Oil reserves are running out, forcing humanity to look for alternative energy sources that can replace “black gold.” One solution is to use a hydrogen engine, which is characterized by lower toxicity and greater efficiency. The main thing is that the supply of raw materials for the production of fuel is almost unlimited.

When did the hydrogen engine appear? What are the features of its device, and what is the principle of operation? Where is this technology used? Is it possible to make such a motor with your own hands? We will consider these and other questions below.

When the hydrogen engine appeared, the main companies leading its development

Interest in the use of hydrogen appeared back in the 70s during a period of acute fuel shortage. The first modern developer to introduce a hydrogen car engine was the Toyota concern. It was he who, in 1997, put on public display the FCHV SUV, which never went into mass production.

Despite the first failure, many companies continue research and even production of such cars. The greatest successes have been achieved by the Toyota, Hyundai and Honda concerns. Other companies are also developing - Volkswagen, General Motors, BMW, Nissan, Ford.

In 2021, the first hydrogen-powered train appeared, which is the brainchild of the German company Alstom (formerly GEC-Alsthom). The new Coranda iLint train is scheduled to begin service at the end of 2017 on the route from Buxtehude to Cuxhaven (Lower Saxony).

In the future, it is planned to replace 4,000 diesel trains in Germany with such trains, moving along sections of roads without electrification.

Norway, Denmark and other countries have already shown interest in purchasing Coranda iLint.

Pros of a hydrogen car

Let's start with the main advantages of the Hyundai Nexo:

1. A car not only does not pollute the atmosphere with harmful compounds and gases, but even helps clean the air. According to the developers, the filtration system they created can remove up to 99.9% of harmful impurities from the processed air. In an hour, the equipment purifies several tens of kilograms of air - this is a “portion” for more than 40 people.

2. Studies have already been conducted proving that 10,000 cars running on liquefied hydrogen replace about 600,000 mature trees in a large city.

3. Hydrogen is one of the most common elements from the periodic table. At the same time, lithium, necessary for the manufacture of electric vehicle batteries, is relatively rare - manufacturers are already waging real “trade wars” for the element.

4. Scientists have access to a new technique for moving and storing hydrogen in machines: a modular installation is used that allows the element to be stored in the form of ammonia. Before use on the same Hyundai crossovers, the equipment converts ammonia back into hydrogen.

5. Possibility of purchasing a used hydrogen car: unlike an electric car, its fuel cells wear out much more slowly than batteries. Thus, the resource of a cell for chemical reactions is 250 thousand kilometers.

Features of hydrogen as engine fuel

In an internal combustion engine, gasoline is mixed with air, after which it is supplied to the cylinders and burned, resulting in the movement of the pistons and the movement of the vehicle.

The use of hydrogen as fuel has a number of nuances:

- After combustion of the fuel mixture, only steam is formed at the outlet.

- The ignition reaction occurs faster than in the case of diesel fuel or gasoline.

- Thanks to detonation resistance, it is possible to increase the compression ratio.

- The heat transfer of hydrogen is 250% higher than that of a fuel-air mixture.

- Hydrogen is a volatile gas, so it gets into the smallest gaps and cavities. For this reason, few metals are able to withstand its destructive influence.

- Such fuel is stored in liquid or compressed form. If the tank breaks down, the hydrogen evaporates.

- The lower level of gas proportion to react with oxygen is 4%. Thanks to this feature, it is possible to adjust the operating modes of the motor by dosing the consistency.

Taking into account the listed nuances, it is impossible to use H2 in its pure form for an internal combustion engine. It is necessary to make design changes to the internal combustion engine and install additional equipment.

How does it work

Since today there are many operating engines of this category, in each individual case the hydrogen installation will operate according to its own principle. Let's look at how one modification works, which can replace the classic internal combustion engine.

Such an engine will necessarily use fuel cells. These are a kind of generators that activate an electrochemical reaction. Inside the device, hydrogen is oxidized, and the reaction results in the release of electricity, water vapor and nitrogen. Carbon dioxide is not released in such an installation.

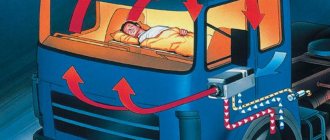

A vehicle using such a unit is the same as an electric car, only it has a much smaller battery. The fuel cell produces enough energy to operate all of the vehicle's systems. The only caveat is that it can take about 2 minutes from the start of the process to the generation of energy. But the maximum efficiency of the installation begins after the system warms up, which takes from a quarter of an hour to 60 minutes.

To prevent the power plant from running in vain, and to prevent the need to prepare the vehicle for the trip in advance, it has a conventional battery installed. While driving, it is recharged due to recuperation, and it is needed exclusively to start the car.

Such a car is equipped with a cylinder of different volumes into which hydrogen is pumped. Depending on the driving mode, the size of the car and the power of the electrical installation, one kilogram of gas may be enough for 100 kilometers of travel.

