In the description of premium car models of the latest generations, the concept of adaptive suspension is often encountered. Depending on the modification, this system can adjust the stiffness of the shock absorbers (a sports car has a hard look, while an SUV has a softer look) or ground clearance. Another name for such a system is air suspension.

The presence of this modification is noticed by those who drive on roads of varying quality: from smooth highways to off-road trips. Fans of car tuning specially install pneumatic elements that allow the car to even bounce. This direction in auto tuning is called lowride. a separate review about it .

Basically, the pneumatic type of suspension is installed on cargo vehicles, but business or premium class passenger vehicles often also receive a similar system. Let's look at the design of this type of car suspension, how it will work, how the pneumatic system is controlled, and what its advantages and disadvantages are.

What is air suspension

Air suspension is a system in which pneumatic elements are installed instead of standard shock absorbers. Any 18-wheeler truck or modern bus is equipped with similar mechanisms. As for modifications of standard cars, the classic spring-type suspension is usually modernized. The factory strut (MacPherson strut at the front, and a spring or spring at the rear) is replaced with air springs, which are installed in the same way as the factory design, but special fasteners are used for this.

You can purchase a similar part in large stores specializing in car tuning. For spring or torsion bar suspension modifications, there are also separate mounting kits.

If we talk about a car suspension, it is designed to absorb shocks and impacts coming from the wheels to the supporting body or frame of the car. Such a trolley not only provides maximum comfort while driving a car on uneven roads. First of all, this system is designed to ensure that the machine does not fall apart after a couple of years of operation.

In standard suspensions, vehicle clearance (a description of this term is here ) remains unchanged. If the vehicle is used in a variety of conditions, it would be practical to have a suspension that can change the ride height depending on the road condition.

For example, when driving at high speed on a motorway, it is important that the car is as close to the asphalt as possible so that the aerodynamics work in favor of the car's downforce. This increases the car's stability when cornering. Car aerodynamics is discussed in detail here . On the other hand, to overcome off-road conditions, it is important that the position of the body relative to the ground is as high as possible, so that the bottom of the car is not damaged when moving.

The first automobile suspension, the operation of which has a pneumatic principle, used on production models, was developed by Citroen (model DC19 of 1955). General Motors is another manufacturer that has tried to introduce pneumatics into the automotive industry.

The production car of this brand, which was equipped with a working air suspension, was the Cadillac Eldorado Brougham (released in 1957). Due to the high cost of the mechanism itself and the difficulty of repair, this development was frozen indefinitely. Thanks to modern technologies, this system was finalized and introduced into the automotive industry.

Pros and cons of modern air suspensions

Since air suspensions are installed on a limited number of foreign car models, many car owners would be interested to know what advantages cars equipped with these systems have. And there are quite a lot of them:

- changeable settings, that is, the ability to adjust the clearance value in a certain range. By changing the height of the car above the road, we simultaneously adjust the stiffness of the suspension. For machines equipped with conventional spring elements, a similar operation is possible, but only by replacing the springs themselves. Agree, this can hardly be called a solution. Note that the use of stiff, shortened springs really gives excellent results on a flat, compacted road, significantly improving handling. But at the same time, comfort fades into the background - if you find yourself on an area with an uneven surface, you will turn the trip into torture. Installing soft and elongated springs will make off-road driving comfortable, but on the highway the car will behave unpredictably. By using air suspension, all of the above problems can be avoided. The driver has the ability to lightly press the corresponding button to switch from hard to soft suspension. In other words, the required compromise is achieved depending on the specific road situation;

- excellent handling is one of the main advantages of air suspension. This is especially evident when cornering at high speed, when even with a small turning radius, a noticeable roll of the car is felt. The air suspension is able to compensate for the difference in the position of the wheels above the road surface. For a spring suspension, one can only dream of such a mode. True, it should be noted that the absence of roll does not mean the absence of centrifugal force during cornering;

