Restoring automobile alloy wheels by applying powder coating to their surface falls into the category of repair work that is carried out only in the presence of minor damage. At the same time, going to a service station is not very profitable for most motorists, since it is associated with significant financial costs.

That is why powder coating of discs with your own hands is the only acceptable option for users who expect to save on repairs and independently control the entire technological process.

- Powder painting at home. Video:

The essence of this technique is that first a polymer powder dye is applied to a previously prepared metal surface in a special way.

Immediately after this, the painted product is subjected to a special heat treatment, as a result of which the powder melts, forming a continuous and evenly distributed film.

There is a similar article on this topic - Do-it-yourself airbrush on a car.

The coating obtained in this way has the following remarkable properties:

- high degree of protection against corrosion;

- good adhesion (adhesion) to the previously prepared base;

- climatic and chemical resistance;

- impact strength;

- decorative appeal and durability.

The advantages of this technology include:

- Possibility of forming a single-layer coating, which is impossible when using liquid paints and varnishes.

- There is no need to use a solvent or control the viscosity of the applied composition.

- Economical consumption of dye, explained by the possibility of reusing the sprayed powder, which does not leave the paint booth.

- The procedure for forming a powder layer does not take much time, which during conventional painting is spent on drying the product. This saving is explained by the fact that immediately after application the coating is subjected to heat treatment (polymerization).

- Environmental safety of the dye used, which does not contain toxic compounds. In this regard, during the spraying process there is no need to use powerful ventilation equipment.

Do-it-yourself powder coating of rims

In any car, after a certain period of use, mechanical damage appears: scratches, chips, microcracks, areas of corrosion. The wheels suffer the most. And this is not surprising, because they are the ones who take on the bulk of external influences. Marks appear on the surface of the wheel rims, which not only spoil the appearance of the car, but can also subsequently become sources of destruction of the material. In order to avoid this, damaged discs must be replaced or painted.

Powder coating of car rims

It is logical that replacing discs is a last resort, and if painting can solve the problem, then you should stop there. In order to repaint your car's wheels, you can seek help from a service station - the easiest way out of the situation. If you want to avoid unnecessary financial costs, improve your skills as an auto mechanic, or simply prefer to solve all the problems yourself, you can paint the wheels yourself.

Wheels are painted using two types of enamels:

- powder;

- acrylic.

The powder method provides a better and more durable coating, so we will look at that.

Material options for restoration

Restoring disks using acrylic paint. The product dries in no more than 15 minutes and is applied to the surface using an aerosol or spray gun. The painting technology is simple - you can easily implement it yourself. However, although acrylic protects against the effects of precipitation, it is not considered a durable coating.

An interesting rim surface can be achieved using Plasti Dip rubber paint. At the same time, it is possible to create a glossy, matte, fluorescent coating: the colors can be very diverse (see photo below). Painting is done in two steps: after the first layer has dried, the product is sprayed onto the surface again. All manipulations take about an hour.

Powder paint

The most reliable way to restore discs is to coat them with special powder paint. It adheres well to any metal and accordingly protects it well. Reviews about the quality are most positive. But to apply this product, a special technology is used, and special conditions are required, which most often do not exist in a regular garage. Although it is still possible to paint it yourself.

Powder coating of wheels. What you need to get started

Powder painting is a rather complex process, which will cause some difficulties if you do it yourself. This is due to the fact that you will need certain knowledge, skills and special equipment.

This enamel is applied to the surface using special sprayers, after which it is polymerized in an oven under certain temperature conditions. Therefore, when deciding to carry out the procedure yourself, you must ensure that you have the necessary equipment and also choose a suitable room for the work.

Car life hacking

Oddly enough, the process of painting car wheels can be greatly simplified by using an ordinary deck of playing cards. If the size of the wheel does not exceed the 16th radius, a deck of 36 cards is suitable; for larger sizes, it is worth purchasing a deck of 54 cards.

The wheel must be removed from the car and washed thoroughly. After this, you first need to carefully rub off large scratches with waterproof sandpaper dipped in water, and then with finer-grain paper, you need to completely process the front side of the disc. It is worth keeping in mind that the lower the number indicated on the back of the sandpaper, the greater the grit it has and vice versa. Ultimately, the car wheel is processed with very fine sandpaper (grit number 1000 is suitable). A prerequisite for grinding is the use of water.

Preparing the premises and equipment

A garage is quite suitable for work if there is little dust, normal temperature and enough space. It is necessary to take care of the quality of lighting - it should allow full visual control over the process. Fluorescent lamps are well suited for this purpose. A well-organized ventilation system is also a prerequisite - otherwise you risk compromising your health.

