Car maintenance is a set of preventive measures prescribed by the car manufacturer. The task of maintenance is to prevent failures and malfunctions, the probability of which in a certain period is quite high. Simply put: it is better to warn in advance than to have long and expensive repairs later.

Maintenance (TO) usually includes mandatory operations (for example, changing the engine oil after a run of 15 thousand kilometers) and operations identified during diagnostic operations (both with and without the use of special equipment - based on the results of visual inspection),

In the technical literature, mandatory maintenance operations are determined by the name of the essence of the work performed:

- Regulating;

- Gas stations;

- Lubricants;

- Fastening;

- Electrical;

- Control and diagnostic.

Based on the results of control and diagnostic operations, a decision is made to perform additional work (adding fluids, replacing worn-out elements, etc.).

Types of car maintenance

The volume and content of operations included in car maintenance are determined by the make and model of the car, as well as factors such as current mileage, seasonality and reaching a certain shelf life if the car has not been used during this period.

Particular importance was attached to compliance with maintenance regulations in Soviet times, when, on the one hand, cars were not as sophisticated and reliable as they are now, and on the other hand, discipline in the operation of vehicles was maintained (especially in organizations).

The rule of inspecting a vehicle before leaving for a trip and eliminating any identified deficiencies is mandatory for every driver and vehicle. And such a requirement, especially for trucks and buses, is completely justified: transportation of people and large cargo requires increased safety measures.

The classification of types of maintenance in Russia has been preserved since Soviet times in the “Planned and preventive system of vehicle maintenance” and includes the following main positions:

- daily vehicle maintenance;

- first vehicle maintenance – TO-1;

- second vehicle maintenance – TO-2;

- seasonal vehicle maintenance.

Manufacturers of modern passenger cars have somewhat modified the numbering and frequency of maintenance:

- The numbering according to the classification of TO-2, carried out, as a rule, at equal intervals of time, has become continuous: from TO-1 to TO-10 or even TO-12.

- For a number of passenger car manufacturers, the need to carry out maintenance according to the TO-1 classification has disappeared, and for some, this operation remains with the code name TO-0.

That is, for passenger cars, the types and numbering of maintenance may look like this:

- daily maintenance;

- zero maintenance – TO-0;

- periodic maintenance (numbered) – TO-1…TO-10 (TO-12);

- seasonal maintenance.

The maintenance schedule, service intervals and content of operations for each type of maintenance are determined by the vehicle manufacturer and are indicated in the service book.

For TO-0 (TO-1 according to the generally accepted classification), the upper mileage limit is, as a rule, 2-2.5 thousand km. Service intervals between subsequent maintenance usually range from 10 to 20 thousand km.

Daily vehicle maintenance

Daily maintenance - ETO (for passenger cars, rather, an inspection before a trip) involves control and inspection operations of the main components and assemblies of the car, primarily those that affect safety on the road. In this case they check:

- inspection - presence of leaks in the brake system, power steering, engine (coolant, engine oil), transmission;

- inspection - fluid levels in tanks and crankcases of main components and assemblies. If necessary, top up;

- inspection and testing - operation of electrical equipment, gauges and dashboard indicators;

- inspection - the condition of the tires. If necessary, inflate (see tire pressure tables);

- testing - starting the engine, testing when starting the brakes, steering, clutch, gearbox.

First maintenance

The first maintenance of TO-1 includes operations included in daily maintenance, as well as additionally the following work:

- body wash, interior cleaning;

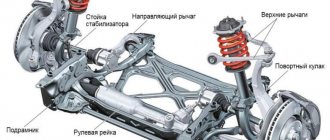

- control, diagnostic and inspection work (in addition to ETO inspection): checking the effectiveness of braking, parking brake, brake drive, free play of the steering wheel, clearances of the steering mechanism, protective covers of chassis parts, checking the condition of springs, levers, rods and suspension struts, free movement of clutch and brake pedals, tension of drive belts of engine attachments;

- adjustment work: free play of pedals, tension of drive belts, parking brake, free play of steering wheel, clearance of steering drive connections, carburetor (for carburetor engines);

- fastening (check and tighten if necessary): mounting the engine, gearbox, steering mechanism, steering rods, swing arms, wheel rims, exhaust system parts, brake mountings;

- refueling stations: changing the engine oil (with replacing the oil filter);

- electrical: checking and, if necessary, cleaning the battery and electrical equipment from dust and dirt, checking the condition of insulation, replacing, if necessary, burnt-out lamps or fuses.

Second maintenance

The second technical maintenance - TO-2 includes operations included in TO-1, as well as additional work on in-depth diagnostics of the main systems, components and assemblies of the vehicle.

In addition to a larger volume of control and diagnostic work during TO-2, more refueling operations occur. In addition to changing the engine oil, depending on the mileage or storage period, the following changes:

- Coolant,

- Brake fluid,

- Gearbox oil

- Oil in the hydraulic system,

- Axle oil (for trucks and passenger all-wheel drive vehicles).

For a given mileage, TO-2 regulates the mandatory replacement of certain elements. For passenger cars this is:

- Fuel filters,

- Air filters,

- Cabin filters,

- Transmission filter (if it is automatic),

- Spark plug,

- Timing belt and rollers (if timing belt drive) and additional equipment.

Fastening work during TO-2 is also carried out to a greater extent than during TO-1. These include checking fastening tightness:

- Cylinder heads,

- radiator,

- Timing covers,

- Engine sump,

- Intake and exhaust manifolds,

- fuel tank,

- Rear axle gear covers,

- Door locks and hinges.

Among the regulatory works, it is necessary to note the regulation:

- Engine valves,

- Timing drive force tension,

- The gap between the brake pads and discs,

- Front wheel hub bearing clearance.

Specific TO-2 operations depend on the make, model and service interval recommended by a particular automaker.

