Comments: no Published: 11/03/2019

Rating:

Most car enthusiasts have a vague idea of silent blocks, since they are located underneath the car in hard-to-reach places. Many drivers know that these chassis parts consist of rubber, polyurethane and a metal cylinder. Considering such signs to be basic, they call any similar parts silent blocks.

It is better to have a clear understanding of the features of their operation, repair or replacement, since knowledge will help to significantly save on repairs.

In what cases is it necessary to replace silent blocks?

Any car part has its own period of operation and silent blocks are no exception. In this regard, some drivers, especially new ones, wonder when it is time to replace them? As practice shows, the parts serve properly when the car reaches 100-130 thousand kilometers.

But here everything mainly depends on the condition of the roads on which the driver mainly moves. There are situations when a car has to be operated in different conditions:

- the driver's driving style is far from careful;

- the condition of the road surface leaves much to be desired;

- there is a need to cover the distance off-road most of the time;

- extremely difficult conditions of northern latitudes and others.

In this case, the service life of silent blocks is reduced by at least two times, if not more. Therefore, experts recommend paying close attention to such consumables and checking their technical condition every 50 thousand kilometers. This will allow you to detect the malfunction in time.

Video - types of silent blocks and their replacement:

Main symptoms of a malfunction

The car's behavior on the road may indicate that it's time to visit the nearest service station. That is, it takes the car more time to respond to steering movements. Other signs include the following:

- when braking, the car loses a little directional stability;

- while driving you can feel the vibration of the body;

- you can also hear squeaks from the front suspension;

- The suspension system itself has become more rigid than before.

All these manifestations should not be left to chance, they say, they will go away on their own. With such a negligent attitude towards the car, the driver jeopardizes not only his own safety, but also the lives of passengers.

Video - how to properly tighten silent blocks after replacing them:

Visual inspection

To accurately confirm the diagnosis of a faulty silent block, a visual inspection of the vehicle should be performed. You can do this yourself or at a car service center. To do this, you will need a pit or a lift and first clean the inspected units from dirt.

First of all, you should pay attention to the condition of the rubber insert of each part. If cracks or tears are visible on it, delamination or swelling has begun - this indicates a failure of the silent block and it needs to be changed as soon as possible

When the rubber inserts rupture, you may notice a crooked arrangement of the suspension arms.

You also need to check for play in the elements. Having taken the mount, it is worth swinging all the nodes with installed hinges. If you feel obvious changes, there is only one verdict - replacement!

Where to replace: in the garage or at a service station?

If a visual inspection reveals a faulty silent blocks, they should be replaced immediately. It is advisable to entrust this work to car service specialists, since they still have a lot of experience. However, this work can be done independently. True, it will be difficult to do this the first time, so you need to invite an assistant.

What is a silent block in a car?

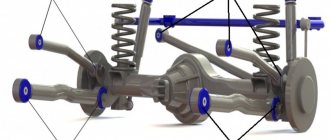

Silent block (rubber-metal hinge) is a device responsible for reducing the transmission of vibration and noise from the suspension to the car body. It consists of a pair of metal bushings, between which there is an elastic insert made, as a rule, of rubber or polyurethane. This is a kind of intermediary that is inserted between the rigid body and the suspension part (shock absorber, subframe, spring, lever). To fully understand why silent blocks are needed, try attaching a metal element to the body. In this case, all the noise and vibrations caused by the vibration of the suspension will be perfectly audible, which will cause a decrease in the comfort of the entire car and its passengers.

The shape, weight and dimensions of silent blocks differ depending on their location in the car.

Many manufacturers claim that the silent block is designed for 100,000 km. But the condition of our roads leaves much to be desired, and climatic conditions also have a significant impact. In connection with the described harmful factors, the service life can be divided into two, or even three.

Untimely replacement of a part provokes a number of problems:

- Reduced comfort while driving. Among the most visible signs are loss of vehicle stability, a feeling of roll, and the appearance of play. All this is caused by the fact that the car misses all the bumps - both large and small.

- Uneven tire wear. That is why you need to monitor the condition of the parts, because replacing tires is a very expensive pleasure.

- Damage to the lever mounts.

An image that clearly shows the location of a silent block that is already in use.