Next, you need to equip a special box where painting will be carried out. It should have a roasting oven - you can easily adapt an oven for this purpose.

Wheels look attractive after painting

For painting you will need a spray gun with the ability to connect compressed air. You can also use a compressor. It must have a high pressure filter included.

To collect unused paint, you will need a recuperator - it can be replaced with a cyclonic vacuum cleaner if desired.

The electrical network in the room must be able to withstand the given load, and also have proper grounding.

Dyeing process

Wheels can be painted with powder paint only after dismantling third-party elements that interfere with the procedure: plastic caps, tires, etc. Wheels cannot be painted with powder in an unassembled form, otherwise the quality of the coating will be impaired during the process of unscrewing the plugs and all efforts will be of little use. After painting, the discs should be perfectly smooth and fully comply with technical standards. If everything is done correctly, the coating will last about 7 years.

The process of painting alloy wheels

Surface preparation

Once you have prepared the room and acquired the necessary equipment, you can begin preparing the surface. Many people, doing the work with their own hands, do not pay due attention to this procedure, which negatively affects the quality of the coloring.

At this stage we must thoroughly clean the surfaces to be treated. Wash the removed discs thoroughly with water and detergent and wipe off all dirt with a sponge. Then wipe dry with a microfiber cloth. Afterwards, degrease and sand with an electric drill with various abrasive attachments. It is necessary to ensure uniform processing. To remove rust stains yourself, sandblasting is a good option if you have the appropriate equipment.

Phosphating the surface will help increase the adhesion of coating particles to the surface of the discs. Afterwards, passivation should be performed - apply a solution of chromium and sodium nitrate compounds. This operation allows you to avoid the occurrence of repeated corrosion processes on the vulnerable surface after preparation. After rinsing and drying, the wheels are ready for the next step.

Powder coating of discs

Now we place the prepared wheels in the box where painting will take place. This is done in a box so that particles do not scatter to the sides and will not settle on the product being processed - they can be reused.

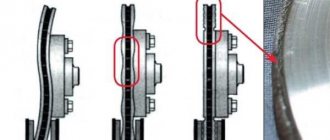

The powder mixture is applied by electrostatic spraying. Electrostatically charged particles are sprayed onto a grounded wheel. This is what painting actually is.

After you have coated the discs with powder paint, you need to bake it in a special oven. The paint layer is melted and a film is formed - this is the essence of the process.

The oven you use should automatically control the baking temperature and the period required for this process. Heating can be done using electric heaters or gas burners.

Powder paint can come in a variety of colors and shades

When doing the work yourself, you should know that a successful process requires a temperature of 150 to 220 0 C. The baking period for the powder mixture is from 15 to 30 minutes. The exact indicators can be found in the reference literature - they will depend on the size of the wheels and the material from which they are made.

After the polymerization period has completed, cool the wheel in the open air. After this, the work can be considered completed.

Preparing for work

Painting discs with powder paint requires high-quality surface preparation:

- Initially, it is necessary to clean the work surface from dirt. The best cleaning method is to use specialized automotive chemicals; it speeds up the procedure and improves the result.

- Elimination of defects: chips, scratches, abrasions, etc., they inevitably appear during the operation of the machine. The easiest way to level the surface is to use sandpaper. Initially, the discs are processed with coarse-grain sandpaper, and then the grit is gradually reduced to the finest in the range. In the end you will get a perfectly flat surface. If deep defects are detected, you will have to use putty.

- Degreasing both sides of the disc.

Do-it-yourself powder coating of wheels: technology

Hello! Nice to see you again! We continue to delight you with new, interesting and, we hope, useful materials. Our hero today is powder coating of wheels.

If you need to restore car wheels, especially alloy wheels, then applying a powder composition is considered the most reliable way. It is the most technologically complex, and the price is fair, but high.

I will say right away that the option of doing it yourself looks doubtful, since applying powder paint has a special technology. Without certain components, you simply won't be able to get the job done right. But let's talk about everything sequentially.

Paint Features

Let's start with the fact that applying powder paint to the surface of wheel rims requires heat treatment.

In short, a composition, that is, paint, is applied to the disk by spraying, and then the roller is exposed to high temperatures (about 200 degrees Celsius) in a special oven, where it is kept for 10 minutes.

Manufacturers produce several types of powder dyes, which differ in composition.

- Epoxy powder. Characterized by increased resistance to acids and alkalis;

- The polyester composition is distinguished by the fact that it can withstand the negative effects of the atmosphere and corrosion. That is, it copes with those factors due to which rust can form on the disk;

- Silicone dye. Not afraid of high temperatures;

- Polyurethane powder. Resistant to contact with abrasive, oil and solvents.