- customization options. Since no two people are alike, each driver has his own driving style and his own preferences regarding the handling of the car. And if we take into account that in most cases, in addition to the driver, there are also passengers in the car, then changing the load will help improve the car’s handling;

- a means of achieving exclusivity. For most car owners, the bravado of being able to change the ground clearance is unacceptable, but there is a category of drivers for whom this is a vital necessity. They will spare no expense to transform their four-wheeled friend;

- Air suspension has been used on trucks for a long time and very successfully. The capabilities provided by such a system in terms of carrying capacity cannot be overestimated. Typically, changes in the degree of load on the wheels have virtually no effect on the driving characteristics of commercial vehicles. Recently, both minivans and pickups have been equipped with air suspension. For these vehicles, congestion levels can indeed vary greatly even within a single trip;

- Finally, one cannot fail to note the excellent performance characteristics of the air suspension, demonstrated at subzero temperatures. This is achieved through the use of rubber elements in the production of air cushions, which have good elasticity regardless of weather conditions. Thus, it is possible to increase the service life of the air suspension.

Considering such an extensive list of advantages, it seems strange that air suspensions have not yet become widespread. This unfortunate fact becomes clear if you know the main disadvantages of pneumatic damping systems:

- Almost zero maintainability. Regardless of what exactly has become unusable, this unit will not be restored. And the cost of air suspension is an order of magnitude higher than that of other types of systems. So the improved comfort achieved at such a high price is unacceptable for most car owners;

- negative temperatures are another scourge of such systems, although the air spring itself hardly suffers from severe frosts. But other components can easily fail;

- road reagents used to combat icy conditions can just as easily lead to the inoperability of the air suspension, which reacts very sensitively to such chemically active substances.

Having carried out a comparative analysis of both lists, we can come to the conclusion that air suspension is the prerogative of only a small number of cars, whose owners are willing to sacrifice significant sums in order to achieve maximum comfort. In Russian off-road conditions, this would be useful for many drivers, but high cost and harsh winters are an obvious limiting factor on the path to mass distribution of pneumatic suspension.

Operating principle of air suspension

The work of air suspension comes down to achieving two goals:

- In a given mode, the car must maintain the position of the body relative to the road surface. If the sport setting is selected, the ground clearance will be minimal, and for off-road performance, on the contrary, it will be the largest.

- In addition to its position relative to the road, the pneumatic suspension must be able to absorb all unevenness in the road surface. If the driver selects the sport driving mode, then each shock absorber will be as hard as possible (it is important that the road is as smooth as possible), and when setting the off-road mode, it will be as soft as possible. However, the pneuma itself does not change the stiffness of the shock absorbers. For this purpose, there are special models of damping elements (details about the types of shock absorbers are described here ). The pneumatic system only allows you to raise the car body to the maximum permissible height or lower it as much as possible.

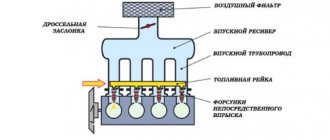

Each manufacturer is trying to outdo the competition by creating improved systems. They may call their developments differently, but the concept of the devices remains similar. Regardless of the modification of the actuators, each system will consist of the following elements:

- Electronic circuit. Electronics better provide fine-tuning of the operation of actuators. Some cars receive an adaptive type of system. This modification installs many different sensors that record the operating mode of the engine, wheel rotation, the condition of the road surface (a night vision system or a front camera can be used for this) and other vehicle systems.

- Actuators. Their dimensions, design and principle of operation are different, but they always provide a mechanical drive, due to which the car is raised or lowered. Pneumatics can have an air or hydraulic drive. In the air modification, a compressor is installed (or a hydraulic compressor in a system filled with working fluid), a receiver (compressed air accumulates in it), a dryer (removes moisture from the air so that the inside of the mechanisms does not rust) and an air cylinder for each wheel. The hydraulic suspension has a similar design, except that stiffness and ground clearance are controlled not by air, but by working fluid, which is pumped into a closed circuit, such as in the brake system.

- Control system. In each car with a similar suspension, a special regulator is installed on the control panel, which activates the corresponding electronics algorithm.

