Content:

- Why is balancing needed?

- Why is balancing accuracy important?

- Main types of imbalance;

- How is wheel balancing performed?

- On a balancing machine;

- Final wheel balancing;

- How often should the wheel balancing procedure be performed?

- Do the rear wheels need balancing?

- What is the difference between quality balancing?

How to balance and how often?

The wheels are balanced on a special stand in a tire workshop using weights made of zinc or lead weighing from 5 to 100 grams. The device itself spins the wheel and selects the weight and location of the compensating weight. Craftsmen glue them or put them on the rim of the disc and hammer them in with a hammer in the places where the tire fits.

Question answer

Is it possible to drive on a flat tire?

The larger the wheel, the more difficult it is to balance. However, during this decade, many factories have undergone re-equipment and are already capable of producing rollers of even a twentieth radius with good accuracy. Therefore, when buying a wheel, you should ask where the tire was made and when the plant opened. If these are old domestic production facilities with old equipment, then it will be more difficult to balance a tire produced there than one manufactured at a newly built Russian enterprise of some famous foreign brand.

In addition, you cannot balance a wheel if large stones are stuck in the tread. When they fall out, the center of mass will shift and the wheel will start to beat again.

In general, wheel balancing must be done after each tire installation. In addition, over time, weights can fall off, leading to imbalance. Therefore, as soon as unwanted vibrations are felt in the car, you can return to the tire shop and repeat the balancing procedure again.

Why is balancing needed?

With uniform weight distribution, the axis of rotation must coincide with the center of mass of the wheel. If this does not happen, an imbalance appears, causing centrifugal force with different vectors of application. As a result, vibration occurs in the wheels, leading to unforeseen loads. When balancing the wheels, it disappears due to the focusing of all applied forces in the center.

To understand why you need to do balancing, it’s worth considering just a few consequences of an imbalance:

Another negative phenomenon is high vibration, which is transmitted to the steering wheel. This greatly complicates the control process and leads to rapid fatigue.

How does wheel imbalance occur?

Imbalance is nothing more than out-of-balance wheel alignment. For example, as we have already said, to balance wheels, tire fitters use special weights (counterweights) that align the wheels so that they rotate evenly around their own axis.

Unfortunately, very often these counterweights fly off on the road. This happens especially often after hitting another pothole or if the car hits a curb.

Another cause of imbalance is uneven tread wear. For example, if you are a fan of driving from a standstill, pressing the gas pedal to the floor and braking sharply in front of traffic lights, then with this driving style the tire tread on your car will wear out unevenly very quickly. In addition, rubber tends to wear out unevenly if you like to take corners.

Moreover, you may not even notice this uneven wear with a quick glance. But you should be aware that even minor changes to the tread when tires wear unevenly due to your driving maneuvers can affect concentricity due to the centrifugal force created as the wheel rotates. For example, at a speed of 100 km/h, an imbalance of just 10 grams turns into 2.5 kilograms per wheel.

Main types of imbalance

Depending on the relative position of the wheel rotation axis and the inertia axis, imbalance can be of two types:

- static.

In this case they are parallel. It can be easily identified by the bouncing movements of the car even when driving at low speeds. This occurs due to a shift in the center of gravity of the tires to one side; - dynamic.

In this situation, the axles are at some angle, and the weight of the wheel is unevenly distributed across the width. Deviations in this case are felt at higher speeds, when it becomes difficult to keep the car in one line.

In rare cases, both types of imbalance may be present. But any balancing machine can easily cope with this problem.

About imbalance and wheel runout

02 July 2019

The problem of wheel balancing has been around since the advent of automobiles. However, while the speed was low and the road surfaces were imperfect, even significant imbalances and wheel runouts were of little concern. But with increasing speeds and improving road surfaces, the situation has changed radically. Imbalance - the presence of unbalanced rotating masses: hubs, brake drums, rims and especially tires makes it difficult to drive a car, reduces the service life of shock absorbers, suspension, steering, tires, traffic safety, and increases maintenance costs. The wheel of any vehicle is an object of rotation. It must have a symmetrical shape, which means that all points on the surface of the wheel in sections must be equidistant from the axis of its rotation, and the center of gravity must lie on this axis. A wheel is considered balanced when its axis of rotation is also the main central axis of inertia. But... both the wheel itself, its components, and the rubber tire are manufactured with certain permissible deviations from the nominal values of the parameters, so it is almost always asymmetrical, and, therefore, unbalanced. There are two main types of imbalance - static and dynamic. Static is such an imbalance of the wheel when the main central axis of inertia (O1 - O1), on which the center of gravity of the wheel (CG) is located, is parallel to the axis of rotation (O - O), but does not coincide with it.