I will also add that reviews say that such dyes are the most durable and reliable. If you spare no expense and order professional restoration of wheel rims using powder paint, you will be 100% satisfied with the result.

Although it is important to note the lack of a wide choice of colors. But wheels are a component that people prefer to paint in fairly standard colors. Therefore, there should not be any special problems with a relatively limited choice of palette.

We bake discs

Depending on the type of dye and the main component included in its composition, the required baking temperature ranges from 175 to 220°C. A hair dryer is suitable for polymerizing paint on small surfaces. To reliably fix the dye on disks of any diameter, a drying chamber is required to ensure uniform heating of the part and maintain the required temperature during the entire baking time (from 10 minutes to an hour and a half).

There is a wide range of drying ovens for powder paint on the market, and on the Internet you can find even more instructions from craftsmen describing the design and step-by-step process of making drying ovens.

To comply with temperature standards and requirements for the duration of heat treatment, electronic control units are used. They provide the highest measurement accuracy and instantly respond to changes in conditions inside the chamber.

Cooling of discs with a polymerized coating occurs by gravity - this method avoids damage to the paint.

Processing technology

Almost any city, such as Moscow, Yekaterinburg, Voronezh, Volgograd, Lipetsk and, of course, St. Petersburg, has a large number of car services and companies ready to offer powder coating services for wheel rims.

But what is this technology? In fact, it has important features that distinguish powder coating from alternative solutions and provide clear advantages in the form of resistance, durability, quality, etc.

In total, the technology is divided into 5 stages.

- Preparing the disk. It is necessary to treat the surface of the skating rink, ridding it of traces of old paint, various contaminants and defects. This is done both at home and at specialized stations with an electric drill, sandblasters and other suitable tools. If the contamination is serious and deep penetration is required, then alkaline and acidic cleaners are used. You get the idea - there should be no dirt before application. Plus, the surface is primed as necessary.

- Painting. Next comes the actual application of the powder dye. A mandatory condition is the availability of personal protective equipment. When working with powder paint, be sure to wear gloves, goggles and a protective suit with a mask. For uniform spraying, an electrostatic sprayer will be required.

- Burning. This is the main technological feature that makes powder processing at home impossible. No, if you have a special stove in your garage, then there is no problem. But in fact, where have you seen something similar in the private garage of an ordinary car owner? That's not the point. In the oven, the disk is heated to 200 degrees Celsius and kept for a certain time.

- Holding and cooling. You can’t take the wheel rim out of the oven right away, otherwise everything will get ruined. The products cool down gradually as the temperature inside the oven decreases naturally. The firing chamber is turned off, after which the disc remains there for about 6-10 hours.

- Varnish coating. The process is completed by treating the powder-painted disc with a layer of varnish. It provides the necessary protection for the composition, plus gives an attractive shine.

If you wish, you can watch the video and understand how this all happens visually.

How much?

The final cost of painting wheels will depend on a number of factors, from the diameter of the product to the type of oven used to cure the paint.

Using homemade equipment will allow you to save money, but will negatively affect the quality of the coating and the duration of its operation, so it is only relevant for small-scale production. Due to the unprofitability of painting single products, homemade equipment for a private box for powder painting can only be used at the initial stage of your enterprise. As your skill grows, the need will arise to purchase professional equipment for working with powder dyes.

Painting rims at a trusted auto repair shop means saving money, effort and time. The procedure itself rarely takes more than a couple of days, and the guarantee from the pros reaches five years, including assurances that the coating is not susceptible to fading in the sun.

What can you do at home?

Keep in mind that you will not be able to follow all the nuances of the technology for processing discs with powder paint at home. The main reason is the lack of a stove.

But it’s possible to do something with your own hands. Be prepared for a lengthy process and time-consuming work.

- Select the necessary components. Special equipment is not available in the garage, but common consumables are easy to find. You need a primer, powder (powder dye in a suitable color) and varnish. Moreover, I strongly advise you to buy all components from one manufacturer. This way the likelihood of achieving a good result will be higher.

- Gather tools and supplies. Discs should be degreased, sandblasted, sandblasted and drilled. It all depends on the condition of the product. If there are deep scratches or damage, they are treated with putty and then primed.

- The primer can only be applied to a completely dry surface. Start from the inside of the disc and end on the outside. To get a high-quality result, apply at least 2-3 layers of primer. Each of them is applied only when the previous one is completely dry. To avoid taking days to dry, use a heater or fan heater. Even a household hair dryer will do.

- To spray powder paint, a spray gun or compressor is required. Don't forget about protective measures. First, the paint is applied to the internal surfaces, and then to the external ones.

