Operating oil temperature and “positive” deviations from it

temperature sensor

During operation of the motor unit, increased pressure and high temperature are created in its working area, which have a destructive effect on all interacting parts. In order to counteract these two dangerous factors, a protective substance is poured into the system - oil, which is designed to maintain an optimally comfortable environment in the installation. The operating temperature of oil in a car engine is 90-105 degrees Celsius. Any deviation from it - up or down - entails interruptions in the operation of the motor. If low temperatures affect engine starting and power, then with “positive” deviations the situation is more serious.

The boiling point of automobile oil characterizes the properties of each ingredient used in its composition. And it is determined by the lowest parameter. So, for example, if one of the additives has a boiling point of 180 degrees, and the other components have a boiling point of 195, then the first boiling point will be set for the motor oil.

The boiling process is accompanied by bubbling of the lubricant, its volatility and the formation of a large number of deposits that clog the interpart gaps and channels of the lubrication system.

Because Since oil, regardless of its base - mineral, semi-synthetic or synthetic, is a flammable product, its properties are also characterized by the main parameter - the flash point of the oil. Reaching a critical value causes ignition of fuel and lubricants. Despite the fact that many manufacturers of technical fluids indicate the ignition temperature in the range from 230 to 240 degrees Celsius, in real conditions it turns out to be much lower and amounts to 150-190 degrees. This is due to the fact that during the combustion of oil in the engine, additional vapors are formed, which cause early ignition of the lubricant. Thus, the actual flash point of the oil depends on the amount of steam produced as a result of its boiling.

How does the engine oil temperature change?

During movement along the engine lines, the lubricant undergoes serious changes, as it is under the influence of high temperature. The metal surfaces of the cylinders can heat up to 300°C. Moving along the line, the lubricant can burn and evaporate. To prevent oil vapors from igniting, a little trick is used, namely, they use those hydrocarbons that have a high ignition temperature and are inactive under standard operating conditions. This feature is determined by a parameter called flash point.

How is this value determined? To find out this parameter, the oil is placed in a crucible. Next, the tank is heated until ignited. This is how the temperature indicator is determined. In practice, this value is 220 g. Still, this parameter is not critical and some manufacturers of automobile oil products do not provide information about the ignition temperature.

Optimal engine oil temperature

Groups of materials used in industry, intended for lubrication of hydraulic transmissions, equipment, measuring equipment, machine tools, have a varied operating mode.

Typically, the operating temperature is in the range of 40–60 °C. But with the development of technology, mechanisms with increased load levels, requirements for oil resistance to oxidation over several thousand hours of operation, and functional modes up to 100 ° C began to appear more and more often.

The operating temperature of the material depends on its viscosity. The higher its level, the higher the thermal loads the operational properties of the industrial oil will be maintained.

Normalization of parameters for low- and medium-viscosity material is carried out at a temperature of 50 °C, and for heavy (high-viscosity) material - at 100 °C.

The operating range of the oil is limited to two values. The lower value is the pour point, and the upper value is the ignition temperature of the vapors.

Any extreme is dangerous for the mechanisms, and when high thermal values are reached, there is a danger of the motor catching fire.

Oil flash

Flashing of the lubricant occurs when it is mixed with fuel. This effect occurs when a gas flame approaches it. The lubricant heats up, high concentration vapors appear, this leads to their ignition. Ignition and flash characterize such a parameter as the volatility of the lubricant. It directly depends on the type of lubricant and the degree of its purification.

If the flash point drops sharply, it means there is a serious problem with the engine. These include:

- problems with the injection system;

- fuel supply failure;

- carburetor failure.

To find out the flash point of a specific lubricant, the working fluid is heated in a special crucible with the lid closed and open. The desired indicator is fixed using a lit wick held over a crucible with hot oil.

When it is heated, the concentration of petroleum product vapor greatly increases. This causes the engine oil to ignite quickly, similar to a fire. Regardless of its type (synthetic or mineral), quality oil not only sparks, it continues to burn.

Engine oil viscosity

The characteristic determines the ability of a liquid material to resist flow due to internal friction. The value is calculated under different conditions, so there are two types:

- kinematic viscosity shows the ability of a material to resist flow under the influence of gravity. It is measured in Stokes (St) or square millimeters per second (mm2/s). Most often, the characteristic is determined for temperatures of 40 and 100 °C;

- dynamic viscosity determines the ratio of force to shear rate. The characteristic shows the ability of motor oil to flow at different temperatures, measured in centipoise (Cp) or in (N s/cm2).

Additives

At the current level of development of engine building, the use of oil without additives is almost impossible, because It is impossible to create oils that would provide effective engine protection and at the same time not deteriorate over a long period of time. All modern motor oils contain a package (set) of additives, the total content of which can reach 20%.

Additives can be divided into several types:

- Viscosity-thickening additives

- Detergent additives (detergents and dispersants)

- Anti-wear additives

- Oxidation inhibitors (anti-oxidation additives)

- Corrosion and rust inhibitors

- Antifoam additives

- Friction modifiers

- Depressant additives.

