Color | Temperatures (°C) | Viability (h) | Volume (ml) | Price, rub) |

| Duxone 2K | white | from +18 to + 25 | 10 | 1000 | from 999 to 1,999 |

| Vika 2K AK-1301 | transparent | from +15 to + 20 | 8 | 850 | from 799 to 999 |

| Mobihel metalik | transparent | from +15 to +20 | 3 | 520 | from 780 to 1,100 |

| PPG D880HS | transparent | from +5 to +25 | 6 | 650 | from 560 to 776 |

| Bosny VG | transparent | from +15 to +20 | 5 | 500 | from 291 to 430 |

| Motip Clear Varnush | transparent | from +20 to +25 | 5 | 520 | from 329 to 530 |

| Duxone Basecoat X1 | transparent | from +18 to +20 | 2 | 1000 | from 1,400 to 1,900 |

Shouldn't we silver plate... the body!

In enamels with a metallic effect, light reflection plays a vital role. As you know, these paints, in addition to color, also contain effective pigments - aluminum particles. They act as tiny opaque mirrors that reflect the incident light, which gives the coating the effect of a characteristic sparkling shine.

Moreover, if you look at a part painted with metallic from different sides, you can clearly see that this shine is not constant - its intensity either decreases or increases. In fact, any “metallic” will look different depending on the viewing angle: the coating glows brightly, sparkles at a certain point, and then gradually darkens as the viewing angle changes (for example, when a car turns). These changes, from light to dark and back again, are called the flop effect.

The main and most difficult task facing a painter when working with metallic paints is to correctly “lay” the aluminum particles in the paint layer. The decorative properties of the resulting coating will completely depend on how these particles fall.

If we can orient these particles as needed, that is, parallel to the substrate and to each other, the coating in this case will have optimal optical properties. But if the “silver” lies chaotically in the paint layer, scattering light in different directions, this will lead to color distortion, disruption of the flop effect and the appearance of “clouds” characteristic of metallics.

As we have already said, silver colors are especially capricious in this regard, since they contain almost no color pigments. Their color is essentially made up of the aluminum grain alone, which is responsible for the flop effect. Working with such colors requires the painter to be especially careful and have a clear understanding of the behavior of aluminum particles in the paint layer.

Factors affecting metallics. Layer thickness and others

The orientation of aluminum particles is influenced by a lot of factors, but all these factors are in one way or another related to the rate of solvent evaporation and the depth of the aluminum grain in the paint layer.

First of all, to ensure uniform decomposition of the “silver”, you should avoid applying the base either too wet or too dry.

A layer that is too wet will contain more solvent, which means it will take longer to evaporate from the painted surface (that is, a thick layer will remain liquid for a longer time). In this case, the aluminum particles tend to "sink" into the bottom of the layer and are oriented vertically relative to the substrate before drying. A deeply sunken grain practically ceases to reflect the light falling on it, which leads to a distortion of color - it darkens.

And vice versa. If the enamel reaches the surface in a too dry state, there will be less solvent in such a layer, it will evaporate faster, and the grain will not have time to sink to the required depth and take the correct position in the paint layer. It will remain on the surface of the layer, reflecting too much light, which will lead to lightening of the coating and loss of color saturation. In addition, the base, which lies on the surface like a hedgehog, leads to increased consumption of varnish, its uneven shrinkage and a decrease in gloss after drying.

In both the first and second cases, the formation of stripes and “clouds” is possible.

The thicker the metallic layer, the longer it will remain liquid, the deeper the grain will have time to sink into it and the darker the overall shade of the coating will be. And vice versa.

How to choose the right varnish consistency

To avoid debris and other unnecessary substances, you should pass the varnish and all additional components through a disposable filter (sold where others). As a last resort, you can use women's nylon tights.

First you need to pour the required amount of varnish into a separate container. Then add hardener there (the proportions are indicated on the can: usually 50%). Add anti-silicone 5-7% to prevent the formation of craters and greasy stains.

You can add about 2-3% accelerator for quick drying. By the way, it is good to use in the cold season. The downside is that some accelerators give a cloudy effect after drying. It helps to correct the situation.

It is important to understand that...

... the fewer additives there are in the varnish, the more its properties will be preserved, and the fewer side effects there will be.

