Any engine is equipped with a fuel system, one of the important parts of which, regardless of modifications, is the fuel pump. Before understanding the device and principle of operation, two main types should be distinguished:

• Electric (most common).

• Mechanical (found in carburetor cars).

1. An electric fuel pump is installed in modern fuel-injected cars. It is often placed in the tank or next to it, in the fuel line. So that the unit has the opportunity to cool, since they get very hot during operation.

The operation of the electric fuel pump is fully controlled by the ECU. When the driver turns on the ignition, the ECM sends a signal to start the pump. Next, an electric motor located inside the pump with rollers or impeller blades generates the required pressure. Due to these actions, the mixture enters the intake zone, and then into the outlet, then sent through the fuel line.

The fuel line “rests” on the so-called ramp, where the fuel is directed under pressure. By the way, before entering the ramp, the “fuel” passes through another filter, in addition to the mesh filter, located directly on the gas pump. Once in the ramp, the fuel is distributed among the injectors. Then, depending on the opening time of the injectors, the required amount of gasoline is injected into the cylinders.

By the way, depending on the type of system, there may be one or several injectors per cylinder.

The role in determining the duration of opening of the injectors and, accordingly, the required volume of fuel is assigned to the controller (ECU) and multiple sensors, for example, the throttle position sensor (TPS), the coolant temperature sensor (DTOS), the crankshaft position sensor (CPS), the knock sensor ( DD), oxygen sensor (OK), air flow sensor (MAF) or absolute pressure sensor (DAS), idle air control (IAC), which transmit data to the controller (ECU).

When the ECU stops sending signals or, conversely, does not receive impulses from sensors about the operation of the internal combustion engine, the relay stops powering the pump. Remember that the pump runs as long as the engine is running. Read below for specific examples of how a fuel pump works, depending on the modification.

Types and features of operation of electric fuel pumps:

• Gear. • Rotary roller. • Centrifugal.

The main differences between them are where exactly they are installed. The first two are similar, as they are mounted directly into the fuel line. It looks like this: discs with rollers are installed on the rotor of the electric motor, all of this is placed in the so-called “cage”, from which there are respectively two outputs. When rotating, the rollers capture the inlet zone, again a vacuum zone is formed, which is why “fuel” is pumped in. Further rotating, the rollers, capturing fuel, move to another outlet (exhaust zone). Pressure arises for the reason that the rotor itself is placed in the “cage” disproportionately, due to which there is a certain displacement, the so-called eccentric arrangement. The gear type works similarly, where gears are installed instead of rollers.

But, in the modern world, you can often find a third type of mechanism, like a centrifugal one. Such systems are mounted directly into the tank, and a pipeline is already connected to it. Feeding occurs due to the rotation of an impeller with blades, which is placed in a special “chamber”. When the impeller rotates, turbulence is formed, causing gasoline to be sucked in and then enter the fuel line under pressure. And then, accordingly, into the injector.

2. As for mechanical fuel pumps, they can now be found on old carburetor cars. Such units are often located in the engine compartment, above the head. This is due to the fact that instead of an electric motor (as in the previous version), the mechanisms are driven by a “camshaft”.

The principle of operation is as follows: on the “camshaft” there is a cam, which, when the shaft rotates, acts on the pump pusher. The latter acts on the drive lever, which pulls the rod where the membrane is attached. In this case, when the rod lowers, a vacuum zone is created, causing the inlet valve to open and the mixture to be pumped in.

VT with electric drive

Long-lasting operation, ease of manufacture and greater efficiency can be obtained by using an electric fuel pump, which is controlled by a special relay. It allows you to create a pressure in the range of 0.3-0.4 MPa (in engines with direct injection - up to 0.7 MPa), which exceeds the capabilities of a mechanical HP. The device largely depends on where the fuel pump is located: in the tank or in the engine compartment. But the operating principle of all VTs of this type can be considered identical. The vast majority of modern cars use a submersible fuel pump, which is located in the tank. Although this is fraught with small mechanical losses and vulnerability associated with the long length of the fuel line, the pump receives much better cooling.

During operation, the fuel washing the housing and passing through the electric motor removes a significant part of the heat. This is why driving with an almost empty tank affects the resource so much.

Device

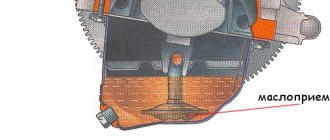

An electric fuel pump consists of two parts: an electric drive (represents a conventional electric motor) and a pump part (pumps fuel from the fuel intake). Submersible pumps are placed in a single housing with a mesh that performs rough fuel cleaning.