Mechanism of action of thickening additives

Viscosity-thickening additives. The mechanism of their action is based on a change in the shape of polymer macromolecules depending on temperature. When cold, these molecules, being rolled into spirals, do not affect the viscosity of the oil; when heated, they straighten out and the oil thickens, or, more precisely, does not become too liquid. In fact, this additive increases the viscosity index of the oil. Oils that contain viscosity additives (up to 10%) are called thickened - these are winter and all-season varieties. Depending on the amount of added viscosity-thickening additive, oils with different viscosities can be obtained. The higher the initial viscosity index of the base oil, the less viscosity thickening additive must be added. If the viscosity index is high enough, it is possible to obtain motor oil that does not contain thickeners. Current trends in the development of motor oils are aimed at creating motor oils with low viscosity ranges. The reason is that such oils typically provide energy-saving properties (i.e., they save fuel) and contain little or no thickener. Why is a large amount of thickener in motor oil undesirable for the engine? The engine has many friction pairs where the oil is subjected to high shear loads, which results in the destruction of the thickener. This leads to a loss of engine oil viscosity, deterioration of lubrication functions (reduction in the thickness of the lubricating film), and the products of thickener destruction are a potential source of carbon deposits and varnish deposits in the engine. Oils with wide viscosity ranges are aimed exclusively at sports use. They are intended only for extreme operating conditions, in which high viscosity properties are most important, and not their stability over time.

Detergent additives. Detergent additives are needed to prevent the formation of varnish and soot (in diesel engines) deposits on engine parts. They, as a rule, consist of detergent components, which wash out the products of oil oxidation and wear of parts and carry them to the filter, and dispersing components, which help crush large soot particles into small ones (no more than a micron).

Detergents. The principle of operation of these additives in the engine is exactly the same as that of detergents used in everyday life. In addition, detergents have alkaline properties, i.e. can neutralize acids. Acids are formed during the combustion of sulfur contained in fuel, especially diesel, and during the oxidation of the oil itself. By neutralizing such acidic products, corrosion of engine parts is effectively prevented. Those. The second important function of such additives is neutralization of acids and anti-corrosion properties.

Action of dispersants

Dispersants. The main task of these additives is to maintain contaminants in the oil in a dissolved state, prevent their deposits on engine parts, oil channels, etc., and disperse (dissolve) large contaminants. Dispersing additives keep dirt in a finely dispersed state, preventing it from sticking together into large lumps and burning to the metal. Naturally, dirt passes through the entire lubrication system, the filter lets it through, but this is much less evil than if it were deposited on the metal. By the way, the results of detergent additives can be observed almost immediately after replacing the old oil with a new one. It seems like I just filled it up, drove it around a little, and it’s already black! Don't worry. In this case, the blackness of the oil indicates the high cleaning ability of its additives - they washed away the dirt from the walls, brought it to a safe consistency, and the oil drives it through the lubrication system.

Anti-wear additives. The main function is to prevent wear of engine rubbing parts in places where it is impossible to form an oil film of the required thickness. They work by absorbing into the metal surface, and then chemically reacting with it during metal-to-metal contact, the more actively the more heat generated during this contact, creating a special metal film with “sliding” properties, which prevents abrasive wear .

Oxidation inhibitors (anti-oxidation additives). During operation, the engine oil is constantly exposed to high temperatures, atmospheric oxygen and nitrogen oxides, which causes its oxidation, destruction of additives and thickening. Antioxidant additives slow down the oxidation of oils and the inevitable subsequent formation of corrosive deposits. The principle of their action is a chemical reaction at high temperatures with products that cause oxidation of the oil. They are divided into inhibitor additives, which work in the general volume of oil, and thermal-oxidative additives, which perform their functions in the working layer on heated surfaces.

Corrosion and rust inhibitors. Corrosion inhibitors are designed to protect the surface of engine parts from corrosion caused by organic and mineral acids formed during the oxidation of oil and additives. Their mechanism of action is the formation of a protective film on the surface of parts and neutralization of acids. Rust inhibitors are primarily designed to protect steel and cast iron cylinder walls, pistons and rings. The mechanism of action is similar. Anti-corrosion additives are often confused with antioxidants. These are different things. Antioxidants, as mentioned above, protect the oil itself from oxidation. Anti-corrosion – the surface of metal parts. They contribute to the formation of a durable oil film on the metal, protecting it from contact with acids and water that are always present in the oil volume.

Anti-foam additives. When the oil is strongly mixed with air, which is particularly observed during engine operation, when the crankshaft intensively agitates the oil in the crankcase, increased foam formation is possible. This process is also facilitated by various contaminants present in the oil. Its formation significantly impairs the efficiency of lubrication of engine parts, which can lead to increased wear and poor heat dissipation. Antifoam additives (usually silicones or polyoxanes) do not dissolve in motor oils, but are present in the form of tiny droplets. Their action is based on the destruction of air bubbles. It is almost impossible to do without these additives, but their presence should not exceed thousandths of a percent - during the thermal decomposition of silicone, silicon oxide is formed, which is a strong abrasive.

Friction modifiers. For modern engines, they are increasingly trying to use oils with friction modifiers, which make it possible to reduce the coefficient of friction between rubbing parts in order to obtain energy-saving oils. The most well-known friction modifiers are graphite and molybdenum disulfide. They are very difficult to use in modern oils because these substances are insoluble in the oil and can only be dispersed in the oil in the form of small particles. This requires the introduction of additional dispersants and dispersion stabilizers into the oil, but this still does not allow the use of such oils for a long time. Therefore, at the moment, oil-soluble esters of fatty acids, which have very good adhesion to metal surfaces and form a layer of friction-reducing molecules on them, are usually used as friction modifiers.