- Sprayed in several layers. Each layer is dried. A hair dryer is usually used because it is quite powerful and produces hot air. Before applying subsequent layers, the previous ones are thoroughly dried.

- Varnishing completes the work. 2-3 layers will be enough.

The quality, of course, is not the same, but in appearance it should turn out very beautiful. But my advice to you. If you want to get in touch with powder technology, order disc processing from specialists.

Read about how to choose wheels for your car here.

That's all! Thanks for reading! Subscribe, leave comments and invite your friends to join us!

(

1 ratings, average: 4.00 out of 5)

Powder coating of wheels: advantages and features

Powder paint is used only for materials subject to heat treatment and consists of applying the dye to a dry surface, followed by firing the product in a chamber at a temperature of +200 °C.

Powder paints can be silicone, epoxy, polyester and polyurethane.

The former are the most heat-resistant, the latter are resistant to acids and alkalis. Polyurethane paints are resistant to solvents and abrasives, while polyester paints have increased corrosion resistance.

Painting forged and cast wheels has the following advantages:

- increase in anti-corrosion properties;

- protection of metal from chemical, mechanical and thermal damage;

- increasing the impact resistance and durability of the product;

- improvement of electrical insulating, physical and chemical properties of metal;

- protection against pollution;

- aesthetic appearance of the wheels, the ability to paint the wheels to match the car body or make them contrasting - the most popular are black, chrome, graphite, silver and bright colors (yellow, emerald, ruby, poisonous pink).

Coating the wheels with powder paint makes the metal waterproof and increases resistance to salt damage from chemicals on road surfaces in winter.

Equipment and materials needed for painting

Painting discs with a powder composition requires the purchase and preparation of a number of materials:

- special powder for rims;

- primer composition;

- varnish for treating automotive coatings;

- paper with abrasive material - several types of grain are prepared;

- solvent, acetone will do;

- putty for metal;

- rubber protective gloves;

- respirator.

It is important to understand that the coloring result will be of the highest quality when using products from one manufacturer.

Painting wheels with powder requires not only materials, but also tools:

- spray gun with compressor unit. They will become assistants for high-quality painting of rims. An aerosol can will not achieve good results;

Optima 650i spray gun

- a grinding machine can be replaced with a drill with an appropriate attachment, otherwise it will be difficult to remove the old coating and there is a risk of leaving pockets of corrosion. After processing with a grinder, the surface will become perfectly smooth;

- construction hair dryer, heat gun, in extreme cases - a household hair dryer. Heat devices are useful for speeding up the drying of paint.

By preparing all the necessary equipment, the process will speed up many times and take a minimum of time and effort.

Equipment for work

Car repair shops use special equipment to spray paint on rims; at home, the work can be done with a minimal set of equipment:

- sandpaper grit 200-600;

- rags for removing dust;

- metal brushes;

- spray gun or spray gun.

In addition, you may need a sandblaster if it turns out that rust is corroding the metal. Instead of sandblasting equipment, you can use an electric drill with various attachments.

When painting rims yourself, it is advisable to have a separate room for the baking chamber, where powerful electric heaters should be placed. In addition, it is recommended to install a hanging system - attach a long wire to a beam in the garage, on which the disc for painting will be suspended.

Good lighting should also be provided - the quality of painting will also depend on visual control of the process. Experienced car enthusiasts advise installing fluorescent lamps.

Their bright but cool light will allow you to see the painted surface of the discs as it appears in daylight.

In addition to lighting and heating devices, according to safety regulations, the garage must have a good ventilation system so that after removing the old coating from the wheels and applying new paint, the smell will disappear faster.

According to safety regulations, the electrical network must withstand heavy loads and have reliable grounding.

Preparation of main and auxiliary equipment

It is advisable to use industrial-grade devices (powder painting gun plus compressor unit) as a mechanism for supplying the dye to the processing site and distributing it evenly over the surface of the disks. At home, it is most convenient to rent expensive painting units for the duration of the main work.

In addition, in order to supply power to the main and auxiliary equipment (thermal furnace, compressor, heating and lighting systems), powerful electrical wiring must be connected to the selected room.

If the specified conditions are met, known methods of drying and polymerization of painted surfaces can be implemented in the following ways:

- in the simplest case - through the use of a system of electric heaters of sufficiently high power;

- with a more professional approach - using a special oven for powder coating of processed products.

It is clear that the implementation of the second option is associated with large material and labor costs, even if you rent furnace equipment for the duration of complex work.

At the same time, painting the wheels yourself will still cost you less than if you contact a car repair shop.

