Stages of work

Engine overhaul can be divided into several stages, preparatory, and the stage of repair of the cylinder block and cylinder head. The stage of assembly, checking the engine operation and diagnosing it.

The preparatory stage includes:

- engine removal, removal, disassembly, cleaning and washing of components, assemblies and parts;

- determining the degree of wear of parts;

- checking the condition of the engine crankshaft, determining the degree of its wear;

- checking the transverse and longitudinal diameters of the engine cylinders, measuring them to determine the degree of wear;

- checking cylinders for taper and ellipse;

- detection of cracks and damage in parts bodies;

- measuring all technological gaps for compliance with regulations and making the necessary adjustments.

Engine overhaul – cylinder block:

- boring for the next repair size of the cylinder block;

- restoration of crankshaft spaces in the cylinder block;

- cleaning the oil system channels;

- repair of the crankshaft, which consists of grinding the main and connecting rod journals to the exact repair dimensions.

Engine overhaul – cylinder head:

- valve replacement;

- valve seats that guide their bushings are changed;

- valve seat chamfers are restored if necessary;

- carrying out welding work followed by grinding;

- replacing the camshaft, compensators (if necessary), replacing rockers;

- cleaning of all channels, oil system, cooling system, etc.

- replacing old valve seals with new ones.

Engine assembly.

To facilitate engine assembly, it is assembled on a special workbench that rotates 360 degrees.

During the engine assembly process, the main thing that people pay attention to is the compliance of all clearances with the standard ones, as well as the correct installation of connecting rods, pistons, pins, installation and correct adjustment of belt tension and thermal clearances. Using torque wrenches correctly, in accordance with technical regulations, tighten engine parts

Using torque wrenches correctly, in accordance with technical regulations, engine parts are tightened.

The final stage.

At the final stage, the so-called engine running-in is performed at idle speed. Subsequently, the engine is turned off, and a visual inspection takes place for possible leaks and malfunctions.

Subsequently, using special instruments and equipment, diagnostics of the operation of all engine systems is carried out. Based on the diagnostic results, precise adjustment of all engine systems is carried out.

As you can see, engine overhaul is a complex type of repair that is practically impossible to perform in a garage environment.

Video.

Stages of engine repair

Rebuilding the engine involves performing the following actions:

- Removing the motor.

- Complete disassembly and removal of accumulated dirt by washing and cleaning.

- Identification of defective spare parts of the block that need to be replaced: inspection of the engine block for cracks, measurement of possible gaps formed, assessment of the condition of the crankshaft, identification of worn parts.

- Overhaul of the cylinder head.

- Restoration of the cylinder block.

- Assembly of the unit and installation on the car.

We recommend: What is a pencil for removing scratches on cars and how to use it?

Disassembly and dismantling of the engine

The process of removing the unit from the car may vary depending on the car model. Dismantling a carburetor engine is much simpler than an injection engine. There are fewer electronics that have to be removed first. Also, the disassembly process will be different for brands with front and rear wheel drive.

The preparatory stage preceding dismantling will be the removal of interfering mechanisms and unscrewing the retaining bolts. The removal of a heavy unit from the car body occurs using a special lift or winch. If there is no such device, then to reduce weight, all possible parts and spare parts of the engine are removed, and it is pulled out manually. This will require the help of several people.

Disassembly follows. The work should be done sequentially, carefully inspecting the parts for wear and placing them in order.

It is worth knowing that a VAZ engine can be disassembled in about 3 hours; disassembling a foreign-made engine takes more time: about 10 hours.

Washing engine parts

Washing is an important step that many people skip.

It is not right. Each detail has a specific meaning. If the spare parts are not washed and deposits are not removed, then the degree of wear can be incorrectly determined, which can cause rapid failure of the entire motor. You should also wash the block and cylinder head with special care to examine for possible cracks.

Diagnosis of damage and defects

Defects are identified visually and using measuring instruments. All spare parts are checked for wear, scratches, cracks and chips. Particular attention should be paid to the following details.

- The cylinder block and head are checked for integrity, special attention is paid to cracks and chips.

- The crankshaft is inspected and measured to check whether wear has appeared, and is also checked for alignment and bends.

- Parts of the connecting rod and crank mechanism: the general condition and the presence of play are determined.

- Gas distribution mechanism.

Cylinder head repair

Repairing this spare part is not too complicated, but many car owners turn to the service for help. If you decide to do the repairs yourself, then you will need to replace or repair the following parts.

- Camshafts.

- valves.

- Guide bushings.

- Valve stem seals.

If cracks are found on the block head, it will need to be replaced or polished. It is possible that there will be a specialist who can weld the damage with argon.

Cylinder block repair

After cleaning and washing the block, it is necessary to restore it, bringing it to a quality close to the factory one. It is necessary to polish the head seat to a mirror shine, eliminating any existing holes and chips. For this, a surface grinder or milling machine is used. Depending on the degree of damage, the cut thickness can vary from 0.05 mm to 1 mm. If there are too deep cavities, grinding may consist of several stages.

Crankshaft repair and restoration

A car's crankshaft can be repaired and bored a certain number of times, depending on the model. For example, the crankshaft on a VAZ needs to be repaired 4 times and is bored to fit different sizes of liners with their subsequent enlargement. Having dismantled the spare part, the first thing you need to check is whether it can be restored. If yes, then you can buy larger earbuds and get started.

The second thing you need to pay attention to is the crankshaft journals. If, upon inspection, wavy grooves and risks are found on them, then you need to get rid of them. This is done by grinding on a special machine. Remember the main thing! Replacing liners without grinding is unacceptable. Repairing a car engine with your own hands will be in vain, the result will be zero.