Hydrogen engine design

Cars with a hydrogen engine are divided into several groups:

- Machines with 2 energy carriers. They have an economical engine that can run on pure hydrogen or a gasoline mixture. The efficiency of this type of engine reaches 90-95 percent. For comparison, a diesel engine has an efficiency coefficient of 50%, and a conventional internal combustion engine - 35%. Such vehicles comply with the Euro-4 standard.

- A vehicle with a built-in electric motor that powers a hydrogen cell on board the vehicle. Today it has been possible to create motors with an efficiency of 75% or more.

- Conventional vehicles running on pure hydrogen or a fuel-air mixture. The peculiarity of such engines is clean exhaust and an increase in efficiency by another 20%.

As noted above, the design of a motor running on H2 is almost no different from an internal combustion engine, with the exception of some aspects.

The main feature is the method of supplying fuel to the combustion chamber and igniting it. As for the conversion of the received energy into the movement of the crankshaft, the process is similar.

Principle of operation

The operating principle of hydrogen engines is worth considering in relation to two types of such installations:

- Internal combustion engines;

- Hydrogen cell engines.

Hydrogen internal combustion engines

In an internal combustion engine, due to the fact that the gasoline mixture burns more slowly, the fuel enters the combustion chamber before the piston reaches its top point.

In a hydrogen engine, thanks to the instantaneous ignition of the gas, it is possible to shift the injection time until the moment the piston begins to move back. At the same time, for normal operation of the engine, a small pressure in the fuel system (up to 4 atmospheres) is sufficient.

Under optimal conditions, a hydrogen motor is capable of operating with a closed power supply system. This means that atmospheric air is not used during the formation of the mixture.

After the compression stroke is completed, steam remains in the cylinder, which is sent to the radiator, condenses and becomes water.

The implementation of this option is possible if an electrolyzer is installed on the machine - a device that ensures the separation of hydrogen from H2O for subsequent reaction with O2.

It has not yet been possible to make the described system a reality, because oil is used to ensure normal engine operation and reduce friction.

The latter evaporates and is part of the exhaust gases. So the use of atmospheric air when operating a hydrogen engine is still necessary.

Hydrogen cell engines

The operating principle of such devices is based on the occurrence of chemical reactions. The element casing has a membrane (conducts only protons) and an electrode chamber (it contains the cathode and anode).

H2 is supplied to the anode section, and O2 is supplied to the cathode chamber. The electrodes are coated with a special coating that acts as a catalyst (usually platinum).

Under the influence of the catalytic substance, hydrogen loses electrons. Next, protons are supplied through the membrane to the cathode, and water is formed under the influence of the catalyst.

From the anode chamber, electrons exit into an electrical circuit connected to the motor. This generates the current to power the motor.

Where have hydrogen fuel cells been used?

The peculiarity of hydrogen fuel cells is their ability to produce energy for an electric motor. As a result, the system replaces the internal combustion engine or becomes a source of on-board power for the vehicle.

Fuel cells were first used in 1959 by a company from the USA.

Generally speaking, fuel cells are used:

- BY ROAD TRANSPORT. In contrast to the efficiency of a standard engine, they show better results. When testing the first bus, fuel cells showed an efficiency of 57%. Today, such devices are tested by many car manufacturers - Honda, Ford, Nissan, Volkswagen and others.

- BY RAILWAY TRANSPORT. At the present stage, more than 60% of railway transport is diesel locomotives. Today, hydrogen trains are being developed in many countries - Japan, Denmark, the USA and Germany.

- BY SEA TRANSPORT. Hydrogen fuel cells are most in demand in submarines. Active work in this direction is being carried out in Germany and Spain, and other countries, including Italy, Greece, and Israel, act as customers.

- IN AVIATION. The first hydrogen-powered aircraft appeared in the 80s of the last century. At the present stage, a new type of fuel is used to create unmanned aerial vehicles (including helicopters).

Hydrogen fuel cells have also found use in forklifts, bicycles, scooters, motorcycles, tractors, golf carts and other equipment.

The hydrogen-powered aircraft will be

| Dmitry Basov , development director of V/O Aviaexport Alexander Rubtsov , editor of the Aviapanorama magazine, candidate of economic sciences, associate professor |

Hydrogen attracted the attention of aircraft designers at the dawn of the development of aviation - at the beginning of the twentieth century. Although, to be completely correct, it would be more correct to speak not about aircraft, but about aeroconstructors, since hydrogen was of interest not as a source of energy, but as a gas lighter than atmospheric air. Hydrogen was used in airship construction. But the disaster with the Hindenburg airship cooled this interest; helium began to be used in airships.

Aircraft designers turned to hydrogen again only in the mid-1970s. The Samara Engine Design Bureau, under the leadership of academician Nikolai Dmitrievich Kuznetsov (currently PJSC Kuznetsov), began work on studying the possibility of using liquid hydrogen and liquefied natural gas (LNG) as an alternative fuel for aircraft engines. The first experimental engine running on liquid hydrogen was the NK-88 engine, created on the basis of the serial engine for the Tu-154 NK-8-2.