Seasonal Maintenance

Seasonal maintenance (SM) is carried out to prepare the vehicle for use in the upcoming winter or summer season.

The fact is that a sharp change in ambient temperature affects the performance of parts, components and assemblies of the car: in the cold season, for example, lubricants with lower viscosity are required, the starting ability of the battery is reduced, it is necessary to ensure trouble-free operation of the heating system, and wheel traction deteriorates with road surface.

Why all types of car maintenance need to be done on time

Physical laws apply the same to all objects. Therefore, the parts of each car are subject to wear and tear during operation. The consequence of this wear and tear is the need for regular car maintenance.

What environmental factors primarily affect a car? These are sunlight, water and dust. Moreover, when driving you cannot avoid overloads and vibrations. Even if driving is on good roads and the car owner uses them carefully. Cars of such owners are only less likely to undergo technical inspection. But in general, car care is performed to the same extent as most car owners.

And some car parts lose their properties even when the car is not in use. This does not apply to all components, but such as rubber seals, oil seals and tires. Working fluids also age. This primarily concerns motor oil. Regardless of whether the car is running or not, fluids absorb moisture and lose their properties. Therefore, it is necessary to maintain the car even if it is not in the garage.

Vehicle operating conditions directly affect the preventive maintenance interval. For example, frequent driving on dusty, unpaved roads or aggressive driving will bring you closer to the next service. If the driver drives the car carefully, mostly on good city and dirt roads, the car may need to be serviced less frequently. The types of work performed as part of various preventive measures will be discussed in the next chapter.

Is it possible to save money on car maintenance?

Maintenance (except ETO) is a paid procedure and many car enthusiasts ask the question: “Is it possible to skip it altogether, thus saving money?” In addition, manufacturers of modern cars claim that their quality and reliability are increasing, while service intervals are also increasing.

This question has two sides: formal and factual.

- Formally, if we are talking about a new car, the absence of a maintenance mark completely deprives the owner of the right to warranty service.

- In fact, service intervals have remained virtually unchanged over the past 15-20 years, and even world-famous automakers have not yet created a completely maintenance-free car.

This means that periodic maintenance is necessary not only for new cars, but also, even to a greater extent, for used cars.

It is not only possible, but also necessary to save on undergoing specific maintenance. At the same time, it is important what period of operation the car is in: warranty (manufacturer’s warranty) or post-warranty.

If the machine is under warranty, then you need to read the corresponding paragraph of the service book about the manufacturer’s warranty obligations. The vast majority of automakers indicate that one of the conditions for maintaining a warranty is undergoing maintenance at authorized dealerships (known for high prices for their services). And although this issue is more than controversial, the bulk of motorists obey this requirement.

Savings when undergoing maintenance during the warranty period are possible by choosing a dealership that offers cheaper services and by purchasing materials for maintenance from a third-party store (sometimes this is half the price than from the dealer, but the provision of your own materials must be agreed upon in advance ).

In addition, you should pay attention to the list of maintenance operations in the preliminary calculation. Sometimes the dealer includes work there that is not provided for by the manufacturer (this is easy to check - using the same service book).

If the car is out of warranty, the opportunities to save on maintenance become wider. The fact is that a number of maintenance operations can be performed independently (no special qualifications are required here): changing the oil and oil filter, air and fuel filters, spark plugs, brake pads, and wheel assemblies.

More complex operations (for example, replacing a timing belt) can be performed at independent auto repair shops with a good reputation. As a rule, the services of such services are significantly cheaper than those from official dealers.

Types of maintenance

Maintenance is divided according to the complexity of the work, regularity and time of implementation. Main types of maintenance:

- Daily inspection (EO),

- Zero maintenance (TO-0),

- First maintenance (TO-1),

- Second technical maintenance (TO-2),

- Seasonal maintenance.

Daily Maintenance

This is a set of measures to control the main components and assemblies by the car owner himself before starting to operate the car. This type of service is able to highlight minor problems that require an emergency solution in order to avoid further more serious damage, which they can result in.

Also, a set of measures included in daily maintenance is aimed at ensuring the safety of the driver and other road users.

Daily inspection includes:

- Inspection of the general condition of the vehicle,

- Inspection of the condition of the body and paintwork,

- Availability and condition of state license plates,

- Checking the vehicle's electrical and electronic equipment,

- Checking the serviceability of sensors,

- Checking the serviceability of the steering system,

- Checking the engine oil level in the engine,

- Checking the level of coolant and brake fluids, the presence of fluid in the washer reservoir,

- Checking the position of the mirrors,

- Checking the functionality of the optics.

These actions will ensure comfortable driving and safety for all road users. It is necessary to carry out these actions on a mandatory basis, because if an accident suddenly occurs and the examination shows that the driver drove a car with a malfunction or did not check the car before leaving, then the blame for the incident will rest entirely on his shoulders.

You should also remember to check the fuel level in the tank before leaving and regularly wash the car and clean the interior.

The last requirement is not even related to ensuring a beautiful appearance of the car, but is made in order to remove excess dirt, which can damage the paintwork and negatively affect other parts of the vehicle.

Zero maintenance (MOT 0)

It is carried out for a new car during the so-called “break-in”. It is carried out after 1,500 km and includes a superficial inspection of the vehicle’s components and assemblies and replacement of the engine oil and oil filter.

Maintenance 1 (MOT 1)

Maintenance 1 is carried out after every 15,000 km or year of operation of the car, regardless of whether the car was driven during this period or not. It is preferable to carry out this type of service at an official service center, because the work that is carried out often requires sophisticated equipment for diagnosing and repairing a car.

The actions that are performed during daily maintenance are supplemented by a set of measures that includes the adjustment of components and assemblies, their diagnostics, and, if necessary, cleaning and lubrication of parts.