Depending on the design of the intake mechanism, there are several types of pump parts:

- roller pump. Fuel is supplied by rotating a rotor with movable rollers. As the space between the roller and the rotor increases, a vacuum is created in the free space, which is filled with gasoline. With further rotation of the rotor, the space decreases, which allows pressure to be created and fuel to be supplied through the exhaust channel;

- gear fuel pump. The principle of operation is similar to the previous view, but changes in the area of free space occur due to the rotation of the gear;

- centrifugal pump. Fuel injection occurs due to vortex caused by the rotation of the impeller in the housing. The supply and removal of fuel is carried out through the corresponding channels inside the housing.

Additionally, hybrid fuel pumps can be distinguished. Structurally, they resemble mechanical devices, but the movement of the diaphragm is carried out not by a pusher drive, but by an electromagnetic valve and a special relay.

Operation logic

In cars in which the main life support components of the internal combustion engine are controlled via a CAN bus, the fuel pump receives the command to start from the electronic engine control unit. Before starting the internal combustion engine, it is necessary to create pressure in the fuel line, so immediately after turning on the ignition, the ECU sends a signal to the relay, which turns on the fuel pump. In some cars, power is supplied to the relay and the fuel pump is turned on when the driver's door is opened. The operating time of the fuel pump in this mode is calculated in seconds, after which the power is turned off. The subsequent start will occur when the starter begins to rotate.

Basic faults, simple diagnostics

The main breakdowns due to which the fuel pump may not work include:

- fuse blown;

- power failure, contact oxidation;

- wear of the brush assembly, as a result of which performance deteriorates, destruction of the commutator, wear of the rotor bushings;

- clogging;

- critical wear of rubbing pairs of roller and gear fuel pumps;

- destruction of the plastic coupling through which the armature shaft of the electric motor is connected to the pump rotor.

To understand why the fuel pump does not work, basic skills in using a multimeter are enough. The presence of power at the VT connector after turning on the ignition will indicate that the fault is in the pump. If power does not come and the fuel pump does not start, then you should check the circuit to the connector, as well as the relay.

Main symptoms of malfunction:

- increase in noise, appearance of extraneous sounds;

- failures when pressing the gas sharply;

- the engine periodically stalls (especially when hot);

- problems with starting.

Relay

One of the most important elements of the fuel injection engine power system is the fuel pump relay. It is used to reduce the load on the on-board network, since the power contacts are controlled by applying a low voltage to the corresponding terminals of the electromagnetic relay. Schematic diagram of connecting a fuel pump.

You can see the principle of operation of the relay, as well as testing methods in the video.

Injection engine: briefly about the fuel pump

The era of carburetor internal combustion engines is over. At least in relation to cars. They were replaced by more advanced and modern injection power units. This fundamentally changed the car's power system, but did not eliminate the need to deliver fuel from the tank to the engine. This function is still assigned to the pumps. Unlike a similar unit in a carburetor engine, the fuel pump of an injection engine has a different design, which means a different principle of operation and malfunctions unique to it. Let's talk about this.

Injection engine: pump design

There is probably no car enthusiast who does not know the structure of a classic fuel pump. And of course everyone remembers, and some probably still encounter it, that it is installed directly on the engine. This is very convenient, you don’t need to think about an additional drive, and you don’t need an autonomous lubrication system. But there is one significant drawback. The pressure that a mechanical fuel pump can create is not enough for the correct operation of an injection engine.

In addition, in an injection engine, the fuel pump must operate in strict accordance with the commands received from the electronic control unit. It is the ECU that selects the operating mode of the pump, based on the analysis of many parameters. It is almost impossible to implement such an algorithm on gears. That is why, unlike a carburetor engine, the fuel injection pump is not mechanical, but electric. In addition, it is installed in the fuel tank. This allowed us to solve a number of problems:

- Significantly increase productivity due to the fact that the pump has become submersible;

- Solve the cooling problem. Gasoline has a very low resistivity, that is, it is practically an insulator. The designers took advantage of this. The windings of the electric motor are in gasoline and are cooled by it.

- Reduce noise. This became possible again due to the fact that the pump is completely immersed in fuel.

Now the very principle of operation of the injection fuel pump. In general, electric pumps can be structurally:

The latter are the most common, so they are the ones we should talk about in more detail.

The key element of a centrifugal pump is the impeller mounted on the electric motor shaft. It is located in the pump housing, which has an inlet and outlet. When the impeller rotates, a centrifugal force arises, which presses the gasoline against the housing and pushes it out into the outlet. At the same time, a vacuum arises in the center of the impeller, which is filled through the inlet with a new portion of gasoline. Thus, there is a continuous supply of fuel to the injectors of the injection engine. Thanks to the special design of the impeller, sufficient pressure is generated in the fuel line for their normal operation. It is maintained even when the pump is not running, thanks to the check valve. That is why experts recommend that when doing any work on the fuel line, the first step is to relieve the pressure. Anyone who has changed the fuel filter knows this. Here, in brief, is everything that concerns the mechanical part of the fuel pump of an injection engine.

