Do-it-yourself repair and restoration of shock absorber struts - is it possible?

Shock absorbers are a kind of consumable item for your car. Moreover, the costs of maintaining the suspension in working condition are inversely proportional to the quality of the roads. Car owners are constantly looking for ways to save on repairs and maintenance of their cars. We will talk about self-repair and restoration of the characteristics of shock absorber struts.

When the front and rear shock absorber struts need to be checked

Typical malfunctions of this unit are known to everyone:

- Depressurization of the rod seal. Leads to oil leakage from the strut. It can leak at any time. Characteristics change until complete loss of performance.

- The rod moves too freely in the pipe. In fact, the shock absorber strut turns into a guide for the suspension spring. The malfunction is related to the internal valves.

- Play during compression or rebound. Associated with production in the rod or cylinder. The consequences are similar to broken valves. The shock absorber does not perform its function in the car, it knocks, rattles and makes other unpleasant sounds, which is why driving in such a car becomes uncomfortable and dangerous.

- External damage - dents on the body, cracks in the eyelet. They affect the chassis as a whole and can lead to more serious damage.

If any malfunction is detected, it is necessary to remove the strut and free it from the spring. Dismantling is carried out in the garage, without the use of special tools.

Sometimes owners of foreign cars, noticing that their struts have leaked, turn to a service station for diagnostics, where they will test them on a stand.

Repair or replacement? What you can do with your own hands

In fact, this is not such a simple task. Before carrying out work, you should carefully study the material and follow safety precautions. First of all, you need to determine whether your shock absorber is collapsible or not. The monolithic body cannot be repaired; opening it with a grinder and welding it is unacceptable.

If there is a nut or retaining ring where the rod enters the pipe, such a shock absorber strut can be serviced and repaired.

This is what a repairable rack looks like

Restoring gas pressure in the rack

- The shock absorber is firmly fixed in a vice, the position is vertical. It is necessary to thoroughly clean the part and blow out the entry point of the rod with compressed air. It is disassembled - the protective cap of the rod is removed.

For convenience, work is carried out in a vice

Use a pressure gauge to control. The method is suitable for gas and gas-oil racks

The process can be seen in the video.

Video on how to pump gas in a gas-oil rack

There are different opinions on how to fill a car shock absorber. Nitrogen, carbon dioxide or just compressed air? In a garage setting, there are few options. Compressed air will not significantly degrade the performance, especially considering that this is a repair and not a factory-made rack.

How to disassemble a shock absorber strut

Attention! The rear strut does not have bearings, so it must be assembled strictly in the same position as it was before disassembly! If you are doing this for the first time, then it makes sense to put marks. In the video I talked about this in detail. But if you suddenly forgot to do this, then it’s okay - the video also shows a way to check the correctness of the assembly.

It all depends on what shock absorbers are installed. Let's start with the original original shock absorber. Its stock looks like this

We need to unscrew the nut and at the same time hold the rod. To do this, we put the already familiar 17 mm wrench on the nut.

And we hold the rod with the head at 9 mm

If you remove the nut while still on the car, as I described above, then it will be much easier now.

Bleeding the shock absorber

- The rack must be completely disassembled and cleaned of dirt and old oil. Check the O-rings and the condition of the inner pipe wall.

Remove drips and other contamination from all rack mechanisms

No special equipment is required to work with oil struts

Video: how to restore the functionality of a non-separable mechanism and is there any point?

Bleeding the shock absorber

- We completely disassemble the rack and clean it. We determine the condition of the rubber seals. Remove jet contaminants and dust from parts.

- The assembled rod is immersed in oil in a pipe (check what exactly the composition of the liquid should be based on the characteristics of the shock absorber). Our next task is to remove all air bubbles. The shock absorber should be positioned vertically and the oil should be drawn in using smooth movements. The procedure will need to be done several times. You do not need any special devices to repair oil struts.

On non-removable racks, a bleeder fitting is installed in their lower part. A hole is drilled, with its help the rack is filled with oil, the hole is welded. By the way, those who own Russian cars with high mileage follow this path.

Replacing the rod, valves, adjusting the stiffness of shock absorbers

The next malfunction is damage to the rod, seals, and valves inside the strut. There is a certain selection of spare parts on the market for repairing dismountable shock absorbers. In addition, an experienced car enthusiast never throws away old spare parts, but tries to repair them. In addition, you can always extract workable parts from them.

- So, let's disassemble the shock absorber.

Don't forget to wear gloves, the job is dusty

Turning work is usually cheaper than the cost of a new shock absorber

Tip: The entire process of disassembling the shock absorber should be photographed. This will avoid problems during assembly.

It is important to ensure the cleanliness of the unit; the ingress of dirt or solid metal particles will quickly damage the restored shock absorber.

Get rid of stains, dirt and dust while disassembling

All parts must be carefully checked

It is recommended to replace the oil seal

After pumping the oil, the rack needs to be pumped as usual

Video: How to repair car MacPherson struts

If you have basic information about how your shock absorbers work, you can save money on replacing them. Most rack models are repairable, and components are either purchased at reasonable prices or made independently.

DIY shock absorber strut repair

Conditions for self-repair

The front shock absorber strut adopts a double-acting hydraulic shock absorber design. The rear strut is usually made in the form of a conventional two-pipe design.

This difference in the design of the struts is explained by the fact that the front struts have a certain influence on the handling of the car, and, consequently, on traffic safety. From here it is easy to conclude - if the shock absorber struts are in perfect order, then the movement of the car will be comfortable and safe.