How to replace silent blocks yourself

You can replace silent blocks directly from the pit on the machine, but it is more convenient to do this with the unit removed. To work you will need the following tools:

- hammer or sledgehammer;

- a set of keys;

- Screwdriver Set;

- vice;

- sandpaper.

The entire operation can be divided into several stages.

Step 1. You should put the car in the pit. In extreme cases, you can use a jack. After this, remove the assembly or assembly with the faulty part.

Step 2. After removing the assembly or assembly, you need to remove the old element. That is, to press it out. There are several ways to do this; let’s look at the most effective of them.

The best option is to use a special silent block puller suitable for your car.

Some car enthusiasts make them from a set of ordinary parts purchased at a hardware store.

Video - do-it-yourself silent block remover:

In some cases, when it is not possible to use a special puller, you can go in alternative ways.

For one such method, you will need a homemade “tool”, which includes a strong metal rod (an M120 bolt works well), a washer and a metal tube with a similar diameter to that of a worn silent block. Hit this structure with a sledgehammer until the hinge comes out of its socket. Usually 5-10 aimed strikes are enough.

You can, armed with a hacksaw for metal, cut the silent block on both sides and remove the rubber insert with a screwdriver and hammer and pull out the bushing. The main thing is that when cutting, do not touch the part itself where the consumables are installed.

In other cases, you can use a blowtorch or gas torch and burn off the rubber. After that, all that remains is to remove the hinge by simply knocking it out using a chisel and hammer.

Step 3. After pressing out the old part, you need to thoroughly clean the seat with sandpaper. And before installing a new silent block, the mounting hole should be rubbed with ordinary laundry soap. It is highly not recommended to use oil, grease and other petroleum products instead.

Step 4. The hinge can be pressed in using special tools (if available).

Or in a vice, squeezing them at a slow speed so that you can control the uniform insertion of the hinge. However, it will not be able to completely install itself in its place, so after pulling out the part, you need to place it on a flat surface

After this, use a hammer or sledgehammer to finally install the hinge, taking utmost care, as there is a risk of damaging the rubber.

Step 5. Now all that remains is to return the removed unit or part to its place.

Video - replacing silent blocks on a VAZ 2110:

How to understand when it's time to replace

Before you set out to press in these parts, you should first of all inspect them thoroughly to make sure that they really require replacement. Check for holes and any deformations, for swollen rubber on the hinges and for cracks. Manipulate the components, determining the presence of backlashes. If the permissible norm is exceeded, then replacement of parts is inevitable. It is not recommended to delay the pressing procedure. Over time, this problem will only get worse and can lead to suspension arm failure. The main indicators that indicate the failure of one part or several:

- Driving the car has become much more difficult.

- When overcoming bumps, the suspension begins to knock loudly. Tires wear unevenly, which has not been observed before.

- It has become much more difficult to adjust wheel alignment.

What can cause problems with the suspension arm?

Depending on road conditions and mileage, a number of problems can arise with this seemingly powerful and simple design. One of them may be wear of fasteners.

The rubber in silent blocks ages, hardens and cracks. In advanced cases, the rubber bands fly apart, exposing the surrounding metal bushings, the suspension begins to make clicking sounds during operation, and the car turns into a “rattle.”

In addition, over time, ball joints are subject to wear, which also leads to play in the suspension, extraneous sounds and other unpleasant symptoms. And even if you think that the wishbone itself, as a metal structure, cannot become unusable, think twice - it can also be bent or broken, and if the car is very old, it can rot and break.

If the lever is slightly deformed and for some reason the driver does not notice this (he is not bothered by vibrations, deterioration of maneuverability, or the car pulling to the side when moving in a straight line), with the next shock load the bent metal may crack - the lever will break. In this case, deformation of a part can occur not only due to a serious impact (hitting a curb or an open well), sometimes it is enough to fly into a hole or into a speed bump at speed. Side impacts are also very dangerous.

Since the suspension design is programmed for vertical travel, even a small blow from the side can cause serious damage not only to the silent blocks, but also to the lever itself. One of the textbook examples is lateral sliding on ice followed by a collision with a curb stone.