Assembly and installation of internal combustion engines

Having prepared the head, cylinder block and crankshaft, we proceed to assembling the engine. For engine capitalization, you may need to purchase the following spare parts from a car store:

- Valves, guide bushings and seats for them;

- Connecting rod and main bearings;

- Connecting rod pins and bushings for them;

- Piston rings;

- Repair kit for pump;

- Oil filter;

- Gasket set.

Engine assembly occurs in the following order:

- Installation of liners and crankshaft shrinkage.

- Installation of pistons and connecting rods.

- Fixing the crankshaft with yokes.

- Installing the gasket.

- Installation of the motor cover.

- Mounting the pump and oil pump.

- Installing the crankshaft pulley.

- Installing the head.

- Fastening the pan and crankcase.

When installing the liners and piston group, lubricate the parts and cylinder walls with a special lubricant. Its further performance and service life depend on the high-quality assembly of the internal combustion engine. It is advisable that it be carried out by a person who knows the principles of operation and the design of the motor.

We install the unit in its original place using a lifting device. After successful installation, it is fastened, then the removed equipment and electrics are installed in reverse order. Before starting the engine, it is additionally recommended to center the clutch and test the engine.

Running in the engine

Having capitalized the engine, you definitely need to break it in properly.

Otherwise, the motor will quickly fail without using up even half its service life. During the break-in period, parts are ground in, and excessive load will harm them. According to existing standards, a car needs to be run in for about 2-3 thousand km. In this case, the speed should not exceed 60 km/h.

Major renovation

There are two types of major repairs - planned and unplanned. With a mileage of more than two hundred thousand and the natural aging of the car, you should expect that sooner or later the engine will start to malfunction. An attentive owner, based on several indirect signs, is able to determine that it is time to prepare for a major overhaul. The first symptoms of a “sick” engine:

- Increased oil consumption, which indicates wear of the piston rings or valve guides.

- Characteristic blue exhaust.

- Sluggish acceleration, which indicates a decrease in compression in the cylinders.

- Significant drop in power and traction characteristics.

- Characteristic knocking noises in the cylinder block or cylinder head.

Scheduled repairs include replacing valve stem seals, grinding valves, adjusting the gap, replacing oil scraper and compression rings, as well as grooving the crankshaft and changing the main and connecting rod bearings. Such actions are advisable provided that there is hon on the walls and there is no exhaust. This is a gentle repair that costs less money and time and does not require replacement of large components.

It allows you to extend the life of the motor by several hundred thousand kilometers, depending on the operating conditions and the fluids used. In this case, there is no question of what is better: a major overhaul or a contract engine. Definitely just a renovation.

Unscheduled repairs are usually required when the driver does not monitor the condition of his car or delays paying the planned capital while continuing to drive the car. Reasons for failure:

- Poor quality oil and fuel.

- Untimely oil change.

- Water hammer (liquid in the combustion chamber)

- Engine overheating.

- Timing belt rupture.

Any of these reasons entails disassembling the engine, overhauling it and installing new parts. Often one of them starts the entire chain reaction and several spare parts gradually or immediately fail.

During a major overhaul, all consumables must also be replaced, such as connecting rod and main bearings, piston rings, and, if necessary, the cylinders themselves. This is done in order to avoid repeated parsing. You should also replace all spare parts that are in doubt.

In some cases, it may be necessary to bore the cylinder block, grind the crankshaft, or grind the valves. All this results in additional financial expenses. If we consider, on average, the cost of repairs and necessary spare parts is equal to the price of a contract engine including labor (sometimes several thousand more).

Another equally important point in this whole undertaking is to find a good specialist who will not screw up the purchased spare parts and the old engine, but will do everything as it should. At the same time, he should understand the quality of the ordered parts and, if possible, make a small discount (a dream).

If your hands grow out of place, then you can try to repair the motor yourself. Buying parts is not a problem now, especially since almost every city has its own trusted suppliers. Do-it-yourself engine overhaul also has several disadvantages:

- Additional equipment (winch, tools, torque wrench).

- Ordering spare parts. Entering the VIN number incorrectly can result in an inappropriate part appearing in the garage.

- Duration. Typically, repairs are carried out during free time and can take a long time.

- There will be no one to blame for poor quality repairs.

But there is one significant advantage - you don’t need to pay for the work, and this allows you to significantly save on major repairs. In addition, the car enthusiast knows exactly what he replaced, what part he installed, and how the work was done.

In general, if the capital is made with high quality, original spare parts are installed, everything is lubricated and adjusted, then the driver receives a new engine capable of running the same amount. At the same time, the car’s engine remains “native” and does not bring with it any additional “surprises”.

What's the result?

As you can see, maintaining all systems in good condition and timely maintenance using high-quality consumables and fuels and lubricants can significantly extend the service life of the power unit before major repairs. But that's not all. The engine operating mode deserves special attention. The degree of wear and tear depends on how the owner drives his car. An aggressive driving style and frequent maximum loads can reduce engine life by 40-50%. We are talking about intense acceleration with the crankshaft spinning up to maximum speed (cut-off), as well as prolonged driving at speeds close to maximum. The service life of the internal combustion engine is also significantly reduced when the driver heavily loads a cold engine without preheating, that is, before the unit reaches operating temperatures. Such actions can damage the engine by 40-50 thousand mileage.

In other words, pre-warming, a moderate driving style and knowledge of what speeds are best to drive at can extend the life of the engine to its full potential. Timely gear shifting on models with manual transmission makes it possible to avoid tight driving, which is very dangerous for the crankshaft and the entire engine.

Taking into account the above, for experienced and responsible drivers, the engine can go much further than the figure that the manufacturer itself defines as the average threshold before the first major overhaul. This is confirmed by many examples of the internal combustion engine of a modern foreign car with a service life of 200-250 thousand km. with proper maintenance and proper operation, it lasted up to 300-350 thousand kilometers or more.

