Installation and repair of automatic transmission oil pump

The automatic transmission pump or pump wheel is located in the torque converter, so repairing it is complicated by the fact that you have to disassemble the entire box to get to the faulty part.

It acts as an oil supply to the turbine. A breakdown of the automatic transmission pump cannot be detected using computer diagnostics. This is done only visually. Therefore, cars with worn-out parts in the automatic transmission come across for repairs, when signs of a malfunction are already falling out, in the form of jolts, jerks, and emergency mode of the automatic transmission.

Write in the comments if you have ever had a pump wheel break down? How did you discover this?

Types of Oil Pumps

Before we start talking about automatic transmission pump malfunctions and how to fix them manually in the garage, let's look at the types of pump wheels. What pumps were installed on the automatic transmission of the same Merc or Foltz.

There are two types of oil pumps in the automatic transmission torque converter:

For example, automatic transmission model 722.6, which is often repaired at car repair shops, from the Mercedes Benz company has a bushing instead of a bearing. If the bushing is finished, then at the service station they try to replace the bushing with a pump with a bearing. Of course, a pump wheel with a bearing damages the shaft faster, but in this case the box can freely travel 70 thousand kilometers.

Volkswagen vehicles are equipped with gear-type pump wheels. This type is used on boxes of the 5HP19 model. The most serious problem is the automatic transmission pump bushing. She most often suffers from overheating on such machines.

On the Ford Focus, the pump is also a gear-rotor type device. It sucks oil fluid from the Ford automatic transmission pan and transfers it to the control valve block.

Automatic transmission oil pump device

Since there are three types of automatic transmission pumps, we will analyze each one separately.

These pumps are generally called vane pumps. The blades of a gear pump are teeth. They are oil pressure boosters.

The general structure of the pump wheel is as follows:

Attention! Overheating and old oil cause the teeth to wear out and the channels between the blades and the inner wall to increase. Therefore, the transmission fluid is no longer pumped, but circulates freely. Because of this, the pressure in the system drops and the automatic transmission goes into emergency mode.

What functions does the oil pump perform?

The oil pump functions as a pressure builder within the automatic transmission system. For example, cams are a kind of displacement devices with a fixed fluid flow. They release a certain part of the liquid after each revolution of the pump wheel.

The gear type also belongs to the type of displacement automatic transmission with a fixed oil flow rate. The functions that this type of pump performs in an automatic transmission are as follows:

Thanks to him, the entire automatic transmission system functions smoothly. If something breaks in the pump, the automatic transmission goes into emergency mode. If minor oil leaks and a decrease in pressure occur, then over time all parts of the machine fail.

Causes of oil pump failure

The reasons that can cause the oil pump to break down may be defective from the manufacturer and, most often, the negligence of the driver.

The oil pump of the automatic transmission torque converter fails for the following reasons:

As well as cold winter starts, sudden car starts - all this has a strong impact on the pump wheel hub and the wheel itself. Gradually it becomes unusable.

A pump wheel malfunction can manifest itself in a variety of ways. But usually there are several signs. We will consider them in the next block.

What are the types of automatic transmission malfunctions?

It is difficult to imagine the modern world without a car with an automatic transmission. Frequent traffic jams and traffic lights at every intersection made the automatic machine an indispensable thing for moving around cities. Perhaps this is why most significant concerns are gradually abandoning mechanics in favor of automatic gear shifting. This trend is gradually coming to our country, and with it the problems associated with automatic transmissions.

Any current design in a car has two operating principles: mechanical and electronic. Automatic transmission is no exception. Physical gear shifting is carried out by mechanisms, and algorithms are calculated by the software component. Therefore, all causes of failure are divided into two large groups:

- mechanical breakdowns. They occur in the hydraulics and physical drives of the gearbox;

- electronic system failures. Malfunctions of programs or electrical parts of the machine.

Let's look at each of these points separately.