Types of silent blocks

There are only three types:

- with rubber (rubber) filling;

- with polyurethane filling;

- "floating" silent blocks.

Elements filled with rubber are exposed to the negative effects of various factors during operation. These may be chemical reagents, petroleum products, high or low temperatures. In cold weather, rubber tends to lose elasticity, and in hot weather it becomes softer. All this affects the wear of the silent blocks themselves and overall handling. However, this does not prevent them from performing their task for quite a long time.

Silent blocks with polyurethane filling are considered more advanced. Their performance properties are somewhat better. They are less susceptible to chemical attack and do not lose their properties even at different temperatures. As a result, the service life of polyurethane hinges is much longer - up to 200 thousand km. mileage, but they also need to be replaced over time.

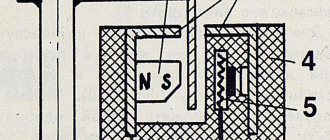

Floating silent block disassembled

It is worth mentioning separately about the so-called “floating” silent blocks. In fact, these are not exactly silent blocks, but a type of ball joint. The central bushing of the spherical hinge rotates in a plastic insert. There is lubricant inside, which is covered with protective covers or seals. This design allows the inner sleeve to rotate smoothly at large angles. Often, “floating” joints are installed in the steering knuckles of the rear suspension or in the reaction rods. The disadvantage of such hinges is rapid wear, especially of the inner bushing, which wears out into an oval and a characteristic knock appears.

Replacement only assembled

The big advantage of these units is that they do not require maintenance. During the operation of the car, you just need to periodically monitor the condition of the hinges. When they are in good working order, there is no friction inside the structure or contact with metal, so if used correctly they last quite a long time.

Silent blocks are characterized by a non-separable design, so they can only be replaced when assembled. The cost of these parts is quite affordable, so there is no point in saving on repairs.

When replacing a rubber-metal joint, it is important to adhere to certain rules. The main thing is to tighten all connections under load. In this case, the machine must have its wheels on the ground.

Each car uses several types of hinges. For example, the camber arm bears virtually no load, so it can be repaired. In other cases, it is better not to take risks, since the wear of more expensive suspension elements depends on the serviceability of this unit. A repaired hinge will not be able to perform its functions 100%.

See also:

Tuning the suspension of the VAZ 2107

Types of silent blocks

Depending on the design, materials used or purpose, silent blocks can be divided into various categories, which highlight their main feature for this case:

- rubber or polyurethane, when the main parameter is rigidity and durability with fixed weight and dimensions;

- rigid or floating, in the second case we are more likely dealing with a more complex hinge, which includes a rubber elastic element;

- working for bending or rotation, depending on the predominant nature of the relative movement of the cages;

- according to the number of clips - sometimes the hinges do not have one or both metal bushings, and the elastic element is fixed with glue or vulcanization directly to the suspension parts; replacement in this case requires special repair structures or is carried out as an aggregate, that is, assembled.

It would not be a big mistake to use the term in cases where the unit is not a classic silent block. In the end, it is more important to reflect the essence of the functions performed in the name than to be academically precise.

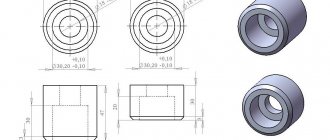

What is a silent block

A silent block is a special vibration isolator made of two metal bushings inserted into each other and an elastomeric (rubber) insert between them. The main feature of this vibration isolator is the strong permanent connection between the elastomer and the metal obtained during the vulcanization process, due to which there is practically no friction force between them. The block is designed to dampen radial, torsional and axial vibrations. In other words, the silent block connects the car’s suspension parts, in particular the suspension arm and the body, and, due to the rubber insert, reduces vibrations between them.

Preventing rapid wear

The rubber-metal hinge is not a rigid suspension element, so its rubber insert should not be heavily loaded. It should be remembered that you cannot leave a car with an overloaded suspension or wheels suspended for a long time.

Often, the rigidity of the block varies along the radius, so there are special marks on it that are clearly visible upon inspection. These are the ones you need to focus on when installing them on a car.