Next, you should thoroughly mix all the components. Some people neglect this, but if you delve into the level of molecules, it becomes clear that molecules, for example, an accelerator, affect the molecules of the varnish precisely with active mixing. The same applies to hardener and antisilicone. It is better to close the resulting varnish mixture with a lid and shake thoroughly for 10-30 seconds. This way the mixture will be homogeneous.

After diluting the varnish with hardener, it is better to immediately begin painting.

. If it stands for some time, it will begin to harden, and as a result, it will become worse to spread on the parts, creating a rough shagreen.

Basic materials - types of car varnish

There is a certain classification of varnishes for cars, but it will take more than one page. It is for this reason that it is worth highlighting the most common of them. Some still use a special cellulose varnish. It is characterized by such qualities and properties as low gloss, rapid loss of color, as well as a certain ability to ignite. Despite this, they are still purchased, and the application process is accompanied by the following features:

- For effective coverage, a minimum of three layers will be required, since its covering power is relatively weak;

- Drying after each layer should be at least 15 minutes;

- The first two layers should be of normal viscosity, as for the last layer, it should be more liquid. The proportion of the last layer consists of solvent and varnish, approximately 3 to 1;

- Final drying should take approximately 40 minutes, with full hardening occurring after five hours.

More modern are special glyphthalic car varnishes, which are characterized by a good shine, even without polishing, and also have relatively good covering power. The drying process is much longer than that of the above-described category of varnishes. It is for this reason that applying them yourself is a little more difficult.

Regardless of the type of varnish used, the application process should be carried out only after complete removal of dust, as well as with high-quality organization of the ventilation system.

At the moment, special glyphthalic varnishes that contain a special hardener and activator are relatively popular. They help increase the strength level of the material. They are much easier to use, but in terms of technical characteristics, they still do not reach acrylic varnishes. There are some features of applying this composition:

- Drying is carried out at normal room temperature, but 60 degrees is recommended;

- This varnish is sensitive to temperature, therefore it is important to carry out the application process at a temperature of 20 degrees, and dilution must be carried out strictly according to the instructions;

- When drying in a normal room, as well as with poor ventilation, it is worth using special thinners. Under their influence, the film forms much faster and becomes of better quality;

- Painting the application of glypthal varnish can be carried out using a hot method, but the formation of the coating is carried out without a solvent.

Considering the cost of modern popular varnishes, the possibility of serious savings on special resins and solvents, these varnishes are becoming increasingly popular. It is the process of their application that will be described in more detail.

Tips for choosing

Choosing a high-quality car varnish is not that difficult. We have selected several criteria that are definitely worth taking into account.

- Price. One of the most important components. It makes no sense to overpay significantly for a more well-known but lower quality brand. Please be aware that not all quality paint models are produced by popular manufacturers. The main thing is to do a good search and find out recommendations from friends or on the Internet.

- Color. There's not much to choose from here. Often these products are transparent or some shade of white. The first option is the most preferable and the more transparent the color, the better. First, you will preserve the paint you applied. Secondly, no matter how strange it may sound, the thinner the layer, the stronger it is.

- Drying time. You should know that at temperatures of +15 and -20°C, the varnish dries in a few hours. And under IR radiation in a couple of minutes. But not all types of these products are susceptible to the effects of such radiation.

Coating a car with varnish

The advantage of such a process as coating a car with varnish does not require any preliminary work. This applies only to the case if the varnish is applied using the “wet on wet” method, that is, the enamel is coated with a varnish composition that is not completely dry.

When coating a car with varnish, it is necessary to use special matting abrasives of category P1000-1500.

You should not use fine-grained sandpaper, as there is a risk of reducing the level of adhesion. If you buy coarse sandpaper, it will scratch the paint.

The matting process is best carried out with the obligatory use of water. Carefully carried out work will allow you to carry out the process of matting with dry abrasive. In the process of cleaning the surface from grease, which is carried out immediately after matting, it is necessary to select a degreasing composition that will not dissolve already applied compositions, for example, a special aggressive solvent produced under number 646. Most likely, it will not only remove all the grease stains present, but but can also leave behind a significantly damaged surface.

Non-shine finish

Nowadays matte finish is becoming more and more popular. A special matting composition for cars will help you make it. The aerosol is applied in several layers directly to the paint. After drying, the surface of the car becomes matte. It is worth remembering that neither products with a “chameleon” effect will be visible through this type of coating.

Matte varnish in the form of an aerosol has several undeniable advantages:

- It is more durable than conventional paint.

- Fills small cracks in the original coating, thereby inhibiting its corrosion.