Mechanical and hydraulic problems

Most often, due to mechanical failures, the following elements break:

- wear of the shafts or gears of the mechanism;

- damage or wear of clutches, discs, brakes inside the transmission;

- problems in the operation of the torque converter;

- wear of the hydraulic unit;

- clogging of the oil channels of the box;

- oil pump failure.

From the above list, you can see that the main problems in the mechanical part begin when parts wear out or the use of unsuitable oil. It is worth noting that this is a real stumbling block for automatic transmissions: more often than not, car enthusiasts simply run out of service life of the internal structures of the box. This once again proves the security of this type of transmission.

It is very important to detect and correct automatic transmission problems early . Otherwise, one malfunction will give rise to another, forming a kind of mutual responsibility. So, when the clutch wears out, the oil transmission channels become clogged, and these will lead to problems with the pumping system. Having procrastinated with one problem, some motorists come to services with an almost completely destroyed machine gun. But we'll talk about the reasons a little later.

Electronics and possible problems

Automatic transmission malfunctions do not bypass the electronic internals. We list common examples of broken elements:

- breakdown of electronic components, automatic transmission controller;

- incorrect operation or broken transmission sensors;

- faulty or worn electrical wiring;

- short circuits;

- malfunction of machines, phase devices.

The automatic transmission is designed in such a way that even if the electronic control fails, the car can continue to move. In this case, backup program algorithms are launched: the transmission goes into emergency mode. More often the car automatically switches to 3rd speed. This helps the driver get to the nearest service station and eliminate the cause. Modern systems notify the owner about problems in the electronics.

You can often hear from fans of manual transmissions that if the electrical component breaks down in a car with an automatic transmission, then, unlike a manual transmission, driving it is impossible. As we can see from the example above, this judgment is not true.

What may indicate a possible breakdown of the automatic transmission pump

When changing gears in an automatic transmission, the driver feels jolts and hears a howling noise as the car accelerates. These symptoms are the first signs that the oil pump is faulty.

On DSG, experienced mechanics include insufficient acceleration dynamics as a variety of symptoms of a malfunction of the pump wheel of an automatic transmission. Friction discs and steel ones can suffer due to the oil pump. They wear out faster. Gears are not changed in a timely manner, since there is no significant pressure on the special parts of the machine.

Attention! If you do not pay attention to the first symptoms of pump failure, the following malfunctions that occur will lead to complete inoperability of the machine. It will require not just restoration, but perhaps even the purchase of a contract automatic transmission. Therefore, it is so important to contact experienced mechanics in time to diagnose the problem and replace the broken part.

Write in the comments, have you already changed the pump wheel or the torque converter as a whole?

Automatic transmission pump malfunctions

The oil pump is subjected to extreme loads during operation and therefore often fails.

To prevent serious damage, it is necessary to follow the operating rules of the unit, monitor the pressure level and lubrication efficiency in the system. Automatic transmission oil pump and its functions

Malfunctions of the automatic transmission oil pump are accompanied by a malfunction in the functioning of the car, the appearance of unnecessary sounds, jerking when driving, increased noise levels, slipping or a complete lack of movement. An oil pump is an eccentric gear pump that is connected to the crankshaft of a car engine. It is necessary to supply oil to the transmission under a certain pressure.

To ensure efficient operation of the automatic transmission, one of the well-known types of oil pumps is installed on it, with the help of which the required pressure in the system is maintained and lubrication efficiency is ensured when the engine picks up speed:

A malfunction of the automatic transmission oil pump leads to an imbalance in the lubrication system, a change in the pressure level in it and a lack of the required pressure in the valve body.

Signs of a faulty oil pump in an automatic transmission

All this indicates a malfunction of the automatic transmission oil pump and the need to contact a service center to perform diagnostics. During inspection and examination of the automatic transmission, signs of pump failure are confirmed and the presence of malfunctions is detected.

When driving away from a parking spot, the driver may notice oil stains on the ground. This is one of the first and most obvious signs that the automatic transmission pump has failed. Particular attention should be paid to yellow and orange spots, indicating a malfunction of the automatic transmission pump.