In addition to factory systems, there are simpler modifications for amateur tuning. This type is controlled using a remote control that is installed inside the car. Using the regulator, the driver changes the ground clearance of the vehicle. When the device is activated, the compressor pumps air into the pneumatic accumulator, creating the required pressure.

This modification provides only manual clearance adjustment mode. The driver can only activate a specific electric valve (or group of valves). In this case, the air strut rises or falls to the desired height.

The factory version of air suspension may have an automatic operating principle. Such systems must have an electronic control unit. The automation operates using signals received from sensors of the wheels, engine, body position and other systems, and automatically adjusts the height of the car.

What cars have air suspension installed on them?

Today, the list of cars on which air suspension is mounted is huge.

The list includes cars and trucks from the following giants of the automotive industry - Lexus, Grand Cherokee, Mercedes-Benz and Rolls Royce.

Other manufacturers worth mentioning are Land Rover, Audi, Subaru and Citroen.

Compared to previous versions, modern air suspensions have become smarter. They now have a sports mode that allows for changes in the mode and ground clearance.

On trucks, automation adjusts the height and rigidity taking into account the weight of the cargo in the cabin.

Lowriders deserve special attention - cars that are popular in the world among car enthusiasts and are distinguished by their low seating position.

Such cars have a memorable appearance, which is often achieved by deteriorating technical characteristics.

What stands out here are the “bombs” - cars dating back to the 30s-50s, which have a number of features - additional lighting, roof visors, an original body shape and a pneumatic system instead of hydraulics.

Thanks to the unique suspension, additional comfort is guaranteed and the rarity of the car is preserved.

Why install air suspension

Typically, a simple air spring is installed on the rear suspension assembly of a car. This modification can be found on many crossovers and SUVs . The dependent type of suspension has little effect from such a modernization, since even with high ground clearance on uneven surfaces, the transverse beam will still cling to uneven surfaces or obstacles.

For this reason, rear air springs are used in conjunction with an independent multi-link design, such as the new Land Rover Defender. A test drive of the second generation of this full-fledged SUV is here .

These are the reasons why some motorists upgrade the shock-absorbing part of the car's chassis.

Adjustability

When the car is loaded (all the seats in the cabin are occupied or the body is full), in a classic car the springs are compressed under the weight of the additional cargo. If the vehicle moves on uneven terrain, its bottom may catch on protruding obstacles. This could be a stone, a hummock, the edge of a hole or a rut (for example, on an unclean road in winter).

Adjustable ground clearance will allow the driver to overcome obstacles on the road as if he were not loaded. Adjusting the height of the car no longer takes several weeks of reworking the chassis, but in a couple of minutes.

Automatic air suspension allows you to more accurately adjust the position of the car depending on the preferences of the car owner. There is no need to make complex adjustments to the vehicle design.

Controllability

In addition to adjusting the ground clearance to the selected mode, the system maximally compensates for even a small angle of inclination of the car at speed (in expensive models). To ensure that all wheels on turns have maximum grip on the road surface, based on signals from body position sensors, the control unit can give a command to the electric valves of each wheel.

When entering a turn in one circuit, the pressure increases, due to which the car rises slightly on the axis of the inner radius of the turn. This makes it easier for the driver to control the vehicle, which improves traffic safety. When the maneuver is completed, air is released from the loaded circuit, and the automation stabilizes the position of the car body.

In conventional cars, this function is performed by the transverse stabilizer. In budget models, this part is installed on the drive axle, but in the more expensive segment, two transverse stabilizers and even a longitudinal stabilizer are used.

The pneumatic cylinder has one useful property. Its recoil rigidity directly depends on the compression ratio. In expensive systems, it is possible to use air springs, which prevent the vehicle from swaying while driving over uneven surfaces. In this case, the mechanical element is controlled both in compression and tension.

Since the adaptive suspension is not capable of working independently, it has its own electronic control unit. Remaking your own car in this case is associated with large material costs.