During maintenance 1, and depending on the conditions in which the vehicle is operated, filters (fuel, air, oil) and gaskets are changed.

The main purpose of maintenance is 1 - prevention of possible malfunctions that can lead to serious damage to the vehicle, measures to eliminate factors that can increase the level of fuel and lubricant consumption, as well as reduce wear on the working parts of the vehicle.

Maintenance 2 (MOT 2)

This type of maintenance is carried out as the vehicle passes every 60,000 km. Includes all measures included in EO and TO 1, but some parts and components are additionally removed and diagnosed, and the gearbox oil and antifreeze are also replaced.

Maintenance of this kind should also be done at a reliable car service center with experienced specialists.

Seasonal service

This type of maintenance is a set of measures to prepare the car for operation at a certain time of the year. Considering the domestic climate, this type of maintenance is mandatory and requires it to be carried out twice a year.

Includes:

- Change tires to ones appropriate for the upcoming season. It is important to change from summer to winter tires on the eve of the first frost, because driving on ice requires more grip, which summer tires do not provide. With the retreat of frost and the onset of the warm season, winter tires should be changed to ensure a longer service life.

- Replacing engine oil with the appropriate one for the season (summer/winter), since operating the engine in extreme temperatures requires special properties of lubricants.

- Checking your vehicle's heating or air conditioning system

Video: Maintenance expert advice

During the operation of a vehicle, as a result of exposure to a number of factors (exposure to loads, vibrations, moisture, air flows, abrasive particles, when dust and dirt enter the vehicle, temperature effects, etc.), an irreversible deterioration of its technical condition occurs, associated with wear and damage of its parts, as well as changes in a number of their properties (elasticity, plasticity, etc.).

Changes in the technical condition of a car are caused by the operation of its components and mechanisms, the influence of external conditions and storage of the car, as well as random factors. Random factors include hidden defects in vehicle parts, structural overloads, etc.

To prevent and eliminate possible problems, perform daily vehicle maintenance.

Daily maintenance (DM) is carried out daily before leaving the line and after the vehicle returns from the line between shifts and includes: control and inspection work on mechanisms and systems that ensure traffic safety, as well as the body, cab, lighting devices; cleaning and washing and drying and wiping operations, refueling the car with fuel, oil, compressed air and coolant. Car washing is carried out as needed, depending on weather, climatic conditions and sanitary requirements, as well as on the requirements for the appearance of the car.

Control work carried out at the EO. First you need to inspect the car (trailer, semi-trailer), identify external damage and check its completeness, check the condition of the doors, cab, platform, glass, rear-view mirrors, sun visors, tail, license plates, door mechanisms, locking mechanism of the tilting cab, constipations platform sides, hood, trunk lid, tailgate of a dump truck, springs, wheels, tires, fifth wheel (towing) devices, road wheels (semi-trailer), make sure the trailer coupling is reliable, etc.

The performing part of the maintenance operations is carried out as needed, based on the results of performing their control part. These lists are general; are specified for specific car models and their modifications in the second part of the Regulations. Based on the lists of basic operations, measures are developed for the organization and technology of monitoring (diagnosis) of the technical condition of rolling stock, and performing other maintenance work. Maintenance of special vehicle equipment (pumps, refrigeration units, etc.) is carried out in accordance with the manufacturer’s instructions.

During the SW process, the following activities must be performed:

– check the correctness and integrity of the sealing of the speedometer and taximeter, the operation of lighting and light signaling devices, the sound signal, windshield wipers, windshield and headlight washers, the heating system and glass defrost (in the cold season), the ventilation system;

– check by external inspection the condition of the power steering, check the play of the steering wheel, the condition of the limiters of the maximum angles of rotation of the steering wheels;

– inspect the tightness of the power steering, brake drive and clutch release mechanism, power supply, lubrication and cooling systems, hydraulic system of the dump truck platform lifting mechanism, check the condition and tension of the drive belts;

– check the operation of units, components, systems, speedometer, taximeter and other instrumentation of the vehicle while driving. Stop the engine and listen by ear to check the operation of the centrifugal oil filter.

Cleaning and washing work carried out at the EO. Cleaning work is usually performed at the beginning or end of the shift.

When cleaning, debris, dust, and dirt are removed manually or mechanically. To organize the mechanized method, electric vacuum cleaners and dust extraction units are used.

Cleaning and washing work is carried out before each maintenance and repair. After cleaning, the machine is washed to remove various contaminants from its surface. The difficulty of removing contaminants depends on their composition.

During cleaning and washing work, the following measures must be taken:

Car Maintenance Technology

Laboratory work No. 1

Car Maintenance Technology

General provisions

Maintenance (MA) is a planned preventative system carried out to prevent failure and occurrence of

car malfunctions.

High-quality maintenance in compliance with established deadlines and in the required volume ensures high technical readiness of rolling stock, increases its service life, reduces the need for repairs and, consequently, the cost of its maintenance.

Maintenance is intended to maintain rolling stock in technically sound condition, reduce the wear rate of parts, as well as to identify failures and malfunctions in order to eliminate them in a timely manner.

Maintenance or repair operations are carried out with or without preliminary control. The main method of control is technical diagnostics, which allows one to determine the technical condition of the vehicle, its components and mechanisms without disassembling it and which refers to one of the technological elements of maintenance and repair.

Compliance with the established maintenance deadlines and its high-quality implementation in the required volume ensures high technical readiness of the rolling stock, increases its service life, reduces the need for repairs and the costs of its maintenance.

Maintenance of rolling stock according to frequency, as well as labor intensity, is divided into the following types: daily maintenance (DM); first maintenance (TO-1); second TO (TO-2); seasonal maintenance (SO); for KamAZ vehicles, in addition to EO, the following types of service are provided: service A; service B; service 1; service 2; service S.