To ensure uninterrupted operation of the automatic transmission, it is necessary to carefully monitor the condition of the automatic transmission oil pump, signs of malfunction of which are easy to notice. The driver should regularly check the oil level in the lubrication system using a dipstick, and after the control measurement, pay attention to the color and consistency of the oil.

Slipping, unnecessary sounds, jolts and jerks when starting to move may indicate that in a car with an automatic transmission there are signs of a breakdown of the first pump gear. Gears transfer oil from the suction channel to the discharge channel.

The efficiency of oil distribution throughout the system directly depends on their serviceability and the frequency of operation of the crankshaft.

Causes of malfunctions and repairs

The oil pump, the signs of malfunction of which are especially pronounced when the vehicle is operated in difficult conditions, can fail for several reasons:

The automatic transmission pump, signs of malfunction of which were noticed by the driver, must be thoroughly examined, the true cause must be found out and the breakdown repaired in a timely manner. This is best done in a car repair shop, under the control of modern equipment necessary for diagnosing problems. A malfunction of the automatic transmission pump, the symptoms of which were detected by the driver, can be eliminated in the service center as soon as possible. It is important, if you notice signs of a breakdown of the automatic transmission pump, to immediately seek help from a specialist.

Source

Replacing the automatic transmission oil pump

The oil pump is replaced when the automatic transmission is completely disassembled. This is the only way to get to it. So if you're replacing the pump in your garage, call a partner to help you remove the pump from under the car. Since the minimum weight of an automatic transmission starts from 70 kilograms.

Pump wheel replacement procedure steps:

Source

Automatic transmission oil pump | Repair | Signs of malfunction | Location

During operation, the oil pump in the gearbox is subjected to the most severe loads, and therefore quite often fails. Problems with the oil pump can be expressed either in the complete inoperability of this element or in a drop in pressure in the lubrication system. Modern automatic transmissions, which use numerous sensors, have the ability to monitor pressure in the system, which allows the car owner to be warned if there are problems with the pump. In most cases, eliminating this breakdown involves replacing the failed element.

Automatic transmission oil pump: device and principle of operation

The automatic transmission of a modern car is a technically complex complex device consisting of individual components and mechanisms. For the normal functioning of this design, an autonomous lubrication system is provided, the main component of which is a specially developed ATF transmission fluid.

Its task is not only to lubricate the rubbing parts, but it also serves as the basis for the hydraulics in the operation of the torque converter, which transmits torque from the engine to the driving elements of the transmission. To maintain the recommended pressure and continuous circulation of fluid in the hydraulic system, an autonomous pumping device is provided.

The automatic transmission oil pump is located inside the gearbox housing, in the front part. The mechanism is driven by a toothed gear located on the engine crankshaft.

Automatic transmission oil pump repair

Signs that suggest repairs

Problems with the oil pump in the transmission lead to insufficient lubrication of the moving parts and an increase in the overall temperature inside the transmission. As a result, significant problems with moving mechanical parts can occur, resulting in the need for costly and complex repairs. That is why at the first sign of oil pump failure, we recommend that you contact experienced specialists. The car owner can identify problems with the gearbox by the appearance of noticeable jerks in the automatic transmission when shifting some gears, which may indicate insufficient lubrication of the clutches, acceleration dynamics suffer, and a continuous howl appears, which changes depending on engine speed. We recommend that you contact the service center as soon as possible, which will allow you to fix the breakdown at minimal cost. Repair of the automatic transmission pump should be carried out by experienced specialists.

To replace the automatic transmission pump, you must first remove the box

Location

The oil pump in an automatic transmission is located inside the gearbox, so if problems arise with this element, it is necessary to dismantle the protective metal casing from the automatic transmission. In most cases, repair work does not require removing the transmission from the vehicle. However, in this case, you must take into account the design features of each specific vehicle and specific modifications of the automatic transmission. Only an experienced technician will be able to quickly determine the location of the oil pump and carry out all the necessary repair work as quickly as possible.