During operation of the machine, it is important to ensure that lubricant, fuel, and automotive chemicals do not get on the rubber parts of the hinges. In addition, after driving on dirty, dusty dirt roads, the suspension components should be washed. Penetrating into cracks, microcracks, dust and water destroy rubber inserts. Moisture is especially dangerous in the winter season. It is also recommended to periodically apply a special lubricant to clean and restore the surface layer of these components.

See also:

How does a car's air suspension work?

Thus, careful operation of the car, control and proper care of the suspension elements will significantly increase the life of the silent blocks.

We change it ourselves or contact a service station

To replace the silent block with your own hands

you will need:

- Ball joint remover.

- Jack.

- Device for pressing silent blocks.

- Set of wrenches.

If you don’t have the necessary tool, it doesn’t matter. Everything can be purchased on the automobile market for a symbolic price. All work consists of several stages:

- Using a jack, lift the desired wheel and remove it.

- Unscrew the nut of the upper ball joint. Let's take it off.

- We remove the upper arm and silent block, press a new one into the same place.

- Lubricate the lever axles with grease and screw it into place.

But any experienced motorist will advise turning to professionals. Every car center has a service station where they will not only quickly and correctly replace the part, but also do a wheel alignment afterwards. After the suspension intervention procedure, this must be done so that the car does not “steer” to the side when driving.

Difficulties when replacing silent blocks on a VAZ Seven

Replacing silent blocks on a VAZ 2107 is a troublesome task, especially if you need to change these parts in the front part of the car.

In addition, there are several silent blocks on the front for each wheel. Unfortunately, there’s no escape from this, so let’s get started:

- We will need, in addition to a set of keys, a jack and a hammer, a puller for ball joints. You may need a blowtorch to warm up stuck parts, as well as ties for the suspension springs;

- first, the silent blocks of the upper arm are replaced;

- Unscrew the upper ball joint nut with a 22 wrench and remove it with a special puller;

- dismantle the upper arm, for which we remove the bumper mounting bolt, and then the remaining fasteners;

- now you need to remove the old bushing and replace it with a new one using the methods described above;

- We install the lever in the reverse order.

Silent block: what is it?

Essentially, a silent block is a rubber-metal hinge consisting of two metal bushings, between which there is a rubber insert.

A characteristic feature of this consumable is that there is no need for lubrication. Also, the part has no gap and, due to its small size and simple design, can last a long time.

And since the silent block is classified as consumables, when it wears out it is simply replaced. It cannot be repaired due to its simple design and inexpensive cost of new parts.

Video - what is a silent block and a suspension arm:

What are they needed for

Almost any mechanism has a frictional force, which has a detrimental effect on the entire car. Take, for example, the suspension of a car - without protective measures it is simply impossible to operate it. Therefore, as soon as such a field as mechanical engineering appeared, the need arose to create a unit where there is no friction. The silent block became such a detail.

In addition, the same suspension perceives various road vibrations that are transmitted from the wheels. Each node performs its own task. Using levers, reliable and movable fastening of the wheels to the body is ensured, shock absorbers eliminate strong vibrations, and thanks to the anti-roll bar, the car does not sway.

Silent blocks also play an equally important role, since they dampen vibrations that spread between nodes. Moreover, their design is made in such a way that it allows vibrations to be perceived simultaneously in any direction. As a rule, these are loads of a radial, axial and angular nature. Thus, the hinge protects the remaining parts of the suspension.

Video - how to replace the silent blocks of the front control arms on a Skoda Octavia:

Where are they located?

As you can already understand, the silent block is located in the chassis of the car.

Most often these are attachment points:

- front suspension arms;

- rear suspension units;

- anti-roll bar;

- gearboxes;

- shock absorbers;

- engine.

When the car drives over uneven surfaces, each silent block takes on heavy loads. For this reason, it is subject to rapid wear. Therefore, if silent blocks are not replaced in time, this may lead to unpleasant consequences, including failure of the entire unit.

Silent blocks, what are they for?

This part is an intermediary between the rigid body structure and the suspension component (link, shock absorber, torque rod, anti-roll bar, spring, subframe, etc.).

If you screw a metal suspension element to a metal body element, the connection will be excessively rigid and every vibration of the suspension will be clearly audible, which will significantly reduce the level of comfort of the vehicle.

