True lovers of car tuning probably cannot imagine their car without forward flow. However, not everyone knows when and on what machines a direct-flow muffler will serve not only as a decoration, but will also perform certain functions. Agree, a growling, well-worn penny with a huge pipe instead of a muffler looks, at least, stupid. Another thing is the “Japanese”, which has pronounced elements of professional tuning, and leaves behind a noble growl, will always please not only your ears, but also from its appearance, you will enjoy it.

Direct-flow mufflers: types, features, manufacturing methods

Car tuning is a way to personalize a standard iron horse to your own taste.

There are so many options to turn your car into a unique means of transportation!

At the same time, amateurs pay attention not only to the external design, but also to the sound effect.

To increase the sound of the engine roar, sports direct-flow mufflers are used, which create an entire acoustic performance around the car.

The main advantage of such products is that they can be bought at any auto store or made independently.

What is a straight-through muffler

To understand what a direct-flow muffler is, you need to have a good understanding of the exhaust systems of modern cars.

So, any standard muffler is designed to perform a number of tasks:

A conventional muffler has several chambers that are separated by partitions.

These obstacles are needed to ensure that the noise of gases invariably decreases from chamber to chamber.

But a direct-flow muffler does not have such partitions. It serves only one purpose - it removes exhaust from the engine.

Moreover, if there is no resistance in the form of partitions, then the engine power invariably increases.

The main feature of direct flows is that they remove gases accompanied by very low frequencies of noise, which is more like the roar of a motor. As a matter of fact, this is why direct-flow mufflers are installed on cars to create an extraordinary sound while driving.

Design differences

If we talk about the design of direct flows, then in general it is similar to the structure of conventional resonator mufflers.

Of course, there are no partitions or cameras. Basalt wool or a similar sound absorber is usually used between the housing and the perforated pipe.

The sound of the muffler's roar depends on the thickness of the packing and the material used.

The use of basalt wool allows you to increase the level of the muffler roar

In addition, characteristic sounds are produced by the exhaust, which passes through the holes in the pipe.

The number and diameter of holes also affect the intensity of the roar.

Perforated forward flow pipe allows sounds to be amplified

Types of mufflers and their differences

There are 4 types of mufflers based on the method of absorbing acoustic waves:

- reflective;

- restrictive;

- absorption;

- resonator.

By design:

- straight-through;

- reverse flow

The reflective circuit is reverse-flow, the rest are direct-flow.

Reflective

If one muffler is installed in a car, then a reflective version is used. It uses the principle of “breaking” the flow of exhaust gases by creating several partitions, expansion chambers and turns. Exhaust volume is reduced to standard levels. For this reason, the vast majority of factory vehicles are equipped with the reflective type.

most popular for factory vehicle configuration

The disadvantage of this type of muffler is the reduction in engine power due to the resistance of the exhaust system to the flow of exhaust gases.

Resonator

A resonator muffler is installed as the first stage in the exhaust system of powerful engines. It consists of a perforated pipe placed in a housing. The body is divided into two or three sections. The energy of the exhaust gases is weakened due to a stepwise reduction in pressure.

installed as the first stage of exhaust energy suppression

The part reduces the force of sound vibrations and maintains engine power with a free flow of exhaust gases.

Restrictive

In restrictive mufflers, the gas flow passes through a diaphragm or cone narrowing, which leads to a decrease in engine power. The acoustic protection of such devices is low, since the diaphragm does not interfere with the rectilinear movement of the sound wave.

Absorption

The damping function for sound vibrations in the absorption muffler is performed by a finely porous non-flammable material located in the space between the perforated pipe and the housing. The design is similar to the resonator type. This type has little effect on power reduction.

Types of modern direct flows

Today on the Russian car market you can find several types of direct-flow mufflers.

At the same time, the price range for these products varies from the most budget to luxury, so any car owner will be able to afford the purchase of direct flow:

Powerful forward flow is the most purchased model in the budget muffler segment

Remus straight flow, originally from Austria, is popular among Russian car enthusiasts due to the optimal combination of affordable price and good quality

A muffler with two exhaust pipes installed on the car increases the roar of the car and at the same time ensures silence in the cabin.

Purchased and homemade direct flows

A straight-through muffler can be freely purchased on the auto parts market, where it will be very easy to select this element of the exhaust gas removal system for any car. The price of such direct flows varies, and the level of workmanship also differs. In most cases, an inexpensive muffler is made of thin-walled sheet metal, so it can burn out very quickly.