Wheel imbalance : a) - static, b) - dynamic

In this case, the gravity force of the unbalanced mass (mn) of such a wheel will create a torque: the wheel freely mounted on the axle will begin to rotate (oscillate like a pendulum) and will stop only when the unbalanced mass (mn ) will take the lowest position. This means that in order to balance this wheel statically, it is necessary to install a correction mass - a balancing weight (mу) - on the diametrically opposite side of the wheel. This balancing is called static balancing. Dynamic imbalance is caused by imbalance across the width of the wheel and can only be detected when it is rotated. In such a wheel, although the axis of rotation passes through the center of gravity, it forms a certain angle α with the main central axis of inertia. The unbalanced masses of the wheel in this case are reduced to two masses (mn) lying in the center plane. When the wheel rotates, at the locations of the centers of gravity of unbalanced masses, centrifugal forces (Pc) will arise, which, acting in opposite directions, will create a pair of forces with a moment of rotation M=P α. This characterizes the magnitude of the dynamic imbalance. Now, to balance the wheel, it is necessary to strengthen the corresponding balancing weights (mу) on the edges of the rim in the plane of action of the specified pair of forces on the inner and outer sides of the wheel, thereby eliminating the dynamic imbalance. Wheel imbalance is a consequence of either its design - the presence of a valve hole in the disk, variable pitch of the tire tread pattern, a hatch for adjusting the brakes in the brake drum, or manufacturability - inaccuracy of the geometric shape, dimensional deviations, heterogeneity of materials, etc. The manufacturing accuracy of wheel parts is assessed by radial and lateral runout, ovality, and local shape deviations. The imbalance is influenced by runout, ovality has practically no effect. Radial runout is characterized by the difference in distances from any point on the tire tread tread to the axis of rotation of the wheel. Lateral runout is the difference in distances of the lateral surface per one revolution of the wheel from the plane perpendicular to the axis of rotation of the wheel. So, the problem of imbalance and runout is related to the quality of manufacture of the unbalanced rotating masses of the car. It is almost impossible to create an ideal wheel without imbalance and runout. Therefore, in practice, during the production of each part of the wheel assembly and tire, certain restrictions and tolerances are introduced, based on their operating conditions and manufacturing capabilities. The tire makes the biggest contribution to wheel imbalance. It is farthest from the center of rotation, has a large weight, a complex multi-component structure, and is made of various materials: rubber, fabrics, steel wire, etc. The farther away from the center the extra mass of tire material is, the greater the effect it has on the imbalance. If the tire is tubed, then its overall imbalance consists of the imbalances of the tire and the riding tube, which also depends on their relative position. The chamber has different wall thicknesses, its joint, especially if it is reinforced with a joining tape, and the valve influence the imbalance. Therefore, in order to reduce it, when making a tube, the valve is installed on the side opposite to the joint, the tube is inserted into the tire so that the valve of the tube coincides with the light spot of the tire. However, the tube imbalance is much smaller than the tire imbalance. The main factors influencing the imbalance and runout of tires: • the joint of the tread, the unevenness of its thickness along the circumference, variable pitch of the tread pattern, in winter studded tires there are studs (in a new tire and as they fall out); • joints in the cord layer, joints of cord layers in the frame and breaker; • joint of the sealing layer in a tubeless tire; • non-concentricity of the bead rings, large overlap of wire in the bead ring; • inconstancy of the angles of inclination of the cord threads in the carcass and breaker layers; • divergence of cord threads in layers; • accuracy of mold manufacturing; • different thickness of side walls and sides; • grouped in one place markings on the sidewall of the tire, etc. Most of the listed factors that influence the imbalance do not manifest themselves externally: they are, so to speak, internal. Possible manifestations of some of them, which can be detected with your own eyes, are presented in photo 1.