As one of the options for a professional approach to arranging a furnace that ensures high-quality polymerization of the dye, the case of making it yourself can be considered. You can familiarize yourself with the procedure for assembling it and connecting it to the network in our future articles.

For those who have decided to do powder painting at home and do without a special oven design, we advise you to pay attention to the possibility of using conventional electric heaters.

When choosing this option, we should not forget that violation of the rules for operating electrical appliances can lead to a short circuit in the wiring and its fire.

That is why, even at the preparatory stage, you should worry about the quality of electrically conductive cables and carefully check the operating modes of all devices connected to them.

Please note: To the listed equipment you should add a powerful vacuum cleaner with a cyclone nozzle, with which you can ensure maximum air purity in the painting area. The need for this household device, as a rule, arises in cases where the painting booth is not equipped with adequate ventilation.

Powder painting at home. Video:

DIY technology for painting wheels with powder paint

Stages of work:

- Preparation of the product surface.

- Coloring.

- Firing in a chamber.

- Applying varnish.

Preparatory stage

Alloy wheels must be prepared:

- The product is cleaned with water to remove dirt and dust.

- Oil stains are removed using a solvent, and the surface is additionally degreased.

- The old coating, pre-impregnated with an alkaline or acidic solution, is removed from the surface of the disk using a sandblaster or electric drill.

- Rust is removed from metal using brushes and sandpaper.

- The surface is treated with iron or manganese phosphate to improve the adhesion of powder-coated metal.

- The product is again washed to remove dust and excess substances and thoroughly dried.

If possible, it is recommended to refrain from using the sandblasting method when cleaning discs - abrasive particles can damage the metal surface, and the product will corrode faster. To remove rust, it is advisable to use chemical compounds.

If deep scratches remain after cleaning, they need to be treated with automotive putty, filling all the depressions and defects until a smooth surface is obtained.

Primer phase

After removing the old coating and preparing the disc for painting, the surface is degreased with a special solution, after which you can begin priming.

Powder primer is applied to a thoroughly dried surface from a distance of 30 cm - it will protect the metal from corrosion and prevent the appearance of rust. First of all, the product is applied to the inner surface of the product.

The primer layer promotes better adhesion of the paint to the metal and its uniform distribution over the surface. For reliability, it is recommended to apply at least 3 layers and dry each of them in a chamber. It is recommended to dry the primed product for 10-15 minutes; this condition applies to each applied layer.

For priming, it is recommended to use zinc-epoxy solutions.

Powder paint application

Painting should be done using special protective equipment (suit, mask, goggles, gloves) and a spray applicator.

Spraying of paint is also carried out at a distance of 25-30 cm using a spray gun, which under pressure delivers a stream of dye through compressed air onto the metal surface. The electrostatic voltage generated during operation of the sprayer allows the dye particles to be retained on the surface of the disk.

Painting in several stages should be done with each layer thoroughly dried, otherwise the undried layer will begin to bubble and ruin the appearance of the disc.

Then the product should be placed in the firing chamber.

Polymerization process

Polymerization involves heating air to a high temperature (about +200 °C) and then melting the coloring material on the surface of the disk. When heated, the powder paint particles melt, gathering into a viscous thick mass that forms a durable film. After the temperature decreases, the film polymerizes and hardens.

The polymerization process should last no more than 25 minutes, as when priming the product. However, depending on the material from which the discs are made and their size, the products can be kept in the chamber for 15-30 minutes. After baking, the product must be removed.

The painted disc should cool for about 8 hours. If the paint is applied unevenly or the color turns out to be unsaturated, you can coat the product with a second layer of spraying by re-placing the disk in the heated chamber.

After this, the product is removed and coated with 2 layers of protective varnish. This stage of work is the final one; under normal conditions, complete hardening of the paint layer will take about 3 days.

Varnishing will extend the service life of car wheels and prevent early damage to the applied paint layer.

Painting stages

It is better to choose components from one manufacturer. In addition, it is better to purchase consumable materials “with a reserve” for the area of the surface to be treated.

Preparatory stage

The ideal preparation would be to sandblast the cast disc, but if such equipment is not available, you will have to work with sandpaper.

The final result of painting depends on this stage. First of all, you should wash the discs with powder or an abrasive cleaner and dry them well, both outside and inside. Then remove the old coating from the surface using sandpaper with different grain sizes (200, 400 and 600) or a drill with attachments. It is better to periodically spray the work area with water. Some car owners prefer to treat it with putty to avoid deep scratches. A special solution, which is sold in specialized stores, will help to degrease the surface. It is also worth remembering about personal protective equipment - goggles and gloves.