In the late 1970s - early 1980s, the developer of fuel automation for aircraft engines MAKB Temp (later NPP EGA, currently JSC NPP TEMP named after F. Korotkov) began creating automatic control systems for the supply of alternative fuels . Special equipment was created to operate on both liquefied natural gas and hydrogen. We manufactured several sets of units that passed the required amount of bench tests and ground tests on the engine.

On April 15, 1988, the first flight of the Tu-155 took place. The right-hand engine in its power plant was the NK-88.

After this, Tupolev Design Bureau, TsAGI, Aviaexport and a number of other aviation organizations attempted to establish international cooperation.

To be fair, it should be noted that the use of hydrogen was then considered only as one of the options for using gaseous fuel in aviation. The use of LNG was considered as the main direction. For the period 1985-1990. Only 5 flights were made using liquid hydrogen. Although this is not much, there were no flights on liquid hydrogen abroad at all.

Hydrogen then gained much greater importance in rocket science. Hydrogen engines (RD-0120) were also used by the Soviet orbital rocket ship Buran.

Unfortunately, due to negative trends in the domestic aviation industry, at the end of the 1990s, further work on the use of hydrogen in aviation was discontinued.

But this did not mark the “end” of the hydrogen topic. Electrochemistry gave a “second wind” to the process of “penetration” of hydrogen into transport in general, and then into air transport in particular. This is what we are talking about.

Both the Tu-155 engines and the engines of hydrogen-powered cars (for example, the RAF-2203 created in 1976-1979 by NAMI) used hydrogen - if such a definition is appropriate here - traditionally, “the old fashioned way”, i.e. - burning it. Moreover, it is not always burned in its pure form, but in a mixture either with gasoline (automobile internal combustion engines) or with kerosene (aircraft engines). But hydrogen can provide energy without burning. Energy – electrical. This energy is produced by fuel cells - devices in which hydrogen combines with oxygen in the atmospheric air, causing a chemical reaction to occur. As a result, water is formed, and an electric current occurs on the separation membrane. Since a fuel cell has no moving parts (unlike, say, a generator), its efficiency is already reaches 90%. Such a fabulously clean and efficient technology is a reality not even of tomorrow, but of today. Fuel cells are widely used almost all over the world, primarily in the UK, Germany, USA, South Korea and Japan. Especially in Japan, which set the goal of building a society based on hydrogen back in 2021.

The use of hydrogen in transport has already passed the stage of pilot projects. Fuel cell passenger cars (such as the Honda Clarity) are mass produced. Such vehicles have fuel cells, compressed hydrogen cylinders, and a battery for cold starts and maintenance of peak loads and accelerations. The output power of mass-produced models is from 70 to 130 kW, the maximum speed is 160 km/h. Moreover, the speed is limited not by the engine itself, but by a software control system that limits hydrogen consumption to within one kg per 100 km. The range of the same Honda Clarity at one gas station is 750 km. For comparison, let’s say that the longest-range battery-electric vehicle can travel 590 km on a single charge. And then - according to the manufacturer - . By the way, in March 2021, a fuel cell electric vehicle with a range of 1000 km was introduced in China, and preparations are underway for its mass production. Audi, BMW, Daimler, Ford, GM, Honda, Hyundai, Mercedes-Benz and Toyota are mass-producing fuel cell electric vehicles (small-scale for now). The cost of such a car is still quite high. Here are the prices of the most common models on the market: Honda Clarity – 51,000 euros; Hyundai ix35 Fuel Cell – 65,400 euros; Toyota Mirai – 78,600 euros. However, according to experts (in particular, the Hydrogen Council), the cost of cars with fuel cells and internal combustion engines will be almost equal over the next 6-8 years. And this will be achieved by expanding the scale of production, because now there are just over 12,000 fuel cell vehicles in operation worldwide. And how the market for electric vehicles is growing can be judged by the fact that in 2010 there were only the same 12,000 battery-powered cars on the world’s roads, and in 2021 there are already 5,000,000! The companies CAT, E-Trucks Europe, FAUN Kirchoff, Linde, Renault/Symbio Fcell and ULEMCo are already producing trucks (low-tonnage for now) that reach speeds of up to 130 km/h and are capable of working a shift at one gas station. The companies Ballard, Daimler EvroBus, Hydrogeniks, Solaris, Toyota, Van Hool, VDL, and Writgtbas produce buses with a capacity of up to 105 people (however, the efficiency of these vehicles is lower - about 55%, and the specific hydrogen consumption is 8-14 kg/100 km). Scooters and even bicycles are produced using fuel cells. 15 countries already have more or less developed networks of hydrogen fuel stations, including Germany, Denmark and Italy, sufficient for the widespread use of fuel cell vehicles. Fuel cells have also found their place in railway transport. The world's first hydrogen fuel cell train, the Coradia iLint, was put into operation in Germany. On the roof there is a hydrogen tank and a fuel cell. The train speed is 140 km/h, the travel range at one gas station is 1000 km, and refueling lasts 15 minutes (!). Initially, the project was developed by the German company LHB, which was then absorbed by the French concern Alston. From July 16, 2021, this transport links the cities of Bremervörde, Bremerhaven, Buxtehude and Cuxhaven. By 2021, the state of Lower Saxony will purchase 14 such trains, which will cost 81 million euros. Well, this is Germany, and the Russian side has already signed an agreement with the Alston concern under which “hydrogen” trains will run on Sakhalin. Fuel cell-powered marine vessels are produced in the Netherlands.