We, caring and prudent car owners, carry out diagnostics of shock absorbers regularly, and it is very easy for us to detect their malfunction by characteristic oil leaks in the suspension area, and sometimes we hear a knocking sound from the shock absorbers while driving. And then we decide that the shock absorber struts need repair, or they need to be replaced with new ones. Some people go to a car service center for this, while others repair the shock absorber struts with their own hands (see the video “Do-it-yourself shock absorber strut repair” below).

How to repair shock absorber struts yourself?

In principle, this will not be particularly difficult, especially if the rack has a collapsible design. If the stand is not collapsible, then it’s better not to try to do anything yourself - anyway, you can’t do it without special equipment. Car repair shops, of course, undertake to repair non-dismountable racks, but at the same time, during the repair process, changes are inevitably made to the rack design. But what are the guarantees for such repairs? Therefore, it is necessary to evaluate in advance the feasibility of repairing non-collapsible racks - how profitable and safe is this?

Only rear-wheel drive cars, the so-called classics, are equipped with shock absorbers with collapsible struts. The shock absorber struts on other cars have a non-demountable design.

– Shock absorbers are repaired or replaced only in pairs.

– For repairs you need: 1) a rack wrench - for cars with rear-wheel drive, 2) springs and ties - for cars with front-wheel drive.

– For repairs, you need to install “goats” under the car.

– It’s easy to remove the strut from a rear-wheel drive car, but to remove it from a front-wheel drive car, you need to compress the spring on both sides with ties equally hard. The compressed spring is installed on the new strut after visual inspection.

– Now we work with the strut: we remove it from the shock absorber, drain the oil, take out and throw away the old stuffing and put a new cartridge in its place, now we reassemble the place of the strut - we install the spring, then the support bearing, and, finally, we put the strut on the car.

This is interesting: Changing the oil in a Renault Duster engine

– After self-repairing the shock absorber struts, it is necessary to adjust the wheel alignment.

– The rear shock absorber strut is repaired according to the same scheme, and only in pairs.

As you can see, repairing a shock absorber strut with your own hands is not particularly difficult.

Video: Do-it-yourself repair of shock absorber struts

If the video does not show, please refresh the page or » style=»color:#CC3333″>click here

Tips for using shock absorbers

1. Do not test shock absorbers for strength, avoid high speeds on bad roads.

2. Do not lift the suspension by installing spacers under the struts: the shock absorber rod will be forced to function in the movement zone and will very quickly become unusable.

3. In the cold season, shock absorbers, like rubber, need to be warmed up. This means that when you get into your car in the morning, start driving for about 5 minutes at low speed - this is necessary so that the oil, which has thickened overnight, warms up and does not damage the poppet valves. How to check shock absorbers? What shock absorbers are best to install on a car?

How to restore shock absorbers: instructions

It is necessary to make a decision on what to do next only after the type and cause of its failure have been studied in detail. And, of course, you will need confidence in your abilities in order to decide whether to restore the shock absorbers or buy a new part.

It is quite possible to restore each type of shock absorbers yourself. The difficulty will be in determining how deplorable its condition is and whether it makes sense to restore it.

By and large, only repairable racks can be revived. If the rack has worked for a fairly large mileage of more than fifty thousand, and its condition is very deplorable, then such a rack is not only repaired, it is strictly forbidden to use it in the future. It's better to play it safe and buy a new part.

There may also be a problem with repairing racks that have an additional function - pumping. Here you will need to apply all your knowledge and skills, since this mechanism is considered more complex than its opponents - hydraulic ones. And their cost exceeds several hundred dollars, given the exchange rate, you will have to pay a decent amount to purchase a new set.

If you listen to the opinion of experts, you can conclude that repairing shock absorbers is not a way out for saving money. Considering the fact that this device performs a large amount of work, repairs will only delay its complete wear and tear. Therefore, it is necessary to make a decision on restoration or complete replacement after the first breakdown. But it does not always happen as you wish, and sometimes it is not possible to purchase new racks. Therefore, I will teach you how to restore a shock absorber with your own hands, and at the same time do everything possible so that the repaired part will last a little longer, until better times.

What will you need?

So, before repairing, it is necessary to carry out certain measures - you need to prepare the tool.

- Special kit for restoring old shock absorbers

- New stock

- Special cleaning agent for electric motors

- Oil for pouring into the rack

- Brush (you can use an old brush to clean your teeth)

- Knife (preferably sharp)

How to recover

In this particular case, I will tell you how to get rid of a problem such as an oil leak. This is one of the main reasons why the device quickly wears out and therefore loses its functionality. Therefore, if you experience loss of working fluid in the rack, you need to solve this problem as urgently as possible.

So, let's look at the recovery stages:

- From the strut rebuild kit, take the lock washers and spacers. You need to carefully cut them off from the casting using a sharp knife. It is advisable to do everything as carefully as possible so as not to leave burrs on these elements during cutting. They will create difficulties during assembly.

- Now you need to remove the racks (you can look at the instructions). After removal, all parts, including the outer side of the housing, must be cleaned with a brush. Next, you need to remove the cap, remove the cartridge, and remove the fastener from the bottom of the rod.

- The holding mode must be removed, and then all silicone rings must be removed. After this, using an engine cleaner, you need to clean the inside of the housing. All remaining dirt and any debris must be removed. After the shock absorber is completely cleaned, it needs to be given time to dry. After this, I recommend lubricating the new rings with oil to avoid the possibility of leakage with the new parts. After this, the stand is assembled.