- After applying the matte coating, the car does not need to be polished.

- Easy care. Simply wipe with a damp cloth.

Car varnish will help protect metal surfaces from destruction, give them shine and protect them from external influences. It is recommended to use it as written in the instructions. Only then will it be possible to create a strong and durable coating.

The division of modern materials into car varnishes and paints is quite arbitrary: most of the products from the first category are paints without the addition of a coloring pigment. those. just colorless enamels. For this reason, the same rules apply to varnishing a car after painting as for paints with a similar base. There is one significant “but”: the varnish layer is external, it is its shine that the observer sees, and it is with it that the external environment first of all comes into contact. On the other hand, despite the composition being close to the base paint, matting the surface for varnishing and applying paint needs to be done differently, which often causes confusion among those who are doing this for the first time.

The process of applying acrylic varnish to the surface of a car

Most of the varnishes described above do not require thinning. This process may only be necessary if there is a slight deviation from room temperature. In addition, dilution may be required if a fairly large area or the entire vehicle is being painted. In this situation, all heavy solvents need to bring their viscosity to approximately 15 seconds, that is, according to VZ-4 (20°C). A 1.6-1.8 mm nozzle is perfect for these viscosity parameters, and the application process should be carried out at a distance of at least 15 cm from the surface.

When working with acrylic varnishes, you must remember that they have a relatively low filling capacity. But again, there are no common characteristics here, since there are different filling abilities. The advantage of acrylic varnish is that acrylic on a car can be applied on top of alkyd enamel, but not vice versa.

The process of coating a car with such varnish is carried out strictly in 2-4 layers. As a rule, the first spraying is minimal, and all subsequent ones are applied to cover the surface of the machine and to effectively correct defects present on the surface. The solvent usually evaporates in about 10 minutes, but if dilution has been made and the drying temperature was below room temperature, it is worth slightly increasing the total drying time.

Brush painting process

“Vika”, “Gravitex” paints, “Raptor” car painting and a number of other compositions can be applied manually. This has several advantages:

- ease of work;

- good adhesion of the substance;

- painting parts with complex geometric shapes.

At the same time, manual painting with a brush also has disadvantages - uneven distribution of the composition. The main thing when painting locally is to choose a car enamel color identical to the old one. This is done in one of several ways:

- using a computer and special programs that determine the shade of enamel from a photo;

- using the VIN code or paintwork name, which is located on the packaging or sticker on the body.

Applying paint with a brush is a very labor-intensive process.

To understand how to apply paint with a brush, remember a number of recommendations:

- move the brush with a slight pressure in a back-and-forth manner;

- dip it into the paint and varnish mixture up to a third of its length;

- prevent materials from drying out on the brush;

- hold the brush at a certain angle, otherwise the thickness of the layer on the surface will be uneven;

- the remainder of the enamel is squeezed from the brush against the edges of the container with paint;

- when using slow-drying enamel, apply it in strips and then blend it, rubbing it a little into the substrate, getting an even surface area;

- After finishing work, wash the brush in solvent, and then in water and soap.

Working with polyurethane varnishes

The main difference between modern two-component varnishes and standard ones is a special hardener system, without which normal drying does not begin. It is necessary to mix the base substance with this hardener strictly before applying it to the car, since the hardening reaction begins almost immediately. Varnish of this type must be applied strictly at a temperature not lower than room temperature, as well as at low air humidity.

This varnish coating is characterized by high strength, but it is all the difficulties described above that scare away many and motivate the use of simpler, time-tested compositions.

Setting up a spray gun for varnish

If the adjustment of the spray gun for each paint is done individually, then for varnish you can only adjust it once. To do this, you need to open the paint and air supply in the torch to maximum. Next, you need to make a couple of test runs and, if necessary, reduce the air supply (to save money, you can also slightly reduce the varnish supply).

It is advisable to blow air on your hands and all clothes before painting (it is better to do this away from the workplace). Before you start painting, it doesn’t hurt to blow off the part itself in case dust particles have settled on it, after wiping it with an antistatic cloth. Then you can apply varnish.

First, it is better to go through the ends and hard-to-reach places of the parts. Next, you can apply the first layer. It is better to make it thin, since this is where the smudges break off most of all. Hard varnish (HS) can be applied in 1.5-2 layers, and soft varnish (MS) - 2-3 layers. Drying between coats should take 7-20 minutes (depending on temperature and humidity).