In addition, in such products, quite often the amount of filler is not enough (it may not be there at all), based on this, with such a muffler the car will be

cry a lot.

A high-quality forward flow, made according to all the rules and from good materials, will be very expensive, and not everyone will agree to buy it, especially for an old domestic car.

But there is always the opportunity to make a direct-flow muffler with your own hands. Its design is simple, and the materials for its manufacture do not require such a large amount.

It is possible to make a forward flow with your own hands using two methods - remaking a standard car muffler and creating it from scratch. The first method is ergonomic in that after this you will not need to think about how to secure the product, because all the fasteners will remain. The disadvantage of this method is the fact that the mufflers are made of narrow metal, so it will not be easy to carry out welding work.

As for the second option, having the necessary materials at hand, it is possible to produce a forward flow of any size and with good metal thickness, which ensures a long service life. But to install a gas exhaust system with direct flow on a car, you will need to think about the mounting method.

How to make a direct-flow muffler with your own hands

To save money on purchasing a factory direct flow, you can make a “glushak” yourself.

Moreover, constructively, this procedure is quite simple, but several nuances should be kept in mind: the muffler must be completely sealed and quickly remove the entire volume of exhaust gases from the system.

First way

The simplest direct-flow manufacturing technology is to remake a conventional muffler.

You can use the muffler that is already on your car or buy a new one.

The main thing is that the workpiece is intact and has no soot, deformations or cracks.

Video: making forward flow from a conventional muffler

Preparing tools

In this case you will need:

Preparation of materials

Of course, if you are going to remake an old muffler, then first of all you need to remove it from the car and inspect it.

If the pipes are not damaged, then they can be considered a necessary material for the manufacture of direct flow.

Based on a standard muffler, a direct-flow muffler can be made without cost or time loss

Job

After preparing all the necessary tools and materials, you can start working:

The straight-through muffler is ready for installation. It should be noted that this manufacturing method allows the car owner to minimize expenses, and at the same time, the “glushak” creates a really juicy and loud roar.

The main thing is to drill the maximum number of holes in the pipe

Second way

You can go another way - for example, make a direct flow from improvised elements, without using a conventional muffler.

This is a more complicated method, since you will have to carefully select each element of the new muffler.

However, if it is possible to get all the pipes and sheets of metal at an affordable price, then the method will fully justify itself.

Video: how to make a direct flow from scrap materials

Preparing the tools

Just as in the first case, you will need a grinder and a welding machine.

Necessary materials

Stainless steel sheets with a wall thickness of 1.5–2.0 mm are best suited. You can also use a cheaper analogue - for example, aluminum.

Job

Depending on the availability of materials, you can immediately find or make a pipe with holes.

The length of the pipe should not exceed 130 mm, and the diameter of the holes should not be more than 2.5 mm.

You will need to find a craftsman who will make two 42 mm flanges for attaching the pipe.

After this you need:

After which the direct-flow muffler can be considered ready for use. The method allows you to create a “glushak” of any size, but the manufacturer must be able to work with electrical equipment.

A tube with holes is the main element of the forward flow

Best passive safety

When will forward flow really be noticeable? Only if the motorcyclist does not violate or exceed the speed limit. A “pot-bellied” cruiser with a loud bass exhaust, slowly cruising in a row or approaching an intersection, will be noticeable to everyone. Also when overtaking, it is important not just to suddenly fly past unsuspecting motorists, but to slowly and sedately drive around them, identifying yourself in advance. And when you need to attract attention, it is better to use the horn rather than the gas. This way you will only irritate the people around you, including pedestrians.

But the best passive safety is still increased visual visibility. Bright clothes, a white or acid-colored helmet, reflective elements on equipment, high-beam headlights during the day - this is what works much better than any forward flow.

How to make forward flow quieter

This is one of the many questions that plague owners of cars with direct flow.

It would seem that a straight-through muffler is installed on a car to roar and make powerful and rich sounds.

But the car owner is not always ready to endlessly listen to lectures from neighbors and law enforcement agencies.

After all, excessive noise is prohibited in residential areas, and therefore your gas supply at night may be a reason to call the police.