Today we will tell you what an engine overhaul is and when it is necessary. What is included in the capital and what spare parts and tools are needed.

Overhaul of a car engine is a list of works associated with disassembling, troubleshooting the internal combustion engine, replacing individual elements and processing (honing, grinding, straightening, etc.) of some of its surfaces and parts in order to bring the characteristics of the engine to the values that a new unit has. Those. Metalworking operations are necessarily carried out under capital conditions. If you simply replace the rings, it will not be a major overhaul.

The material was prepared by specialists from the website Skrutit-speedometr.ru.

Running in the engine after a major overhaul

Running in an engine after a major overhaul is reminiscent of running in an engine in a new car. New parts installed in the engine require “grinding in”, when microscopic irregularities on the engine parts are smoothed out. A well-run-in engine significantly extends the life of the engine after a major overhaul compared to a non-run-in engine.

There are several options for running the engine.

- Cold running on the stand. This is the optimal running-in option, allowing you to control all processes in the car’s engine. With this option, all parts and components of the motor operate normally, but the engine itself is not started. To do this, the car engine is connected to the stand, oil and coolant are poured into it. The drive is provided by an electric motor, which is connected through a cardan shaft to the crankshaft of the car engine. The entire process is controlled by a computer program that sets the number of revolutions based on sensor readings.

- Hot running on the stand is also carried out by service station specialists. It is carried out in two modes: without load and with load. During hot running, the car engine starts. In the first mode, the engine first runs at low speeds, starting from 1000 RPM. Gradually, the speed increases, the last stage is carried out at the maximum possible engine speed. At the second stage, a run-in with a load is carried out, the loader being the electric motor of the stand. The engine is loaded with full fuel supply. The speed at the beginning of running under load is 1200 RPM, then the number of revolutions increases.

- Natural running-in of the engine. In this option, the car owner independently runs in the engine while operating the car.

When running in on your own, you must carefully follow the recommendations of specialists and under no circumstances put a full load on the engine. The first start of the engine after a major overhaul is the most crucial moment during natural running-in. New engine oil is poured into the engine up to the top bar of the dipstick.

Before starting, it is necessary to fully charge the battery so that it can make the first turn of the crankshaft. On carbureted vehicles, you must pump fuel manually. After starting the engine, it is necessary to monitor the oil level in the engine. If the low oil pressure light does not go out after a few seconds, you should immediately turn off the engine. The engine warms up to a level of about 90 °C. During the heating process, you again need to control the oil pressure; its level should be from 0.4 to 0.8 kg/cm2. After heating to the specified values, it is necessary to turn off the engine. As soon as the engine cools down to a temperature of 30–40 °C, the engine starts again. In total, 1–2 dozen such cycles need to be completed. Next, the engine is run in at higher speeds - 1000 RPM, 1500 RPM and 2000 RPM. In each mode, the engine runs for 3–5 minutes

In the future, you can carefully start moving. First 2–3 thousand

km, the maximum speed of the car should not exceed 60–70 km/h; after reaching this milestone, you need to undergo maintenance, where the engine oil should be replaced, since wear products accumulate in it. Valve clearances, idle speed and timing chain tension are also adjusted. After maintenance, the maximum speed can be increased to 90 km/h.

The final grinding in of engine parts and components occurs at around 10 thousand kilometers after a major overhaul. After this, the engine is ready for full recommended loads.

Source

By what factors can you find out about the upcoming major overhaul of the internal combustion engine?

Initially, the following subjective factors appear:

- drop in engine power;

- slow acceleration;

- hard to start;

- loss of agility during acceleration;

- The car doesn't feel like it drives as well as before.

These factors, although they do not indicate wear and tear on engine parts and components, are reasons that, when they appear, are worth thinking about checking.

In addition to the listed subjective factors, there is one objective factor that clearly indicates that not everything is in order with the engine. We are talking about oil consumption. Any engine consumes a small amount of oil, but when its consumption reaches 300-600 ml per 1000 km, this is no longer normal.

How long does my Lada last without major repairs - an expert opinion

Practice shows that some VAZ engines do not even survive the warranty age and mileage. That is 3 years and 100,000 km. At the same time, there are many Lada owners who talk about mileages exceeding 250,000 km without major repairs. Both are true. Why is there such a big difference?

The service life of most imported motors, when used correctly, varies within +/- 20%. And the owners of modern Ladas, just like thirty years ago, can say about their car that they were lucky (or unlucky) with the engine. In this case, the initial resource of one VAZ engine may differ several times from the resource of another, similar one. But even a successfully assembled engine is not always the key to its long life. The resource can be reduced significantly by using low-quality operating fluids, consumables and spare parts.

The owner can decide to overhaul the engine in two cases:

- Emergency motor failure.

This is when the engine stalls, won't start, and may not turn over. - Engine performance has deteriorated.

The engine starts, but there are: huge oil consumption, smoking, decreased power, poor starting due to spark plugs covered with soot.

Do-it-yourself engine overhaul: is it worth it?

If you have never done this before, it is better not to take risks, but to entrust the engine overhaul to professionals. After all, this procedure is not easy. In addition, many works require complex equipment, which a priori cannot be in the garage. You also need access to manufacturer information with relevant specifications.

Remember that the procedure is not cheap. In some cases, you will have to pay a third of the cost of the car (or even more) to overhaul the engine. But if you entrust everything to a professional technician, you will get an almost new engine with a considerable resource.

How to check the operation of the motor after a major overhaul?

After assembling the internal combustion engine, it is run-in, which occupies an important place in the grinding in of new parts and the entire unit. It is not recommended to put a large load on the engine; sudden starts and jerks should be avoided until the mileage exceeds 2 thousand km

Break-in is carried out as after purchasing a new car, which means that the following rules are adhered to:

- warm up the engine before driving;

- smooth acceleration alternates with gradual braking;

- you need to drive at low speeds;

- Do not brake with the engine;

- It is not recommended to move at the same speed for a long time;

- Towing heavy loads is contraindicated.