On a note

If you need to make a transition, then it is better to spray the paint at an angle of 45 degrees, and apply the transition with varnish in the narrowest place. If it appears over time, it will be minimally noticeable.

At the end of the work, be sure to thoroughly wash the spray bottle. This must be done not only for the sake of beauty, but also so that at important moments nothing falls off or drips from it. Ideally, you need to disassemble it and wash it in a solvent.

On a note

In a hurry, you should at least remove the tank and head for cleaning. Without this minimum maintenance, the enamels will not only clog all the holes, but also mix with other paints, changing their shade.

It is very good when you use one spray gun for paint, and the other only for varnish. This eliminates the need to constantly reconfigure the spray gun and makes it possible to choose the best nozzle option for paint and varnish. Thus, painting a car with varnish is as comfortable as possible and is fully respected.

Area of application

Varnishes in the form of aerosols belong to the group of paints and varnishes (paint and varnish materials) and have a variety of areas of use in the household. The most well-known and widely purchased universal formulations can be used in this way:

- as a car varnish for body repair;

- for covering wood, varnishing various types of furniture;

- for applying a protective coating to works of art, bathroom and kitchen accessories;

- for varnishing toys;

- in the construction industry;

- in the electrical field.

Other varnishes are used narrowly, for example, they are bought only for cars or wood coating. Some acrylic products are designed solely to protect electrical components from damage. And yet, many paints and varnishes in cylinders are interchangeable; they can be sprayed onto various types of substrates. All aerosol varnishes have one thing in common - the area for their application should be small. To cover the floor, you should purchase regular paint and varnish from a jar.

Why does varnish deteriorate?

The car shines beautifully right out of the showroom. If the owner takes proper care of it, it will look good for several more years. However, some factors are beyond the driver's control. These primarily include rain (contains chemical impurities) and ultraviolet rays, which wear out the varnish. Of course, cars that are parked in a garage are less susceptible to these adverse factors.

It is enough to wash the car from time to time, dry it thoroughly, apply wax and polish, the paint will shine like new. Automatic car wash brushes also negatively affect the condition of the paint, as they cause minor scratches.

Initially they are invisible, but frequent use increasingly damages the paintwork. It can also be damaged by parking, impacts or hail. In such cases, various dents most often occur on the car body. This requires additional sheet metal work.

Sludge

Sludge is a low-temperature, pasty deposit that is a mixture of hydrocarbon oxidation products, emulsion and water. The result of overrun, oxidation and watering of the oil. Visible at the end of the oil change procedure.

Reasons for the appearance of sludge in the engine

- Excessive mileage and, as a consequence, low activity of detergent-dispersant additives;

- acids and water getting into the engine oil;

- antifreeze getting into the engine oil;

- urban operating mode;

- a large amount of varnish and carbon deposits in the engine;

- poor crankcase ventilation.

Recommendations for the prevention of varnish deposits in the engine

Regular use of engine oil additives will help protect the internal combustion engine from the negative influence of operational factors.

MOTUL Engine Clean Auto

Compound

Ashless active detergents without chlorine, capable of forming adhesive layers in combination with metal-containing anti-wear components that protect the engine when cleaning in a low-viscosity solvent.

Recommendations for use

Add Motul Engine Clean to running engine oil at a dosage of 60 ml per 1 liter when the engine is warm.

Let the engine run for 15 minutes at idle speed without load.

Drain the running oil from the engine while it is hot.

Add new engine oil and replace the filter

Application

Passenger cars, trucks, 4T motorcycles, 4T water equipment, 4T garden equipment.

The product is fully compatible with the material of gaskets and seals.

Advantages of additive components

• The solvent breaks down the secondary varnishes that hold large particles together. This leads to a reduction in the size of contaminant varnish particles and their subsequent easier removal from the system in the form of micelles;

• Detergents help to dissolve primary varnishes and remove them into the oil volume from the surface of parts. This leads to the cleaning of piston rings from varnish and equalization of compression in the cylinders;

• Dispersants form a stable emulsion and help remove moisture;

• Anti-wear components enhance protective properties, which compensates for oil dilution.

Effect of use

— Compression equalization

in all cylinders of the engine and as a result: smooth engine operation, reduced fuel consumption, reduced oil waste, reduced carbon formation in the combustion chamber and the negative impact on sensitive after-treatment systems. Saving on repairs.

— Improved protective properties

new oil, which is important when there is a sudden increase in the amount of abrasive contaminants during the destruction of varnishes.