Table: maximum noise level of direct-flow mufflers

| Types of mufflers | B1, dB | B2, dB | H1, dB | H2, dB |

| Standard | 81,9 | 76,4 | 95,7 | 84,3 |

| Powerful | 81,8 | 78,7 | 108,9 | 90,0 |

| ASSO | 83,4 | 82,6 | 111,0 | 91,8 |

| Remus | 84,0 | 81,3 | 109,8 | 90,8 |

| SVR | 84,0 | 80,3 | 110,2 | 90,6 |

| SVR assembly | 84,4 | 80,8 | 115,9 | 94,0 |

| Supersprint assembled | 82,2 | 82,6 | 115,8 | 92,7 |

| B1 - in the area of the front seats B2 - in the area of the rear seats H1 - in the near field H2 - in the far field * results recalculated on scale A | ||||

To make forward flow quieter, there is a special plug for the exhaust pipe.

It's called a silencer. Using a silencer is very convenient: you just need to insert a plug into the exhaust, and the sound will practically disappear, while the operation of the exhaust system will not be affected at all.

The nozzle fits onto the exhaust pipe and reduces noise levels

You can buy a silencer at a regular car store; the main thing is to choose the right size of the product.

About direct flow or PG

A direct-flow muffler (PG) is an improved alternative to a stock exhaust, which is not capable of ensuring a quick and timely release of gases from the engine system (ICE). The standard exhaust system especially suffers (chokes) after installing a sports camshaft or after boring the cylinder head cylinders (in other words, on a forced engine).

A straight-through muffler is designed to improve the exhaust system

The GHG is designed to modernize the exhaust system, which increases gas emissions. In addition, a correctly installed PG will provide an increase in internal combustion engine power by 10–15 hp. However, you need to be prepared for drastic changes: everything will need to be replaced, from the catalyst to the tip.

Increasing the power of a power unit using a PG, unfortunately, also has a “other side of the coin”, associated primarily with a loud sound attack of about 120 dB. This is the norm for sports cars, but hardly for civilian ones. And this explains the mass of cases of fines issued by law enforcement inspectors to the owners of such cars.

To minimize this modernization flaw, craftsmen use various methods to reduce sound. Installing a flute muffler, oval or round resonator are all types of methods to improve the performance of a forward flow muffler. “Form and content” can make it quiet.

For example, craftsmen say that a square resonator installed in the middle of the path (the path for gases to escape into the aircraft) reduces noise much better than an oval or round one. And in general, it’s better not to use a round one, but to use an oval one as a last resort, since it has a larger volume of cans and, accordingly, a quieter sound.

Oval resonators from Volvo S60R and Saab have proven themselves to be quite good.

Before thoroughly understanding what GHG is, you should remember the functioning of the vehicle exhaust system. Many motorists do not even suspect how many tasks it performs, although it does not seem so at first glance.

The forward flow kit is a ready-made option for tuning

Of course, the main task of the exhaust is to remove gases. But an equally important function is to ensure timely and high-quality ventilation of the internal combustion engine cylinders.

Ventilation of the cylinders is carried out as follows. When the valves of one cylinder of the internal combustion engine are closed, a vacuum is created in the exhaust manifold. It moves through the system at high speed, and, having been reflected from obstacles, returns to the collector. At the moment the gases leave the cylinder, a reduced pressure is created here, which promotes better ventilation and purge.

Among other things, the exhaust system (ES) is designed to combat noise. This is what the muffler is designed for.

Compared to a conventional standard muffler, the PG does not have many separate sections inside. Accordingly, it has a more simplified design. It is this fact that allows craftsmen to make it at home or in the garage.

But is it even worth it for an ordinary motorist to change the standard muffler to a PG one? Certainly not. If he does not prefer active driving, does not intend to use the car for sporting purposes, does not have complexes about a “gray” car that does not stand out from the general traffic flow, then he should not carry out modernization.

On the contrary, if the bassy and thoroughbred roar of the engine resonates in the soul of the car enthusiast, then the installation of direct flow must be carried out. Moreover, this gives many advantages of the following nature:

As for the disadvantages of modernization, these are:

Do not confuse forward flow with a muffler. The fact is that the entire exhaust system is called direct flow, and in most cases only part of it is subject to modernization - the muffler.

Installing an additional resonator

The resonator must dissipate low-frequency sounds. In case of dull noise, this action will once again dampen the sounds, which makes the machine operate quite quietly.