What mileage should be before overhaul?

The resource for internal combustion engines in middle-class cars up to the “capital” range is approximately 200 thousand km. There are vehicles that manufacturers position as “million-dollar” vehicles, capable of covering up to 1 million km. However, modern engines practically do not have such parameters, especially in domestically manufactured cars.

The VAZ plant for model 2114 set an average mileage of 150 thousand km, which is comparable to the performance of most Russian cars. This parameter can be extended if all current problems are resolved in a timely manner. Popular foreign cars have a range of 200-300 thousand km before engine overhaul.

Recommendations for proper engine operation

Doing an engine overhaul with your own hands is only partially possible. Because we need machines, the cylinder head and cylinder head have to be sent for boring and grinding. You can do the rest of the work yourself. The simpler the car, the easier it is to repair. Making capital on VAZ, GAZ, UAZ, NIVA cars yourself is not difficult.

To increase the engine life of any car you need:

- buy high-quality spare parts and consumables;

- undergo maintenance in a timely manner;

- the most important thing is to change the engine oil every 6-7 thousand kilometers;

- A neat, smooth ride without jerking also increases the service life of the car.

After a major overhaul of the engine, the oil must be changed at the following intervals:

- After 500 km of travel - the first replacement.

- After 1000 km of travel - the second replacement.

- After 1500 km of travel - the third oil change.

- After 2000 km of travel - the fourth replacement and, further according to the schedule, every 10-15 t.km.

The video shows some types of internal combustion engine overhaul work.

In what situations can engine overhaul be delayed?

There are situations when major engine repairs in Moscow can be postponed for some time. When to do this:

- Advice, recommendations from people who do not have professional knowledge, as well as divorce in a low-quality and unprofessional service station;

- Engine problems can be caused by poor performance of the power system, fuel system, exhaust system;

- The internal combustion engine “eats up” the oil, but this has not reached critical levels.

Therefore, before you finally send your engine for major repairs, make sure that the poor performance is not related to any other vehicle systems. Otherwise, the repair will be in vain.

Engine overhaul: when to do it

First of all, the engine mileage before major repairs may differ for a variety of reasons on two absolutely identical models. The fact is that the engine life is greatly influenced by the quality of engine oil and fuel, driving style, timely maintenance, etc.

It is for this reason that the technical condition of an engine, for example, with a mileage of 200 thousand km, may turn out to be noticeably better than that of exactly the same unit, which has covered only 120-130 thousand km. It turns out that determining the condition of the internal combustion engine only by mileage is not always correct.

In practice, it is not always necessary to start from the resource that the manufacturer himself has laid down. For example, if the manual says that the manufacturer determines the planned resource at a conditional mark of 300 thousand km, then it is clear that even a normally operating engine with a mileage of 250-270 thousand km. will need repairs earlier than a serviceable unit with a mileage of about 150 thousand.

Although this information is more for reference, since responsible owners often had motors that lasted 350-400 thousand km when the stated 300 thousand. Quite the opposite is the case with motors that are not serviced in a timely manner and are subject to difficult operating conditions. With a declared conditional life of 300 thousand, such engines often “die” already at 100-150 thousand.

It becomes clear that the need for overhaul is determined not by mileage, but by the general technical condition of the engine. If we are talking about an internal combustion engine, the declared resource of which is the same 300 thousand km, while the odometer shows only 120-150 thousand km

honest mileage, then you should pay attention to the real condition of the power unit, and not look at the mileage figure and compare this indicator with the estimated resource of the unit

Signs of an imminent engine overhaul

To determine the condition of the engine, such a motor needs diagnostics. Diagnostics can be both in-depth and superficial. Moreover, even based on the results of a preliminary assessment, it can be determined that the power unit will need to be rebuilt or overhauled very soon or even now.

First of all, serious problems are indicated by knocking while the engine is running, both “cold” and “hot”. Typically, knocking noises indicate worn crankshaft bearings and journals, problems with the pistons, etc.

In the case when such knocking noises are clearly audible without the use of additional devices (phonendoscope), and the oil pressure lamp is on or blinking (reduced pressure in the lubrication system), then the engine requires urgent repair.

Increased engine oil consumption, as well as blue smoke from the exhaust pipe, in many cases indicates problems with the CPG (wear of cylinders, pistons, piston rings, etc.). Note that the engine can “eat” oil for various reasons, but most often it is critical wear of the CPG elements on used engines that leads to excessive consumption of lubricant and oil exhaust.

The decision that it is time to disassemble the engine (do a major overhaul or overhaul) can be made if, simultaneously with increased oil consumption, a decrease in compression across the cylinders is also noted, and insufficient oil pressure is noted, especially at low speeds.

The only thing you can decide whether it will be possible to limit yourself to only a partial overhaul and not a “overhaul” of the entire engine is if the compression has dropped due to burnout of the valves, and oil consumption has arisen due to problems with the valve stem seals or stuck piston rings. In any case, the unit must first be disassembled and the engine troubleshooted.

When your engine is seriously ill

I once had to personally observe how an engine literally died. No, the car was moving, but it was doing it with great difficulty. At the same time, my friend claimed that everything was fine, this was the usual behavior of his car. But I somehow doubted that the engine on a relatively new Audi should work exactly like that.

My suspicions were confirmed a few days later, when a friend took the car to a service station, and the result of the check was an unpleasant verdict - major repairs or a landfill. By the way, my advice to you. Living in Samara, Moscow, St. Petersburg or any other city and being the owner of a car, make useful acquaintances with car service workers. This will allow you to receive services at a high level, and for the service station you will be a regular and therefore profitable client. It is better to spend more money on trusted specialists than to try to save money by doing repairs in dubious garages.