| Photo 1. Variable tread pattern pitch as a “source” of tire imbalance |

| Photo 2. Carcass layer joints as “sources” of tire imbalance | |

| a) – single joint | |

| b) – two joints | |

| c) – two joints side by side | |

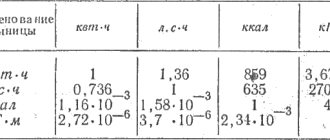

Increasing the requirements for technological accuracy of all production processes of tires and wheel parts is an indispensable condition for improving their quality, and therefore reducing imbalance and runout. But since it is impossible to avoid imbalance and beats, GOST 4754-97 regulates the requirements for these indicators. When operating a vehicle, it is advisable to check the imbalance of the wheels and tires every 2-3 thousand km, and the wheels and tires must be re-balanced every 10 thousand. Extract from GOST 4754-97 PNEUMATIC TIRES FOR PASSENGER CARS, TRAILERS, LIGHT TRUCKS AND BUSES OF ESPECIALLY SMALL CAPACITY (Technical conditions) 5.1.7 When inserting a tube into a tire, the light part of the tire must be aligned with the valve camera and marked on the tire with a mark in the form of a circle with a diameter of 5-10 mm, applied with durable indelible paint so that it is not covered by the wheel rim. 5.1.8 Dynamic imbalance of the tire and wheel assembly must be corrected by applying the corrective mass specified in Table 4 on each side of the wheel rim. Table 4.

| Tire designation | Nominal rim diameter, inch | Correction weight, g, no more |

| Radial (all designations) 215/80R16C 225/75R16C | 12 | 50 |

| 13 | 60 | |

| 14-16 | 70 | |

| 16 | 140 | |

| 16 | 160 | |

| Diagonal (all designations) 175/80-16С 6.50-16С | 13 | 80 |

| 14 | 100 | |

| 15 | 140 | |

| 16 | 120 | |

| 16 | 150 |

5.1.9 Tire runout should be no more than the standards specified in Table 5. Table 5

| Tire designation | Tire runout, mm, no more | |

| radial | lateral | |

| Radial with bore diameter, inch 12-14 15-16 | 1,0 1,5 | 1,5 2,0 |

| Diagonal of all symbols | 2,0 | 3,0 |

Such an extract from GOST 4754-97 must be posted in every tire shop.

Savosin V.S. ( TOPOF.RU

) Honored Innovator of the Russian Federation

How to balance wheels

The procedure is performed only on a fully assembled wheel. There are several methods by which balancing is performed:

- using a classic balancing machine;

- finishing;

- internal, or also called automatic.

When automatically balancing, a special material or sand is used, which is poured inside the tire. Due to centrifugal force, it is distributed over its inner surface, ensuring weight balance. The main disadvantage of the method is its limited application - mainly for trucks and SUVs.

Why balance wheels?

Balancing performed by car service technicians allows you to reduce the weight to a minimum, since it is impossible to achieve the ideal. Thanks to this procedure, the longitudinal and transverse runout of the slopes is minimized. If you neglect this phenomenon and drive on unbalanced wheels, then you need to prepare for the following consequences:

- Traffic safety problems. In an emergency situation, when the outcome is decided in a split second, an imbalance can prevent you from going around an obstacle or braking in time.

- Runout causes accelerated wear of rubber. The slopes wear out in the most unexpected places - a “bald patch” in the form of a spot forms in the middle of the working part or on the edge. It is doubly offensive to a car enthusiast when the tread height on the opposite side remains within the normal range.

- Vibration becomes the main destroyer of suspension and transmission. Tire vibrations are transmitted to the ball joints, rods and steering rack. The “grenades” of CV joints and hub bearings wear out faster.

Article on the topic: Replacing the timing belt on a Hyundai Tussan 2.0 with your own hands

During the Soviet era, when balancing machines were considered a curiosity, drivers quite often threw away car tires with the same defect - the tread worn out in one place. This confirms the need for balancing.

Vibration that lasts for years reduces the life of the body and weakens all threaded connections. When, crawling under the car, you find loose bolts and lost nuts, there is reason to think about the technical condition of the wheels. This is why balancing is needed, which saves the components and assemblies of your car from premature wear.

Some drivers of front-wheel drive cars make a half-hearted decision - they balance only the wheels of the front axle. They say that the rear ramps do not affect control and “run” like a trailer. When “bald spots” form on the tread, reaching the metal cord, they blame the tire manufacturers or complain that they bought a fake. These drivers do not take into account an important nuance: imbalance always generates beating and vibration, the consequences of which are described above. The greater the weight difference within one slope, the wider the amplitude of vibration vibrations and the more intense the wear of the chassis.