- Depending on the type of shock absorber, their assembly algorithm may have some differences, but in most cases the sequence is as follows: a small gasket, then a silicone ring, then a large gasket, and again a silicone ring. Afterwards, a small spacer is placed, as it acts as a holding clip.

- Apply oil to the threads of the rod and insert it into the threads of the cartridge or stand.

- Fill the shock absorber body with oil, focusing on the beginning of the thread. Get rid of bubbles by moving the piston. The shock absorber then needs to be compressed. After these procedures, an elastic membrane must be inserted into the shock absorber cap.

- After this, you need to bleed the shock absorber. Place it vertically; oil must be filled to the level until an oil dome appears above the edge of the housing. After this, move the rod up and down. This will remove all bubbles. After this you can complete the assembly. If necessary, you can look at the instructions.

If you have problems with the racks, then they must be resolved without delay. Of course, it is better to replace them with new ones. Good luck.

“How to restore a shock absorber”

After watching the recording, you will learn how to bleed the shock absorber of your car at home and what tools you need to prepare for this.

Source: https://mineavto.ru/remont/hodovaya/kak-vosstanovit-amortizatory-2454.html

How to repair car shock absorbers

An article about how to repair car shock absorbers - types of breakdowns, methods for eliminating problems. At the end of the article there is a video about do-it-yourself shock absorber repair.

A car shock absorber is a device that absorbs vibrations or various shocks passing from the road surface to the body. Such vibrations of various systems are suppressed by pistons operating in viscous media. Thanks to such media, the amplitude of oscillations decreases.

Modern motorists are often faced with complete failure or breakdown of the suspension system, the main parts of which are shock absorbers. Therefore, urgent repairs are required, which will save the car owner from further complications. Such repairs should begin with detailed diagnostics.

Shock absorbers are available in rear and front. Repairing such critical parts requires detailed knowledge of the structure itself.

Shock absorber restoration

This, of course, is also an option, but there are a lot of “BUTs” in this matter. Let's start with the fact that the warranty for such shock absorbers is no more than six months, the maximum is a year, but this is debatable. Next we will focus on the quality and safety of the restored shock absorber.

Its operation cannot be considered reliable for a simple reason - there is sufficient damage to the structural elements on the car's strut mechanisms, even if everything is done using special equipment and the mechanic's hands are “golden”.

And the “components” used are most often second-hand, and the degree of this used is not always normal. And the quality of the master’s work is not always normal, you didn’t stand nearby and didn’t see what and how he did there. Therefore, such an option as restoring shock absorbers cannot be considered ideal; it is rather doubtful.

After the repair and inspection of the shock absorber struts has been completed, there are important points to remember!

• You should not check the operation of repaired shock absorbers at a decent speed. This is especially not worth doing if the road is very bad.

• Never lift pendants with the currently fashionable “attachments”. The body must be lifted only with shock absorbers of suitable size, otherwise the rod will fail; its operation in an increased movement zone guarantees this.

• Start driving in winter no earlier than after 5-7 minutes of warming up. The oil in the shock absorbers must warm up, like other car components, otherwise your absorber will again “die for a long time.”

To ensure that your car is always in good working order and does not cause you big problems, try to inspect and check the operation of different systems more often. A car is like a woman – it requires constant attention and care. Good luck on the roads!

Video instructions for self-restoring shock absorbers

The serviceability of suspension elements is an important component of safe movement. It is especially important to pay attention to this part of the car for cars that have a high mileage on domestic roads. If necessary, it is necessary to carry out preventive or restoration measures in a timely manner, for example, repairing shock absorber struts with your own hands.

Working in a garage will help you save a lot of money that you would have to pay at a car service center. The main thing in such a situation is to have a set of tools and stock up on an arsenal of spare parts.

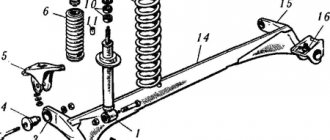

Shock absorber device

A modern shock absorber is a complex device consisting of different parts. Shock absorbers are replaced exclusively in pairs. If one strut is damaged or broken, the car owner will have to replace both. When restoring or repairing a shock absorber, you must use the vehicle’s operating manual. A detected malfunction requires careful study and appropriate decisions.

It is necessary to prepare accordingly for the shock absorber repair process.

To do this you will need the following tools and materials:

- car kit;

- screeds;

- support trestles;

- rack key;

- new cartridge.

After preparing the listed devices, you can begin the actual repair work.

Current safety standards require the vehicle to be mounted on pre-prepared trestles. In this case, it is necessary to set them correctly. The lever mounting bolts and the rod nut are unscrewed, then the fastenings are removed and the shock absorber is removed. If the fasteners are properly unscrewed, removing the shock absorber is quite easy, but do not forget to remove the internal thread.

Having completed dismantling the shock absorber, you can remove the internal parts from it. First, the old cartridge is removed, in its place a new one is installed and tightened with a nut. After replacing the cartridge, you can return the shock absorber to its place using the described steps.

After the repair is completed, the vehicle should be sent to a service center to have the wheel alignment adjusted. Experts also advise that when repairing or restoring shock absorbers, perform diagnostics and check the main elements of the car suspension, including the steering rod, brake hoses, racks, and blocks.

Do I need to tighten the springs on the rear struts?

By and large, springs in the rear struts do not require ties. It is quite possible to do without them, since the spring is practically in a decompressed state.

But I still recommend having zip ties for several reasons:

1. There is a groove on the rod into which the support should fit. If you compress the spring by tightening the nut without ties, the support may become slightly skewed and not fit into this groove. The nut will tighten and it will seem to you that everything is fine. But after a couple of hundred meters of driving, the support will sit in its place and the nut will not be tightened, which will lead to knocking, and can also break the support and the threads on the rod.