So that you, my dear friends, do not bring the car to its limit, I have prepared a list of the main symptoms indicating the approaching end of the life of your power unit.

If you notice the signs below, know that you urgently need to send your car to a good car service center and have the engine repaired:

- Soot appears on the spark plugs every now and then, although you regularly clean it or change the spark plugs;

- oil is consumed with activity close to fuel consumption;

- Blue or bluish smoke comes out of the exhaust pipe;

- The engine's appetite increases significantly; you have to stop by the gas station more often;

- low compression in cylinders;

- the car loses power at least 15%

- a lot of crankcase gases are formed;

- knocking noises are heard when the power unit is operating;

- the lubrication system experiences a shortage of pressure;

- the engine constantly overheats, the temperature sensors go off scale;

- the engine is unstable in different modes, etc.

We recommend: Do-it-yourself repair of the starter retractor relay

Just keep in mind that the end of the engine’s life and the need for major repairs is indicated by a set of symptoms presented. If symptoms appear separately, this may indicate a malfunction of individual components or even ordinary consumables. So if you have blue smoke coming from your rear tires, don't panic.

Stages of overhaul

If you watch various videos about major repairs, and also study the instructions, then all the work can be divided into several stages.

- Disassembly and cleaning. Without disassembling and cleaning the engine, it is impossible to objectively say where there are problems, which components are out of order, what needs to be changed, and where repairs can be done. A full check of literally every element forms the final cost of capital. In addition to purchasing spare parts, you also have to pay for the services of the masters themselves. It is not uncommon for the amounts to be comparable.

- Making decisions. Here the master, together with you (if your presence is necessary), decides what to do with this or that node. It's not always rational to change everything. Sometimes simple repairs can return the unit to its previous good condition.

- Working with the cylinder block. One of the main stages. When capitalizing, it is bored, honed or sleeved. At the same time, a complete replacement or restoration of the crankshaft may be required.

- Reassembly, testing and starting at idle speed. You should not begin reassembly until you are sure that the work was done correctly. After all, then you will have to disassemble and redo everything again. The assembly must be approached very responsibly. When the engine is assembled, basic adjustments, adjustments and further running-in are carried out.

Post-capital run-in

Many people forget about such a concept as running-in, which must be carried out after completing a major engine overhaul.

If you follow all the rules and carry out the repairs professionally, then after restoration the engine can receive a resource no less than its original safety margin provided by the manufacturer.

In fact, the break-in is carried out according to the same rules that must be followed after purchasing a new car from the showroom:

- Before driving, you need to warm up the engine briefly;

- gradual acceleration is replaced by smooth braking;

- You can drive at low speeds;

- Driving in high gear is prohibited;

- It is strictly not recommended to brake with the engine;

- You cannot drive for a long time at the same speed and speed;

- trailers, towing and transportation of heavy loads is contraindicated.

And you should do this for the next 1 thousand kilometers. This is the minimum value. Although experts say that optimal performance after running-in is achieved after approximately 5-10 thousand kilometers. Increase the load on the engine gradually so that you do not have to contact the car service again. Already by 30 thousand kilometers the car can be operated in the manner familiar to you, hitch trailers, accelerate to high speeds, etc. But is it worth doing this?!

Don't forget to change lubricants. The first replacement is made approximately 1000 kilometers from the start of the run-in, and then after 5 thousand. Another mandatory replacement is carried out after approximately 6-8 thousand km. All subsequent activities are carried out at the usual intervals, as before the major overhaul.

What spare parts are needed

Consider the list of spare parts for major repairs of the power unit:

Piston group kit, it includes pistons, piston rings, piston pin. If the block is sleeved or such a need arises, then sleeves are purchased accordingly. When purchasing a piston group, there is no need to rush; you must first take the block to where you are going to sharpen it, and only after measuring the master will tell you what type of repair the piston needs to be purchased. It's a matter of desire; if you want, you can purchase pistons with recesses, especially useful if you are experimenting with split gears, etc. And the chain, despite its reliability, can break once every 20 years and then the meeting of the pistons with the valves is inevitable. Main and connecting rod bearings are purchased after the crankshaft has been ground. After grinding the crankshaft, the master will tell you which bearings you need to buy - 0.25, 0.50, 0.75, 1. This depends on the degree of wear of the crankshaft. It is better to take original earbuds. Oil pump. This matter is quite controversial, but I prefer to change it when conducting capital

Many people say that it can last for a very long time - I don’t take into account such stories, do it like that. Camshaft

I also recommend replacing it, but if finances are really bad, you can postpone replacing it, but this is not very advisable. Although if the camshaft is in good condition, you can leave it. The intermediate shaft (drive shaft of auxiliary units, pig) is the shaft that rotates the distributor and the oil pump and is driven by a motor chain. This shaft greatly affects the pressure in the lubrication system - if the bushings are heavily worn, the oil pressure drops significantly. When overhauling an engine, the bushings must be replaced, processed with reamers, and the shaft is also either ground or replaced with a new one. There is also an intermediate shaft on ball bearings; this, in addition to increasing the service life of the industrial shaft, also allows you to increase the pressure in the lubrication system. From all this, it is necessary to take away that at the time of sending the block for grooving, you need to purchase a new one or take with you an old washer so that you can replace the bushings and grind the shaft (if you leave the old one), at least this is the case with us. If the cylinder head is also being repaired, then it is necessary to purchase valves, valve seals, and springs (if the old ones do not hold the force). I also recommend replacing the entire motor chain tensioning system, as well as the motor chain itself, this includes: crankshaft, camshaft, shaft sprockets, motor chain, motor chain tensioner shoe, motor chain tensioner, motor chain damper. Beware of fakes, there have been cases when the motor chain tensioner shoe was made of non-oil resistant rubber and it collapsed quite quickly. I try to install a plastic damper, since even if it breaks, it may not harm the engine as much as a rubber-metal one. The crankshaft seals, rear and front, must be replaced. You also need to purchase a set of gaskets, you can buy all paper gaskets separately, and buy them separately for the pan, valve cover and under the cylinder head. Also check the bearing, which includes the gearbox input shaft, at the end of the crankshaft. If there is play in the bearing, it must be replaced. If the engine knocks or the connecting rod bearing turns, then the connecting rod must be replaced. Also, do not forget about all the consumables - oil, filter, coolant.