But let's return to aviation. It is clear that the use of fuel cells here can only go in line with the development of electric aviation. What picture are we seeing here?

On the one hand, there are undoubted successes - electric gliders are produced (and successfully sold!) in Germany, Slovenia produces (and no less successfully sells) light electric aircraft, a light electric helicopter was created in China (and is operated in the UAE as an unmanned air taxi). The electric plane has already flown around the Earth. But... none of this has anything to do with fuel cells: the plane that flew around the earth was powered by solar panels, and the rest of the aircraft mentioned use rechargeable batteries.

To date, in most countries, fuel cells have only “penetrated” unmanned aerial vehicles. The British company Cella has developed solid hydrogen pellets and in March 2021 launched a drone in Scotland loaded with hundreds of such pellets (each about one square centimeter in area). Unfortunately, the company does not report the flight duration and speed, but an undoubted achievement is that this entire system (fuel cells, pellet supply) is more than three times lighter than lithium batteries of the same output characteristics.

But it is the weight of even the most modern batteries that prevents the creation of a real electric helicopter. The Chinese air taxi in Dubai, of course, is not like that - it is a “toy” drone that lifts one passenger with a backpack into the air for 15 minutes. And how in demand the electric helicopter is is evidenced by the fact that work on its creation is going on all over the world from China to the USA (in our country, unfortunately, they are little noticeable). Because, unlike, say, an electric car, the advantages of an electric helicopter over a conventional one using an internal combustion engine come down not only to the environment. The environmental factor is not even the main one here. The advantages of an electric helicopter are as follows:

- An electric helicopter does not need such a complex, heavy, vulnerable and expensive unit as a gearbox. Which makes it (all other things being equal) simpler, lighter, more reliable and cheaper.

- An electric helicopter does not consume petroleum products, which is extremely important everywhere, and especially in the Far North (considering the cost of delivering aviation fuel there).

- An electric motor is much easier to control than an internal combustion engine, which is extremely important for unmanned aerial vehicles. (The constant expansion of the scope of application of BLP is also a reality today.)

- An hour of flight time of an electric helicopter is significantly cheaper than an hour of flight time of a helicopter with an internal combustion engine. This is all about civil aviation. If we talk about military aviation, then a 5th point needs to be added to these points:

- Efficiency ICE – about 30%; 70% of energy is converted into heat. The temperature of the helicopter exhaust gases is 900 degrees Celsius. Electric motor efficiency is over 90%. The electric helicopter is almost “cold”. This makes it significantly less noticeable to modern infrared target detection systems.

But manned fuel cell vehicles have already appeared in Germany, China and the USA. A collaboration between aircraft manufacturer Pipistrel, fuel cell developers Hydrogenics and scientists from the universities of Ulm and the German aerospace center Institute for Aerodynamics Engineering has brought the day of the launch of zero-emission, environmentally friendly passenger aircraft closer. The hydrogen-powered four-seat, single-engine HY4 made its first 15-minute flight around Stuttgart Airport.

The HY4, which is 21.36 meters long, consists of two cabins located on either side of the engine - this unusual design made it possible to optimally distribute the load over the area of the entire aircraft, which reduced fuel consumption and increased the overall payload capacity. Each fuselage is equipped with a 9-kilogram container for hydrogen fuel, which feeds four low-temperature exchange membranes of the fuel modules. A sophisticated system converts hydrogen and oxygen into water, generating the electrical energy necessary for the functioning of transport.

With full tanks and optimal flight conditions, an eco-plane can travel up to 1,500 kilometers, which, by modern standards, is not that much, but it is worth considering that the flight of HY4 does not harm the environment, unlike modern air vehicles. Maximum and cruising speeds are 200 and 145 km/h, respectively.

Opponents of hydrogen energy often appeal to the increased explosiveness of hydrogen. But increased compared to what? With peat, coal, firewood? So these energy carriers have never been used in aviation. And the flammability or, moreover, explosiveness of hydrogen is lower than the flammability or explosion of kerosene.

Well, how are things going in Russia today with the introduction of hydrogen into aviation? We have already talked about the use of hydrogen as a fuel for jet engines above, and with the use of hydrogen in fuel cells - in general, the same as throughout the world: unmanned vehicles using fuel cells are flying, and in manned aviation there are first timid attempts.