Depressant additives (for mineral oils). When the temperature of the oil drops significantly, paraffin crystals begin to form in it, which leads to a loss of oil mobility and, as a result, low-temperature engine starting and oil pumpability through the channels deteriorate. During the production of base oils, some of the paraffins are removed, but their complete removal is impossible for technological and economic reasons (the costs of obtaining the base oil greatly increase). Typically, mineral base oil has a pour point of about -15°C. The possibility of obtaining mineral motor oils with pour points of -30°C...-35°C is achieved by introducing depressant additives into the oil. These additives prevent the accretion of paraffin crystals, but do not prevent their appearance at all (the principle of action is the same as that of diesel antigels).

Maximum synthetic

Synthetic oil is a synthesis of basic synthetic substances, including additives that are useful for the engine, which increase its wear resistance, protect against corrosion and ensure cleanliness.

The oil, which is called “synthetic,” is designated Fully Synthetic on the container. Maximum syntheticity is usually called the excellent quality of the oil, its minimal combustion and preservation of synthetic properties. There is a classification of motor oils. On the canister it is designated SAE (systematization of substances developed by the American Association of Automotive Engineers). It divides all motor oils into viscosity classes: from 0W to 60. The number indicates liquid oil (used at negative temperatures), and the higher the number, the thicker it is (for positive temperatures).

Base oils

Motor oil consists of a base oil and additives. The properties of the oil are determined primarily by the chemical composition of the base, while additives are designed to adjust and improve these characteristics. Using additives, you can significantly improve the performance properties of motor oils, even those made from not the best base oils. But during long-term operation and especially under high loads, the additives are destroyed, and the final quality of the motor oil, which has worked in the engine for more than half of its intended period, is determined by the quality of the base oil. Oil bases are mineral (i.e., obtained by purifying the corresponding fraction of oil) and synthetic (i.e., obtained by catalytic synthesis from gases). A combination of mineral and synthetic bases, with at least 25% synthetic base oil, is called a semi-synthetic base.

Mineral and synthetic oil molecules

Oils are hydrocarbons with a specific number of carbon atoms. These atoms can be connected either in long and straight chains or in branched ones, like the crown of a tree. The more “straight” the chains are, the better the oil properties will be. For example, it is easier for “branched” molecules to curl into a ball because they are more compact - this is how freezing occurs. That is, they will freeze at a higher temperature than their “colleagues” consisting of straight chains. So, we need to get an oil consisting of beautiful identical straight hydrocarbon chains. No harmful impurities, unsaturated bonds or rings. The oil obtained from petroleum goes towards the “ideal”, weeding out everything unnecessary using more or less sophisticated methods. If less is a regular mineral water, more is hydrocracking oil. In the process of catalytic hydrocracking, “straightening” of chains occurs—isomerization, but the formation of selected molecules cannot be obtained in this way. Well, what about synthetic oil? It is obtained from light gases by “increasing” the chain length to the required number of carbon atoms. The conditions of this reaction are much better controlled, so that almost linear chains of a given length can be obtained.

Conditional performance characteristics (ascending quality), in% (mineral base oil is taken as 100%)

- Mineral, normal quality - 100%

- Hydrocracking, improved mineral - 200%

- Synthetic, polyalphaolefin - 300%

- Synthetic, ester - 500%

According to the American Petroleum Institute (API) classification, base oils are divided into five categories:

- Group I – base oils that are obtained by selective purification and dewaxing with solvents (regular mineral oils)

- Group II - highly refined base oils, low in aromatics and paraffins, with increased oxidative stability (hydrotreated oils - improved mineral oils)

- Group III - base oils with a high viscosity index, obtained by catalytic hydrocracking (HC technology). During special processing, the molecular structure of the oil is improved, bringing the properties of group III base oils closer to group IV synthetic base oils. It is no coincidence that oils in this group are classified as semi-synthetic (and some companies even classify them as synthetic base oils).

- Group IV – synthetic base oils based on polyalphaolefins (PAO). Polyalphaolefins obtained as a result of a chemical process have the characteristics of a uniform composition, very high oxidative stability, a high viscosity index and do not contain paraffin molecules in their composition.

- Group V – other base oils not included in the previous groups. This group includes other synthetic base oils and vegetable-based base oils.

The chemical composition of mineral bases depends on the quality of the oil, the boiling point of the selected oil fractions, as well as the methods and degree of their purification. Mineral base is the cheapest. This is a product of direct distillation of petroleum, consisting of molecules of different lengths and different structures. Because of this heterogeneity, instability of viscosity-temperature properties, high volatility, and low oxidation resistance occur. Mineral base is the most common in the world of motor oils.

Improvement of mineral base oils is carried out in two main directions. The first, in which the oil is purified only to such an extent that the optimal content of resins, acids, sulfur compounds, nitrogen remains in it and, additionally, additives are introduced to improve some functional properties. This method does not allow obtaining oils of a sufficiently high quality level. The second direction, in which the base oil is completely purified of all impurities and molecular modification is carried out using the hydrocracking method. The result is an oil with valuable properties for heavy duty operation (high resistance to shear deformation at high speeds, loads and temperatures, high viscosity index and stability of parameters).