Another resonator is mounted between the base resonator and the muffler. It is installed in the area where the base resonator was located. This new resonator must have sound-absorbing material. It should fill its internal space.

Two resonators

The sound of a running machine can be reduced as much as possible by installing an additional final muffler. This type of noise reduction device is a specific can, which is crossed by a pipe with holes, and the rest of the sound reduction mechanism is saturated with heat-stable soundproof fiber, which is fixed with a fine mesh. This system for reducing the intensity of a sound wave is called an absorber.

The area for mounting another muffler should be the area between the catalyst and the standard muffler. To attach another sound reduction device, cut a piece of pipe of the required size between the base muffler and the catalyst. Fit the muffler to the resonator using strong clamps in combination with asbestos sheets to create gas-tight joint walls. The sealing must be done very carefully - a missed gap will lead to a lot of noise.

As a result of these actions, when sound waves move through the installed muffler, it is absorbed by the porous substance, which will help reduce the noise from the operating machine. A sound wave, reaching a porous substance, provokes vibrations between different fibers and, appearing during this friction, is transformed into thermal energy. Consequently, sound vibrations are converted into heat. A significant advantage of such a noise reduction device is that there is no need to increase the length of the exhaust system.

Exhaust system design

Technology for creating and mounting an additional resonator:

- Creating a body (barrel) from a fragment of a steel pipe. It should have thin walls. You can also use two halves of sheet steel;

- Creating holes in a certain area of the exhaust device pipe behind the base resonator;

- A combination of body halves on a pipe with holes. Then they are scalded;

- Placement of basalt-based mineral wool into the hollow space of a newly created body;

- Welding the ends of the resonator;

- Adaptation of the ignition and fuel delivery system. This must be done due to transformations in the exhaust pipe.

Upon completion of all production operations, the welds must be cleaned, and the part that was made must be painted. It must be chosen very carefully. It must be very resistant to temperature fluctuations.

After installing the additional resonator, the ignition system and fuel supply should be tested. You need to realize that all changes to the exhaust system will affect the engine. It will be very annoying if, by reducing the volume of the running engine, you are forced to increase fuel consumption or reduce the power of the car. When choosing a method by which you will create a silent muffler, take into account the difficulties associated with it. It is especially necessary to know that absolutely all methods of producing a silent exhaust system increase the severity of the mechanism.

Therefore, the car owner must strengthen the brackets and rubber shock absorbers. Always be aware of the changing balance of incoming air and exhaust gases into the engine. When upgrading the exhaust device, do not forget about the need to thoroughly test the engine's capabilities at various speeds. It is also worth carrying out additional adjustments to the fuel supply and air separation devices.

What is required to build an ASG (direct-flow exhaust system): tuning kit

Undoubtedly, installing a PG is a tuning, a modernization. And everything you need to build such a sporty exhaust option is available in stores.

The first is the resonator. Note that the sports PG does not have partitions that prevent the escape of gases. Its entire design is aimed only at ridding the internal combustion engine of excess gases generated during fuel combustion. As a result, power increases due to increased airflow.

Interesting point. On cars equipped with a naturally aspirated internal combustion engine, installing a sports PG allows you to increase power by 10 percent of the standard power, and on turbocharged cars - by 20 percent or even more.

The second necessary element, of course, is a new direct-flow flame arrester. The universal damper is intended as an alternative to the standard catalyst when constructing a direct flow. Such an element must be made of stainless steel (there is an option of aluminized steel). The internal part of such a flame arrester has a universal design, designed to increase the power of the machine’s power unit.

The structure of the muffler in the form of a diagram gives a complete picture of it

Fastening elements and other accessories, which must include various adapters, adapters, flanges, thermal tape for the exhaust manifold, etc., are also part of the system.

And finally, the muffler pipe, made of stainless steel or aluminized. The pipe itself must have an increased diameter (usually in the range of 38–76 mm). The length of the pipe is about 1000 mm, the wall thickness is 1.5 mm.

Types of devices

The standard exhaust system of a modern car includes a resonator (the first one comes from the engine) and the muffler itself.

The resonator cuts off low-frequency vibrations, and the muffler cuts both low-frequency and high-frequency vibrations, which together leads to a good result.

But the above scheme, both jointly and separately, may include the following types of mufflers:

Aluminized steel

Devices made of aluminized steel are characterized not only by a long service life, from 5 to 10 years, but also by a high price.