Plus, not every mechanic can understand the operation of the system, because in addition to mechanical elements, it contains a large number of electronic devices. They must be correctly connected to the control unit so that the device correctly captures signals from all sensors.

Getting Optimal Performance

When choosing a new car, every motorist evaluates the handling and ground clearance of the intended purchase. The presence of air suspension allows the owner of such a vehicle to change these parameters depending on operating conditions without additional intervention in the car’s design.

When adjusting the chassis, the driver can focus on handling or make the car as comfortable as possible. It is also possible to achieve a golden mean between these parameters.

If the car is equipped with a powerful power unit, but its full potential cannot be used on public roads, you can adjust the suspension so that in normal mode the car is as soft and comfortable as possible. But as soon as the driver gets to the racetrack, the sport mode can be activated, also changing the suspension settings.

Car appearance

Although manufacturers offer new car models with already low ground clearance, such vehicles are ineffective in many regions. For this reason, very low models occupy only a small niche in the global car market. As for tuning, in the direction of stens cars, the height of the car is of great importance.

Most often, independently lowered cars are obtained as a result of modifications to the chassis, which is why the vehicle loses its practicality. There are few people today who are willing to invest heavily in a single car that will only be used to put on a show at a car show and spend the rest of the time just gathering dust in the garage.

Air suspension allows you to lower the vehicle as much as possible, but, if necessary, raise it. Usually, at the entrances to a gas station or overpass, low cars suffer from the fact that they are not able to overcome the slight slope of the roadway. The adjustable design allows the driver to personalize the car without sacrificing practicality.

Loading the vehicle

Another useful feature of air suspension is that this system makes loading/unloading the machine easier. Some owners of SUVs with variable ride height appreciated this option.

To overcome off-road conditions, most large vehicles have large wheels, which makes it much more difficult for a short driver to put cargo in the trunk. In this case, the car can be lowered slightly. In a similar way, you can use this system on a tow truck. During loading, the height of the body can be minimal, and during transportation, the tow truck owner raises the vehicle to a comfortable driving height.

Flaws

The system is excellent in terms of comfort, but it has disadvantages. Structurally, this is a fairly reliable design, but in real life the air suspension faces problems.

Mostly the air cylinders and compressor break down, but these breakdowns are interconnected. Typically, dust, sand and dirt get on the cylinders, and when the height changes, the sand gradually scratches the rubber of the cylinder. Over time, a slight breakdown and air leaks appear and the compressor constantly works, maintaining pressure and, of course, burns out.

Rarely do cylinders burst and even less often do body position sensors fail. Since the compressor and air struts are the most expensive elements of the system, we will pay attention to their preservation.

Everything is quite simple, in order for the cylinders to last a long time, you need to periodically wash them to remove sand and dirt. To do this, at the car wash, raise the car to the highest possible position and wash the entire system. Some even treat rubber with special means. In this case, the racks can easily run for 100 thousand kilometers or even more.

Pneumatic cylinder design

The North American company Firestone produces high-quality air cylinders. Its products are often used by truck manufacturers. If we roughly classify these products, then there are three varieties:

- Double. This modification is adapted for poor road surfaces. Outwardly, it looks like a cheeseburger. This pillow has a short working stroke. It can be used on the front of the suspension. In this part, the shock absorber is located close to the point of maximum load.

- Conical. Such modifications are not installed as a front shock absorber, despite the fact that they have a larger stroke. Their work has a linear principle, and they can withstand less loads than the previous ones.

- Roller. These air springs are also smaller in size than double air bags (they have a thin, tall bulb). Their operation is almost identical to the previous modification, so similar pneumatic shock absorbers are also installed on the rear of the vehicle’s bogie.

Here is a drawing of the most common air suspension connection diagram:

A) compressor; B) pressure gauge; C) desiccant; D) receiver; E) air spring; F) inlet valve; G) exhaust valve; H) spare valve.

Let's look at how a pneumatic cylinder is designed.