Powder painting process for alloy wheels

Painting alloy wheels with powder paint is the same as polymer painting of wheels. It is considered the most effective method at present. In factories and professional car repair shops, it is performed using special equipment - a gun with an electrostatic effect. The essence of the method is that paint particles stick to the part due to a static charge. Application stages: disc preparation, application of powder dye, polymerization. The zones are interconnected by a “transport system” - a network of guides for moving the suspended module for fastening products. After painting, the disc is kept in a special chamber at a temperature of 200 0 C to achieve polymerization of the paint.

Paint baking process

This is the last and perhaps the easiest stage. After the powder paint is applied, the disc is placed in the oven or a special oven, preheated to 210 0 C. The paint needs to be baked for about 15 minutes. You can periodically open the oven to check the condition of the coating. Once the paint has completely dried, remove the disc and wait until it cools down. But remember that the metal will be quite hot and soft.

Technology of painting car wheels with powder paint

Wheels not only play a practical role, but also give the car a pleasant, aesthetic appearance. During the period of operation, they are very susceptible to wear and tear, as a result, their appearance deteriorates. Taking into account the level of prices for alloy wheels, drivers do not have the opportunity to constantly change them with the onset of the new season, as a result, there is a need for their restoration to give them their original attractive appearance.

Nowadays, two main methods are used for painting wheels:

- Powder coating of wheel rims.

- Or a choice of acrylic paint.

Today we will talk about the first option.

Of course, to paint discs with powder paint, the best option would be to contact a specialist. This process is a little more difficult to carry out on your own, but as we know, nothing is impossible. Powder paint fully provides the protection functions necessary during operation.

Let us highlight several advantages of this material:

- High resistance to external negative factors, including temperature changes.

- It tolerates the effects of alkaline compounds very well.

- Resistant to chemicals.

- Has a low abrasion rate.

- Withstands possible shocks during operation.

- Has a wide variety of colors.

- Quite reasonable prices.

To ensure a complete preparatory stage, working surfaces are cleaned with a sandblasting unit. Thanks to its effect, the working area takes on the best appearance, is perfectly cleaned of rust and all contaminants that need to be removed. The preparation process is necessary for high-quality application of paint and varnish, and to ensure durability of further use.

Powder coating of wheels is carried out in several steps, interconnected with high-quality processing and subsequent painting:

- The procedure for removing dirt and old unnecessary coating, while simultaneously leveling the working surface.

- A degreasing procedure using a chemical action that removes grease stains that lead to poor paint adhesion.

- Priming the disk surface.

- Final painting of the wheels.

- Heat treatment.

Powder coating technology for wheels

Powder-type paint is based on polymer compounds applied to the product by spraying and subsequently subjected to heat treatment in a special oven.

The work consists of 3 main stages:

- The preparatory part consists of cleaning from contaminants, degreasing procedures, increasing adhesion properties and protecting against rust.

- Application by spraying powder paint. Painting takes place in a special chamber, manually using an electrostatic sprayer. Due to the action of electrically charged particles, the powder is evenly distributed over the disk surface.

- The heat treatment procedure in a special oven lasts at least 10 minutes at a temperature of up to 200 degrees Celsius. Thanks to this procedure, the powder particles are melted and evenly attached to the work surface.

- Having completed the heat treatment process, varnish is applied to the disk surface to consolidate the result of the work and ensure the resistance of the surface from negative influences.

As a result, wheels painted in accordance with the technology will last for more than a year.

When painting yourself, the principles of work change slightly, however, you must adhere to this sequence of steps.

Equipment for powder coating of wheels

To carry out work on applying powder paint yourself, a compressor or spray gun will be useful.

If it is not possible to find these devices, you can use acrylic spray paint. Also, a regular drill and a hair dryer for drying are perfect for the cleaning procedure.

Be sure to use protective equipment while working, because... these types of paints are very toxic.

Preparatory stage for independent work

- Preparation of the necessary components - primer, powder paint and varnish. It is advisable that there is only one manufacturer. In addition to a sandblaster, a regular drill with various attachments or sandpaper is perfect for removing worn-out coatings. For degreasing it is necessary to use a special mixture.

- Preparing the work area. The final result depends on the quality of the work performed. The discs are washed using an abrasive cleaner or regular powder. After complete drying, they are processed using sandpaper with different grains of 200, 400, 600. Then, using a drill using sandpaper, the surface is completely sanded, first with coarse grains, places that are difficult to get to must be processed manually. During operation, the surface can be periodically moistened with water. If there are sufficiently deep scratches, the disc can be puttyed.

- Priming the disc surface. The primer is applied to a completely dry surface. To begin with, the inner side is subjected to processing, then the front side; processing is carried out in at least 3 layers, with each of them completely drying. After applying the final layer, the disc is finally dried; for this you can use, for example, a fan or a heater.