EO includes control and inspection work aimed at ensuring traffic safety, as well as work to maintain proper appearance; refueling with fuel, oil and coolant, and for some types of specialized rolling stock - sanitary treatment of the body. EO is performed at the ATP after the rolling stock is running on the line. Monitoring the technical condition of cars before leaving the line, as well as when changing drivers on the line, is carried out by them at the expense of preparatory and final time.

TO-1, TO-2 and A, B, 1, 2 - service - includes control and diagnostic, fastening, adjustment, lubrication and other work aimed at preventing and identifying malfunctions, reducing the wear rate of parts and preventing deterioration of technical condition parameters rolling stock, saving fuel and other operating materials, reducing the negative impact of vehicles on the environment.

The frequency of maintenance is established for category I vehicle operation in temperate climates. They, as well as other standards, should be adjusted depending on the specific operating conditions of cars in a given area, taking into account the nature of the road surface and the mileage of cars to KP, as well as depending on the availability of cars in the ATP and the number of technologically combined groups of rolling stock. Maintenance (MOT) is a preventive measure carried out as planned after a certain mileage or operating life of the rolling stock.

To promptly take into account changes in the design of rolling stock and operating conditions, the Regulations provide two parts. The first part of the Regulations sets out the basics of maintenance and repair of rolling stock, defines the system and principles of maintenance of rolling stock. It establishes systems and types of adjustment of standards, principles of organizing maintenance and repair of rolling stock and other fundamental points.

The second part, in relation to specific models of various families of cars, establishes the types of maintenance and repair, lists of operations performed and their labor intensity; overhaul intervals; contains a chemmotological map and other materials necessary for planning and organizing maintenance and repairs. It is developed in the form of separate annexes to the first part and approved by the Ministry of Road Transport of the RSFSR as the design of vehicles, their operating conditions and other factors requiring adjustment of the initial settings of the first part of the Regulations change.

When planning maintenance, the following recommendations must be taken into account::

1. The frequency of maintenance of KamAZ, MAZ, GAZ trucks and LAZ buses is established by the second part of the Regulations for a specific family of rolling stock.

2. The permissible deviation from the maintenance frequency standards is ± 10%.

3. The frequency of changing oils and lubricants is specified depending on the types (models) and design features of units and mechanisms, as well as the brand of oil or lubricant used.

4. The frequency of maintenance of trailers and semi-trailers is equal to the frequency of maintenance posts of their tractors.

5. CO is carried out 2 times a year and includes preparation work

rolling stock for operation in summer and winter.

6. As a separately planned type of maintenance, maintenance of rolling stock is recommended to be carried out in areas of very cold, hot dry and very hot dry climates. For most conditions, CO is combined primarily with TO-2 with a corresponding increase in labor intensity.

7. All types of rolling stock maintenance are carried out in accordance with the list of main operations given in the appendix. 5 and the chemotological map of the Regulations. In relation to specific models of rolling stock, maintenance operations are specified in the second part of the Regulations.

8. Maintenance must ensure trouble-free operation of the rolling stock within the established frequencies when performing the required maintenance operations.

9.The labor intensity standards TO-I and TO-2 do not include the labor intensity of EO.

10. CO standards in relation to the labor intensity of TO-2 are 50% for areas of very cold and very hot dry climates, 30% for areas of cold and hot dry climates and 20% for others

climatic regions.

11. Labor intensity standards do not take into account labor costs for

performing work not exceeding 30% of the total labor intensity of maintenance and repair work for ATP.

The auxiliary work includes : maintenance and repair of equipment and tools; transport and loading and unloading operations related to maintenance and repair of rolling stock; moving cars inside the ATP; storage, acceptance and issuance of material assets; cleaning of industrial premises related to maintenance and repair of rolling stock.

Daily maintenance of rolling stock consists of cleaning and washing, control and inspection, lubrication and refueling

work performed by a special team.

Cleaning and washing work includes cleaning the body (cabin) and platform, washing and drying the car (semi-trailer), sanitary treatment of special rolling stock, cleaning and wiping the rear view mirrors of headlights, sidelights, turn indicators, rear lights and brake lights, front and cab side windows and license plates.

Control and inspection work includes an external inspection of the vehicle (trailer, semi-trailer) in order to identify external damage, as well as checking the functionality of the most important units, mechanisms and systems. An external inspection checks the condition of the cab doors, platform, glass, rear-view mirrors, sun visors, tail surfaces, license plates, door mechanisms of the locking mechanism of the tilting cab, platform side locks, hood, trunk lid, tailgate of the dump truck and its locking mechanism, frame , springs, wheels, fifth wheel (towing) device, semi-trailer road wheels, reliability of the trailer coupling, correctness and integrity of the speedometer and taximeter sealing, operation of lighting and light signaling devices, sound signal, windshield wipers, windshield and headlight washers, heating systems and glass heating (at low temperatures), ventilation systems.

You should also check the condition and tightness of the power steering, the play of the steering wheel, the condition of the limiters of the maximum angles of rotation of the steered wheels, the brake drive and clutch release mechanism, the power supply, lubrication and cooling systems of the engine, the hydraulic system of the dump truck platform lifting mechanism, and the tension of the drive belts. The operation of the speedometer, taximeter and other instrumentation, engine, clutch, steering, brakes must be checked while the car is running. When stopping the engine, check the operation of the centrifugal oil filter by listening to the characteristic hum.

Specific control and inspection work on buses consists of inspecting the condition of the floor, steps, handrails, seats, glass windows and doors of the bus interior, checking the serviceability of the mechanism for opening the ceiling ventilation hatch covers, the tightness of the air suspension, checking the operation of the door opening mechanisms for buses with a hydromechanical gearbox gears - the speed of rotation of the engine crankshaft at idle speed (if necessary, you need to adjust it so that the unbraked bus remains motionless on level ground with the gear engaged and the accelerator pedal released).