In order to understand the location of the oil pump, familiarize yourself with the automatic transmission structure as a whole.

As mentioned above, repair work with the oil pump consists in most cases of replacing this element. It is not very expensive, so car owners and service workshop specialists do not recommend restoring a damaged unit and replacing it with a new pump. In this case, we recommend using only original spare parts, which will guarantee the durability and trouble-free operation of this unit.

Let us recall the common reasons that contribute to automatic transmission pump breakdowns. First of all, such reasons include insufficient oil level in the system. That is why the car owner needs to closely monitor the oil level in the gearbox. It is recommended to carry out this procedure every month on a special overpass or inspection pit.

Wear of the oil pump automatic transmission ZF 4HP20

If the gearbox is repaired incorrectly, problems may occur with the flexible disk, which is necessary for attaching the automatic transmission torque converter to the engine. If the installation technology is violated, the gearbox cannot maintain the size of the end gap, which also leads to problems with the oil pump. Quite often, a car owner operates his car in the most severe mode, which involves fast driving and sharp braking. This mode of operation leads to rapid wear of the entire gearbox and the pump in particular. Problems with the oil pump in the gearbox can occur if the vehicle is not properly maintained.

If it is necessary to repair the oil pump, you must contact experienced specialists who repair gearboxes. If you have special diagnostic equipment, the technician will be able to accurately determine the breakdown and fix it as quickly as possible. In most cases, repair work to replace the oil pump in the gearbox takes about one working day. At the same time, the oil and oil filter elements are replaced. This ensures maximum durability and trouble-free operation of the vehicle.

Source

Preventing oil pump breakdowns

To extend the service life of the transmission it is necessary:

- Fill the gearbox with oil of a suitable brand recommended by the unit manufacturer;

- Change the transmission fluid within the prescribed period (at least every 60-80 thousand kilometers, depending on operating conditions);

- Avoid oil starvation;

- Adhere to a calm driving style, avoiding driving on rough terrain or towing other cars;

- In the winter season, before the trip, warm up the automatic transmission to 50-60% of the operating temperature of the engine.

Avir Group specialists . After a professional inspection and work carried out, we transfer the serviceable unit to the warehouse, deliver it to the client’s site (in Moscow and Moscow Region) or arrange shipment to another region of Russia by an agreed carrier.

Source

How to determine if an oil pump is faulty

There are two types of pump testing - without dismantling it and with dismantling it. Without removing the pump, you can verify its malfunction only when it is already in a “dying” state, so it is better to remove it to perform detailed diagnostics.

How to check the oil pump without removing it

Before directly testing the pump, it makes sense to check the oil pressure in the system using a pressure gauge. This way you can make sure that the oil pressure light is working correctly and did not light up in vain. To do this, a pressure gauge is screwed in instead of the emergency lamp pressure sensor.

Please note that the pressure value often drops precisely “when it’s hot,” that is, when the engine is warm. Therefore, the test must be carried out on a warm engine and at idle speed. The minimum and maximum pressure values will differ for different machines. For example, for a VAZ “classic” (VAZ 2101-2107) the minimum emergency pressure value is 0.35...0.45 kgf/cm². It is under such conditions that the emergency lamp on the instrument panel is activated. The normal pressure value is 3.5…4.5 kgf/cm² at a rotation speed of 5600 rpm.

On the same “classic” you can check the oil pump without removing it from its seat. To do this, you need to dismantle the distributor and remove the pump drive gear. Next, evaluate her condition. If there are numerous scuffs on its surface on the blades or on the gear axis, then the pump must be dismantled. It is also worth paying attention to the gear splines. If they are knocked down, it means the pump is jammed. This is usually due to debris and/or sludge in the oil.