Source

What spare parts are purchased?

It is impossible to say for sure what parts will be needed during an engine overhaul. It all depends on the inspection of worn-out engine parts, so the price of the overhaul is not exactly known before it begins. Naturally, new “consumables” will be needed: crankshaft oil seals, distributor oil seal, oil filter, air filter. Also, most likely, oil seals, pan gaskets, cylinder head and valve cover will need to be replaced. You can purchase an oil pump, liners and seals, bearings, hydraulic compensators, oil scraper and compression rings in advance. You can also change the timing belt at the same time. Otherwise, the need to purchase new spare parts depends on the faults found and wear of parts. Ultimately, you may need many parts, including a new piston group and engine mounts. Therefore, the price of a major car repair, taking into account the cost of work, may even exceed the purchase of a used or new engine as a whole.

Recommendations for proper use of the car

The car owner needs to remember that most internal combustion engines are not designed for significant load and do not tolerate operation well at speeds of more than 5000 crankshaft rotations per minute. Under such significant loads, the engine is poorly lubricated and wear increases, which leads to serious malfunctions that can only be eliminated by major repairs.

Another common mistake when operating a car is the incorrect choice of gears on a manual transmission. The car owner allows the engine to work at a stretch, and untimely switches to a lower or higher gear. As a result, problems arise both in the operation of the gearbox and gearbox, and the engine suffers from a lack of high-quality lubrication of moving elements, which is the main cause of serious engine breakdowns.

Late service is one of the most common reasons for critical breakdowns and the need for expensive major repairs. Many car owners rely on the recommendations of the car manufacturer, which require such work to be performed every 12-15 thousand kilometers, or they know about the need for more frequent service, but at the same time save on car maintenance, rarely changing the oil in the car. All this leads to serious wear; dense deposits may appear in the oil channels, which will be impossible to get rid of with regular flushing. The engine needs to be opened, and the cost of such repairs will be extremely high.

The engine should not be allowed to idle for long periods of time. In modern engines that are equipped with turbocharging, this often leads to coking of the engine, after which it must be opened and cleaned of existing dense contaminants. Often, when idling for a long time, problems appear with the valve stem seals, the valve group suffers, which will subsequently require an expensive and complex restoration of the unit.

The car owner will need to monitor not only the timeliness of oil changes, but also regularly check the current amount of lubricant in the engine. If along the way a warning signal appears about a decrease in pressure in the lubrication system, then you should immediately turn off the car, check the oil level with the engine cooled down, top it up if necessary and, if possible, go for a service. Operating a vehicle with the low pressure warning light on is strictly prohibited.

If the car owner hears any extraneous sound in the lower or upper part of the engine, the car should be immediately turned off and then taken to a service center using a tow truck. These may be symptoms of a broken timing belt, and by turning off the engine in a timely manner, damage to the valves can be avoided. In such a case, the repair will not be ruinous for the car owner, who will only need to spend money on diagnostics and delivery of the car by tow truck.

Also during operation it is necessary to pay attention to the condition of the cooling system. It is on its correct operation that the engine temperature and the absence of serious damage to the unit will depend.

Often the water pump or thermostat fails, resulting in insufficient engine cooling. The engine overheats, which can lead to cracking of the cylinder head, and this is one of the most expensive engine elements, the replacement of which is equivalent to the cost of a major overhaul.

Owners of modern cars need to monitor the condition of the injection system, since when using low-quality gasoline, a thick coating appears on the injectors, which leads to problems with fuel combustion. The engine's lambda probe and expensive catalyst may fail; the internal coating of the cylinders also suffers, which quickly burns out, and subsequently such an engine must be replaced. Therefore, it is necessary not only to refuel with high-quality gasoline or diesel, but also to check the condition of the injection once a year, for which the car is taken for a comprehensive check to a specialized service station.

conclusions

Engine overhaul is always a significant expense for the car owner. Such expenses could be avoided by properly operating the car, regularly performing servicing, using high-quality gasoline, and not overloading the engine during operation. Such simple rules and recommendations will eliminate the occurrence of complex breakdowns, the engine will last as long as possible, without causing any trouble to the car owner.

Source

Tips and tricks

As already mentioned, the service life of an internal combustion engine before overhaul depends on many factors. In order to delay major engine repairs, it is necessary to pay special attention to the quality and correct selection of engine oil in relation to a specific type of engine, and promptly change the air, oil and fuel filters. Also, the power unit must be able to operate correctly, avoiding constant peak loads and tight driving. It is equally important to monitor the condition of the engine, quickly eliminate problems that arise, and carry out preventive procedures.

- The main reason for rapid engine failure is oil changes, which are not carried out according to regulations. Increasing the replacement interval, taking into account the low quality of fuel and dusty roads in the CIS, leads to the fact that the engine ultimately runs on lubricant that has oxidized and lost its properties. Dust and deposits also enter the unit through clogged filters. As a result, the associated rubbing parts begin to work under conditions of increased wear, the channels of the lubrication system become coked, the power system suffers, etc.

Stages of overhaul

Engine overhaul has several stages:

- Preparation. The engine is removed and all its components are cleaned. The degree of engine wear, the presence of cracks and any damage to the housing are also determined.