2. It may turn out that your car does not have original shock absorbers or springs. For example, Kayaba shock absorbers have a slightly shorter rod and without ties it will be more difficult to assemble the strut.

3. The price of screeds is not high. About 150 UAH. for a couple. This is about 6 usd or 400 rubles. Moreover, they will be useful to you in the future on the A-pillars. And there you can’t do without screeds.

In general, unscrew the nut...

...and remove the support

Removing the spring cup

Anther

Bumper

Remove the spring and rubber gasket.

Next, we proceed to troubleshooting the rack elements. Most often, only the support and its gasket require replacement. Everything else has gone through more than one shock absorber replacement.

Here is a worn out and specifically tired support

Service life

Just like any product or part, shock absorbers have their own service life and replacement periods. Restoration or repair of the device should be carried out immediately after detection of a breakdown or malfunction. As for their complete replacement, it is performed every three years.

To increase the service life, it is recommended to follow the following simple rules:

- refuse to use deliveries to lift the suspension, which can damage the shock absorber rod;

- avoid high speeds when driving on damaged roads;

- In winter, preheat the oil in the shock absorbers.

If you decide to raise the car body, you need to take care of installing shock absorbers of appropriate sizes. Clumsy handling can cause rapid wear not only of the shock absorbers, but also of the entire suspension. And in winter, to start driving, you need to use low speed and low gears.

If all of the above operating rules are observed, timely diagnostics, as well as repair or restoration of shock absorbers, a significant increase in the service life of the entire vehicle is possible. Repair work is carried out in accordance with the nature of the detected malfunction. Don’t forget about the innovative non-separable models of shock absorbers that cannot be repaired.

Typical breakdowns

Every experienced car enthusiast is familiar with the typical malfunctions of this unit. If oil leaks, this indicates depressurization of the rod seal, which can cause complete loss of performance of the part.

You should also be wary if play occurs during rebound or compression. The consequences will be the same as with broken valves. The device will no longer be able to perform its direct functions, and the car will make knocks, rumbles and other unpleasant sounds while driving. Driving in such a car is not only uncomfortable, but also quite dangerous.

External damage can include cracks in the eyes or dents on the housings. Such minor problems can lead to more serious damage and even affect the chassis. Having found any sign of such a breakdown, the strut is removed and freed from the spring.

The best way to detect shock absorber problems is to check the stability of the car itself, both at high and low speeds.

The owner should pay attention to how his “iron horse” reacts to bumps or holes and how quickly it restores its balance when encountering such unevenness.

If even the slightest deviations are detected, it is necessary to examine the shock absorbers in detail. When analyzing the state of protection, you should inspect the anthers. For such purposes, overpasses or special pits are used, which allow you to inspect both the front and rear shock absorbers from below.

If the anthers are torn or even slightly damaged, it is better to install new protection. It is the anthers that are responsible for protecting shock absorbers from small particles of dirt entering the holes, which over time leads to various types of breakdowns or damage. If the shock absorber is deprived of such protection, its service life is significantly reduced.

Shock absorber diagnostics

Taking into account the main function of shock absorbers - reducing the rolling of the car on uneven road surfaces, the fault can be determined quite easily. The main sign of failure of this device is an increase in vibrations and the appearance of excess noise that was not felt before.

If the wheels of the car fall into a hole, you will be able to hear a piercing sound, which is also considered an additional sign of failure. This way you can find out if your shock absorbers need to be replaced or repaired quickly. However, a more detailed study of the problem will be required.

First, a visual inspection of the part and its careful study is necessary.

If an oil leak is detected, you should definitely carry out repairs and return the shock absorber to working condition. It is necessary to take into account that the process of diagnosing this device on a stand is a rather complicated task, so many people try to immediately purchase new shock absorbers or repair the struts using a repair kit on their own.

A shock absorber is considered to be a consumable item that must be replaced after a three-year period. The poor condition of Russian roads reduces this time significantly - the suspension fails much earlier than the time specified by the manufacturer. However, you should not despair in advance, nor should you throw away a broken part. If the shock absorber cannot be repaired, it can always be replaced.

Before choosing a method, you need to take into account several factors, including the cost of a new part - if it costs the car owner the same as the repair, you shouldn’t get your hands dirty. In addition, repairs require certain skills. Do not also forget that a reconditioned shock absorber will not last long.

This is interesting: Design and adjustment of the VAZ 2107 carburetor

In general, a shock absorber is a multifunctional part that is responsible not only for damping body vibrations, but also for braking. It ensures the stability of the car. Therefore, having well understood the essence of the operation of such a device, the driver will be able to understand the problem in a timely manner and make the right decisions to eliminate it. Even after undergoing maintenance, shock absorbers may suddenly creak or leak, so you need to constantly monitor them.

Most modern cars are equipped with so-called non-separable shock absorbers. This means that they cannot be repaired. Unlike collapsible analogues, they have a five-year warranty period. And on high-quality highways they will last longer.

There are also shock absorbers with pumping. In such models, the gas pressure has been changed, which adjusts the performance characteristics if the car is subject to heavy loads. They work perfectly until they break down, fulfilling the additional option described above. If such a shock absorber fails, it will be quite difficult to repair it.

The fact is that models with pumping during repairs block the hydraulic fluid tubes, which are responsible for the serviceability of the entire part. It is almost impossible to carry out such repairs without the intervention of specialists and special equipment. And purchasing a new part will cost several hundred dollars.