What class do these oils belong to? In terms of price, “hydrocracking” is closer to “mineral water”, and in terms of quality, as the seller assures, it is no worse than “synthetics”. But we understand that if this were the case, such an expensive pleasure as synthetic oil would die out as a class... Hydrocracking oil is closer to mineral oil not only in price, but also in the method of production, because it is also made from oil. Why is it better then? As the name suggests, it undergoes deeper processing using hydrocracking. And at the first stages, its production is no different from the production of mineral oil. Undesirable impurities, such as sulfur or nitrogen compounds, asphaltene (bitumen) substances and aromatic polycyclic compounds, which increase coking and the dependence of viscosity on temperature, are removed from ordinary mineral oil using a variety of physical and chemical methods. Dewaxing removes paraffins that increase the pour point of oils. However, it is clear that it is impossible to remove all unnecessary impurities using this method - roughly speaking, this is the reason for the worse properties of the “mineral water”. Oil processing can continue further. After all, there are still unsaturated hydrocarbons that accelerate the aging of the oil due to oxidation, and impurities also remain. Hydrotreating (exposure to hydrogen at high temperature and pressure) converts unsaturated and aromatic hydrocarbons into saturated hydrocarbons, which increases the oil’s resistance to oxidation. Thus, hydrotreated oil has an additional advantage. What about hydrocracking? This is an even deeper type of processing, when several reactions occur simultaneously. Which ones? The same hated sulfur and nitrogen compounds are removed, long chains are broken (cracking) into shorter ones with a homogeneous structure, the break points in new shortened molecules are saturated with hydrogen (hydrogenation). Hence the name – “hydrocracking”. Thus, with hydrocracking, all the signs of synthesis are evident - the creation of a new compound from the initial raw material, with a new structure and properties. Therefore, hydrocracking is often called NS synthesis. But it's not that simple. Some components of oil that are generally considered harmful can be quite valuable in places. For example, resins, fatty acids and naphthenic acids improve the stickiness and durability of the oil adsorption film and thereby improve the lubricity of the oil. Some sulfur and nitrogen compounds have antioxidant properties. Thus, when oil is deeply cleaned, some of its lubricating, anti-oxidation and anti-corrosion properties may deteriorate. This problem is corrected by special additives, which are added at oil mixing plants.

So, hydrocracking oils are products of distillation and deep purification of oil. Hydrocracking discards everything “unnecessary”, but if something “useful” is captured, the necessary properties are imparted with the help of additives. But it is difficult to clearly filter out unnecessary impurities - therefore, there is greater carbon formation and “promotion” of corrosion in hydrocracking oils compared to “synthetics”. Hydrocracking oil is similar in quality to “synthetic”, but ages faster and loses its properties. But they have a high viscosity index, antioxidant resistance and resistance to shear deformation, and can protect against wear even better than synthetic ones. On the other hand, “synthetics” are more homogeneous in the sense of linearity of hydrocarbon chains, which gives advantages, for example, in freezing point. There is one more nuance. Hydrocracking is a catalytic process, as is synthesis. But if the first one uses, for example, nickel, then the second one uses carbon. It is clear that carbon is better in this sense, since the oil will be free of unwanted impurities of catalyst compounds.

The most interesting thing is that the vast majority of motor oils positioned as semi-synthetic, and even fully synthetic, are nothing more than hydrocracked oils. This is a general trend among the largest oil producers. The BP (except Visco 7000), Shell (except 0W-40), partly Castrol, Mobil, Esso, Chevron, Fuchs program is based on hydrocracking. All oils from the South Korean company ZIC are hydrocracking only.

Semi-synthetic is a mixture of mineral and synthetic base oils, and can contain from 20 to 40 percent “synthetics”. There are no special requirements for manufacturers of semi-synthetic lubricants regarding how much synthetic base oil (synthetic component) should be in the finished motor oil. There are also no regulations regarding which synthetic component (Group III or Group IV base oil) to use in the manufacture of a semi-synthetic lubricant. According to their characteristics, these oils occupy an intermediate position between mineral and synthetic oils, i.e. their properties are better than conventional mineral oils, but worse than synthetic ones. In terms of price, these oils are much cheaper than synthetic ones.

Synthetic oils have exceptionally favorable viscosity-temperature characteristics. This is, firstly, a much lower pour point than mineral ones (-50°C, -60°C) and a very high viscosity index, which makes starting the engine much easier in frosty weather. Secondly, they have a higher viscosity at operating temperatures above 100°C - thanks to this, the oil film separating the friction surfaces is not destroyed under extreme thermal conditions. Other advantages of synthetic oils include increased resistance to shear deformation (due to the homogeneity of the structure), high thermal-oxidative stability, that is, a low tendency to form deposits and varnishes (varnishes are transparent, very durable, practically insoluble films deposited on hot surfaces, consisting of from oxidation products), as well as low volatility and waste consumption compared to mineral oils. It is also important that synthetics require the introduction of a minimum amount of thickening additives, and especially high-quality varieties do not require such additives at all, therefore, these oils are very stable - after all, it is the additives that are destroyed first. All these properties of synthetic oils help reduce overall mechanical losses in the engine and reduce wear of parts. In addition, their resource exceeds the resource of mineral ones by 5 or more times. The main factor limiting the use of synthetic oils is their high cost. They are 3-5 times more expensive than mineral ones.