At the Zhukovsky air show (August 27 – September 1, 2019), a domestic aircraft (although it might be more correct to call it a full-size mockup) powered by hydrogen fuel cells was demonstrated. It is a domestic light two-seater aircraft "Sigma-4" converted for hydrogen propulsion. The plane has a wingspan of 9.8 m and a length of 6.2 m. The hydrogen power plant takes the place of the passenger - the plane has become single-seat. The take-off weight is now 600 kg, the flight range, according to the creators of the machine (the board did not fly) is 300 km.

The main part - the fuel cell - was developed (together with the group) by the Institute of Chemical Physics of the Russian Academy of Sciences, the leading organization in the project to create a hydrogen aircraft. The project leader is Professor Yuri Dobrovolsky. The power plant, including hydrogen storage tanks, gearboxes, flow meters, fuel lines, a humidifier, a compressor, fuel cell cooling systems, air preparation and supply, as well as control systems, were created by the department of hybrid and electric power plants of CIAM named after. P.I. Baranova. Future plans include replacing one propeller with many small ones located along the leading edge of the wing. The issue of designing a new airframe has already been discussed with the St. Petersburg Polytechnic University. Peter the Great.

CIAM plans to test the power plant in flight, but in a “reduced form,” i.e. ... on batteries. However, firstly, this, even according to the initiators of the experiment, will reduce the flight time to 15 minutes, and, secondly, testing a hydrogen power plant without hydrogen...

But why is everything so modest here: we don’t have a hydrogen car, a hydrogen plane doesn’t fly, and a hydrogen train is imported? It seems to us that the answer to this question is given in the very interesting report “Hydrogen Economy - the Path to Low-Carbon Development” prepared by the Energy Center of the Moscow School of Management SKOLKOVO. (In this article we have repeatedly used materials from this report. Its authors: Tatiana MITROVA, Yuri MELNIKOV, Dmitry CHUGUNOV). The report can be found on the Internet. So - let's quote verbatim - it says: “Russia still lacks not only a national hydrogen program, but even visible coordination of various research groups and interests .

Moreover, the real state of affairs is no better than reflected in this report. Largely due to the lack of coordination, our national “hydrogen potential” is not being built up, but, on the contrary, the existing positions are being “surrendered.” Thus, the report talks about our largest manufacturer of electrolysers - PJSC Uralkhimmash (Ekaterinburg), which produces units with a capacity of 4 to 300 cubic meters of hydrogen per hour. The plant ceased to exist. The electrolyser market is completely dominated by foreign companies.

The National Association of Hydrogen Energy (NAHE), on which the speakers pin some hopes, is limited to the fact that, working in a number of technical committees, it introduces standards in Russia that are analogues of international standards in the field of hydrogen technologies. The matter, of course, is also useful, but there is no talk of any coordinating role in terms of the development of national hydrogen energy. By the way (or - not by the way) to say, this national association itself positions itself - see its website - as the representative office in Russia and the CIS of the International Association of Hydrogen Energy (IAHE), which can be contacted - again see the website - in ... Miami, Florida .

In the current situation, the role of coordinator in the development of hydrogen energy as a whole is within the capabilities of only a government agency. So far, the very first, and therefore modest, steps are being taken. But the main thing is to start. Moreover, this is being done as an integral part of a more comprehensive work - the use of non-traditional energy sources in aviation (primarily gaseous fuels). Therefore, we will return to the topic of using hydrogen, as well as other alternative fuels, in aviation in our next publication.

Advantages and disadvantages

To understand the features and prospects of a hydrogen engine in a car, it is worth knowing its pros and cons. Let's take a closer look at them.

Pros:

- ECO-FRIENDLY. The introduction of a hydrogen engine is an opportunity to forget about the problem of environmental pollution. With a global transition to this type of fuel, it will be possible to reduce the greenhouse effect and, possibly, save the planet. The environmental friendliness of new developments has been confirmed by Toyota. The concern's employees have proven that car exhaust is safe for health. Moreover, the water that comes out can be drunk, because it is distilled and purified from impurities.

- DEVELOPMENT EXPERIENCE. It is known that the hydrogen engine was created a long time ago, so there should be no problems with its use in cars. If you go deeper into history, the first semblance of a hydrogen engine was created at the beginning of the 19th century by François Isaac de Rivaz, a designer from France. In addition, during the siege of Leningrad, almost 500 vehicles were converted to a new type of fuel.

- AVAILABILITY. An equally important factor in favor of H2 is the absence of deficit. If desired, this type of fuel can even be obtained from wastewater.

- POSSIBLE OF APPLICATION IN DIFFERENT POWER INSTALLATIONS. There is an opinion that hydrogen is used only in internal combustion engines. This is wrong. The new technology is used to create a fuel cell, with the help of which it is possible to generate electric current and power the electric motor of a vehicle. The advantages are safety and the absence of fossil elements, which eliminates environmental pollution. At the present stage, this scheme is considered the most secure and is in greatest demand among developers.