It will be difficult to choose such a muffler for your car, since only a few companies produce such devices, and making it yourself will be problematic.

Stainless steel

The devices are in the inexpensive segment, but their service life is only from 2 to 5 years. A big plus is that you can match the element to almost any car.

Limiters

They are usually used as an additional device installed in front of the main one.

The operating principle is based on creating low acoustic resistance.

Structurally, this is done like this: in the pipe, a large diameter turns into a small one, then there is a sharp increase in volume according to the principle of a large bottle with a narrow neck. The sound, entering a large space, decreases.

Reflectors

Used as a secondary muffler installed after the main one.

Exhaust gases entering the device encounter a group of acoustic mirrors on their way. Reflecting from them, the gases dissipate their energy one by one, and the output is a weak sound.

Absorbers

Can be used as a main muffler. The principle of operation is based on the absorption of vibrations by a porous material, usually glass wool, the fibers of which are heated by oscillating, thereby converting sound into thermal energy. Structurally close to direct-flow analogues.

They are considered ineffective because they absorb only high-frequency vibrations and transmit low-frequency ones.

Resonator type

As a rule, they are used first in exhaust systems as additional ones.

The principle of noise absorption is based on the presence of chambers of different sizes, through which the sound is effectively muffled.

Everything is arranged like this: a pipe with slots runs through the center of the resonator, which is surrounded by chambers of different volumes. Through the slots, exhaust gases penetrate into the chambers, where their energy is lost.

Do-it-yourself PG from handy materials

If you can’t buy ready-made tuning kits from the store, then that’s okay. You can make a homemade muffler from handy materials. However, it is not recommended to use old, used mufflers for this, since as a result of repeated heating cycles, their metal loses its original properties.

Made of stainless steel

Stainless steel exhaust gas is the most expensive method of exhaust modernization, but also more effective. But if we also take into account the high levels of protection against aggressive environments, then this option can last for many years, and thereby save money.

To make a homemade PG from stainless steel, you need to do the following:

Metal brushes are designed in the direct-flow muffler to reduce noise

Metal mesh is needed to wrap the direct-flow muffler and eliminate noise

Wrapping the muffler with a metal mesh should be done very tightly

Ursa mineral wool gets clogged inside the muffler

Filling the hole with a fireproof mixture is a mandatory step in the operation of making a homemade muffler.

All that remains is to install the fasteners and clamps and install the new system on the car.

From a fire extinguisher

PG can also be made from other materials. For example, from a fire extinguisher (its frame). The method is not bad, although it is budgetary.

It is advisable to choose a powder fire extinguisher.

Here are some other materials you'll need:

Algorithm for performing the operation:

The pipe is welded to the fire extinguisher body

To check the welds, you need to close one of the muffler holes. Pour water into the other. If the seams are not sealed, water will seep through them.

From a thermos

A metal thermos like this can be used as a material for the muffler.

How to make a straight-through muffler quieter

The PG becomes quieter as it is collected. And each craftsman does this differently, using mineral wool, metal shavings, brushes or asbestos. It is also recommended to arrange several compartments inside the homemade muffler, creating additional resonance.

The installation of direct flow in various ways involves the use of mineral wool, shavings and other fillers

A car with an exhaust louder than 96 dB does not pass inspection, does not cross the border, and does not drive around the city. This is the law. Sound today is limited even in motorsport, where it would seem there should be no restrictions or boundaries.

Having decided to suppress the GHG, you need to understand that this should in no way affect the effectiveness of the new system. None of the components of the GHG system should create resistance to exhaust gases.

Flute

The flute or silencer in the PG is a simplified design used by tuners. Its task is to “calm down” the SG, obtaining legitimate dB at the output.

Making a flute is not difficult. It will be enough to use as a muffler a piece of a perforated 20-centimeter tube with a diameter that is slightly larger than the exhaust (by 1/3). A disk or conical washer must be fixed to the pipe to act as a plug. Fastening is carried out using bolts at the air cut. The washer, in fact, creates a structure that resembles a flute.

The flute is used in PG to reduce noise

The cost of ready-made silencers in stores varies from $8 to $150. Chinese models are very cheap, but don’t expect quality from them. Original, good European-made flutes can be purchased for $100–$150.

You can assemble a flute for the PG yourself. Below is a diagram by which you can easily make such a model.