Saving on balancing is an unaffordable luxury . One peddling tire will quickly wear itself out and cause damage to other parts, forcing you to spend money on repairs more often. By the way, even plastic decorative caps of dubious quality can cause a slight imbalance.

On a balancing machine

This method is familiar and familiar to almost every driver - this equipment is available in almost every tire service center. The main goal is to identify places for attaching special weights that eliminate weight imbalance. To do this, when balancing the wheel, it spins, and after a complete stop, data on the weight of the weight and the location of its attachment is displayed on the monitor. To improve accuracy, they are mounted on the inside and outside of the wheels. Despite its relative simplicity, this type of wheel balancing is highly accurate.

Most often, padded weights are attached to the wheels. But their main drawback is damage to the paintwork of the disc, leading to corrosion. When balancing light alloy wheels, self-adhesive weights are predominantly used. They spoil the aesthetics of the wheel less, but over time they can come off due to a decrease in the holding power of the double-sided tape.

Procedure technology

Equipment

It is important to prepare the wheels for the balancing procedure, namely, thoroughly clean the tread and disk from sand and dirt. If this rule is neglected, the operation may be performed inaccurately and will have to be repeated. If the car has already been balanced, the technician must remove the balancing weights before starting.

It is very important to check the tire pressure: the tires should not be flat. Before balancing the wheels, the center of gravity is determined, which is monitored by balancing machines. Devices can range from ordinary computers to huge systems with laser sensors and measurement mechanisms. Once determined, the machine automatically installs the balancing weight.

To carry out the procedure, a balancing machine is used, which aligns the position of the wheel along the center of the rotation axis during the procedure.

The type of balancing weight depends on the type of discs. Weights with fastening brackets are installed on steel disks, and with landing on the inside - on cast disks. They are mainly made from zinc, lead or steel.

Weight also depends on the level of imbalance. The weight of the balancing weight with bracket fasteners varies from 5 to 100 g. The weight of the weight for alloy wheels is from 5 to 60 g.

The complexity of the procedure also depends on the mass. The larger the weight, the more likely it is that the wheel needs to be checked for its external qualities: tread condition and general geometric qualities such as symmetry.

In the cold season, due to temperature fluctuations, adhesive weights may come off, which cannot happen with padded ones.

There are special types of weights for stamped wheels. They are stuffed between the disk and the tire, installed on the edge of the disk. Padded weights are not suitable for low-fusible discs. For this type, there are Velcro - self-adhesive weighting agents with an adhesive base. They are practically invisible, because they practically do not stand out from the general appearance. However, they are used only on a perfectly flat surface.

The process of balancing car wheels

The procedure for balancing a car starts with removing the discs, regardless of the characteristics of the model. Balancing occurs according to the following method: remove the wheel, balance it, put it back, then move on to the next one. This completes the procedure for all wheels.

The result depends mostly on the artist, and only a small part is due to the equipment. If the device is modern, then the specialist can only monitor the condition of the rubber and the progress of the procedure.

After cleaning the tread from stones and dirt, a plate is selected, depending on the number of holes in the disc. The specialist places the plate on the disk, tightening the nuts well. After that, he goes to the machine to balance the wheel.

Before balancing, remove any dirt or stones from the tire tread.

After identifying the problem area, the process of installing weights begins. Upon completion, the master returns to the equipment and re-checks the geometric condition of the wheel. If the procedure is successful, the wheel is installed in its place and the next one is taken. Otherwise, the procedure is repeated.

Errors during the procedure

It happens that specialists make mistakes by performing the procedure incorrectly. Let's look at the most common mistakes:

- Neglecting the procedure for cleaning the wheel from stones, sand and dirt. In this case, it will not be possible to achieve an imbalance value close to zero.

- Carrying out the procedure on a damaged wheel.

- Installing weights on top of old ones.

- Insufficient tightening of nuts and bolts on the wheel.

Closely monitor the work of specialists. Even the most experienced workers make mistakes. At the end of the procedure, make sure that the balancing was successful.

Safety precautions

The most basic safety rules during surgery include:

- Wheel balancing can only be carried out by a specialist who has reached the age of eighteen, has passed a medical examination and received permission to perform work of this complexity.

- Wheels weighing more than 20 kg are transported on trolleys or other devices.