Compressors

In order for an air shock absorber to change its height, it must be connected to an external air source. It is impossible to create one pressure in the system once, and the machine will be adapted to different operating conditions (number of passengers, cargo weight, road surface condition, etc.).

For this reason, air compressors must be installed on the vehicle itself. This allows you to change the characteristics of the car right on the road, and in some models even while driving.

The pneumatic system will consist of at least one compressor, a receiver (a container in which air is accumulated) and a control system (we will consider their modifications a little later). The economically justified and simplest modification is to connect one compressor and a 7.5-liter receiver. However, such an installation will lift the car for a couple of minutes.

If there is a need for the suspension to lift the car in just a couple of seconds, then a minimum of two compressors with a capacity of 330 kg/square inch and a minimum of two receivers with a volume of 19 liters will be required. You will also need to install industrial pneumatic valves and pneumatic lines at 31-44 inches.

The advantage of such a system is that the car rises immediately after pressing the button. However, there is also a significant drawback. This design does not allow for fine adjustments - the car rises either too high or not enough.

Pneumatic lines

An integral part of all air suspensions is a plastic air line designed for trucks. This is a high-pressure line that makes it possible to connect all components of the system. These modifications are able to withstand pressures of 75-150 psi (pounds per square inch).

If a more efficient pneumatic system is installed, for greater confidence, instead of a plastic line, you can use a metal analogue (it is used in brake systems). Standard flare nuts and adapters can be used to connect all components. The system components themselves are connected to the main line using flexible high-pressure hoses.

Front suspension

The first developments of pneumatic systems received mechanisms with which it was possible to slightly move the front shock absorber. The reason is that the air spring does not have an area for installing a shock absorber, as in a MacPherson strut (it is located inside the spring).

The front suspension air spring kit includes special brackets that allow the shock absorber to be installed offset without compromising its performance. However, if a small car has non-standard large rims (such tuning is popular nowadays) with low-profile tires, the use of air suspension in some cases will be impossible. Details on how to choose low-profile tires are described separately .

Among the latest developments, there are complex pneumatic shock absorbers that are installed instead of a classic strut. This modification is much more expensive, but such mechanisms are much easier to install.

Before choosing this modification, it is worth considering that on some chassis it is less effective compared to systems in which the air spring and shock absorber are separate. Sometimes, with reduced ground clearance due to the design of the chassis, the wheel clings to the fender liner while driving. In this case, a stiffer shock absorber is required.

For this reason, for those who are primarily interested in maximum comfort, and not just a visual change in their transport, it is better to opt for a separate system.

Rear suspension

On the rear of the trolley, the installation of a pneumatic system depends on the type of vehicle suspension. If there are MacPherson struts there, and the design is multi-link, then installing the cylinders on the stock support will not be difficult. The most important thing is to choose the appropriate modification. But when using a combined modification (the shock absorber and cylinder are combined into one module), you may need to slightly alter the design of the car’s suspension.

If the car has a spring suspension on the rear axle, then the installation of pneumatics can be done in two ways. Before changing the suspension, you need to take into account that all spring leaves cannot be dismantled. The reason is that these elements, in addition to the spring effect, stabilize the rear axle. If you completely remove all the springs, you will need to install a linkage system, and this is a serious intervention in the design of the car, which requires considerable engineering experience.

So, the first method of installing air springs on a spring suspension. We leave a few sheets on each side so that they continue to perform the function of stabilizing the axis. Instead of the removed sheets (between the body and the springs), an air spring is installed.

The second method is more expensive. It is usually used by those car owners who want to “pump up” the car’s suspension as much as possible. All springs are removed, and instead a 4-point design with an air spring is installed on each side. For such modernization, many manufacturers have already created special sets of fasteners that allow you to install pneumatics with minimal welding work.

There are two types of levers available for the 4-point upgrade:

- Triangular. These parts are used on passenger cars for everyday use.

- Parallel. Such elements are used in trucks. If a passenger car is used for drag racing (the features of these competitions are described here ) or other types of auto competitions, then the same type of levers is used.