- Using special equipment for powder paint or using paint from spray cans, we paint the surface of the discs. Work also starts from the inside then the front side. Each layer must be dried using a fan or a hair dryer.

- An important step in painting wheels is varnishing. The varnishing stage is carried out in 2 layers, and each layer is subject to mandatory drying. If the surface of the disc is not treated with varnish, the service life is significantly reduced, the paint coating remains without protection from the influence of external negative factors. After the final stage of varnishing, the discs are dried for at least 3 days.

Powder painting of alloy wheels follows the same principle as painting regular wheels. The only difference is that casting discs must be warmed up before priming. And only after this the alloy wheels are powder coated . This is necessary to ensure the painting has the best adhesion properties.

What to consider?

Do-it-yourself powder coating of discs has differences compared to industrial painting technology. The main difference is the use of a different type of paint, so drying is not carried out in an oven, but simply in the open air or using household appliances, for example: a hair dryer, heater or fan. As a result, painting may take several days, depending on weather conditions. Accuracy plays an important role in this type of work. Great importance is given to the quality of the materials used, from the solvent to the dye. A varied color palette will allow you to realize any idea.

Paint with polymer paint

ATTENTION! A completely simple way to reduce fuel consumption has been found! Don't believe me? An auto mechanic with 15 years of experience also didn’t believe it until he tried it. And now he saves 35,000 rubles a year on gasoline! Read more"

Powder paint is durable and abrasion resistant. This is the method used to paint alloy wheels at the manufacturer's factory. Do-it-yourself powder painting of discs is usually not done: this procedure requires special, expensive equipment.

If you decide to do powder (polymer) painting, then you should take a closer look at the process. Of course, rubber from car wheels must be removed.

Technologically, painting car wheels with powder paint occurs as follows:

- Checking the discs for beating, cracks and scratches;

- Removing the old paint layer and traces of corrosion using sandblasting;

- Degreasing the surface to increase the adhesion of the new coating;

- Painting the surface with a liquid primer, which seals microscopic scratches and reveals missing large ones;

- Application of powder paint to the entire surface in an electrostatic field;

- Varnishing and drying in a thermal oven.

Using polymer, you can paint cast wheels yourself, as well as those made of stamped steel or forged ones. The minimum guaranteed mileage period is two years. Among the expensive equipment, it is worth highlighting a special electromagnetic chamber in which powder paint is applied to the element. You can replace a sandblasting machine with a drill with a rubber disk on which coarse sandpaper will be put on. In this case, your

and it will be difficult to remove all the old paint with your hands and you may need to change two or three abrasive disk attachments.

In the oven, the powder paint first melts, then it polymerizes. The rubber is put back on the cooled disk, and the wheel assembly is ready for installation on the car. Any colors are available, both individual and combined: you can paint the car’s rim in different colors.

Do-it-yourself powder coating of discs and video of technological processes

It will not be a revelation that car wheels are the first to perceive all the “delights” of the road in the form of crushed stone, tar and parking curbs. The consequences do not at all decorate the wheels; they lose their former gloss and color, but they are a stylistic addition to the exterior. This is especially true for light alloy structures, which, in addition to the original design, are not at all cheap, which does not allow them to be changed every season. Therefore, there is reason to think about restoring the appearance of car wheels.

Features of painting car rims with powder paint: advantages and equipment

The technology of surface restoration using powder paints is quite popular. Experts explain this with a number of positive aspects from using this technique:

- Durability and resistance to mechanical stress and chemical reagents.

- Do-it -yourself powder coating of discs in the video is quite affordable and requires minimal consumption of materials.

- Possibility of creating paint of any shade.

However, the option is practically impossible to implement at home, because there is a technological need for special equipment:

- Spray booth.

- Electrostatic spray gun.

- Drying oven.

Accordingly, you will need a compressor and a reliable power source, preferably a three-phase type. However, there are craftsmen who were able to equip a workplace from improvised means, for example, they use household ovens as ovens. How justified this is for a single use, everyone can judge for himself, but it is quite obvious that the total cost of the event is too high.

This suggests a conclusion - restoring the appearance of wheels using an aerosol can is the best option. However, we will not talk about it; below we will consider what painting wheels with powder paint is and the main nuances of the method.

Equipment for work

The main disadvantage of the powder painting method is the rather complex technology and expensive equipment, although in certain cases the use of household appliances is allowed:

- A dry spray paint booth must be equipped with a recuperator that collects powder paint residues. They are subsequently reused. At home, our “homemade” ones have adapted to using a conventional cyclone-type vacuum cleaner.

