Every car owner is familiar with such a device as a tachometer. Every car has it, but not all drivers know what this device is and what it is needed for. Moreover, few people know how to correctly use the values provided to them. Let's understand the principle of operation and the main functions of the device.

The purpose and design of a car tachometer.

Tachometer - what kind of device is it?

To learn how to use the device, you need to clearly understand what a tachometer is in a car. A tachometer is a device for reading and displaying information about the frequency of rotation of the crankshaft in the engine. If you are not good at mechanics, this definition will not clarify the situation. In simple terms, a tachometer is needed to monitor the rotation of the engine and not exceed its permissible speed. The main task of the device is to facilitate the selection of the required gear and allow the correct distribution of engine resources. The closer the needle is to the red zone, the higher the gear should be. You can adjust the speed both while driving and at idle.

What is a tachometer sensor

A tachometer sensor is any device designed to record important signals necessary for the operation of the measuring instrument. Among such sensors are the idle speed sensor and the crankshaft sensor.

The crankshaft sensor records the angular position of the crankshaft at certain points in time. The sensor can be installed at the rear or front of the engine, most often near the flywheel. Such a device allows you to accurately measure the speed and transmit the corresponding signal to the car’s dashboard.

The idle speed sensor is installed in the vehicle's intake system. He also takes part in determining the crankshaft speed based on the amount of fuel supplied. The idle speed sensor is installed on the engine carburetor and, through wires, sends the impulse necessary for the tachometer to operate.

Another option for connecting the device involves connecting it to an electronic engine control unit. Finding it is not difficult, since not a single wire will stick out of it. Thus, the sensor works in close cooperation with the ECU and transmits the corresponding readings to the measuring instruments.

That's probably all you need to know about a car's tachometer. As you can see, with due attention this is a fairly simple and important device that should not be neglected at all.

How the device works and what it measures

The tachometer is a very important component of the car. It helps to use engine resources to the fullest without consequences. Each engine has its own technical characteristics, which indicate the highest torque and maximum power depending on the speed. It is these parameters that the tachometer measures, giving the driver the opportunity to maintain speed within acceptable limits and change gears in a timely manner. So, for example, you can achieve the best acceleration, traction gain and even fuel economy.

Note: a constant decrease in speed significantly increases fuel consumption and reduces the life of the internal combustion engine.

The principle of operation of the tachometer is simple: the device captures and records the number of impulses from the sensors and displays the received data in the form of certain values (hours, minutes, seconds, meters). The accuracy of the device is approximately 500 rpm and varies depending on the type of device. Tachometers are divided according to the principle of data display and installation method. According to the second criterion, they are standard and remote. Remote tachometers are used primarily in motorsports for thorough speed correction. The device also signals the achievement of certain indicators. Let's take a closer look at the varieties of tachometers we are used to.

Basic faults

If the tachometer is faulty, the driver will have to determine by ear to what speed the engine has spun the flywheel and, depending on this, begin to change gear or press harder on the gas pedal. The first signs that the tachometer is faulty and gives distorted readings are incorrect needle behavior: hanging or jamming in one place, sudden movement along the scale during uniform movement.

If the device fails, you must first check the circuits of the device:

- The supply wire is checked; for digital and analog devices, the supply wire is insulated with gray plastic. The wire starts from the stator or motor, then power goes to the ignition switch and to the frequency meter.

- Check the supply voltage – 12 V.

- Correct connection of the ground wire.

- Functionality of the fuse.

If no fault is found in the supply circuit, the tachometer components are checked.

Types of tachometers

All tachometers can be divided into three categories: analog (with a needle and dial), digital (with a display) and mechanical, which are found in older car models.

Mechanical

These devices were installed back in the twentieth century. They communicated directly with the engine crankshaft. The principle of their operation was as follows: the gear on the crankshaft and the drive cable transmitting torque to the coil were engaged with each other. A coil is an electromagnet of a device, due to which magnetic induction occurs, affecting the position of the device’s needle. The mechanism is simple, but the error was about 500 rpm.

Analog

Developing technologies have led to the creation of analog tachometers. The principle of their operation is similar, but there is a significant difference: the device reads revolutions using the frequency of energy supply to the ignition coil. The coil converts low voltage to high voltage, and when a short pulse of low voltage is applied, a spark appears at the spark plug. The same pulse simultaneously hits the electromagnet winding and the electrical circuit of the tachometer. The strength of induction and the deflection of the needle directly depends on the number of pulses supplied to the winding. The device error varies, but can also reach high values.