Another check without dismantling the pump is to check the play of its rod. This is done in the same way, with the distributor removed and the gear removed. You need to take a long screwdriver and simply move the rod with it. If there is play, it means the pump has failed. On a normal working pump, the gap between the surfaces of the rod and the housing should be 0.1 mm, respectively, and there is practically no play.

Oil receiver mesh

For further inspection it is necessary to dismantle and disassemble the pump. This is also done in order to subsequently flush out any accumulated debris. First you need to unscrew the oil receiver. In this case, it is necessary to check the condition of the sealing ring present at the joint. If it has hardened significantly, it is advisable to change it. Pay special attention to the oil receiver mesh, since most often it is the reason that the pump does not pump oil well. Accordingly, if it is clogged, it needs to be cleaned, or even the entire oil receiver complete with mesh must be changed.

Checking the pressure relief valve

The next item to check is the pressure relief valve. The task of this element is to relieve excess pressure in the system. The main components are a piston and a spring. When the extreme pressure value is reached, the spring is activated and the oil is poured back into the system through the piston, thereby equalizing the pressure. Most often, the malfunction of the oil pump pressure reducing valve is due to the failure of the spring. It either loses its rigidity or bursts.

Depending on the design of the pump, the valve can be dismantled (flared). Next you need to evaluate piston wear. It is advisable to clean it with very fine sandpaper and spray it with an aerosol cleaner for further normal operation.

It is imperative to inspect the place where the valve fits onto the body. There should be no risks or scratches. These defects can lead to a decrease in system pressure (reduced pump efficiency). As for the valve spring for the same VAZ “classic”, its size at rest should be 38 mm.

Pump housing and gears

It is necessary to inspect the condition of the internal surfaces of the cover, the pump housing, as well as the condition of the blades. If they are significantly damaged, the efficiency of the pump will decrease. There are several standard tests.

Checking the gap between the gear and the oil pump housing

The first is to check the gap between the contacting blades of the two gears. The measurement is made using a set of special probes (tools for measuring gaps of different thicknesses). Another option is a caliper. Depending on the model of a particular pump, the permissible maximum clearance will differ, so the relevant information must be clarified further.

For example, the new original oil pump of a Volkswagen B3 has a gap of 0.05 mm, and the maximum allowable is 0.2 mm. If this gap is exceeded, the pump must be replaced. The VAZ “classic” has a similar maximum value - 0.25 mm.

Development on the oil pump gear

The second test is to measure the clearance between the end face of the gear and the pump cover housing. To take measurements from above, you need to place a metal ruler (or similar device) on the pump housing and, using the same probes, measure the distance between the end side of the gears and the installed ruler. It’s the same here, the maximum allowable distance needs to be clarified further. For the same Passat B3 pump, the maximum allowable gap is 0.15 mm. If it is larger, a new pump is needed. For VAZ “classics” this value should be in the range of 0.066…0.161 mm. And the maximum emergency gap is 0.2 mm.

In a VAZ oil pump, you also need to pay attention to the condition of the bronze bushing of the drive gear. Removed from the engine block. If there is a significant amount of scuffing on it, then it is better to replace it. Similarly, it is worth checking the condition of its seat. It is advisable to clean the bushing before installing it.

If damage is detected to the “mirror” and the blades themselves, you can try sharpening them using special equipment at a car service center. However, this is often either impossible or impractical, so you have to buy a new pump.

Additional Tips

It is also worth noting that to avoid problems with the oil system, including the pump, it is necessary to periodically monitor the oil level in the crankcase, check its quality (whether it has become too blackened/thickened), change the engine oil and oil filter in accordance with the regulations. And also use motor oil with the characteristics prescribed by the car engine manufacturer.

Repair of oil pump VAZ 2110 1996 VAZ

1. Remove the oil pump from the car (see subsection 2.14.1).

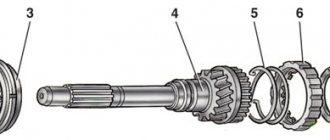

2. Unscrew bolt 1 of the fastening and remove crankshaft position sensor 2 (only for engines with a fuel injection system). 3. Remove the six bolts securing the pump cover. 4. Using two screwdrivers, lift the pump housing until the dowel pins on the housing come out of the holes in the pump cover and remove the pump housing from the cover.