The synthetic base is usually polyalphaolefins (PAO) or esters, or a mixture of them. PAOs are hydrocarbons with a chain length of about 10...12 atoms. It is obtained by polymerization (in other words, joining) of short hydrocarbon chains - monomers of 3...5 atoms. The raw materials for this are usually petroleum gases - butylene and ethylene. Esters are esters - products of neutralization of carboxylic acids with alcohols. The raw materials for production are vegetable oils, such as rapeseed, or even coconut. Esters have a number of advantages over all other known bases. Firstly, ester molecules are polar, that is, the electric charge is distributed in them so that the molecule itself “sticks” to the metal. Secondly, the viscosity of esters can be set at the stage of base production: the heavier alcohols are used, the greater the viscosity. You can do without any thickening additives, which “burn out” during operation in the engine and lead to “aging” of the oil. Modern technology makes it possible to create completely biodegradable oils based on esters, since esters are environmentally friendly products and can be easily recycled. However, all these advantages may seem too expensive. The ester base costs 5...10 times more than the mineral one! Therefore, their content in motor oils is usually limited to 3-5%, and they are used only in the most advanced products, which usually form the top of the product range of leading companies.

Symptoms of oil burning

There are four main symptoms of lubricant boiling. Among them:

- change in thermostat readings. Each car is equipped with a special indicator on the dashboard, with which the driver can always monitor the temperature of the engine lubricant. When the engine is well warmed up, the indicator needle should point to the average value (small deviations - no more than one division - are permissible in both directions). But as soon as the vehicle owner noticed that the arrow was slowly but surely creeping towards the red line, then it was time to sound the alarm - the temperature of the car oil began to rise.

- the sound of boiling. Not in all, but in many cases, when such a problem occurs, a sound characteristic of boiling oil occurs. It is impossible to confuse it with anything.

- smoke. Another symptom of a critical increase is smoke billowing from the engine compartment. Please note that its appearance can signal not only boiling oil, but also boiling coolant. In the latter case, it will be localized mainly in the area of the tank intended for filling antifreeze or antifreeze.

- black exhausts. If you did not notice the first three symptoms, or for some reason they did not form, but the oil temperature increased excessively, then the exhaust gas will begin to turn blue-black. Its intensity will increase, and it will be impossible not to notice it.

Low temperature

Low temperature parameters

It is important to remember not only the temperature outside, but also the working pace. in the engine, as it is affected by vehicle mileage and load.

In the engine of each car, two modes of lubricant supply are usually applicable:

- boundary, in which lubrication around the pistons is carried out without pressure;

- hydrodynamic, when the crankshaft is lubricated under pressure.

There are low temperature lubrication parameters. These include:

- crankability, indicating the dynamic viscosity of motor oils and the temperature regime that makes the product liquid, such that it is possible to start the engine;

- pumpability is a condition that allows oil to be pumped through the lubrication system.

It is worth noting that the operating temperature of pumpability is 5 degrees lower than the temperature state of crankability.

Temperature table

There is a table of temperature states of petroleum products.

For all-season and winter motor oils, low temp is important. solidification. When starting a cold engine or while driving at a low temperature, the liquid enters the most remote places.

The pour point, which affects the flow of working fluid to the rubbing parts, must be lower than the temperature. environment. Pace. solidification of the motor oil product should be 5-10°C lower than the engine starting temperature.

Temperature table

Flash and ignition of industrial oil

These two parameters relate to high temperature critical operating points.

Definition

As the temperature of the material increases, its evaporation begins, forming a gas mixture above the surface. If you bring an open flame source to the resulting cloud, a quick-extinguishing flash will occur, which will not ignite the oil.

The lowest temperature at which the described process occurs is called the flash point of the substance.

If you continue to heat the material, at some point the oil itself will ignite, and the fire will last for five seconds or longer. At this moment, the combustion temperature of the oil is recorded.

Causes

Firstly, the thermal parameters of a substance can change during its operation. When using a lubricant, oxidation processes and internal chemical reactions occur. Mixtures with varnishes and paints are formed, carbon deposits appear, inclusions of small particles formed during friction of engine parts.

These processes are accelerated when the unit operates at elevated temperatures and self-ignition.

Secondly, when a fuel leak occurs, for example, in a car engine. Gasoline or diesel fuel have lower thermal flash ratings. When mixed with lubricant, they lower the flash point of engine oil.

For liquid substances, flash indicators are most often established and used. There are two methods for determining its temperature in an open container (Cleveland) and a closed crucible (Penksi-Martens). These two methods give approximately the same values, the error is no more than 20 °C.

For fuel, the flash point is determined in a closed crucible in accordance with GOST 6356-75, while for motor oils the Cleveland method (open) is used.

Let's consider the values of thermal indicators for some liquids.

| Product | Flash point, °C |

| Motor gasoline | –39 |

| Diesel fuel | 78 |

| Fuel T-1 | 28 |

| Motor oil MK-22 | 259 |

| Lubricant TP-22 (turbine fluid) | 198 |

| Industrial oil I5A I20A I50A | 140 200 225 |

| Naval fuel oil F-12 | 158 |

| Ethanol | 13 |

The table shows that the thermal performance of the fuel is noticeably lower than that of substances used to lubricate engines.

For oils used in the cooking process, the “smoke point” indicator is used. This is the temperature at which the substance begins to decompose and lose its properties.