- Cylinder block repair. If necessary, boring is carried out using special equipment to the required size, and the places under the crankshaft are restored. The moment when the entire oil system should be cleaned is very important. Carrying out work to repair the crankshaft involves grinding the connecting rod and main journals to the required size.

- Working with the cylinder head. This includes complete replacement of existing valves. If the need arises, the seat chamfers are restored, the camshaft and compensators are replaced. All existing channels are cleaned.

When assembling the engine, you need to ensure that all gaps fully comply with standards and regulations. Torque wrenches should be used that can tighten the bolts to the required level.

What does engine overhaul include?

Such a serious repair of the power unit may include repair of the cylinder head or repair of the cylinder block itself. Sometimes crankshaft restoration also occurs. Engine overhaul can be complete or partial. To understand which one should be performed in your situation, it is necessary to conduct a thorough examination and diagnosis .

When contacting a service station, service center specialists will inspect the condition of the cylinders of your power unit. A mandatory measurement of the diameter of the crankshaft journals is also carried out and checked for play in the pistons and pins.

Timely computer diagnostics and maintenance of a gasoline engine will cost much less than its complete replacement

Sometimes an engine overhaul may only include replacing the piston rings, but if their wear is high, this will definitely not help.

Also, when the engine is overhauled, the cylinders are bored, the cylinder head is polished, and the crankshaft is restored.

What are the consequences of poor quality repairs:

Assembly and installation of internal combustion engines

Sequence of engine assembly after major overhaul:

- Install the half-shaft bearings and seat the crankshaft.

- Install connecting rods and piston group parts.

- Correctly install and tighten the yokes (arc-shaped crankshaft mounting).

- Install the gaskets correctly, check that the gasket does not cover the channel holes.

- Installation of covers covering the motor.

- Install the oil pump and water pump.

- Install the engine crankshaft pulley. We have already learned how to remove the crankshaft pulley.

- Install the cylinder head.

- Install the pan, crankcase.

- Collect small knots.

If you decide to make a capital with your own hands for the first time, after all the work before assembly, it is better to carry out the assembly with an experienced specialist in this matter. The lifespan of the entire car depends on the quality of the assembly.

The nuances of repair work

After contacting a service station, you don’t have to fold your arms and wait for the final result. Even then, there may be certain difficulties that must be dealt with. For example, the base cost for engine repairs includes boring the cylinder walls for a new piston. But depending on the degree of wear, the entire liner may need to be replaced. This will lead to the need to purchase a set of cylinders, after which they must be repressed. The same actions may occur when working with the crankshaft. The entire final result will be known after the engine is completely disassembled by specialists.

Important! You should never purchase spare parts prematurely, especially rings, pistons and bearings. The master who carries out the work will tell you all the information about them (labeling, number).

Additional equipment is used by specialists if, for example, the cylinder block is damaged. This will require processing using argon welding. In addition, grinding of the cylinder head may be required.

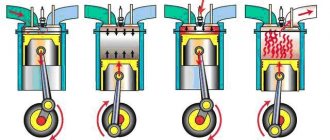

ICE device

Structurally, engines are divided taking into account the design and layout of the equipment on which they are installed. But the principles remain unchanged, the same for the design of any internal combustion engine.

The engine is equipped with the following structural components:

- cylinder block - the main part of the body with openings for the working chambers, a cooling jacket (for liquid-cooled engines), mounting holes for installing heads and crankcase, seats for the crankshaft and other structural elements;

- crank group - with a crankshaft to which connecting rods are attached, driving the pistons moving inside the cylinders; rotational inertia is maintained by the flywheel;

- gas distribution mechanism - a system that supplies a fuel-air mixture to the combustion chambers, with exhaust outlet; includes a camshaft, valves actuated by rocker arms, a belt or chain connected to the crankshaft;

- fuel system - supplies fuel to the combustion chambers after enrichment with air; includes a tank, a system of tubes for supplying supply fluid, a carburetor or injector (taking into account the features of the design device), nozzles, a pump, a filter element;

- lubrication system - with the supply of lubricant to the rubbing parts; includes an oil pump driven by the crankshaft, a system of pipes and cavities, a filter and a pan; a “dry” or “wet” sump device is provided;

- ignition system - to ignite the fuel-air mixture; used only on gasoline engines, since on diesel engines fuel and air ignite independently at a certain pressure;

- cooling system - can be air or liquid, to reduce the temperature of the motor housing to prevent wear and failure of elements;

- electrical system - the source of electricity necessary for the operation of the motor; includes battery, generator block, starter and wiring with sensors;

- exhaust system - to remove combustion products into the atmosphere, with additional purification of this mixture, reducing noise from engine operation, and a filter element.

The design of components is being improved as new materials and design solutions become available.

Taking into account the design features of various engine elements, it is important to consider the following points:

- cylinders can be made separately, pressed into the block body, or together with the body; monoblock systems do not provide for restoration, due to the fact that the sleeve cannot be replaced;

- engine housings are made of cast iron or aluminum alloys that are resistant to temperature changes and high pressure;

- the cylinder head is made together with it or as a separate part; with a separate version, it is possible to use different materials for the cylinder head and block;

- the operation of the crank mechanism can be balanced by balancer shafts located on the sides of the crankshaft and leveling the influence of inertial forces; as a result, vibration and noise are reduced and engine overloads are eliminated;

- the negative influence of springs during fast operation of an engine with a mechanical gas distribution mechanism is reduced due to the desmodromic engine control system - with a complex cam configuration;

- sticking of valves is eliminated by lightweight materials for the manufacture of these parts and spring elements, and a pneumatic drive;

- an alternative to the traditional timing belt design is the sleeve method developed by Knight; provides for the use of sliding sleeves instead of valves, operating silently and durable; this method was no longer used due to high consumption of lubricating fluid, with the development of an overhead valve design;

- early engine models were equipped not with starters, but with alternating current generators (magneto) driven by the crankshaft; this required cranking the engine shaft to start;

- the harmful effects on the environment of exhaust gases are partially reduced by a catalytic converter that oxidizes and chemically transforms the exhaust;

- electronic systems further improve engine performance; changing the valve timing changes the load on the engine, taking into account the gear engaged, reducing fuel consumption; cylinder deactivation regulates the volume of compression chambers, turning off unnecessary cylinders; adjusting the compression ratio changes the volume of the combustion chambers, taking into account the operating modes of the engine.