We recommend: Connecting a tachometer with your own hands: pros and cons

Silent blocks VAZ 2106

Quite high loads are constantly placed on the silent blocks of car suspensions, especially on roads with poor surfaces. Such conditions significantly reduce the life of these parts, as a result of which they fail and need to be replaced. Since the controllability of the car depends on the condition of the silent blocks, you need to know not only how to identify a fault, but also how to replace these suspension components.

What it is

The silent block is a rubber-metal product, structurally made of two iron bushings with a rubber insert between them. Through these parts, the components of the car's suspension are connected, and thanks to the rubber part, vibrations transmitted from one suspension element to another are dampened.

Silent blocks connect suspension elements and dampen vibrations

Where installed

On the VAZ 2106, silent blocks are pressed into the arms of the front suspension, as well as into the reaction rods of the rear axle, connecting it to the body. The condition of these elements must be periodically monitored, and if they are damaged, repairs must be made in a timely manner.

The front suspension of the classic Zhiguli consists of the following parts: 1. Spar. 2. Stabilizer bracket. 3. Rubber cushion. 4. Stabilizer bar. 5. Lower arm axis. 6. Lower suspension arm. 7. Hairpin. 8. Lower arm amplifier. 9. Stabilizer bracket. 10. Stabilizer clamp. 11. Shock absorber. 12. Bracket bolt. 13. Shock absorber bolt. 14. Shock absorber bracket. 15. Suspension spring. 16. Steering knuckle. 17. Ball joint bolt. 18. Elastic liner. 19. Cork. 20. Insert clip. 21. Bearing housing. 22. Ball bearing. 23. Protective cover. 24. Lower ball pin. 25. Self-locking nut. 26. Finger. 27. Spherical washer. 28. Elastic liner. 29. Pressure ring. 30. Insert clip. 31. Bearing housing. 32. Bearing. 33. Upper suspension arm. 34. Upper arm amplifier. 35. Compression progress buffer. 36. Buffer bracket. 37. Support cap. 38. Rubber cushion. 39. Nut. 40. Belleville washer. 41. Rubber gasket. 42. Spring support cup. 43. Upper arm axis. 44. Inner bushing of the hinge. 45. Outer bushing of the hinge. 46. Rubber bushing of the hinge. 47. Thrust washer. 48. Self-locking nut. 49. Adjusting washer 0.5 mm 50. Distance washer 3 mm. 51. Cross member. 52. Inner washer. 53. Inner sleeve. 54. Rubber bushing. 55. Outer thrust washer

What are there

On the VAZ “Six” and other Zhiguli models, silent blocks made of rubber were installed from the factory. However, instead of them, you can use polyurethane products, thereby improving the performance of the suspension and its characteristics. Polyurethane hinges have a longer service life compared to rubber ones. The main disadvantage of polyurethane elements is their high price. If a set of silent blocks made of rubber for a VAZ 2106 costs about 450 rubles, then made of polyurethane it will cost 1,500 rubles. Hinges made of modern material not only improve the behavior of the car, but also better absorb shock and vibration, reducing noise.

Silicone silent blocks, despite their higher cost, improve the characteristics and performance of the suspension

What is the resource

The service life of rubber-metal joints directly depends on the quality of the products and the operation of the vehicle. If the car is used mainly on good quality roads, then the silent blocks can last 100 thousand km. If you frequently drive through potholes, of which there are many on our roads, the service life of the part is noticeably reduced and repairs may be required after 40–50 thousand km.

How to check

Problems with the hinges can be judged by the behavior of the car:

- controllability deteriorates;

- Vibrations appear in the steering wheel and knocks in the front when driving over uneven surfaces.

To make sure that the silent blocks have exhausted their service life and require replacement, they should be checked. First, the parts are visually inspected for damage to the rubber. If it cracks and partially comes out, then the part is no longer able to cope with its tasks.

Hinge wear can be determined by visual inspection

In addition to inspection, you can move the upper and lower arms with a pry bar. If knocking and strong vibrations of the silent blocks are observed, then this behavior indicates a lot of wear on the hinges and the need to replace them.