- Before the procedure, the condition of the wheel is checked.

- The workplace should be clean, not cluttered with parts.

- Work is not carried out by specialists under the influence of alcohol or drugs.

You should trust your car only to qualified technicians.

How often should you perform wheel balancing?

During scheduled maintenance, the presence of an imbalance is checked and corrected. Also, mandatory wheel balancing is performed when replacing tires. But there are a number of factors that require unscheduled completion of this procedure:

- when weights are displaced or lost. This can happen when driving off-road due to rocks and potholes. Self-adhesive weights can be dislodged when washing the car with a dense jet;

- when the wheel geometry changes, for example, when colliding with a curb or driving into a deep hole;

- An overly aggressive driving style causes increased tire wear. Due to its unevenness, the axes shift, which also requires more frequent balancing.

If there are no visible violations in the design, you will have to focus on the behavior of the car on the road - vibrations of the steering wheel, jumping, etc.

How often should balancing be done?

All types of tires need to be corrected for imbalance; this is done not only when installing new tires. It is also ordered as the tires wear out, compensating for the negative impact of the wearing tread.

When to check balance:

- Installation of new tires. The procedure is repeated after a 500-kilometer run on new tires.

- Change tires according to the season.

- When driving all-season models, you need to check it at least once a year.

- After suspension repair. The same applies when restoring a car after an accident.

- Every 5000 kilometers.

All owners of new cars should heed these tips. And if your car is reaching its last years, you should have it balanced every 2-3 thousand kilometers. This way you will prevent serious suspension injuries and possible emergency situations. And don't be afraid to lose money and time. An accident will cost much more, and modern types of balancing reduce the time of this procedure several times.

What is the difference between quality balancing?

Distribution of mass is carried out using weights that cling to the outer and inner (if technologically possible) surface of the rim. To perform quality work, a specialist must:

- correctly determine the position for fastening;

- select a weight of appropriate weight;

- choose the right number of weights.

Balancing must be performed using a minimum number of fasteners. Ideally, he should be alone. But achieving this, especially with significant damage to the rim, is almost impossible. Therefore, when evaluating the work, you need to look at the number of weights used (there should be a minimum number) and location on the rim (preferably closer to the spokes).

There are no strict requirements for how often wheels should be balanced. Manufacturers recommend doing it every 15 thousand km. Fans of high-speed driving, sharp skidding and braking can safely divide this distance in half. All wheels need to be balanced on time so that the car does not cause an accident.

How to do the balancing procedure - step by step instructions

- The technician removes the wheel from the car and sends it to the wash. What is it for? Of course, to eliminate foreign inclusions - stones in the tread, petrified dirt and other factors that affect the basic balance of the disc.

- The washed wheel is placed on the machine, secured to the calibration shaft. An experienced tire fitter knows how to properly place a rim on the machine to find static imbalance without extensive testing. Novice masters begin testing immediately, without relying on their eye.

- The testing process begins with basic measurements. The machine computer calculates the axial and radial runout, and then gives advice on how to correct these defects.

- Correcting the imbalance involves attaching zinc or lead weights to the surface of the disc. Moreover, padded expansion joints are fixed to the discs mechanically, while adhesive expansion joints are simply glued to the rim.

- After attaching each weight, the master starts repeated testing. If its results correspond to the permissible runout, the wheel is returned to its place.

How to determine the quality of balancing? It's easier than you think. Firstly, take a closer look at the beginning of the work - if the master has not washed the tread and disc, then there can be no question of any quality. Secondly, assess the condition of the machine. If you have a modern model with a 3D scanner, you don’t have to worry about quality. But only an experienced and meticulous master can handle a manual machine. Therefore, before manual balancing, check the qualifications of your car mechanic. Thirdly, after completing the work, evaluate the strength of the weights. If they do not move under pressure, the balancing has been done correctly.

How to check wheel balance

It is convenient to check wheel balancing when the season changes. Those who store seasonal tires usually change them themselves, so it will not be difficult for them to check the balancing themselves. It is important that the wheels are clean. For the procedure you will need regular chalk.

- Spin the wheel.

- Wait until the wheel stops completely and scratch with chalk anywhere. For example, in the middle of the tire.

- Repeat the first two points five to ten times.

- Check where the marks are located. If they are close to each other, then balancing is required.

- Otherwise, everything is fine with the wheel and you can save on the procedure.