You should also check the operation of the alarm system from the cabin to the driver, the serviceability of the lighting devices in the cabin and running boards, side lights, the presence of route signs, the serviceability of the ventilation system, interior heating (at low temperatures), loudspeaker device, the condition of the body base, pneumatic cylinders, suspension, storage cash registers and composters. It is necessary to clean the interior, clean the upholstery of the cushions and seat backs, and empty the bins for used tickets.

For a vehicle with an engine running on liquefied or compressed gas, before leaving for the line, it is necessary to check the condition and fastening of the gas cylinders, reducer, valves, mixer (carburetor-mixer), solenoid valve and other equipment, the tightness of the gas system connections by ear with open consumables and main valves, ease of starting and engine operation at idle and at various crankshaft speeds, engine operation on gasoline.

Purpose of the work : to study the technology, types, frequency of maintenance and lubrication map for cars.

Work order

1. Indicate the frequency of maintenance for the 1st category of operating conditions in the form of table. 1.1. Preliminarily determine the category of operating conditions, as instructed by the teacher, and the frequency of maintenance for the given conditions.

Table 1.1

Types and frequency of vehicle maintenance

| Type of vehicle maintenance | Car maintenance frequency |

| 1 category | Given |

| 1 EO | |

| 2 Service A | |

| 3 Service B | |

| 4 TO-I (Service 1) | |

| 5. TO-2 (Service 2) | |

| b. SO (Service C) |

2. Indicate opposite each element of the car in the form of a table. 1.2 in coded form the operations performed for the corresponding type of maintenance. First, enter in the “Car Elements” column those components and assemblies that are part of a car of a given brand. Describe the distinctive features of EO, TO-I, TO-2.

Table 1.2

General provisions

Over the depreciation life of the engine, operating costs account for about 70%, of which - the crank mechanism 15-20%, the gas distribution mechanism 4-5%, the lubrication system about 1%, the cooling system 2-3%, the power system 12- 15% l ignition system 30-35%.

During engine operation, the main operating parameters deteriorate with increasing operating time, failures and malfunctions appear: compression in the cylinders decreases, noise and knocking appear, and gas breakthrough into the engine crankcase increases. Malfunctions and wear of parts of the cylinder-piston group cause a decrease in engine power by 15-20% and an increase in fuel and oil consumption.

The technical condition of the engine during operation is determined by listening, checking the pressure in the cylinders at the end of the compression stroke, measuring air leakage in the cylinders, as well as by external signs - the color of the exhaust gases, the appearance of smoke from the oil filler neck, thermal disturbances, weak compression, increased consumption oil, the presence of knocks and traces of water in the oil pan, interruptions in the operation of the cylinders, uniform heating of the exhaust manifold pipes during the engine warm-up after starting

Changes in the crank mechanism occur as a result of wear of the piston rings, pistons and cylinder liners, main and connecting rod bearings and crankshaft journals, piston pins, holes in the piston bosses or bronze bushings of the connecting rod upper head, damage to the cylinder head gaskets or loosening of the heads. block. External signs of these malfunctions are characteristic knocking sounds.

In order to correctly determine the cause of its occurrence based on knocking (noise), you need to know the nature of knocking noises during various malfunctions. Thus , the knocking of the pistons is characterized by a dull silky sound, which is heard above the plane of the crankcase connector with a sharp decrease in the crankshaft speed immediately after starting a cold engine. The knocking of the main bearings is accompanied by a strong, dull, low-pitched sound that is heard in the plane of the engine crankcase connector when there is a sharp change in the crankshaft speed.

The knock of connecting rod bearings is sharper and louder than the knock of main bearings. It can be heard in the rotation zone of the crank of the corresponding cylinder. The disappearance or noticeable decrease in knocking when the ignition or injector in this cylinder is turned off indicates a bearing failure.

The knock of the piston pin , sharp, sonorous, high-pitched, is heard in the area where the cylinders are located, in places corresponding to the upper and lower positions of the piston pin, when the engine crankshaft speed changes. However, this knock should not be confused with detonation knocks, which appear at a high ignition timing and disappear when it decreases. A decrease in oil pressure in the system is mainly due to an increase in clearances in the crankshaft bearings as they wear out. This malfunction is eliminated during engine repair. However, first of all, you need to make sure that there is the required amount of oil in the engine sump and that the pressure gauge is working properly.

Listen to the engine running using a stethoscope. Some characteristic shades of knocks and the corresponding areas for listening to them: metallic knocks, intensifying with increasing crankshaft rotation speed, indicate breakage of the valve springs or jamming of the valves; knocking in the upper part of the cylinder block, which increases at low engine speeds and decreases with increasing frequency, can be caused by scuffing on the surface of the liners and pistons; knocks caused by increased gaps between the piston pins and the holes for them in the piston bosses and in the bushings of the upper heads of the connecting rods or wear of the connecting rod and main bearings are heard, as a rule, when the load on the engine increases, with a sharp change in the fuel supply; if in the engine at any crankshaft rotation speed a metallic knock with a high tone and frequency is heard in the area where the valves are located against the background of a general and dull noise, then the valves are knocking due to a large increase in the gap between the toe of the rocker arm and the valve stem; sometimes during startup, especially at first, after starting a cold engine, a sound reminiscent of the knocking of pottery is heard, which may decrease or disappear as the engine warms up. This means that the pistons are worn and the gap between the pistons and cylinders is increased.

Increased oil consumption and increased exhaust smoke can be the result of stuck piston rings or increased wear, as well as the result of oil leakage through leaks in the connections. The latest malfunctions are eliminated by tightening fittings, plugs and fastenings of units and components of the lubrication system, connecting hoses, replacing sealing elements or worn piston rings.