For example, unrefined sunflower oil becomes unsuitable for consumption already at 107 °C. And the highest heat treatment can be carried out using ghee. It maintains characteristics up to 252 degrees Celsius.

Signs

Reasons to suspect a critical increase in temperature in the engine may be:

- readings from instruments that are mounted in cars and on some industrial equipment: if the thermostat needle approaches the red zone, measures must be taken to cool the mechanism;

- the characteristic sound of lubricant boiling or a popping sound during a flash;

- the appearance of smoke around equipment or from under the hood of a car;

- car exhausts are black.

If one or more signs of engine overheating occur, you should immediately begin to eliminate the problem that has arisen.

Danger

When overheating, the viscosity of the lubricant decreases.

This in turn leads to:

- reducing the gap between mechanism parts;

- acceleration of oxidation processes, entry of the composition into chemical reactions, aging of the oil;

- the appearance of soot and deposits that can provoke a detonation explosion of the engine;

- the formation of a film that is baked on internal surfaces;

- flash and fire of a mechanism that can destroy equipment or a vehicle in a matter of minutes.

Fuel viscosity

Lubrication is used to avoid dry friction inside the parts located in the engine, otherwise they will quickly wear out and the engine will fail. The oil product must eliminate the possibility of friction and be efficiently pumped through the channels.

Table of lubricant viscosity values and characteristics according to SAE.

Combustion temperature is an important parameter indicating the health of the lubricant. The lubricant must be viscous. This criterion directly depends on temperature. Therefore, it is important that all processes in the engine work smoothly and do not exceed acceptable standards.

When creating engines, manufacturers calculate the optimal viscosity of the engine oil. The fact that under the influence of certain temperatures it can change is also taken into account.

Flash is determined by heating in an open or closed crucible. To fix this parameter, you need to hold a lit wick over the location of the lubricant.

For the operating temperature of the engine oil, one important rule must be observed: this criterion can only increase by two degrees per minute. As for the lubricant, it should burn.

An important parameter of motor oil is its viscosity. It should not go beyond the normal limits; only in this case can normal engine operation be achieved.

The flash point is characterized by the presence of fractions in it. This indicator is related to the volatility of the material.

The optimal temperature is 225 °.

Fractions in the composition of combustible materials indicate their poor quality. Using this type of oil will cause rapid evaporation and burnout. Temperature properties will be affected.

Lubricants and combustible materials must always be of high quality. Otherwise, it will affect the operation of the engine. The temperature must be optimal, otherwise the viscosity will decrease and the fuel will evaporate faster. This points to one constant fact: everything in the engine must work harmoniously.

Increased loads are created inside a running engine - high temperature and powerful pressure. One of the main requirements for any motor oil is its ability to maintain its properties at elevated temperatures. There are two indicators by which the quality of the lubricating fluid is determined:

- Flash point and pour point.

- Viscosity.

The boiling point of the engine oil must be within the specified range. This is only possible if the lubricant product meets the declared characteristics - the oil must be of high quality. An increase in temperature can lead to damage to the internal combustion engine. Boiling of the lubricant occurs when the power unit is not properly maintained and a load is created above the permissible level.

What to do if the oil boils?

If you are stuck in a traffic jam or in a parking space and notice oil burning, turn off the engine immediately. There is no need to panic, the main thing is to stop the engine.

If smoke appears from the engine compartment while driving, stop the car as follows:

- Minimize the load on the power plant - to do this, take your foot off the gas pedal to lower the speed.

- Turn on the car heater to maximum airflow - this will remove some of the overheated air from the working area and reduce its concentration in the engine.

- If road conditions permit, coast until the vehicle comes to a complete stop. The oncoming wind will cool the engine compartment.

- As soon as the car stops, wait another 5 minutes and only then turn off the engine.

Remember! When the temperature inside the propulsion system increases, sudden braking of the vehicle should not be allowed.

The influence of oil viscosity on engine stability

Lubricants are necessary to reduce friction forces between the surfaces of working parts and components of the power unit. When operating “dry,” jamming occurs, rapid wear and failure of the entire motor occurs. The main requirements include the following functions:

- Elimination of friction between parts.

- Free passage of lubricating fluid through all channels of the oil system.

The viscosity index of the lubricant is an important parameter. It is directly dependent on the engine temperature and the environment. The viscosity value may deviate from the optimal values due to an increase in temperature inside the motor. To ensure the coordinated operation of all power unit systems, it is necessary that all work processes take place within acceptable standards.

Why is high temperature dangerous?

If the temperature of the oil material rises above 105 degrees Celsius, then its viscosity quickly decreases, and the parts begin to come into contact with each other due to a damaged protective layer. As soon as this happens, the friction force inside the power structure will increase, which will cause a reduction in the thermal gap between the elements. Increasing the temperature of the engine oil activates its oxidation and rapid aging.

Deposits on the oil intake

The circulation of spoiled lubricant in the engine leaves particles of sludge, varnish and carbon deposits on all components of the structure. Due to oil combustion, the amount of harmful deposits increases significantly.

Carbon deposits form on the surfaces of parts as a result of carbon oxidation and are an accumulation of solids. Among them are lead, iron and other metal particles. In large quantities, carbon deposits provoke engine friction, glow ignition, and can even cause a detonation explosion.

As a result of oxidative reactions in the power plant, oil films are formed - varnishes, which, under the influence of high temperatures, are baked on the moving elements of the system.