These and other features have structurally improved the performance of internal combustion engines.

When is repair needed?

Reasons why an internal combustion engine may be needed:

- Increased fuel and oil consumption. This occurs due to the appearance of excessive gaps, clogged piston rings, and decreased elasticity of oil scrapers.

- Decrease in vehicle power.

- The appearance of dark blue smoke from the exhaust pipe, which indicates mixing of oil with the fuel mixture.

- Constant light on oil pressure indicator.

- The engine knocks or makes other strange noises. This problem occurs due to wear of the crank mechanism.

- There is a decrease in compression. This indicates wear of the gaskets and piston rings.

- Formation of plaque and carbon deposits on spark plugs.

- Unreasonable overheating of the unit.

Mileage and guarantees when performing major repairs

When is an engine overhaul necessary? You will find accurate information only in the manual of your car. In general terms, we can answer this: for domestic cars, the mileage before carrying out the appropriate repair work is about 150 thousand kilometers, for European foreign cars - about 200 thousand, and for “Japanese” ones - 250 thousand.

As for the guarantee for work performed, the issue here is not only and not so much in the repair procedures, but in the quality of the spare parts used. In a nutshell, they must come with a guarantee . Unfortunately, in our time, buy an outright defect or a fake. Therefore, try to buy spare parts in stores that have the appropriate licenses, and preferably from trusted sellers. This will minimize the risks of purchasing low-quality goods and, accordingly, increase the likelihood of compliance with the warranty.

Many self-respecting workshops themselves offer their customers tested, original and certified spare parts.

Carrying out major repairs

Currently, almost all service stations that perform major engine repairs provide a guarantee on their work. As a rule, it is 20...40 thousand kilometers. Although if the engine is well repaired, then problems should not arise at significantly higher mileages. It must be remembered that after a major overhaul, the engine is most susceptible to new breakdowns due to the grinding in of new parts and assemblies. Therefore, during the first 10 thousand kilometers, try to drive in a gentle mode, without sudden jerks, accelerations and not at high engine speeds.

Due to the fact that during a major overhaul, craftsmen have to perform many complex procedures, the time spent on it can be significant. For example:

- If the required spare part is not available at the service station and you need to wait for it to be delivered from abroad, then the repair period may take 15...20 or more days (largely depends on the delivery time of the necessary part).

- If the necessary parts are available or there is no equipment to carry out repairs, the period may extend for 5...8 days.

- If there is a major repair at a service station, it usually takes 3…4 days, unless additional obstacles or difficulties arise.

Before work, it is advisable to discuss in advance with the craftsmen not only the cost of the repair, but also the timing of its completion. It’s better to conclude a formal contract that has legal force. This will save you from possible misunderstandings in the future.

Frequently replaced parts during engine repairs

Aggregate belt

Belt drive is one of the most important systems of a car, necessary for transmitting torque. Without it, the car simply won't move. Due to the forces of engagement or friction, forward movement occurs.

The belt drives the gas distribution, cooling and other mechanisms. Including auxiliary ones, but not of secondary importance. At the end of their service life, the belts must be replaced.

Three types are known:

- wedge;

- polycline;

- serrated.

If you monitor the oil level, do not allow extreme tension, and prevent cracks from appearing in time, the belt will last longer. However, if the timing belt is incorrectly selected, its storage conditions are unfavorable, or the tension method is incorrect, adjustments cannot be avoided.

Oil seals

Oil seals seal the gaps between the moving and stationary surfaces of the engine. If an oil leak is noticed, it means that the oil seal has dried out and has ceased to perform its general function. Upon closer inspection, you can see that it has shrunk in size, lost elasticity, and is worn out. Changing seals is not difficult, but requires skill. Sometimes this requires the help of a specialist, and sometimes the use of special devices.

Chain tensioner

If the chain is tensioned without sagging, the engine will run like a clock. Factory specifications may change due to:

- normal wear and tear;

- chain stretching;

- weakening of links;

- changes in the physical properties of the metal.

They will make themselves felt: with a specific clanging sound when starting up or at high speeds. It's bad if the grinding of metal is heard even at idle.

Engine chain

The belt chain is responsible for the coordinated operation of the entire automotive mechanism. Every 120 thousand mileage it is recommended to replace the chain. It is impossible to prepare for when it bursts: during a long tour, before leaving for work, at the moment of overcoming a mountain serpentine.

Replacing gaskets and caps

Just one burnt gasket - and the “iron horse” is motionless. These tiny elements only seem insignificant, but in fact they ensure efficient operation. They are responsible for tightness, cleanliness and dryness, maintaining high pressure inside the systems, and sealing the housing. Popular are both classic gaskets made of cardboard, fiber, balsa wood, and metal ones: steel, copper.

Repair of the block head (cylinder head of the internal combustion engine)

Although it is not difficult to carry out repair work on the cylinder head, for some reason many people try to send it to a service center.

Repair of the block head consists of the following types of work:

- We replace the camshaft (all that is in this engine).

- We change the suction and exhaust valves.

- We change the guide bushings.

- We change valve stem seals and seats.

- If there are cracks in the cylinder head, then we either change the head and grind it again, or weld these cracks with argon.

We recommend: The principle of operation of a supercharged engine. Mechanical supercharger. Part 5