To eliminate “sticking ” of the piston rings, it is necessary to warm up the engine, and then pour 20-25 g of a mixture of equal parts of kerosene and denatured alcohol into each cylinder for 8-10 hours. After this, pour a little oil into the cylinders, start the engine and let it run for 20- 25 min. The softened carbon burns out and is released with exhaust gases. After completing the carbon removal operation, it is necessary to change the oil in the engine crankcase.

If this method does not give a positive result, then to remove carbon deposits it is necessary to partially disassemble the engine by removing the cylinder heads and gaskets. To soften it, it must be generously moistened with kerosene using a rag and after a few hours removed with wooden or textolite scrapers from the bottoms of the pistons, valve heads and cylinders. After cleaning, it is recommended to rinse the surfaces of the parts with kerosene.

If the engine was running on leaded gasoline, then before cleaning the carbon deposits, it is necessary to soak the parts in kerosene, while observing the rules for handling toxic deposits of leaded gasoline.

To avoid damaging the head gasket, extreme care must be taken when removing it. Before installing the gasket, its surfaces on both sides are rubbed with graphite powder to prevent sticking to the surfaces of the head and cylinder block. The gasket areas adjacent to the holes for the bolts or studs securing the cylinder head are lubricated on both sides with a special paste to prevent water from penetrating the threaded connections.

The presence of water in the lubrication system may be the result of loosening of the bolts (nuts) securing the cylinder heads of the injector cups, the presence of cracks in the cylinder head or block, as well as a violation of the seal of the liners from the cylinder blocks. Loose bolts (nuts) securing the cylinder heads and injector cups should be tightened, and faulty cylinder liner seals (rubber rings) or cracks in the cylinder liners and heads should be eliminated during engine repair.

The sequence of tightening the bolts (nuts) securing the cylinder heads is shown in Fig. 2.1

| The sequence of tightening the cylinder head bolts (nuts) is shown |

Rice. 2.1. The procedure for tightening the bolts (nuts) securing the cylinder head of car engines: a-GAZ-53-12; 66-P; -14 “Seagull”; b-ZIL-130, Ural-375D, LiAZ-677 buses. LAZ-695N, - 699R; c — MA3-5335: d — GAZ-24, -3102 “Volga”; d - KamAZ-5320; e - ZIL-4331; g - Ikarus-260; h - socket wrench with torque handle

The tight fit of the head to the surface of the block is ensured by proper tightening of the bolts (nuts) securing the cylinder heads. To ensure uniform tightening and prevent warping of the head, tightening begins from the middle of the head. For cast iron heads, the bolts (nuts) are tightened on a warm engine, and for aluminum alloy heads - on a cold one. The final tightening is carried out using a socket wrench with a torque handle.

If the cylinder head is loosely tightened, the seal of the cylinders may subsequently be compromised, which can cause the gasket to burn out and coolant to enter the cylinder. As a result, starting the engine becomes difficult, the engine operates unstably at low crankshaft speeds, and sometimes stops. If you tighten too much, the bolts (studs) stretch and may even break.

Table 1

| Options | Parameter values for crankshaft positions | |||

| I II III IV | ||||

| Rotation angle, degrees | ||||

| Variable Valve Cylinder | 1; 5 | 4; 2 | 6; 3 | 7; 8 |

Turn off the fuel supply, then remove the cylinder head covers. Check and, if necessary, tighten the head bolts

Set the flywheel lock to the down position.

Remove cover 1 of the clutch housing hatch.

Inserting a crowbar into holes 2 on the flywheel, turn the crankshaft as it rotates until the latch, under the action of the spring, engages with the flywheel.

Check the position of the marks on the end of the fuel injection advance clutch housing and the flange of the drive coupling half of the high pressure fuel pump drive. The marks must match and be in the upper position.

If the marks are at the bottom, disengage the lock from the flywheel and turn the crankshaft another 1 revolution; in this case, the latch should again engage with the flywheel.

Set the lock to the top position.

Rotate the crankshaft in the direction of rotation (counterclockwise if

viewed from the flywheel side) at an angle of 60° (rotation of the flywheel by the angular distance between two adjacent holes corresponds to a rotation of the crankshaft by 30°), that is, to position I. In this case, the valves of the 1st and 5th cylinders are closed (the valve rods turn easily by hand).

Using a torque wrench, check the tightening torque of the nuts securing the rocker arms of the adjustable valves (Mkr = 4.2 - 5.4 kgf⋅m).

Using a feeler gauge, measure the gap between the toe of the rocker arms and the end of the valve stems of the 1st and 5th cylinders. A feeler gauge with a thickness of 0.30 mm for the intake and 0.40 mm for the exhaust valves must enter freely, a feeler with a thickness of 0.35 mm for the intake and 0.45 mm for the exhaust valves must enter with force. If necessary, set the required gap as follows:

loosen the adjusting screw nut using a valve adjuster or wrench and screwdriver;

insert a feeler gauge of the required thickness and, turning the screw with a screwdriver, set the required gap;

Hold the screw with a screwdriver, tighten the nut and check the gap. The tightening torque of the adjusting screw nut should be 4.2 – 5.4 kgf m.

Carry out further adjustment of the thermal clearances in the gas distribution mechanism in pairs on the cylinders indicated in the table. 1, turning the crankshaft 180°.

Start the engine and check its operation: if the clearances are correctly adjusted, there should be no knocking in the valve mechanism.

Install the clutch housing and cylinder head covers.

Purpose of the work : to study the methodology and equipment for carrying out maintenance and routine repairs of the crank and gas distribution mechanisms of the engine.

Work order

1. Give in the form of a table. 2.1 malfunctions of the crank and gas distribution mechanisms, methods for identifying and eliminating them.