The composition of varnishes includes ash, oxygen, hydrogen and carbon. They pose the main danger to pistons, piston rings and grooves, as well as internal combustion engine cylinders.

As soon as the temperature of the engine oil exceeds 125 degrees, it will completely lose its former viscosity and begin to leak through leaks in the structure. Thus, the motor system will begin to experience oil starvation.

The most dangerous consequence of overheating of motor lubricant can be a fire - after which it will be impossible to restore the car.

Oil selection rules

As mentioned above, the choice of a particular motor oil should be based not only on viscosity readings and car manufacturer tolerances. In addition, there are three more mandatory parameters that need to be taken into account:

- lubricant properties;

- oil operating conditions (engine operating mode);

- design features of the engine.

The first point largely depends on what type of oil - synthetic, semi-synthetic or completely mineral. It is desirable that the lubricating fluid have the following performance characteristics:

- High detergent, dispersing, stabilizing and solubilizing properties in relation to insoluble elements found in oil. The mentioned characteristics make it possible to quickly and easily clean the surface of the working parts of the engine from various contaminants. In addition, thanks to them, it is easier to clean the parts from dirt when dismantling them.

- The ability to neutralize the effects of acids, thereby preventing excessive wear of engine parts and increasing its overall life.

- High thermal and thermo-oxidative properties. They are needed to effectively cool the piston rings and pistons.

- Low volatility, as well as low oil consumption due to waste.

- Lack of ability to form foam in any condition, be it cold or hot.

- Fully compatible with seal materials (usually oil-resistant rubber) used in the gas aftertreatment system, as well as in other engine systems.

- High-quality lubrication of engine parts in any, even critical, conditions (frost or overheating).

- The ability to be pumped through the elements of the lubrication system without problems. This not only provides reliable protection of engine elements, but also makes it easier to start the engine in cold weather.

- Does not enter into chemical reactions with metal and rubber elements of the engine when it is idle for a long time.

The listed indicators of engine oil quality are often critical, and if their values are below normal, this is fraught with insufficient lubrication of individual engine parts, their excessive wear, overheating, and this, as a rule, leads to a decrease in the service life of both individual parts and the engine. in general.

Every car owner should periodically monitor the level of engine oil in the crankcase, as well as its condition, since the normal operation of the engine directly depends on this. As for the choice, it should be made based primarily on the recommendations of the engine manufacturer. Well, the above information about the physical properties and parameters of oils will certainly help you make the right choice.

Source

Why is high engine temperature dangerous?

The temperature range of motor oils is quite wide. When the power unit warms up to operating condition, the viscosity of the engine fluid shows normal values. When overheated, these indicators begin to decrease, lubrication deteriorates, and the oil film is not able to adhere to the surface of the parts.

Oil heated to 125℃ begins to bypass the piston rings, mixing with fuel and begins to burn out. Irreversible changes are taking place. The lubricating fluid actively evaporates. This can be detected by increased material consumption.

Excessive heat causes boiling, which can lead to serious problems with the internal combustion engine.

To avoid overheating of the engine oil in the engine, experts recommend:

- avoid long trips at high speeds;

- replace lubricants in a timely manner;

- take the choice of motor oil seriously, exclude the use of low-quality and questionable products;

- track temperature.

Another important condition for the smooth operation of a car engine is to follow the manufacturer’s recommendations for vehicle maintenance, and when choosing a lubricant, the official approvals of motor oils should be taken into account. Deviation from factory recommendations can lead to engine overheating and premature wear.

Operating temperature and its changes

The oil in the engine crankcase has different degrees of heating. The highest lubricant temperature during engine operation is achieved on the surface of the cylinder mirrors and the piston bottom. Part of the lubricant entering the working chamber is burned or emitted with exhaust gases. If a turbine is installed on the power unit, part of the lubricant is diverted to the bearing supports. The permissible rate of consumption of working fluid depends on the manufacturer of the power plant (ranges from 500 ml to 1.0 liters per 1000 km).

Table of temperature parameters at different points for gasoline engines

The table below shows the normal operating temperature of the oil in an atmospheric engine with spark ignition.

| Measuring point | Value, °C |

| Cams and rocker arms of the gas distribution mechanism | +50. +80 |

| Piston end surface | +340. +368 |

| Bottom of cylinder block | +140. +220 |

| Crankshaft and connecting rod lower parts | +115. +185 |

| Oil pan | +80. +150 |

The table shows that the maximum temperature loads are achieved in the combustion chamber and on the side surface of the cylinder. The degree of heating decreases along the piston body as it moves away from the surface affected by hot gases.

For example, in a VAZ-21083 engine (carburetor power system, working volume 1.5 liters), the bottom has a temperature of +337. +357 °C, and the inner part of the piston does not warm up to more than +190. +210 °C. Accordingly, the filled oil operates under variable conditions and has different fluidity.

Temperature table for diesel engines

A table of the degree of lubricant heating in diesel engines with atmospheric mixture formation is given below.

| Measuring point | Value for air-cooled units, °C | Value for liquid-cooled units, °C |

| Piston crown | +270. +298 | +265. +310 |

| Inside the piston opposite the combustion chamber | +177. +217 | +165. +220 |

| Cylinder block at the bottom of the liner | +130. +155 | +93. +137 |

| Crankpin | +127. +157 | +128. +150 |

| Molar neck | +112. +139 | +107. +137 |

Temperature loads in engines with compression ignition are lower due to the reduced rotation speed and reduced calorific value of the fuel. Power units are used on trucks where they experience increased loads. The oil used forms a stable protective film between rubbing parts under conditions of changes in rotation speed.