Also the advantages include:

- Minimum noise level;

- Improving power, throttle response and other engine parameters;

- Large power reserve;

- Low fuel consumption;

- Ease of maintenance;

- High potential for use as an alternative fuel.

Disadvantages of a hydrogen engine:

- DIFFICULTY IN EXTRACTING H2 FROM WATER. As noted, this gas is considered the most common element on the planet, but it is almost non-existent in its pure form. This gas has minimal weight, so it rises and is retained in the upper atmosphere. H2 atoms quickly bond with other elements, resulting in the formation of water, methane and other substances. This is why in order to use hydrogen it must be extracted, and this requires large amounts of energy. At the moment, such production is unprofitable, which slows down the process of introducing hydrogen engines. According to rough calculations, the price of a liter of liquefied H2 is from 2 to 8 euros. The final costs largely depend on the method of fuel extraction.

- LACK OF THE REQUIRED NUMBER OF REFUELS. No less a problem is the shortage of gas stations ready to refuel cars with hydrogen fuel. The problem is the high cost of equipment for such gas stations (compared to a regular gas station). Today, many projects for hydrogen refueling stations have been developed - from large to small gas stations, but due to the high cost and lack of widespread use of hydrogen engines in cars, the process of implementing the idea can take decades.

- EXPENSIVE MODERNIZATION OF THE ICE IS NECESSARY. As noted, hydrogen fuel can theoretically be used to refuel internal combustion engines. But to use H2 as the main fuel, design changes are required. If nothing is changed, the motor power drops by 20-35%, and the life of the power unit is significantly reduced. But this is not the main drawback. The danger is that such a mechanism will not work for long and will quickly fail. When burning, the hydrogen mixture releases more heat, which leads to overheating of the piston and valve system, and the engine operates under increased loads. In addition, high temperatures negatively affect the materials from which the power unit is made and lubricants. As a result, the working elements of the engine will quickly wear out. This means that without upgrading the internal combustion engine, the use of H2 is impossible.

- EXPENSIVE COST OF MATERIALS. The main “stumbling block” in the development of hydrogen technologies is the high cost of materials. Platinum is used as a catalyst, the price of which is very high for the average car owner. It’s easier to spend money and give an expensive ring to your wife than to give it away to install a new part. Hope remains with scientists who are looking for alternatives to the expensive catalyst. Elements that can replace the precious metal are being tested.

In addition to those already discussed above, it is worth highlighting a number of disadvantages:

- Fire or explosion hazard.

- Risks for the planet, because an increase in the volume of hydrogen can lead to irreparable consequences for the ozone layer.

- Increased weight of the machine due to the use of powerful batteries and converters.

- There are problems with storing hydrogen fuel - under high pressure or in liquefied form. Researchers have not yet reached a consensus on which option is better.

Air or direct cooling system

In a direct cooling system, the engine is cooled directly by air passing through it. This is the same cooling system that is used for motorcycle engines.

It keeps the air in direct contact with the engine, hence it is also known as direct cooling system.

The air cooling system is used for small engines such as bicycles, lawn mowers, etc.

Advantages of an air cooling system

- Engine design becomes simpler.

- Repair is easy in case of damage.

- The absence of a bulky cooling system makes system maintenance easier.

- There is no danger of coolant leakage.

- The engine is not subject to frost.

- It is a self-contained device as it does not require a radiator, header, tanks, etc.

- Installation of an air cooling system is simple.

Disadvantages of air cooled engines

- They can only be used in places where the ambient temperature is lower.

- Cooling is not uniform.

- Higher operating temperature compared to water-cooled engines.

- Produce more aerodynamic noise.

- Specific fuel consumption is higher.

- Lower maximum allowable compression ratios.

- The fan, if used, consumes almost 5% of the power generated by the motors.

The dangers of hydrogen fuel

The disadvantages discussed above mentioned the danger of using hydrogen fuel for the engine. This is the main disadvantage of the new technology.

When combined with an oxidizing agent (oxygen), the risk of hydrogen ignition or even explosion increases. Studies have shown that 1/10 of the energy required to ignite a gasoline mixture is sufficient to ignite H2. In other words, a static spark is enough for hydrogen to flare up.

Another danger is the invisibility of the hydrogen flame. When a substance burns, the fire is almost invisible, which complicates the process of fighting it. In addition, excessive amounts of H2 lead to suffocation.

The danger is that it is extremely difficult to recognize this gas, because it has no odor and is completely invisible to the human eye.

In addition, liquefied H2 has a low temperature, so if it leaks onto exposed body parts, there is a high risk of severe frostbite. This gas must be located in special storage facilities.

From what was discussed above, the conclusion suggests itself that the hydrogen engine is dangerous, and using it is extremely risky.

In fact, hydrogen gas is lightweight and if leaked, it will disperse into the air. This means that the risk of ignition is minimal.