5. Remove the drive and... 6. ... driven gears of the pump from the cover. 7. Remove the pressure reducing valve plug. Please note that there is an aluminum O-ring installed under the plug. Replace a badly compressed ring.

8. Remove the pressure reducing valve spring. 9. Remove the relief valve by gently tapping the body on a clean wooden board. If the valve does not come out, remove it using a pointed wooden stick. 10. Inspect the aluminum cover. In the contact area of the gears there should be no noticeable signs of wear, scuffs or deep scratches. Otherwise, replace the cover.

11. Inspect the pump housing. There should be no noticeable signs of wear, scuffs or deep scratches on its working surfaces. Otherwise, replace the housing.

12. Measure the diameter of the driven gear socket on the pump housing. The maximum permissible diameter is 75.1 mm. If the size is larger than specified, replace the housing. 13. Measure the width of the pump housing segment in the middle part. If the width is less than 3.4 mm, replace the housing.

14. Measure the thickness of the drive gear. If it is less than 7.42 mm, replace the gear. 15. Measure the thickness of the driven gear. If it is less than 7.35 mm, replace the gear. 16. Check the axial clearances of the gears. To do this, install the drive gear in the housing, place a metal ruler on the housing and measure the gap between the ruler and the gear with a feeler gauge.

17. In the same way, measure the axial clearance of the driven gear. The maximum permissible axial clearance is 0.12 mm for the drive gear and 0.15 mm for the driven gear. If the clearances exceed the specified values, replace the gears. 18. More accurately, the axial clearances of the gears can be obtained by calculation. To do this, measure with a micrometer the thickness of the housing along the outer surfaces and... 19. ...the thickness of the housing in the area of the gear socket in several places (along milled surfaces). Calculate the axial clearance as the difference between the arithmetic mean of the socket depth and the thickness of the gears.

20. Inspect the pressure reducing valve seat. There should be no burrs or deep scratches on its inner surface. Otherwise, replace the cover. 21. Replace the pressure relief valve if it has nicks or deep scratches. 22. Replace a bent, broken or cracked relief valve spring. The height of the spring in the free state should be 44.72 mm, and under load (4±0.24) kgf - 31.7 mm. Otherwise, replace the spring.

23. Install the driven gear into the pump housing. In this case, the chamfers on the gear teeth should face the housing.

24. Install the drive gear into the pump housing. In this case, the chamfers on the gear teeth should face the housing.

25. Install the cover on the body and tighten the bolts securing it.

26. Lubricate the pressure relief valve with engine oil and install it in the seat with the bottom down. Then install the spring and tighten the plug with the O-ring. 27. Fill the pump with engine oil through the hole under the oil receiver. 28. Rotate the pump gears a few turns to lubricate their working surfaces.

Automatic transmission repair: procedure

A modern automatic transmission is a complex type of transmission, the design of which involves the use of a huge number of parts. Due to the complexity of its design, an automatic gearbox breaks down much more often than its mechanical “friend”. Do-it-yourself automatic transmission diagnostics and repairs are quite complex, but with the right approach they are quite doable procedures. Today we’ll talk in more detail about machine malfunctions, how to identify and eliminate them. Interesting? Then be sure to read the material below to the end.

A few words about the service life of the automatic machine of modern passenger cars

Automatic transmissions released in recent years have become noticeably more reliable than their predecessors. Despite this, the complexity of the design of such a transmission requires its owners to properly operate and maintain it. Often, violations in the organization of these particular events provoke typical unit breakdowns, in which the automatic transmission hums or begins to “kick” or “push.”