A homemade flute is easy to assemble

A homemade flute is easy to assemble:

It is recommended to fasten it with all 3 bolts, but you can do it with 1. It will be much faster.

Damper

A SG with a damper is a universal opportunity to simultaneously increase the power of an internal combustion engine and ensure quiet forward flow. A design of this type has been known to car enthusiasts for a long time; it is even found as standard on some BMW models.

The operation of the GHG damper is based on the following principle. When the engine operates at low speeds, gases exit through a standard, conventional muffler. At this time, the SG is closed by a damper. But as soon as the internal combustion engine reaches high speeds, the damper in the PG opens, and due to enhanced ventilation, optimal torque is produced.

The damper is controlled automatically, for example, on a BMW. But manual models are also known.

The price of a ready-made system with a damper can be high, especially for cars with automatic transmission. So, the cost of such a system, together with a titanium spider, is approximately 2-3 thousand dollars.

Analogue models, similar in capabilities to the original ones, are more moderately priced. However, a successful upgrade of this option may require the specific knowledge of an experienced minder.

Direct flow with a damper is considered the most effective option for increasing the power of an internal combustion engine

You can make a damper yourself, but it is impossible to predict the result of such an installation. It's better not to take risks.

Whatever option for manufacturing PGs is chosen, ready-made models and kits should not be excluded. In some cases, it will be much easier to buy them than to bother with pipes, a welding machine and fillers.

Source

What is a straight-through muffler

Many people have sometimes noticed how tuned cars roar along the highway. What gives them extra power, a deep roar and instant acceleration? Improved exhaust system, namely the installation of a direct-flow muffler. Do not underestimate the exhaust system, because by changing its configuration, you can “play” with the power of the power unit without spending money on complex and expensive tuning of the gearbox or engine. You can make a direct flow in the garage, having a small set of tools with you; installing it is also not particularly difficult.

What is a direct-flow muffler, how does it differ from a regular one? This is a muffler in which the so-called “labyrinth” system has been removed in one of the resonators, due to which the exhaust gases escape faster than on a standard muffler. Installing direct flow is more than justified if the car has a tuned power unit. A more powerful engine produces more exhaust, so it is very important that the exhaust system does not “suffocate” it.

Does forward flow make it noticeable on the road?

It is impossible to give a definite answer to this question. Several important factors influence whether motorists can hear you:

- Speed. If you’re racing 150 around the city on a sportbike and fly into an intersection, suddenly jumping out from behind the cars, no one will have time to hear you. Such racers often find themselves in the side door of a turning car before the sound reaches the driver and gives him time to react;

- If you are flying with your forward flow, overtaking the flow and playing “checkers”, in the hope that the motorists driving ahead will hear your roar and refuse to change lanes from lane to lane - slow down. Otherwise, you will catch up with the car before the sound of your exhaust reaches the driver, and he may want to maneuver, having no idea that a biker will be nearby at that moment. In most cases, the roar of the engine in the car will only be heard when the pilot of the two-wheeled rocket has already flown far ahead;

- Vehicle type. It’s one thing to drive in an old Zhiguli or even a cheap foreign car, in which you can hear everything that rumbles on the road. And it’s completely different – in a maximally soundproofed premium jeep. In such a machine, your forward flow will go unnoticed;

- Music. If the car's speakers are turned on at full power, the driver won't care about your exhaust.

The difference between a direct-flow muffler and a conventional one

A straight-through muffler is the same muffler, but without baffles to dampen low-frequency noise. It may contain mineral wool padding, which dampens high-frequency noise but allows low-frequency noise to pass through.

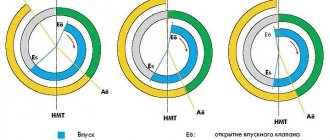

The diagram shows that the direct-flow muffler does not have transverse partitions. The standard muffler consists of a rather complex system of pipes and grilles in which noise is dampened. Parts of the exhaust system on a modern car also include a lambda probe, a catalytic converter, and an exhaust gas temperature sensor. Thus, a standard muffler compared to a forward flow muffler is a slightly more complex system. The standard muffler consists of a complex system of pipes and grilles

Direct-flow muffler device

For proper tuning of the exhaust system, it is advisable to install a different, improved exhaust manifold in combination with forward flow, remove the catalyst and install a receiving pipe of increased diameter. After all, in a tuned exhaust system, all obstacles that stand in the way of exhaust gases have been removed.