In the case of suffocation, such a situation is possible, but only when in a closed room. Otherwise, a leak of hydrogen fuel does not pose a danger to life. In justification, it is worth noting that exhaust gases from internal combustion engines (namely carbon monoxide) also carry a fatal risk.

Why are hydrogen cars better than electric cars?

If we take a hydrogen installation with fuel cells, then such a car will be identical to the electric car that we are used to seeing on the roads. The only difference is that the electric car is charged from the network or from a terminal at a gas station. Hydrogen transport generates its own electricity.

As for the cost of such cars, they are more expensive. For example, Tesla models in basic configuration will cost from 45 thousand dollars. Hydrogen analogues from Japan can be purchased for 57 thousand.e. Bavarians sell their cars using “green” fuel at prices starting from 50 thousand dollars.

If we take into account practicality, it is easier to fill the car with gas (this will take about five minutes) than to wait half an hour (with fast charging, which is not permissible for all types of batteries) in the parking lot. This is the advantage of hydrogen installations.

Another plus is that fuel cells do not require much maintenance, and their working life is quite long. As for electric vehicles, their huge battery will require replacement after about five years due to the fact that it undergoes many charge-discharge cycles. In cold weather, the battery in electric vehicles discharges much faster than in the summer. But the element in the hydrogen oxidation reaction does not suffer from this and stably produces electricity.

Modern cars with hydrogen engines

The possibility of using hydrogen fuel engines has attracted the interest of many manufacturers. As a result, more and more cars running on this gas are appearing in the automotive industry.

The most popular models include:

- Toyota has released the Fuel Cell Sedan. To eliminate problems with limited space in the cabin and luggage compartment, containers with hydrogen fuel are placed on the floor of the vehicle. The Fuel Cell Sedan is designed to transport people, and its cost is 67.5 thousand dollars.

- The BMW concern presented its version of the Hydrogen car. The new model was tested by famous cultural figures, businessmen, politicians and other popular personalities. Tests have shown that switching to a new fuel does not affect the comfort, safety and dynamics of the vehicle. If necessary, fuel types can be switched from one to another. Hydrogen7 speed is up to 229 km/h.

- Honda Clarity is a car from the Honda concern that impresses with its power reserve. It is 589 km, which is something no other low-emission vehicle can boast of. Refueling takes three to five minutes.

- General Motors' "Monster" premieres in October 2021. The peculiarity of the car is its incredible reliability, which is confirmed by studies carried out by the US Army. During testing, the vehicle traveled more than 3 million kilometers.

- Toyota has launched the Mirai hydrogen model on the market. Sales began in 2014 in Japan, and in the United States in October 2015. The Mirai takes five minutes to refuel and has a range of 502 km per fill. PHOTO 21 22 Recently, representatives of the concern announced that they plan to introduce this technology not only into passenger vehicles, but also into forklifts and even trucks. The 18-wheeler truck is already being tested in Los Angeles.

- Manufacturer Lexus is planning its hydrogen-powered version of the car in 2021, so few details are known about the vehicle.

- Audi presented the H-tron Quattro concept in Detroit. According to the manufacturer, the car can travel about 600 km on one tank, and it can reach speeds of up to 100 km/h in 7.1 seconds. The car has a “virtual” cockpit that replaces the standard dashboard.

- BMW, in collaboration with Toyota, plans to release its hydrogen vehicle by 2021. The manufacturer assures that the power reserve of the new model is more than 480 km, and refueling will take up to 5 minutes.

- In 2013, Ford announced that active production of hydrogen engines would begin by the end of 2021 in collaboration with Nissan and Mercedes-Benz. But it has not yet been possible to implement the plan in practice - the concern’s employees are at the development stage.

- Mercedes-Benz presented the GLC SUV at the Frankfurt Motor Show, which will appear on the market at the end of 2021. The car is equipped with a 9.3 kWh battery, and the range is 436 km. Top speed is electronically limited to 159 km/h.

- Nikola Motor presented a hydrogen-powered truck with a range of 1,287 to 1,931 km. The cost of a new car will be 5-7 thousand dollars per month for rent. Production is planned to begin in 2021.

- The Hyundai manufacturer has created a new Tucson line. To date, 140 vehicles have been produced and sold. The Hyundai Genesis brand presented its GV hydrogen-powered car. The vehicle was first presented in New York, but its production is not yet planned.

- The UK is also not lagging behind in terms of new technologies. The Riversimple Rasa hydrogen car can already be rented in the country for three or six months. The car weighs just over 500 kg and can travel about 500 km on one fill.

- The design house Pininfarina has created the H2 Speed hydrogen fuel car. The peculiarity of the car is its ability to accelerate to hundreds in just 3.4 seconds, and the maximum speed is 300 km/h. Refilling time is only three minutes. The cost of the new model reaches 2.5 million dollars.

Difficulties in operating hydrogen internal combustion engines

The main obstacle to the introduction of new technology is the excessive costs of obtaining hydrogen fuel, as well as the purchase of component materials.