To prevent a kicking transmission from causing inconvenience to the owner, first of all, he must study in detail the rules of operation and maintenance of the machine. With the proper approach in these procedures, automatic transmission malfunctions will bypass any motorist, and its unit will cover its entire operational mileage without any problems. By the way, the service life of many automatic transmissions of modern cars is designed for the service life of the engines with which they are equipped. That is, the service life of an average automatic machine is 300,000-600,000 kilometers. Quite a lot, right?

Let us repeat, the main thing in achieving maximum “exhaust” from an automatic transmission is timely maintenance of the automatic transmission and its proper operation. Otherwise, repair of the automatic transmission may be necessary even after several hundred kilometers. Thus, it can be stated that errors in the operation of the automatic transmission when the car’s mileage is low are the full fault of the motorist, which he could well have avoided.

Signs of problems with automatic transmission

Automatic transmission disassembled

It is no secret that during the operation of a vehicle, heavy loads are placed on the automatic transmission, which can cause gearbox failure. And although automobile manufacturers have recently been doing everything to increase the service life of these units, the automatic transmission is still considered one of the most vulnerable components. As for malfunctions and their symptoms, they can be very diverse. For example, if there is a malfunction in the valve body, shocks and jerks may occur during gear shifting. However, shocks can be very different, there are many types of them and they all indicate different breakdowns.

We recommend: What to do if a hernia appears on the wheel

Especially if the breakdowns progress, the shocks and jerks may change. If such problems arise in the operation of the unit, the vehicle owner should troubleshoot as quickly as possible or contact specialists. It should also be noted that malfunctions of the automatic transmission can be expressed in the inability to switch one or another speed. Or in complete blocking of gears. If you are faced with a similar problem, then under no circumstances should you use your vehicle, otherwise the problem may worsen.

Sometimes automatic transmission malfunctions can be determined using regulators and other sensors with which the unit is equipped.

Such devices allow the motorist to identify and warn him about:

- insufficient level of transmission fluid in the system;

- insufficient pressure of the working lubricant;

- overheating of the automatic transmission;

- failures of other sensors;

- problems with switching modes.

Actually, the on-board computer can do the same thing by sending a message to the driver on the control panel by activating the Check Engine light. However, it should be noted that most of these reports of transmission failures are inaccurate. Accordingly, only complete computer diagnostics or disassembly and reassembly of the unit will allow you to accurately determine automatic transmission faults. It should also be noted that in some individual cases even diagnostics will not help, resulting in the need to dismantle the transmission.

Possible automatic transmission breakdowns

The situation in which the car was driving quite well, but then suddenly, when changing gears, the automatic transmission malfunctioned, and the corresponding error code was displayed on the instrument panel, is familiar to many automatic transmission owners. We have already figured out why this happens, but we have not yet considered what exactly can happen to the node. Let's correct this situation.

Let us immediately note that the automatic transmission can push, kick, shift incorrectly, go only in reverse, or otherwise work incorrectly due to numerous reasons. However, all of them can be divided into three large groups:

If everything is more or less clear with the first category of machine malfunctions, then regarding the remaining malfunctions many people may have some questions. In order to answer most of them, our resource decided to present to all readers a list of the most common automatic transmission breakdowns and their symptoms. As a result, we were able to identify the following problems with the machine:

As you can see, an automatic transmission can twitch, fail to change gears, or work incorrectly for a variety of reasons. That is why checking an automatic transmission for stable operation has always been considered a complex procedure, and not all motorists dared to carry it out with their own hands.

Automatic transmission diagnostics

Repairing automatic transmissions just like that, at random, is impossible. For its high-quality organization, it will be necessary to diagnose the unit. Even if the automatic transmission fails again after repair, it would be irrational to blame the previously broken unit again, because there are more than a hundred elements in the design of the automatic transmission. Each of them may well break down at the most inopportune moment.

Determining what exactly has gone wrong in the box takes place in several inseparable stages:

In general, there are no particular difficulties in answering the question of how to check an automatic transmission. Diagnostics of the box is carried out by organizing the steps noted above. Of course, some steps are not so easy to implement, but you cannot do without them, so you should be prepared for difficulties. If you are not ready to check the machine yourself, then it is better not to experiment and entrust this work to professionals. This approach will not only simplify the repair of the unit, but will also speed up its progress several times.