Experts recommend using only original components during repairs and not trusting cheap counterfeits - after all, the coherence of the system and machine components depends on this device. We must not forget that when an appropriate case arises, insurers intervene in every verification procedure, studying all the details in order to find the reason and, if possible, refuse payment.

Video about do-it-yourself shock absorber repair:

Change or... repair: how and why shock absorbers are repaired

Of course, a sharp-tongued reader will say: someone who buys a car for several million can easily spend a hundred or two on racks. This is, of course, true, but only at first glance. Firstly, consider the quality of the road surface, which is far from desired, and imagine how quickly new shock absorbers installed on a car weighing more than 2.5 tons will die. Secondly, one should not discount the fact that people driving a GL500 have the ability to calculate expenses. And at the end of the virtual tour, imagine that you, the owner of the X5, are told: “Repairing one shock absorber will cost you 350 euros.” Almost 5 times cheaper! And what will be your decision after this?

We won’t talk about the design of shock absorbers: enough was said in the article about replacing struts . Today we will focus exclusively on breakdowns and their elimination.

Breakdowns

One of the most common shock absorber malfunctions is leakage of working fluid through a damaged oil seal. There are several reasons why it comes to an end, and the main one is friction. The simplest option is when the service life has expired and the sealing part has worn out. But it happens that the shock absorber begins to “sweat” or leak before reaching half of its service life.

Articles / History Softness and hardness of the suspension - what is more important for comfort? Almost every car owner is sure that a soft suspension provides comfort, while a hard one makes the car sportier and allows better grip on the road. But as in many other cases,... 86824 0 37 03/05/2015

The reason for this may be winter - or rather, frost . For example, you drove out of a warm garage somewhere, stopped to drink hot chocolate and sat for a while in a coffee shop. Due to heating and subsequent sharp cooling in the cold, grains of ice formed on the shock absorber rod. They will tear the seal on a relatively new shock absorber. In addition, death of the seal can also occur after dust and dirt get on the rod due to damage to the boot.

The rod itself is difficult to “kill,” but it moves in the guide sleeve, into which Teflon rings are, in turn, pressed. These rings, of course, wear out, and then the rod begins to experience shock loads in the contact surface. If you do not pay attention to this in time, you can break the entire guide sleeve - and this is already a disaster from the point of view of driving safety. Well, there’s nothing to say about the shock absorber bushings; they can break first. Replacing them is not a big problem, but it happens that this is simply not provided for structurally.

Piston valves are perhaps the most durable elements of the assembly: there is essentially nothing to break in them. But it happens that small particles of dirt get inside the shock absorber through a damaged oil seal and broken Teflon rings. So they can cause a number of troubles, the saddest of which is a loose valve fit. Then the shock absorber will “dangle” during the compression or rebound stroke - depending on your luck.

Gas or air that has gotten inside the shock absorber can also be a problem. This manifests itself in audible shocks from the shock absorber during its operation. The impact occurs when an air bubble passes through the valve and piston, causing the strut to suddenly sag.

Articles / Practice When it’s better not to start up: what can break down in a car in severe frost Epiphany time is the best time for the next portion of horror stories about frosts. So, it’s a frosty morning, it’s dark, but for some reason you needed to go. It would seem that when the starter, groaning, managed to... 58628 30 38 01/19/2017

How can air get into a monotube shock absorber? Yes, very simply - through a worn out sealing ring of the separating piston. It wears out gradually, so at a certain point it begins to “poison” the gas into the cavity with the working fluid. If problems with tightness are not identified in time, then regardless of whether you have a double- or single-tube shock absorber, foaming of the working fluid will occur with a loss of damping properties and a sharp increase in wear of the rubbing surfaces. If the shock absorber is double-pipe, then due to wear or, again, the ingress of foreign particles, the bottom valve responsible for the compression stroke fails.

With the piston, everything is simple: the sealing ring is more likely to wear out than the piston itself. But for the sake of truth, it is worth saying that there are “craftsmen” in our open spaces who “put this part on both shoulder blades.” The cylinder also rarely attracts attention, and the only thing that can make you sad is scuffing due to the same dirt.

In the case of electronically controlled shock absorbers, in addition to purely mechanical damage, problems arise with the rebound and compression bypass solenoids. If one of them jams, for example, in the open position, it will make the suspension very soft in only one direction.

Diagnostics

Every car enthusiast knows: if you rock the car and it oscillates, as if on waves, it is clear that not everything is in order with the shock absorbers. Leaks of working fluid also quickly reveal at least wear of the oil seal. But if suddenly the rocking of the car does not provide any understanding of the problem, and the behavior of the car in motion is noticeably different from normal, a special diagnostic stand can come to the rescue. There are many of them on the market - for example, we used Emmetec.

The shock absorber is fixed in the stand: the body - in the moving part, the rod - to the plate with a strain gauge. The stand simulates the operation of a shock absorber, moving it either slowly or quickly. Thanks to the sensor, a graph of shock absorber stiffness is drawn during rebound and compression strokes in different operating modes. The master knows what the graph should look like, and if, instead of smooth curves, he suddenly sees any jumps or sharp transitions, he will give an approximate, but more specific conclusion about the technical condition of the “shock.”

Repair

In any case, if the shock absorber ends up in a repair shop, it is disassembled - although this is not so simple. The fact is that in the old days, shock absorbers were initially collapsible. Repair kits for them could be purchased at any store... or almost any. Nowadays, it is not profitable for manufacturers to have a part that can be repaired, so they are either welded or rolled from the factory.