Table 2.1 Malfunctions of the crank and gas distribution

mechanisms, ways to identify and eliminate them

| Malfunctions of the KShM and timing belt | Causes of malfunctions | Troubleshooting methods | Troubleshooting Methods |

| 1.Reduced engine power 2.Increased oil consumption 3.Increased fuel consumption 4.Smoking | |||

| 5. Knocks when the engine is running |

2 Make a list of maintenance operations for crank and gas distribution mechanisms and indicate the frequency of maintenance by type of maintenance in the form of table. 2.2.

Table 2.2

List of maintenance operations for engine crank and gas distribution mechanisms by type of maintenance

| Maintenance operations | EO | I Service A | Service B | TO-1 | TO-2 (Service 2) | SO (Service C) |

3. Draw diagrams of stethophonendoscopes, describe their structure and the procedure for checking the motor connections. Check the engine connections using the SFSC stethophonendoscope in the maintenance laboratory. Draw conclusions about the condition of the engine elements.

4. Describe the method and carry out grinding of the valves of the gas distribution mechanism in the maintenance and repair laboratory.

5. Provide a diagram and procedure for removing valves from car engines.

6. Measure the diameter of the valve stem with a micrometer in the central, upper and lower parts in different positions to take into account possible ovality. Valve stem wear should not exceed 0.03 mm.

To determine the degree of wear of the guide bushings and valve stems on the head with the combustion chambers facing upward, slightly lift the valve by the plate and rock it in different directions. If the play is noticeable, measure it with an indicator. The maximum permissible play is 0.08 mm. If replacing the valve does not change the backlash value, then the valve guide must be replaced. Normal play is 0.022-0.055 mm for intake valves and 0.029-0.062 mm for exhaust valves.

CONTROL QUESTIONS

1. What effect does maintenance have on the condition of the crank and gas distribution mechanisms?

2. List the fastening operations of the crank and gas distribution mechanisms and the types of maintenance in which they are performed.

3. What groups of operations are carried out during shift maintenance (EO) for crank and gas distribution mechanisms?

4. What are the features of carrying out TO-1, TO-2 of the crank mechanism?

5. Explain the purpose of checking and tightening the cylinder head bolts.

6. Why is compression checked on a warm engine?

7. During what maintenance do engine mounts be checked, tightened and adjusted?

8. Name the parts whose technical condition affects the amount of compression

cylinders

9. Name the causes of malfunctions in the gas distribution mechanism and how to eliminate them.

10. At what maintenance is the compression value checked?

11. Name the causes of knocking in the crank mechanism and methods for identifying them

12. What consequences during engine operation can result from incorrectly installed (adjusted) thermal clearances between the toe of the rocker arms and the end of the valve stems?

13. Name the main malfunctions of the gas distribution mechanism, their characteristic symptoms and causes.

14. Tell us about possible methods for detecting and eliminating malfunctions of the engine gas distribution mechanism.

General provisions

The engine lubrication system must ensure an uninterrupted supply of oil to the rubbing surfaces in order to reduce power losses due to friction, reduce wear of parts, protect them from corrosion, remove heat and wear products from the rubbing surfaces,

The reliability of engine operation largely depends on the good condition of the lubrication system, timely maintenance and troubleshooting during vehicle operation.

To ensure normal engine operation, it is necessary that the temperature of the coolant in the system is maintained within certain limits; 80-95 0C for cars ZIL-130, ZIL-131, EIL-375YA5; 75-95 0C for ZIL-375YAT, ZIL-645; 80-98 0C for KamAZ-740; 80-90 0C for 3M3-53. When the warning lamp for emergency coolant overheating comes on, the engine must be stopped to eliminate the cause of overheating.

Engine overheating occurs when there is insufficient coolant in the cooling system, the fan belt slips due to weak tension or oiling, or the thermostat malfunctions. The cause of engine overcooling is the blinds sticking in the open position and malfunctioning thermostat.

The reliability of engine operation largely depends on the good condition of the lubrication system, timely maintenance and troubleshooting during vehicle operation.

During the operation of the vehicle, it is necessary to periodically check the level and condition of the oil in the engine crankcase, change the oil in a timely manner, clean and rinse the filters, change the fine filter element, monitor the oil pressure in the lubrication system and prevent oil leakage from the filters, oil cooler, and engine crankcase and oil pipe connections.

When the oil level is elevated, carbon deposits appear on the walls of the cylinder heads, piston heads and valve heads. Excess oil leads to leakage through oil seals and gaskets.

A low oil level in the engine crankcase leads to disruption of its supply to the rubbing surfaces, to their overheating and even to the melting of the antifriction alloy of the crankshaft bearing liners.

relationship between lubrication and cooling systems

. At reduced thermal conditions, the oil reaches the rubbing surfaces with a delay and does not spray well. General monitoring of the condition of the lubrication and cooling system is carried out by the driver using instrumentation. But during maintenance, a deeper check of these systems is necessary.

Purpose of the work : to study the frequency, content of operations and methods of carrying out maintenance and routine repairs of the engine cooling and lubrication system.

Work order

1. Give in the form of a table. 3.1 malfunctions of the engine cooling and lubrication system, methods for identifying and eliminating them. Eliminate malfunctions as instructed by the teacher in the vehicle maintenance and repair laboratory.

Table3.1 . Malfunctions of the engine cooling and lubrication system, methods for identifying and eliminating them.

| Malfunctions of the engine cooling and lubrication system | Causes of malfunctions | Troubleshooting methods | Troubleshooting Methods |

| Engine overheating | |||

| Excessive engine cooling | |||

| Low oil pressure | |||

| Increased oil pressure |

2. Give in the form of a table. 3.2 list of maintenance operations for the engine cooling and lubrication system by type of maintenance

Table 3.2 List of maintenance operations for the engine cooling and lubrication system by type of maintenance.