- Sandblasting machine for cleaning surfaces with an abrasive-air mixture. It is possible to use homemade devices or, as a last resort, manual cleaning with sandpaper of the appropriate grain size.

- A compressor unit that is capable of providing a working pressure of up to 5 atmospheres to ensure the operation of a sandblaster and a paint gun. It is necessary to have an oil trap and a filter with a sorbent for preparing compressed air.

- Tribostatic or electrostatic paint spray gun. The first one is suitable for working only with epoxy stains, and the second one is suitable for working with all types of powder paints. There are homemade options, for example, made from a plastic bottle and a metal cap.

- Drying chamber with exhaust hood, providing a temperature of 200°C.

- Powerful electrical network with grounding.

In all videos, for high-quality and effective painting of wheels with your own hands, it is recommended to buy or rent a good paint gun. Without practice, it is not advisable to get involved with making a homemade device for the first time, since this process can take a lot of time, and its result does not guarantee one hundred percent implementation.

Base materials

When painting car wheels, the following types of powder paints are used:

- Polyester

coatings are resistant to corrosion and harsh atmospheric conditions. - Epoxy

- the layer of this paint is especially resistant to alkaline and acidic environments. - Polyurethane

- the coating retains its original appearance even after abrasive action, and is also resistant to oils and solvents. - Silicone

– especially resistant to high temperatures.

There are a large number of products on the market, with which it is easy to choose the desired color, texture (glossy or matte), as well as the structural type of polymer surface (shagreen, antique, etc.). The most popular brands of paints are:

The range of colors that is common in Russia is determined by the RAL standard, but manufacturers also offer a number of paints of other standards.

In the absence of sandblasting, you can use a drill with attachments, however, as when painting stamped car wheels ; In this case, sandpaper with different abrasive numbers (P200-P600) will also help. For degreasing you will need a solvent and special wipes.

Technology for painting discs with powder paint yourself and video of the process

The principle of powder coating is as follows: in the spraying device, paint particles are electrified, which in the process are attracted to the grounded plane of the part. The surface polymerization procedure is carried out in a heat chamber. The technology includes three stages:

Preparatory stage

Some motorists neglect this point when painting car rims with powder paint, and, I must say, in vain. Without quality preparation it is impossible to achieve the appropriate quality of coating. Masters use the following methods:

- Chemical and abrasive treatment

is a procedure for removing rust and old paint. For implementation, a metal brush, sandpaper, sandblasting machine, as well as acid and alkaline preparations are used. - Pickling

is the removal of contaminants and corrosion that did not respond to the initial stage of processing. The operation is performed using solutions of phosphoric, hydrochloric, nitric or sulfuric acid. - Phosphating

– treatment with iron, manganese or chromium phosphate. The method increases the adhesion of powder paint to the surface of the car several times. - Washing and drying

– removal of products from previous processing stages and final drying of the part.

Primer phase

So, the tire is dismantled, now it’s time for the primer. It should be noted that the technology does not provide for this stage, but when painting car wheels, experts recommend implementing it. This contributes, according to them, to better adhesion and anti-corrosion resistance.

After the soil has dried, its surface is cleaned using fine-grained sandpaper. Epoxy-zinc and epoxy primers are commonly used.

Powder paint application

Further painting of car rims with your own hands in the video is carried out in a special chamber using a special spray applicator that works on the electrostatic principle. The charged powder is applied to the grounded part using compressed air.

Thanks to electrostatic voltage, the paint is further retained on the surface of the wheel. The method has proven itself well when painting alloy wheels ; they look even better than new ones.

Polymerization process

The part, coated with polymer powder paint, is finally installed in a thermal cabinet in which the temperature is maintained at 190-220°C. Drying time is from 40 to 60 minutes. All professional cameras are equipped with an electronic control unit.

In a garage environment, you can construct a drying chamber with your own hands. For this, a box with insulation is assembled, where the role of a heater is assigned to ordinary heating elements. In order to organize air convection inside the chamber, you need to consider a simple system with a fan that is installed outside the cabinet.

0 0 vote

Article rating

A few words about the importance of primer

All auto centers that paint alloy wheels in Moscow use multi-layer priming of parts as the last step in preparation for painting. For powder paints, you should select a heat-resistant epoxy or epoxy-zinc primer. When starting to apply it, pay attention to a number of nuances:

- First, the inner surface of the discs is processed;

- Application in 4-5 layers is considered optimal;

- After applying each layer, the time specified by the manufacturer should be maintained until complete drying.

Applying a primer not only increases the adhesion of powder paint, but also prevents the appearance of corrosion.