Rolling also varies, and the difficulty of disassembly depends on this. If the shock absorber is single-tube gas-filled, then the gas is first bleed from it. After cutting off the retaining part and pulling out the insides, all parts are thoroughly washed in kerosene.

In any case, after disassembly, whatever the initial reason, the piston o-ring, the oil seal and the Teflon ring of the guide sleeve, as well as the shock absorber fluid are replaced.

If corrosion is found on the rod, it will undoubtedly be replaced. It will not be possible to sharpen and polish it - this is not a cylinder block with repair dimensions , this is not included structurally, and in addition there is a need for chrome plating.

The latter is a rather expensive pleasure, and therefore impractical. But in case of very minor “grinding”, the rod can still be polished with GOI paste.

Particles getting under the valves can be “treated” by regular washing and checking the surface so that the valve fit is normal.

The problem of the bottom valve in two-pipe systems was discussed above: so, in the event of a malfunction, this valve is replaced as an assembly.

For monotube shock absorbers, the sealing ring of the separating piston is replaced. The inner surface of the piston cylinder is also polished. Sometimes it happens that turning a rod yourself is easier and cheaper than ordering a new one - this applies to various types of tuning shock absorbers. And in our case, not only the rod was machined, but also the external gas-filled cylinder of the shock absorber, since the original one had lost its seal.

By the way, one of the problems on the way to repairing shock absorbers may be their “Americanness” - the inch calculation system, which can get in the way of selecting seals. In general, there is no shortage of components and repair kits, which is why repairs are overall cheaper than new ones.

The liquid used to fill shock absorbers is different and from different manufacturers, but the search for the ideal one never ends.

Our master said that a long search for the ideal working fluid in terms of price/quality ratio led to AMG-10 aviation oil. It turns out cheap and of very high quality, and at the same time you don’t overpay for a sensational brand.

Test drives / Single After the rain, on Thursday: test drive of the KIA Sportage 2.0 AT AWD off-road A lot of time has passed since the start of Russian sales of the fourth-generation KIA Sportage, but in cities it is still exotic, and outside of them - in general unprecedented. The desire to speed up the course of history... 15026 0 3 09/05/2016

Well, another – perhaps the most pleasant – feature of the repair is that the master has the opportunity, albeit within a small range, to reconfigure the characteristics of the shock absorber. This will be clearer with an example, fortunately there was one: a Kia Sportage was brought from a Middle Eastern country. In general, the car is like a car - but driving on the domestic road surface was comparable to jumping on a jackhammer. The owner got tired of it, and he turned to the workshop. For the master, this was the first experience of “opening” a completely new shock absorber, which had traveled 300 kilometers. The owner was very pleased with the result of the reconfiguration - due to the fact that he received a normal suspension for relatively little money.

In addition, if you wish, the shock absorber can be made adjustable by installing a cover with a spool. By increasing or decreasing gas pressure, you can slightly interfere with the characteristics of compression and rebound stiffness.

After renovation

After completing all repair operations, the shock absorber is assembled together. Having already disassembled a non-separable part, there is no point in making it non-separable again. What do you do with “opened” shock absorbers? They cut off part of the body and weld on a new one, the same size, but with a thicker wall so that threading can be made.

To ensure the reliability of the seam, use a special cutting and welding stand. Assembly is completed by installing and tightening the fastening nut.

Now the shock absorber with working fluid must be filled with gas to create a gas boost. If the shock absorber is double-tube, then a special adapter is used for this, installed above the rod and slightly expanding the lip of the oil seal.

If the design is single-pipe, then a cover with a spool is made, which is installed in the housing.

It is worth mentioning that there were designs that made it possible to fill a single-pipe without interfering with the structure or compromising its integrity. We are talking, for example, about the shock absorbers of the old Audi A8. Single-pipe, collapsible - happiness for a repairman... But they too have sunk into oblivion.

Having assembled the shock absorber completely and filled it with gas, it is again sent to the stand to calm the conscience of the master who repaired it. If everything is in order with the schedule, the shock absorber goes to the warehouse and then to the owner. If desired, the body can be painted in the “original” black color.

Resource

The most exciting question that bothered us at the beginning of the conversation concerned the service life of the shock absorber after its repair. From smart books, for example, we know that after a “overhaul” the life of an internal combustion engine is restored to no more than 70–80% of the new one. In the case of shock absorbers, the master assured that the service life is restored by almost 100%. Some manufacturers provide a one-year guarantee on new shock absorbers without mileage limitation - well, not all, but a certain part of the workshops can confidently give the same guarantee after repair. But it’s up to you to decide whether to repair them or change them.

Afterword

It’s an interesting thing: they say that if a car has been driven on good roads, like European ones, it means that its shock absorbers are initially in good order and can last for more than one thousand kilometers – not like over our potholes. But in practice, it turns out that they are replaced at approximately the same frequency, regardless of geography - just the nature of wear is different. Due to large strokes and extreme points, bushings and oil seals break. They have small strokes, but this only means that the rod will be subject to increased load in a very small range, which will “wipe” it. So a good road is not always the key to “immortal” shock absorbers.

Special thanks for the preparation of the material and consultations to the company Master Service (MSG), contact details +7 (800) 350-99-23 (Moscow), +380 (57) 738-33-08 (Kharkov).

Survey

Have you encountered problems with shock absorbers?

Your voice

Total votes:

DIY shock absorber repair

Almost every car enthusiast can repair shock absorber struts if he is not afraid of dirty work under the car. At the same time, you will also be able to save a good amount of money. After all, as soon as dull knocks begin to appear in the car’s suspension when driving over holes and potholes, then it’s time to get serious about repairing the shock absorbers.