Symptoms of a problem

A sign of faulty suspension joints can be a characteristic squeaking sound from the wheels. This is also indicated by deterioration in vehicle handling. The steering wheel may respond with a noticeable delay, which is not beneficial. The passage of any obstacles, be it rails or various irregularities, obstacles, can be well felt for yourself.

Uneven tire wear, which can be observed on the inside of them, also indicates that the silent blocks of the front control arms have failed. In some cases, unexplained vibration appears.

All these signs clearly indicate that things are not going well with the suspension. You should visit your nearest service center for an inspection as soon as possible, or carry it out in your garage.

When to change hinges?

Signs of critical wear of rubber-metal joints are often accompanied by the following effects:

- Question answer

How dangerous is an unbalanced wheel? Steering wheel vibration. Usually, when accelerating, even well-balanced drive wheels begin to hit. The reason for this is the play that appeared in the levers.

- The steering wheel is pulled to the side. Broken silent blocks do not hold the steering gear levers well, and when the car moves, the wheel may deviate to the sides. The car reacts to the resulting play and gradually moves to the edge of the road. Backlash in the bushings creates parasitic movements of the suspension parts, as a result of which the wheels steer and the trajectory has to be adjusted.

- Uneven tire wear. Frequent wheel deflections cause rapid tread wear. If the hinges are severely broken, the suspension adjustment angles lose their fixed position and the sidewalls of the drive wheels begin to wear out.

- Loss of control when braking. During emergency deceleration, play in the joints can cause the car to slightly drift off the trajectory. If the deceleration occurs in a rut, then the car yaws a lot. The rear axle steers and threatens to lose control.

Which silent blocks are better, polyurethane or rubber?

If you are thinking about how to replace silent blocks, then you need to make an important choice about what material they will be better from. There are several available options on the market.

Signs of wear or malfunction of the car's front suspension ball joint

Rubber silent blocks

Rubber silent blocks based on rubber are distinguished by their low cost, but have several disadvantages:

- have a low resource;

- cause squeaking, even if they are new;

- quickly become unusable under the influence of harmful environmental factors.

Polyurethane silent blocks

Silent blocks made of polyurethane significantly improve the performance of the suspension and the entire vehicle. Their advantages are as follows:

- long service life (up to five times longer than rubber).

- improving the behavior of the car on the road, eliminating the “squeezing” effect that appears when using rubber, as well as reducing deformation in the suspension elements, therefore, the part functions in the mode in which it should;

- absorption of vibration, shock, noise reduction;

- improved handling.

silent blocks made of polyurethane will improve the behavior of the car on the road, reducing unnecessary deformations in the suspension and eliminating the “squeezing” effect characteristic of rubber parts.

The only drawback of polyurethane silent blocks is their high cost. But the miser pays twice, so it is better to initially use a more durable and effective material.

The main installation locations for silent blocks are the car suspension

Right choice

The choice is made after diagnosing the malfunction or during a planned replacement. It is necessary to understand what role the part plays in the suspension. Its task is to dampen vibrations that inevitably arise due to unevenness on the road.

Vibrations during movement are transmitted to the suspension springs, where they are partially damped by shock absorbers. The vibration then spreads to the frame through the connecting nodes. It is partially damped by silent blocks due to the presence of a soft base between the bushings. Therefore, the quality of the base must be of a high level. The factory version of the suspension is equipped with rubber-based silent blocks. This is a proven material, but there are better ones - for example, polyurethane.

Advantages of polyurethane:

- The service life is increased by 5 times. This allows replacements to be made after long mileage intervals and the suspension to be loaded more aggressively.

- Increased thermal stability. Polyurethane tolerates temperature changes well. The material works just as well in cold weather as at high temperatures.

- Thanks to the dense structure of the material, vehicle handling is improved.

Rubber and polyurethane are equally popular. Drivers themselves choose what to focus on. With rubber spacers you can get increased riding comfort, but improved handling can only be achieved with polyurethane. But in the latter case, comfort decreases, which is especially felt by passengers.

We recommend: CVT gearbox for cars

When purchasing a part, it is better to consult a specialist in the store. The fact is that vibration isolators are difficult to distinguish from each other in appearance - they are almost similar. But their outer diameter is sometimes slightly different, which will cause installation difficulties.