Causes

Before getting acquainted with methods for eliminating breakdowns, it is necessary to consider their main causes.

Lever link

In old automatic transmissions, where the selector is mechanically connected to the transmission, the gearbox lever often breaks, making it impossible to switch the operating mode. In this case, the repair consists of replacing the faulty selector and rocker. Such malfunctions are detected by difficult movement of the automatic transmission selector. As a result, the lever does not move and the transmission must be repaired. Some brands of automatic transmissions cannot be repaired without removing them from the car, making repairs easier.

We recommend: Advantages and disadvantages of all-season tires

Oil leak

A popular problem with automatic transmissions is oil leaks at the seals. Therefore, it is advisable for the car owner to periodically visually inspect the box on a pit or lift. If you detect oil leaks on the gearbox, you need to contact a car repair shop. In this case, the problem is solved by simply replacing the gaskets and gear lubricant.

Control block

Electronic components can break down for various reasons. Sometimes there are problems with the functioning of the automatic transmission control unit. The unit may incorrectly select the speed for the gears, or it itself blocks the operation of the transmission. Troubleshooting the operation of this unit, as well as the electrical circuit of the box, consists of replacing control cables and faulty units.

You need to know that driving a car with a faulty unit is dangerous, so it is recommended to contact a workshop at the first sign. And if the automatic transmission does not want to work at all, then you should not start the engine, but it is better to move it to a service center using a tow truck. The causes of ECU failure may be:

- Exposure to moisture.

- Heat.

- Effect of vibration loads.

- Mechanical impact.

- Sudden voltage drop.

These reasons can lead to damage to the control unit, which requires expensive repairs or replacement. Car service centers can tell you how to check the electronic unit of an automatic transmission. Fault diagnosis is carried out using special instruments that allow us to identify the nature of the fault, which makes it possible to eliminate it at the lowest cost. In many cases, ECU repair comes down to replacing burnt out chips and boards. This work is quite complicated, since it requires desoldering microcircuits from boards and replacing failed capacitors. Sometimes it is easier to replace a faulty unit with a new one. This makes it possible to get rid of problems with the automatic transmission.

Qualified repairs should be carried out only in a certified center that has sufficient experience in automatic transmission repair. There is no need to skimp on qualified repairs and turn to garage technicians.

Valve unit malfunctions

One of the important components of an automatic transmission is the valve body, which is responsible for the gear shift process. This unit, according to the masters, is the brains of the automatic transmission. The valve body plays the role of organizer of the movement of transmission oil through the box. There are different hydraulic block designs, depending on the type of box.

During operation, the valve body takes on heavy loads, so if it is poorly maintained or used incorrectly, the valve body may break. Malfunctions of the automatic transmission valve body may occur due to improper operation of the transmission. For example, in cold weather, a driver can not wait for the oil in the box to warm up, but immediately start driving with heavy loads. In some cases, there are problems with the cooling system that arise due to infrequent oil changes and improper operation of the oil receiver. This can lead to malfunctions of the valve body and the entire box.

Failures can be determined by various signs of the valve body. You need to know that despite the progression of computer diagnostics of machines, it is difficult to determine the malfunction of this unit. Therefore, during maintenance, specialists can accurately diagnose only by removing the box from the car.

Torque converter malfunction

This mechanism is an element of the automatic transmission. It makes it possible to create smooth gear shifts for the gearbox. Its design is constantly being modernized and complicated. Now the torque converter on an automatic transmission works as a clutch. When changing gears, this unit disconnects the engine from the gearbox. After engaging the gear, it takes over the torque, which ensures the smoothest speed change.

If problems arise with this unit, only repair it is necessary. In general, these works cost less compared to the electronic unit and valve body. Torque converter malfunctions are identified by the symptoms we indicated above.