A straight-through muffler is made so that its throughput is higher than that of a standard muffler, and it more freely removes exhaust gases from the engine. As a result of such tuning, cylinder purging improves, less carbon deposits on the pistons and valves, which, in turn, increases the life of the power unit. Its power increases by about 15%.

A related factor is a slight deterioration in noise performance compared to the standard muffler. The straight-through muffler has a harsh roar that can attract the attention of the traffic police, cause a fine, or provoke the anger of neighbors when a tuned car revs under their windows early in the morning.

When installing an improved exhaust system, these factors should also be taken into account, otherwise tuning may cause pointless costs in the future. The absence of internal partitions and noise-absorbing padding makes direct flow relatively simple to manufacture.

Standard and direct-flow mufflers with remote “labyrinth” and noise absorbers

What does direct flow give?

A significant improvement in the power performance of a car with the installation of a direct-flow muffler occurs when the power unit is fully operational, maintains normal compression, is little worn, and even better - if any of its components have been modified. Thus, forward flow will increase power if the cylinder head, the intake system have been tuned, or the cylinder block itself has been bored to a larger volume. If the car owner has not yet taken on serious modifications to the engine, but wants to spend money on exhaust tuning, then by doing so he will still increase the power of the power unit, receiving in addition a bass rumble, making the car a little more dynamic.

What forward power should you expect?

If you are concerned about this question, it is difficult to answer right away. The useful power of the motor will depend on many parameters. Planning to install a direct-flow muffler without improving the exhaust system is an absolutely fool's errand. You don't have to wait for a noticeable effect. The only thing is that you can get at best two percent, and that’s not a fact.

If you want to achieve results, do everything comprehensively. This included replacing the catalyst with a more efficient one, installing a new resonator, and modernizing the fuel system. From this you can get twenty percent, or even more. The main thing is to approach tuning correctly. Also, take your time; in this case, high-quality adjustment of all components together is important.

When planning to install a direct-flow muffler on your car, take into account the car model and engine type. The specificity of such installation is important. Especially, is it possible to make changes or modify the rear bumper?

Source

Design and principle of operation

There are 4 ways to suppress powerful sound impulses implemented on various vehicles:

Article on the topic: Decoding the VIN code of a car

A limiting device is the simplest version of a muffler, used on some tractor models. The element is a tapering pipe placed inside a metal tank. The disadvantages of the product are obvious - noise is partially suppressed, and engine power is noticeably reduced.

Mirror elements are installed on motorcycles and scooters. The principle of operation of the muffler is as follows: gases from the exhaust elbow enter the reflective can, change the direction of movement and are thrown out. Due to reflection, sound vibrations are dampened and the noise level is reduced. The part works successfully with two-stroke engines, but its efficiency is not enough for a car.

The third method is implemented in automobile resonators. Inside the steel tank there are several partitions, and between them there are resonance chambers connected by steel tubes. Smoothing of noise pulses is achieved due to two factors:

It must be understood that the resonator design is not universal for all machines. Cars are equipped with engines of different power, producing noise of different amplitudes and frequencies. The sound absorber is developed separately for each make and model of car.

A cross-section of a car muffler operating on the principle of noise absorption is shown in the diagram.

As in the resonator, partitions and jumpers in the form of tubes are installed here. Only in the latter are many holes of different diameters (perforation) made, and non-flammable absorbing material is laid on the sides. As a rule, basalt or kaolin wool is used for these purposes, which can easily withstand gas temperatures of 600–700 °C.

Sound waves, passing through adjacent pipes with holes, are partially scattered and damped by overlapping each other. The second part of the vibrations is absorbed by the filler, and the third is smoothed out due to partitions and a change in the direction of flow.

How to make a direct-flow muffler with your own hands

Direct-flow mufflers are produced and sold freely, in different configurations, for many brands and models of cars. Different price categories and the price-quality ratio are of concern to everyone who decides to change the exhaust in their car.

Budget versions of direct flow systems may not only fail to improve power characteristics, but may also cause harm. Most often, they are made of thin metal, which, due to the external environment, humidity and aggressive combustion products contained in the exhaust gases, will fail faster than a standard muffler. A high-quality forward flow from a well-known tuning studio or simply made from durable materials will be very expensive.