Each automaker uses its own design developments to dampen vibrations when the vehicle is moving. But shock absorbers are present in almost all modern passenger cars.

The lifespan of a shock absorber is determined by the driving style of the car and the quality of the roads. For example, many 10-year-old cars from Europe with mileage of more than 200 thousand km come to us with “original” shock absorbers. And in our road conditions, a rare suspension part survives up to 100 thousand km.

At the end of this article you will find a visual video tutorial on how to repair the shock absorber strut of a VAZ 2110 car.

Below we will talk about what the main malfunctions of shock absorbers are, and how you can fix them yourself, if you have certain skills, tools and the desire to do this.

How to extend the life of shock absorbers

To extend the life of the struts, regularly carry out anti-corrosion treatment on the underbody of the car.

When driving in the cold season, try not to make sudden actions for some time after the start (about 5-10 minutes). Rapid acceleration and sharp braking when the oil in the shock absorber is not warm will greatly reduce the service life of the shock absorber struts.

Proper operation, as well as timely inspection of the car will guarantee that the car racks will last a very long time.

To begin with, if you are unsure of the normal operation of the shock absorbers of your car, you need to diagnose them. You've probably seen more than once how a car owner, with a smart and thoughtful look, pushes the hood of his car and carefully watches how his car sways.

If the shock absorbers work well, he is satisfied. But not many people understand that only if the shock absorber is “dead” forever will the body sway. And if “reanimation” is still possible, this will not happen.

The driver's ears and eyes are the primary diagnostic tools. If there are oil leaks or knocking noises, and you are sure that the suspension is in full working order, your shock absorber needs attention. There is another type of diagnostics, but this is only for an experienced driver who knows his car perfectly. The same turn must be passed several times at a certain speed. The car skidded while turning - the shock absorber requires attention. Or you can do it even simpler - go to a service station, pay some money and carry out diagnostics on a vibration stand.

You are firmly convinced that your shock absorber requires repair, which means we will repair it. But first, let's define what exactly we are dealing with.

Shock absorbers come in different types. Here are the main types:

• double-pipe hydraulic oil shock absorbers;

• gas-oil, or combined;

• adjustable absorbers (there are electronic, magnetic and hydraulic-mechanical adjustments);

Repair of different types of shock absorbers, of course, is completely different. And the very first thing you should do is read the car’s Owner’s Manual and find out the type of shock absorber. To the great regret of many car owners, today almost 90% of modern cars have non-separable shock absorbers. But there is no need to rush to the auto store for a new one; there is another solution - restoring shock absorbers.

We will talk about this in more detail later. Now let’s look at the process of restoring absorbers or, simply put, repairing shock absorber struts with your own hands, the most common types.

Main malfunctions of shock absorber struts

The main malfunctions of shock absorber struts are:

- Free movement of the rod in the cylinder,

- The presence of knocking noises when compressed or stretched,

- Oil leaks.

It is quite easy to detect all these problems without even removing the shock absorbers from the car.

To determine the performance of the shock absorbers, it is necessary to press firmly with your entire body weight several times on the fender or bumper of the car directly above each shock absorber in turn. If, after the car stops rocking, further vertical vibrations occur, then the shock absorber is faulty. Typically, a serviceable unit stops swinging immediately after the impact on it ceases.

Knocks in the shock absorber strut are detected in the same way. To do this, you should rest your palm on the top attachment point of the stand and swing it up and down with sharp rhythmic pressures. Impacts will be clearly felt upon contact.

To detect leaks in shock absorbers, just look between the wheel and the arch of the car. Turning the wheel to one side will help improve visibility. It is even more convenient for these purposes to use an inspection hole, overpass or lift.

Read more about methods for checking the serviceability of car shock absorbers in our article on how to check shock absorbers on a car.

Major damage to shock absorber struts

Racks are subject to various breakdowns, among the most common:

- Shock absorber depressurization.

- Damaged rod

- Deformation and wear of the boot and sealing ring.

- Wear of the silent block.

- Broken threaded connection.

- Presence of air in the cylinder

- Eyelet tear

To determine the malfunction, it is necessary to carefully inspect all parts. If oil stains and drips appear, then the shock absorber has undergone depressurization and can no longer cope with its functions - it is preferable to replace it. To better see the shock absorber struts, turn the wheels to the side. You can use a viewing hole or overpass.

To avoid climbing under the car, swing it from the desired side. After rocking, pay attention to the behavior of the car. If it makes more than 2 oscillatory movements before returning to its original position, then the shock absorbers are faulty. And if the car suddenly stops while rocking, then most likely the shock absorber is jammed.

If you hear a knocking sound from the rack, then most likely there is mechanical damage. In this case, it is necessary to carry out diagnostics at a service center on a special stand - this is how the force of each shock absorber is determined.

Removing shock absorbers

Repair of shock absorber struts begins with their dismantling. Removing shock absorbers usually does not cause problems. Unless the fasteners force the motorist to swear loudly and resort to drastic measures (“grinder” or gas “cutter”).

Here are a few points to consider when removing shock absorbers for subsequent repair or replacement:

- Often, the part of the car where the shock absorber is removed has to be lifted using a jack. Be sure to install stops under the threshold or bottom so that the car does not accidentally move during repairs.

- For better access to the lower fastening elements of the shock absorber, you need to remove the corresponding wheel.

- The upper mounting points for the struts in most cars are usually located under the hood and in the trunk.