Digital

Digital models are gradually replacing previous versions of the device. Their work is based on measuring and counting the number of pulses on the primary winding of the ignition coil. Alternatively, a time interval that corresponds to the pulse intervals is measured. All information received is translated into numbers and displayed on the board. As practice shows, analog versions of the device are most easily perceived by drivers, since the turns of the arrow are already familiar to the eye. Complex digital values are not always clear, and not everyone can interpret them correctly. Next, we will clarify how to do this correctly.

Design and principle of operation

The main element of the device is the crankshaft position sensor, which reads its rotation frequency. Data transmission occurs through a cable in the mechanical structures of the tachometer or through pulse counting for analog and digital instruments.

According to the type of data transmission, tachometers are divided into groups. The most common of them are digital, analog or electromechanical and mechanical.

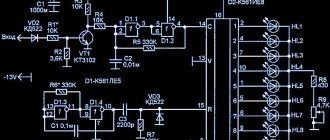

The design of an analog device uses a magnetic coil, a microcircuit, a data transmission drive or cable, and a dial scale. For digital instruments, other elements are used in the design: processor, ADC (converter), optocoupler, etc. Digital tachometers often use a liquid crystal display instead of a graduated scale with an arrow. As a rule, it is more convenient for drivers to use a standard dial gauge, which displays the speed scale while the car is moving.

How to use tachometer information

The most important question is how to use the tachometer and the information obtained with it. There are some useful points to be aware of. The device suggests the optimal time to start moving. This is especially useful in winter, as the device determines whether the engine is ready to start. Many modern cars cannot tolerate a sharp start when the engine is still cold and produce too many revolutions. Typically, drivers in such situations wait until the coolant temperature approaches the optimal temperature. But with a tachometer everything is much simpler: you can start moving at the moment when the instrument needle is close to the values at idle (standard - 750 rpm - 800 rpm), and the number of revolutions is 1000. Then you can safely hit the road - engine will warm up quickly and with minimal fuel costs. To accelerate, motorists adhere to the following plan:

- First gear is engaged (up to 3800 rpm), then second gear.

- The number of revolutions drops to 2300.

- The second one is turned on again to reach 3600 rpm, after that the third one is turned on.

- The rpm drops to 2400.

- Acceleration in third to 3500, transition to fourth.

- Resetting the value to 2500.

- Turning on the fourth and so on.

For maximum acceleration, the highest possible speed is required (up to 5500 per minute). This will allow you to accelerate the car very quickly, but with high resource and fuel costs. Acceleration at idle has the same effect. Another important function of the device is routine maintenance. Any repair specialist will confirm that high-quality diagnostic work is impossible without a tachometer.

Which tachometer is better to buy

Today you can purchase the device at almost any automotive supply store. You can also order from a trusted online store. Such devices can cost from 400 to 6,000 rubles. The cost depends on the manufacturer and type of tachometer.

Motorists are not advised to purchase Chinese products , as they often have a strong error. Among domestic companies, the following stand out:

- "Amphiton";

- "Orion".

The products of these manufacturers are considered to be of very high quality and reliable . In addition, it is characterized by an affordable price. As for foreign manufacturers, you should pay attention to the following companies:

- Bosh;

- Helios.

If you want your car tachometer to last as long as possible, you will have to spend quite a lot of time. You need to choose a device as carefully and responsibly as possible. Branded equipment is quite expensive , but low-quality devices will produce errors.

A tachometer for automobile transport is an indispensable device. With its help, drivers find out the speed of revolutions. This information allows you to identify the malfunction in a timely manner.

Is it possible to determine the speed of movement using the device?

As already mentioned, tachometer values can be displayed in different quantities:

- In time (hours, minutes, seconds);

- In distance (kilometers, meters, centimeters, etc.);

- In units;

- In speed (m/s, km/h).

To determine the speed using the tachometer, you just need to change the way the information is displayed on the display. Note that this is only possible in those models that display different quantities. You can also find out the speed on earlier models by examining the existing device and comparing the units of measurement.

Is it necessary to purchase a tachometer and how to choose the right device

This is not to say that a tachometer is a mandatory element in a car. But one cannot deny its importance and usefulness. The measuring device helps:

- Increase and optimize engine power;

- Get the required effort in traction;

- Save fuel resources;

- Extend and even increase engine life.

When choosing a device, you need to consider many factors. For example, electronic models are developed for engines with different numbers of cylinders (information can be found in the technical specifications). By installing the device in a car with the wrong number of cylinders, you can get unreliable information. Before purchasing the device you must:

- Study its technical characteristics;

- Check with specialists whether a specific model is suitable for the car brand;

- Take into account the engine (petrol and diesel devices read information differently).

The tachometer is installed according to the size and design. Installation is possible using brackets, instead of any other equipment on the panel, and even using double-sided tape. It's still worth buying a tachometer. It will help in solving many questions regarding cars, especially for beginners. Ask any questions you have in the comments, and we will be happy to help you!