Test measurements were carried out in summer at an air temperature of +20 °C. In winter, the degree of heating of parts decreases by 20-30 ° C (depending on the climate zone).

Causes of engine oil overheating - how to deal with them

- First, whenever possible, you should select lubricants with improved temperature characteristics. In this case, there is a direct connection with the type of base. Mineral oil boils faster, and often operates at boundary conditions that are close to being incompatible with temperature tolerances. If your engine operates under increased loads (for example, a turbine or a highly accelerated design), then it is better to use synthetic or semi-synthetic oil.

- Secondly, you need to deal with the oil cooling system. Some engines have a lubricant cooling radiator, or its role is played by special ribs on the engine crankcase or its sump. The outer walls of the engine must be clean; a coat of oil and dust impairs heat transfer.

- Of course, the motor itself should not overheat. A faulty cooling system (pump, radiator, thermostat) not only leads to overheating of the cylinder block. Engine oil also gains extra degrees.

- Inside the power plant there are numerous channels through which lubricant is distributed throughout the entire volume. When the filter is in normal condition and the pump is functioning, the engine oil moves intensively inside the engine. In this case, the hot lubricant from the piston operating area is actively changing from the already cooled lubricant from the bottom of the crankcase. The overall temperature of the lubricants is stabilized.

- And, of course, it is necessary to carry out routine maintenance in a timely manner. As the lubricant wears out, its characteristics, including temperature, change.

Testing motor oils by heating - video

Reasons for the problem

Let's look at the reasons why the engine oil temperature begins to rise:

- The main reason for the increase in the operating temperature of the protective lubricant is its low quality. If you are trying to save money on the maintenance of your vehicle, immediately prepare for unpleasant surprises in its operation. Low-quality motor oil cannot cope with constant temperature fluctuations inside the power plant: it quickly loses its performance properties, turning into a watery liquid, which not only begins to rapidly drain from the mechanisms, leaving them without protection, but also begins to burn and evaporate.

A similar situation occurs with a high-quality lubricant after it has become obsolete. If the car owner neglects to change the oil, the oil product can also cause an increase in temperature inside the engine system.

- Faults in the cooling system can also cause the oil temperature to rise sharply. For example, this can be caused by a break or loosening of the fan drive belt or cooling system pump, a malfunction of the fan drive fluid coupling, contamination of the radiator and other design imperfections.

These are the two main reasons that can cause oil to boil inside the power plant.

And finally

As has already become clear from the above, an increase in the operating temperature of the lubricant is a dangerous ailment that every car enthusiast can encounter. You can protect yourself and your vehicle with timely maintenance. At the same time, saving on lubricating fuel and lubricants is not appropriate: the low flash point of motor oil can have a negative impact. The lubricant used for automobile engines must fully comply with the requirements of the automaker.

Standards and Specifications

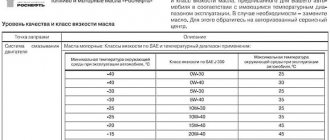

SAE J300

The classification of viscosity-temperature properties of lubricants SAE J300 was developed by the American Society of Automotive Engineers Society of Automotive Engineers. The system divides oils into two types: summer and winter (marked W - winter). For materials intended for operation at low temperatures, the limits of pumpability (MRV test - Mini Rotary Viscometer) and crankability (CCS - Cold Cranking Simulator) of the crankshaft are additionally regulated. For summer varieties, shear strength under extreme heating is determined (HTHS test - High Temperature High Shear Rate). The SAE J300 viscosity grade indicates the operating temperature range of a particular brand of engine oil. The designation of all-season varieties combines two indicators: winter and summer. For example, 5W-40.

Viscosity grades of winter motor oils SAE J300

| Low temperature viscosity | High temperature viscosity | ||||

| Class viscosity SAE | CCS, MPa-s. Max, at temperature, °C | MRV, MPa-s, Max, at temperature, °C | Kinematic viscosity, mm2/s at 100 °C | HTHS, MPa-s. Min at 150 °C and 10L6 s-1, | |

| Min | Max | ||||

| 0W | 3250 at -30 | 30000 at -35 | 3,8 | – | – |

| 5W | 3500 at -25 | 30000 at -30 | 3,8 | – | – |

| 10W | 3500 at -20 | 30000 at -25 | 4,1 | – | – |

| 15W | 3500 at -15 | 30000 at -20 | 5,6 | – | – |

| 20W | 4500 at -10 | 30000 at -15 | 5,6 | – | – |

| 25W | 6000 at -5 | 30000 at -10 | 9,3 | – | – |

Oil pour point

When the lubricant hardens, it becomes inactive and its viscosity completely disappears. The lubricant hardens due to the crystallization of paraffin. At low temperatures, motor oil dramatically changes its properties. It gains hardness and loses plasticity.

The lubricant must have an optimal temperature range between the flash and solidification coefficients.

The values of this parameter with a shift, closer to one or another coefficient, leads to a decrease in lubricating properties and loss of performance of the internal combustion engine.