Compressors

It is quite obvious that the air shock absorber can be lifted by an external air source, such as a pneumatic compressor. However, such a solution immediately cuts off one of the main positive qualities of the air suspension: the ability to adjust it depending on the conditions of the road surface, vehicle loading, etc.

In this case, you would have to connect the compressor every time you loaded the vehicle with additional weight - passengers, gasoline, cargo.

Since the benefits of adjustable suspension are obvious, the best solution is to use an air source directly on the vehicle. Air shock absorbers have a small volume, making it nearly impossible to accurately adjust them with an external air source to best suit current conditions.

The built-in pneumatic system consists of at least one compressor, a storage tank (receiver) and some kind of control system. The most cost-effective and at the same time simple solution that allows you to achieve decent parameters is to use one compressor with a 2-gallon storage tank.

On the other hand, if you want the car to rise or fall in just a couple of seconds, you need to install a pair of 150 psi (pounds per square inch) compressors and 2 or more 5-gallon tanks, huge industrial air valves and 31/44-in. pneumatic lines.

However, such a performance setup can make fine-tuning the suspension much more difficult, similar to the case with an external compressor: with a fast-acting system, each button press results in a sudden 20 psi change in pressure.

Varieties by number of circuits

In addition to the design features and power of the actuators, of all types of air suspensions, there are dual-circuit and four-circuit options. The first modification was used on hot rods in the second half of the 1990s.

1) Single-circuit; 2) Double-circuit; 3) Four-circuit

Let's look at some of the features of these systems.

Dual-circuit

In this case, two air cylinders installed on the same axis are connected to each other. As for installation, such a system is easier to install. It is enough to install one valve per axle.

At the same time, such a modification has a significant drawback. When the car turns at speed, air moves from the loaded cylinder into the cavity of the less loaded one, which is why, instead of stabilizing the car, the body roll becomes even greater. In passenger vehicles, this problem is solved by installing a transverse stabilizer of greater rigidity.

Four-circuit

Due to significant shortcomings of the previous pneumatic system, a four-circuit version is installed on modern cars. The connection formula has independent control of each air spring. To do this, each pillow relies on an individual valve.

This modification is reminiscent of a roll compensation system for cars adapted for track racing. It provides more precise adjustment of ground clearance depending on the position of the car body relative to the road surface.

Why air suspension?

Stunts like this can only be done with air suspension.

To understand the advantages of this device, first of all, you need to understand the design and understand the differences between air suspension and conventional one. In a classic suspension, the main element that absorbs all the unevenness of the road surface and transfers the load to the car body is metal elastic elements. These include springs, leaf springs and torsion bars. In contrast to the standard suspension, the car's air suspension device is distinguished by the presence of pneumatic elastic elements that are able to maintain ground clearance regardless of changes in the weight of the car, making, if necessary, a “rigid” air suspension. This function is achieved by adjusting the volume and air pressure in the elastic elements.

Article on the topic: Nuances when choosing car covers

Control systems

In most cases, a four-circuit system will be powered electronically. Only this control option allows you to change the state of the suspension within a small range. True, this system is much more difficult to install (you need to correctly connect all the installed sensors with the control unit), and costs much more.

As a budget option, the car owner can install a manually controlled system. This option can be used on both a two-circuit and a four-circuit system. In this case, to control the pressure in the line, a pressure gauge and a control button are installed on the center console.

An expensive but more effective option is to install an electronic regulator. For such a system, solenoid valves are used, which are controlled electronically. Such a modification will consist of a control unit, a set of sensors necessary to determine the position of the car and the degree of inflation of the cylinders.

The latest developments can be equipped with several control systems. Let's look at how each of them works.

Pressure sensing control system

In theory, this system determines the position of the air cylinder (the electronics are adjusted to this parameter to determine the amount of ground clearance). Pressure sensors in the system transmit signals to the control unit, allowing the electronics to determine the ground clearance. But such a control system has a significant drawback.