Table 3.2

| Type of maintenance | ||||||

| Maintenance operations | EO | Service A | Service B | TO-I (Service 1) | TO-2 (Service 2) | SO (Service C) |

3. Draw and describe a circuit for checking the operation of the thermostat. Have the thermostat function checked in a maintenance laboratory. Enter the obtained data into the table. 3.3.

Table 3 .3 Results of checking the thermostat condition

| Status Options | Water temperature, aC | Valve stroke, mm | |

| required | measured | required | measured |

| Thermostat valve begins to open | |||

| Thermostat valve fully open |

Control questions

1. Name the reasons for changes in the main operating parameters of the cooling system.

2. What effect does maintenance have on the condition of the cooling system?

3. List the control and adjustment operations of the cooling system and the types of maintenance during which they are carried out.

4. What groups of operations are carried out during maintenance-2 for the lubrication system?

5. What are the features of carrying out TO-1, TO-2 of the cooling system?

6. How often and how is the lubrication system flushed?

7. During what maintenance and how is the tension of belt drives checked and adjusted?

8. What elements of the cooling system are checked during TO-2?

9. What methods of checking crankcase oil do you know?

10. Explain the essence of the method of checking oil viscosity using a garage viscometer.

11. Explain the essence of the oil drop test method.

Laboratory work No. 4

Checking Thermostats

The opening temperature and the stroke of the thermostat valve are determined as follows. Immerse the thermostat below the flange in a bath of water with a capacity of 3 liters and begin to heat it and a mercury thermometer with a division value of no more than 1 °C.

Check with an indicator that the thermostat valve begins to open: at a temperature of 80±2 °C, the valve stroke should be 0.1 mm, and it opens completely at a temperature of 93±2 °C. The full valve stroke should be less than 8.5 mm.

The allowed temperature for the start of opening is 80±3 °C, for full opening is 93±3 °C, the loss of valve stroke is no more than 20%.

Laboratory work No. 5

General provisions

The power supply system must ensure the preparation of a combustible mixture of the required composition and quantity depending on the operating mode of the engine. Engine performance indicators, such as power, throttle response, efficiency, durability and ease of starting, depend not only on the technical condition of the power system, but also on the quality of the air-fuel mixture. The use of lower quality fuel can lead to abnormal engine operation (detonation, carbon deposits, excessive fuel consumption, burnout of cylinder head gaskets, valve heads, etc.).

Untimely and insufficient care of power supply system devices, pipelines, fuel and air supply control drives can lead to the risk of fire, disruption of fuel supply, over-enrichment and over-leanness of the combustible mixture, excessive fuel consumption, disruption of normal engine operation, loss of power and throttle response, difficult starting and unstable engine operation at idle. Before you begin troubleshooting the fuel system of a carburetor engine, you must make sure that the cause of deterioration in vehicle performance is not due to defects in other components and systems, especially the electrical equipment system.

Maintenance of the power system consists of timely checking the tightness and fastening of fuel lines, fuel mixture inlet and exhaust gas outlet pipelines, the action of the throttle and air damper drive rods of the carburetor, and checking the functionality of the maximum crankshaft speed limiter. Also in cleaning and washing fuel and air filters according to the established maintenance intervals, in disassembling, washing and adjusting the carburetor.

Daily Maintenance (DM)

Daily maintenance (DM) must ensure the release of a serviceable and clean vehicle in a condition that ensures its trouble-free and safe operation.

SW is carried out daily and includes:

- control work - monitoring the technical condition of parts, devices, components and assemblies that ensure the operability of the vehicle, road safety, fire safety, control of the vehicle as a whole

- cleaning and washing work (can be additionally performed at line dispatch stations or route terminals. In this case, the labor intensity must correspond to the actual volume of work performed)

Maintenance after break-in is carried out in accordance with the vehicle manufacturer's operating instructions.

TO-1 and TO-2

The first maintenance (TO-1) and the second maintenance (TO-2) are carried out periodically, after the mileage established in the regulatory documentation, and include a set of operations that prevent malfunctions, reduce the wear rate of vehicle parts, reduce the consumption of fuel and operating materials and reduce the negative environmental impact.

The frequency of TO-1 is set to a multiple of the frequency of TO-2. The actual frequency of vehicle maintenance may differ from the standard by no more than ± 15%.

The scope of maintenance work after running-in, TO-1 and TO-2 of vehicles includes:

- cleaning, washing and cleaning work

- technical diagnostics before performing maintenance

- inspection and control of the technical condition of parts, devices, units, assemblies, and vehicles in general

- control of fastening connections of parts, devices, components and assemblies

- adjustment of devices, components, assemblies and systems

- lubrication, oil change

- performing routine repair (TR) work of low labor intensity. To calculate its labor intensity, it is allowed to use no more than 20% of the adjusted labor intensity of the corresponding maintenance

- quality control of maintenance performance

Depending on the scope of work, TO-1 and TO-2 can be divided into the following types:

- every first maintenance (1 maintenance-1, 1 maintenance-2)

- every second maintenance (2 maintenance-1, 2 maintenance-2)

- etc.

The difference between maintenance and car repair

If repair is a necessary measure and must eliminate breakdowns, maintenance is a preventive measure. Roughly speaking, if a car is in an accident, it needs repairs. If the car passed the maintenance on time, the brakes were checked, an accident was avoided, there is no need for repairs.

The purpose of maintenance is to prevent breakdowns, prevent premature wear, and eliminate minor breakdowns that threaten repair. Types of vehicle maintenance and repair can be different and differ in level of complexity.

During the maintenance process, the following are carried out: diagnostics, checking fasteners, lubrication, refueling, adjustment, etc. A distinctive feature of scheduled maintenance is that machine units, as a rule, are not disassembled, and individual components are not removed.

In case of repair, on the contrary, technical components are disassembled, removed and repaired or replaced.

During maintenance, oil, spark plugs, filters, and other consumables are usually changed.