There are also problems with storing H2. Thus, to maintain the gas in the required state, a temperature of -253 degrees Celsius is required.

The simplest way to produce hydrogen is electrolysis of water. If H2 production is required on an industrial scale, high energy costs cannot be avoided.

To improve production profitability, the capabilities of nuclear power are required. To avoid risks, scientists are trying to find alternatives to this option.

Moving and storage requires the use of expensive materials and high-quality mechanisms.

We must not forget about other difficulties that one has to face during operation:

- Explosion hazard. If there is a gas leak in a closed area and there is little energy for the reaction to occur, an explosion may occur. If the air is overheated, this only makes the situation worse. High H2 penetration causes gas to enter the exhaust manifold. That is why the use of a rotary motor is considered more preferable.

- When storing hydrogen, containers with a large volume are used, as well as systems that prevent gas volatilization. In addition, devices are used that prevent mechanical damage to containers. If this feature is not of great importance for trucks, water or passenger transport, a passenger car loses valuable cubic meters.

- Under heavy loads and high temperatures, H2 provokes the destruction of the elements of the cylinder-piston group (cylinder-piston group) and lubricant in the engine. The use of special alloys and lubricants increases the cost of producing hydrogen engines.

The future of hydrogen engines

The use of H2 opens up great prospects and not only in the automotive sector. Hydrogen engines are actively used in railway transport, airplanes and helicopters. They are also installed on auxiliary equipment.

Many concerns, which were already mentioned above, are showing interest in the development of such engines - Toyota, BMW, Volkswagen, General Motors and others.

Already today there are real cars on the roads that run on hydrogen. Many of them are discussed above - BMW 750i Hydrogen, Honda FSX, Toyota Mirai and others.

Almost all large concerns that are trying to find their niche in the market have joined the work.

The main disadvantage remains the high price of H2, the lack of gas stations, as well as the shortage of qualified workers capable of servicing such equipment. If the existing problems can be solved, cars with hydrogen engines will definitely appear on our roads.

Competing technologies

Attention to hydrogen engines is dissipating due to the fact that the technology has competitors.

Here are just a few of them:

- HYBRID VEHICLES are vehicles capable of running on multiple energy sources. Many concerns combine a conventional internal combustion engine and an electric motor. Another option for a hybrid car is the combination of an internal combustion engine and a power unit that uses compressed air as fuel.

- ELECTRIC CARS (ELECTRIC VEHICLES) - vehicles that are driven by one or a group of electric motors powered by batteries or fuel cells. In such machines, internal combustion engines are not used. Electric cars should not be confused with cars that have an electric supply, as well as with electric public transport (trolleybuses and trams).

- CARS WITH LIQUID NITROGEN. The energy source, as the name suggests, is liquid nitrogen (located in special containers). The motor works as follows. The fuel is heated in a special mechanism, after which it evaporates and is converted into high-pressure gas. Next, it is sent to the motor, where it acts on the rotor or piston, thus transferring the available energy. Liquid nitrogen machines have been presented to the public, but at the present stage they are not widely used. One of these cars “played” in the film “Liquid Air” in 1902. The developers claim that such a vehicle can travel more than 100 km on one tank.

- COMPRESSED AIR VEHICLE. The peculiarity of the vehicle is the use of a pneumatic motor, thanks to which the vehicle moves. The special drive is called pneumatic. Instead of an air-fuel mixture, the energy source is compressed air. As noted above, this technology is part of hybrid cars.

Short story

Hydrogen internal combustion engines appeared during the same period when the internal combustion engine principle was being developed and improved. The French engineer and inventor designed his own version of the internal combustion engine. The fuel he used in his development was hydrogen, which appeared as a result of the electrolysis of H2O. In 1807, the first hydrogen car appeared.

Isaac De Rivaz filed a patent in 1807 to develop a tractor for military equipment. He proposed using hydrogen as one of the power units.

The power unit was a piston, and ignition in it occurred due to the formation of a spark in the cylinder. True, the inventor’s first creation required manual generation of a spark. Just two years later, he finalized his work, and the first self-propelled hydrogen vehicle was born.

However, at that time, the development was not given importance, because gas is not as easy to obtain and store as gasoline. Hydrogen engines were put into practical use in Leningrad during the siege in the second half of 1941. Although, it is worth recognizing that these were not exclusively hydrogen units. These were ordinary internal combustion engines GAZ, only there was no fuel for them, but at that time there was plenty of gas, since they were fueled by balloons.

In the first half of the 80s, many countries, not only European, but also America, Russia and Japan, began experimenting with this type of installation. So, in 1982, through joint work with the RAF automobile enterprise, a combined engine appeared that ran on a mixture of hydrogen and air, and a 5 kW/h battery was used as an energy source.

Since then, various countries have attempted to introduce “green” vehicles into their model lines, but in most cases such vehicles either remained in the prototype category or had a very limited circulation.