The average car owner should think about creating a direct flow with his own hands, especially considering that it does not require too much material and time expenditure. All you need is materials, tools and patience with perseverance.

There are several ways to create a forward flow:

However, you will have to think through many points - from the length and diameter of the pipes to the methods of mounting the muffler and vibration damping methods. Let's consider a method for producing a direct-flow muffler from an old, standard muffler.

A drawing of a direct-flow muffler, suitable for domestic cars, can serve as the basis for making your own direct-flow muffler

What tools will you need?

To make a direct flow, you will need tools, access to electricity, and personal protective equipment. When working with a welding machine and metalworking tools, you should protect your eyesight and limbs.

Materials for making direct flow

Having collected the necessary tools, you need to purchase materials. The main ones will be:

Having made sure that all materials and tools are ready, we can begin production of a direct-flow muffler:

The standard muffler must be free of holes and burns. The seams must be thoroughly welded. The muffler has cut out intake and outlet pipes. The pipe must be perforated with a drill or grinder. Mineral wool is used to stuff the muffler

The muffler is ready. You can install it on your car, enjoy the bassy sporty sound and improved power characteristics.

Video: how to make a direct-flow muffler with your own hands - detailed instructions

Pros and cons of installing direct flow on a car

Installing a direct-flow system has both pros and cons.

Each motorist decides for himself how appropriate it is to modify the car muffler in favor of direct flow. Pros of direct flow:

- If a pipe with a slightly larger diameter than originally installed is welded on, it is possible to increase the exhaust gas throughput. An increase in airflow leads to an increase in engine power, up to 15%;

- Increasing the service life of the muffler. Most often, the muffler “from the factory” is not made from the best materials, but with such a modification, the motorist can use good pipes, even titanium options. If you want to increase the “lifetime of the pipes,” then after welding the resonator, you need to remove the end of the muffler with a grinder and solder a new pipe in its place, having thoroughly cleaned and primed it in advance.

Disadvantages of forward flow:

- Increased noise. Many car enthusiasts consider this parameter a plus and install the direct flow with their own hands solely for the purpose of increasing the “rumble” of the car when driving;

- Reducing the vehicle's ground clearance if pipes of larger diameter are welded onto the muffler;

- Problems during maintenance. Increased noise and the absence of a catalyst will lead to problems during maintenance;

The method of installing a direct flow with your own hands, described in this article, can be called “collective farm”. In professional racing cars, the direct-flow system is much more complex and is designed primarily to improve engine performance. At the same time, such a forward flow is unlikely to bring much benefit, only changing the sound of the car, which, in most cases, is the goal of independent tuning.

Materials and tools for manufacturing: – pipe, diameter is selected depending on the brand of car (VAZ usually has a diameter of 52 cm); – welding; – grinder and discs for cutting metal; – iron sponges for washing dishes (50-100 pcs.).

About the direct-flow system

Any car muffler reduces engine power by creating significant resistance to the flow of flue gases. This is the price you have to pay for comfort and an almost silent exhaust. But for motorists who are tuning their “iron horses”, there is an alternative option - a direct-flow type sound absorber.

The task of this element is to reduce power losses while continuing to absorb sound vibrations from engine operation. Forward flow is a compromise solution because, for the sake of power, it dampens noise not as effectively as standard car elements. What does this muffler consist of:

Article on the topic: How to dry clean a car interior with your own hands?

Sounds traveling through a straight pipe with holes are partially absorbed by the fiber, but the other part passes out unhindered, because there are no partitions or resonance chambers. Therefore, cars equipped with forward flow make a rumbling sound, especially when you press the accelerator pedal.

The highest level of tuning is a combined exhaust system with a damper controlled from inside the car. With its help, the gas flow can be switched between two branches: the first has a conventional effective muffler, and the second has a forward flow. This allows you to use the power of the engine only when necessary, and under normal conditions, drive around the city without unnecessary “roar” from the exhaust pipe.

Forward flow - myths and reality

Regarding the benefits of direct flow, two questions open up a heated fiery debate:

- Does forward flow increase engine power?

- Does forward flow make a motorcyclist more visible?

Increasing horsepower is what many motorcycle owners strive for. Of course, for some, just a pleasant sound is enough, but they don’t care at all about fillies, but oh, these endless conversations: I’ll install a forward flow, let everyone see and I’ll fly like a Boeing. with the same whistle.