In front-wheel drive vehicles, removing the strut will require more work. The complexity of the work depends on the type of shock absorber strut.

- Collapsible shock absorber designs are more difficult to dismantle the strut. To remove such a unit, you will have to unscrew the hub nut and remove the strut along with the hub.

- Non-separable shock absorbers have a simpler strut design. At the lowest point, the shock absorber is inserted into the cup, where it is secured with one or two bolts.

The upper mount for both types of struts is usually located under the hood (for front shock absorbers) and in the trunk (for rear shock absorbers). Here you only need to tighten two nuts.

Shock absorber struts on front-wheel drive vehicles are usually removed along with the springs.

Recovery

First, the dismantled device must be washed and then carefully inspected. If there are cracks or jams, repairing the shock absorber makes no sense: it is better to scrap it and buy a new one. The whole body requires further checking: pull the rod up and push it down - if there is play or jamming, replace the spare part. There are two types of shock absorbers, disassembling each of them has its own characteristics:

- double-pipe: pull out the rod completely to gain access to the fastening nut, which can be unscrewed with a special wrench;

- single-pipe: there is a protective cap at the top, which must be knocked down, and then unscrew the fixing nut to remove the rod together with the cylinder or cartridge.

Peculiarities

If the shock absorber is oil, you need to drain the oil from the cylinder by pressing on the valve spring. Then knock down the bushing, remove the rod with the piston, remove the valve from the other side of the cylinder. If the device is gas or has a replaceable cartridge, simply unscrew the fixing nut and install a new one.

Recovery methods

There are two ways: the first involves completely replacing the rod along with the cylinder with a new cartridge, the second involves replacing the parts of the device. It’s worth going into more detail here, because in the first case, the financial costs will be 5-10 times higher (it all depends on the car model). To independently restore the shock absorber with complete disassembly, you must purchase a repair kit.

If you have a foreign car manufactured after 2000, then it is very difficult to find such a set - it is easier to buy a new shock absorber.

To disassemble the product, unscrew the fastening nut and pull out the piston. Further:

- replace the compression valve, which is installed by pressing in by hand;

- install the piston and guide bushing;

- fill in the oil (you can use the old one if it is clean and transparent) - hydraulic fluid for automatic transmission, power steering or the Russian product AZh-12T.

Liquids produced in the West do not have any advantages over materials from the Russian Federation.

Press the rod into the cylinder and fill in 200-250 ml of liquid. Next, slowly insert the cylinder while simultaneously pulling out the rod so that the oil penetrates into the cavity and does not leak out. When the cylinder is fully inserted, pull the rod out and put it back in several times to allow the oil to completely fill the body. Then tighten the nut and pump the shock absorber again 4-5 times.

We recommend: We treat the plastic interior from scratches. Proven methods!

On a two-pipe device, all of the above restoration procedures must be carried out by putting the upper pipe on the lower one. As you do this, push it down while holding the rod in place. Next you need to bleed the device and tighten the nut.

If the shock absorbers were restored on a MacPherson type front suspension, then the camber and toe will have to be adjusted.

Features of installing shock absorbers on the VAZ2108-15

All operations to restore performance are no different from those described above. But before installation, the shock absorbers must be well pumped (this also applies to new products), otherwise they will not work fully. How to do it?

Bleeding the oil shock absorber

- place the device with the rod down and press the rod until it stops;

- hold the shock absorber in this position for a couple of seconds;

- Without releasing the rod, turn the part over and hold it in a compressed position for 5-6 seconds so that the air comes out;

- extend the rod completely, pause for 2-3 seconds and repeat the operation 5-6 times.

Bleeding the gas shock absorber

- turn the product upside down;

- slowly press the rod in and leave the part in this position for 5-6 seconds;

- turn the product over and hold for 5-6 seconds;

- extend the rod all the way;

- turn the shock absorber over and repeat the procedure 3-4 times.

DIY shock absorber repair

To determine the cause of a malfunction of the shock absorber strut on a front-wheel drive vehicle, most likely it will have to be completely disassembled. For more information on disassembling, reassembling and repairing the shock absorber, see the video tutorial at the end of this article.

An indispensable device for disassembling the shock absorber will be zip ties. This device for compressing springs is a powerful pin, on one end of which a left-hand thread is cut, and on the other, a right-hand thread. There is a hex key at the end of the stud. Clamps (with left and right threads, respectively) are screwed onto the ends of the stud, which will securely cling to the coils of the shock absorber spring when it is compressed.

- To compress the spring, two such tension devices are required. They are installed on opposite sides of the spring. Tightening is done by alternating rotation of the pins.

- When the spring is compressed enough that it can “move” freely in the strut, you can unscrew the top nut, remove the support bearing with the rubber bumper, and carefully remove the spring.

After a careful inspection, it may turn out that the cause of the knocking noise lies in a worn rubber bumper. A tight rotation with a squeak is observed when the support bearing fails.

- The collapsible shock absorber is unscrewed from the body using a special key. Some motorists have successfully completed this job using a hammer and a suitable steel bar.

- After replacing defective parts, reassemble the shock absorber strut in the reverse order.

- When the top nut is securely tightened, the spring must be slowly released to working condition. It is important that the first turns fall into their sockets, which prevent it from moving.

After this, all that remains is to install the shock absorber strut in place, tighten the wheel and lower the car.

Repair of shock absorber struts should be carried out without haste and in compliance with safety regulations. It is necessary to compress and release the springs especially carefully and carefully. Then the repair will take place without damage to the vehicle or human injury. And after repairing the shock absorber struts, the car will drive smoothly and quietly.