— Extending the service interval

new engine oil by reducing the amount of remaining varnish, sludge, oxidizers and water. Saving on motor oil.

Compression results show that when using Motul Engine Clean, compression increases by removing varnish from the piston rings.

Timken ASTM D2782 test results show that there is no loss of oil protection properties when using Motul Engine Clean, although viscosity is reduced by 10%.

Corrosion test results show that there is no reduction in the anti-corrosion properties of the engine oil when using Motul Engine Clean.

MOTUL Hydraulic Lifter Care

Compound

A powerful package of ashless anti-wear (Ashless EP) additives in a base oil similar to that used in motor oil.

Recommendations for use

For professional use. It is recommended for use when characteristic noise occurs from the elements of the gas distribution mechanism.

Pour Motul Hydraulic Lifter Care into the lubrication system at a dosage of 60 ml per 1 liter of engine oil. The product works during operation.

Application

Passenger cars, trucks, 4T motorcycles, 4T water equipment, 4T garden equipment. The product is fully compatible with the material of gaskets and seals.

Advantages

Active anti-wear components of the product create secondary structures in friction pairs, predominantly operating in boundary modes, which ensures:

- Additional protection against wear in friction pairs where the gaps are already increased;

- reducing the noise level of hydraulic compensators and timing chains;

- protection of the turbine mechanism after replacing the repair kit.

Effect of use

Additional protection of loaded sensitive friction parts such as hydraulic compensators and timing chains in extreme conditions.

Timken ASTM D2782 test results indicate that Motul Hydraulic Lifter Care has excellent anti-wear/extreme pressure properties. This product can be used anywhere where there is not enough protection.

MOTUL Engine Oil Stop Leak

Recommendations for use

For professional use. Use when oil leaks occur through the seals.

Check the engine oil level - top up to the level if necessary.

Add Motul Engine Oil Stop Leak to the oil at a dosage of 60 ml per 1 liter of engine oil.

The product works during operation.

Application

Passenger cars, trucks, 4T motorcycles, 4T water equipment, 4T garden equipment. The product is fully compatible with any type of motor oil.

Advantages

Active solvents are introduced into the structure of oil seals and gaskets, leading to softening of materials, which ensures

- Maintaining the elasticity of seals due to the component penetrating into the seals;

- stopping oil leakage through the valve stem seals into the combustion chamber.

Tips and tricks

Popular brands of varnishes are:

- Mobilehel 1K. Used for painting cars. Forms a dense layer without drips. Transparent, applied over paint as a topcoat. Dries completely in 60–90 minutes.

- Brulex. Acrylic varnish spray creates a decorative glossy coating on surfaces made of wood, metal and plastic. Air dries and does not turn yellow.

- Holex. Acrylic spray for body painting, dries quickly (less than an hour). Very durable, does not become cloudy.

Before applying, it is better to practice on an inconspicuous place, especially if the work is being done for the first time. Remember to shake the bottle of varnish before use so that the composition is uniform. When working indoors, you should use a respirator and protective gloves, since many varnishes contain toxic solvents. These tips will help you varnish with excellent results and be safe for your health.

Features of application of materials

Before starting work, it is important to properly prepare the base. If varnish is applied over new paint, the coating must be dry and even. Old enamel layers will have to be cleaned and degreased. As a result, there should be no dirt, dust, or rust left on the surface, otherwise after varnishing you will get “shagreen.” Requirements for the work space: closed, well-lit, ventilated, with a temperature of 20 degrees.

The operating procedure is as follows:

- Shake the container with the material well;

- apply a developing (semi-dry) layer of varnish, spraying it from a distance of 35–40 cm; you cannot linger in one place - otherwise there will be drips;

- let the product dry (the time is indicated in the instructions for the specific product, usually 10 minutes);

- make another 2-3 layers of varnish;

- dry completely (naturally or using infrared heaters).

If there is any varnish left, it can be used later. You just need to clean the sprayer. To do this, turn the can over and spray until it stops completely.

Aerosol can device

The concave bottom protects the cylinder from high pressure. Inside there is paint (varnish) and inert gas and there is a tube through which the paintwork material flows upward. It ends with a spray head with a valve, the latter does not allow the product to escape until pressed.

The varnish in aerosol form contains a sufficient amount of diluent (solvent), so it is sprayed in very small drops. But liquid varnish can be applied in several layers, which gives a better result.