If the car is well loaded (there are a maximum number of passengers in the cabin, and there is a heavy load in the trunk), then the pressure in the line will certainly jump. Based on pressure sensors, the on-board computer will determine that the machine is raised to its maximum height, but in fact it may be too low.

Such a control system is suitable for passenger vehicles, which rarely carry heavy loads. Even filling fuel to the full capacity of the gas tank changes the vehicle's ground clearance control. For this reason, the automation will incorrectly set the ground clearance.

Also, the large error of this type of active control system depends on the maneuvers that the vehicle performs. For example, when a car goes through a long corner, one side of the suspension is loaded more heavily. The electronics detect this change as one side of the car rising. Naturally, the body stabilization algorithm is triggered.

In this case, the loaded part of the line begins to descend, and more air is pumped into the unloaded part. Because of this, the roll of the car increases, and it will sway when cornering. The dual-circuit system has a similar drawback.

Control system that controls ground clearance

More effective in dealing with the large number of variables in the load on individual cylinders is one that records the actual distance from the underbody to the road surface. It eliminates all the errors characteristic of the previous version. Thanks to the presence of sensors that determine the suspension's response to an increase in pressure in specific circuits, the electronics more accurately sets the ground clearance depending on the situation on the road.

Despite this advantage, such a control system also has a drawback. For adequate vehicle handling, it is important that the suspension stiffness is approximately the same. The difference in pressure between different air cylinders should not exceed 20 percent.

But when the electronics tries to level the car as much as possible, in some situations this difference exceeds this parameter. As a result, one part of the suspension is as stiff as possible, and the other is very soft. This negatively affects the handling of the car.

Combined systems

To eliminate the errors and shortcomings of both control systems, combined control systems were created. They combine the advantages of both the one that controls the pressure in the circuits and the one that determines the amount of clearance. Thanks to this combination, in addition to monitoring the position of the vehicle itself, these systems also neutralize each other’s work.

A similar control system was developed by Air Ride Tec. The modification is called Level Pro. In this case, the electronic control unit is programmed for three modes. Maximum, average and lowest landing of the car. Each of these modes allows you to use the car in different operating conditions, from track races to off-road.

The set of pneumatic cylinders and solenoid valves operates both automatically and manually. When a car approaches a speed bump, it will not rise on its own to overcome this obstacle. To do this, the electronics must have a larger number of sensors that scan the road surface in advance. Such systems are very expensive.

Modified systems

The systems listed above are adapted for conventional road passenger cars. For trucks and professional sports cars, there are modified control systems that provide fast and accurate automatic tuning of the vehicle.

From a practical point of view, it is better to install a specially designed ready-made kit on an SUV, pickup truck or powerful hot rod than to try to create an adaptive suspension yourself. In addition to the fact that such development will take a lot of time, there is a high probability that the mechanic may perform the calculations incorrectly, and the suspension will not cope with the loads.

When choosing a ready-made kit, the car owner just needs to look at the list provided by the manufacturer: whether these products are suitable for this car model or not. It takes into account the distance between the wheels and fender liners, the dimensions of the ball joints, the size of the variable axle and other parameters, on the basis of which the automation determines how large a volume of air needs to be pumped into the cylinders.

Pneumatic lines

Most kits use commercial, certified plastic air lines designed for large truck applications. These air lines make it easy to connect compressors to air shock absorbers. The pressure range in the system is usually from 75 to 150 psi - these values are normal for the effective operation of these air lines.

MacPherson strut? No problem. Air Ride Technologies produces the AirStruts system for most of today's popular vehicles, which completely replaces the factory struts. These kits have slotted mounting holes and eccentrics, which eliminate the need to install special plates required to adjust the wheel position at low ground clearance.

For a custom solution, you can install a steel rigid line, like a brake or fuel system, using standard flare nuts and adapters. To connect pneumatic elements, it is necessary to use flexible hoses - the design of the pneumatic lines in this case is essentially similar to the design of the hydraulic line of the brake system.

In addition, similar to the brake system, it is preferable to use stainless steel hoses instead of rubber tubes.