Now a little about its electrical component. The electric motor of the pump is powered by a voltage of 12 V, and it is controlled, as already mentioned, from the motor controller. It would seem quite logical that it is from the ECU that power is supplied to the electric motor terminals. But no. Its power, at least 60W, does not allow this to be done directly. Therefore, a relay is introduced into the fuel pump power circuit. It’s called the fuel pump relay (FPR). This is where power is supplied from the controller. When activated, the relay closes the fuel pump power circuit with its contacts. Looking ahead, we can say that the relay is one of the main reasons for the unstable operation of the fuel pump, and ultimately the injection engine itself. But this is a topic for a separate conversation, but for now let’s briefly summarize. So:

- The fuel pump of an injection engine is electric, submersible and is most often installed in the fuel tank;

- It has a centrifugal design and provides pressure through the rotation of the impeller;

- The electric motor of the fuel pump is cooled directly by the fuel;

- The fuel pump is powered by a constant voltage of 12 V;

- The engine controller controls the fuel pump through the RBN.

Types of fuel pumps

Let’s immediately say that this is not the only type of fuel pump. Until the mid-70s (and in the Soviet Union and Russia until the 2000s), carburetor cars with a mechanical fuel pump were widespread, which was located directly on the engine and was driven mechanically - from the camshaft cam via a pusher. By pressing the lever at a certain interval (depending on engine speed), the pusher pumped fuel into the carburetor. There was no great pressure, as you may have guessed, in such a system, nor was there any need for it. With the advent of the fuel injection system, mechanical gasoline pumps have sunk into oblivion, giving way to high-performance electric units. If the former could pump fuel under a pressure of 0.3-0.5 atmospheres, then the latter, on average, produce all three.

Main advantages

VAZ 2110

Engineers decided to improve the engine, so the injection circuit became popular in VAZ 2110 cars. In this case, the fuel mixture enters under pressure directly into the combustion chamber from the injectors.

The injector has gained a huge advantage over a carburetor engine, and, despite the fact that its cost is much higher, the use of carburetor systems is practically no longer practiced anywhere. After all, all information about the engine is collected by a computer, so it becomes possible to accurately dose the amount of fuel in all engine operating modes. Due to this, you can significantly reduce fuel consumption and use fuel pump resources more efficiently.

Regardless of the type of injection, and it can be of two types - multi-point or single-point, the VAZ 2110 injector instantly responds to changing loads.

Cold start and warm-up

The injector operates differently depending on the air and engine temperature. In any case, the fuel pump system precisely doses the fuel supply to the injectors, due to which you can quickly reach the required idle speed.

However, if the fuel pump's electrical circuit burns out, problems may occur during its operation. Because of this, the response to changes in loads at minimum fuel consumption and optimal torque may be slow, which can lead to pump failure.

Fuel pump VAZ 2110

Fuel atomization

In the carburetor systems of VAZ 2110 cars, the fuel pump sprays droplets of 100-120 microns in size, and the injector - 20-60 microns.

Principle of operation

The electrical circuit needs to be constantly checked, because if one of its contacts is broken, the fuel pump will start to work incorrectly, so the operating principle will change.

Actually, during normal operation of the fuel pump, the following main stages occur:

- Fuel is supplied to the filter through the fuel pump. In a VAZ 2110 car, this filter can be located both inside the pump and on the fuel line;

- After this, the fuel passes into the fuel rail, where it is supplied under pressure to the injectors;

- The electrical circuit of the fuel pump is designed in such a way that if any excess fuel remains, it is cut off by the pressure regulator and then drained back into the gas tank;

- The computer device gives a pulse that opens the injectors at the right moment, after which fuel is supplied through the fuel pump.

Where is the fuel pump located

When faced with the need for repair or replacement for the first time, many car enthusiasts ask where the fuel pump is located. The pump is located directly in the gas tank and is in direct contact with the fuel, that is, it is immersed in gasoline. On most civilian vehicles, the gas tank is located at the rear of the vehicle under the floor.

The fuel pump is installed so that it is located at the top of the gas tank. Thanks to this placement, the pump can be accessed directly from the cabin. To do this, you need to remove the rear sofa, since the fuel pump is located directly under the seat on the left or right side.

Imported fuel pump

If you have an imported device, then it is more difficult, or you will have to buy a new one or contact a specialized workshop. But not even all workshops undertake to repair imported gasoline pumps, since components for them are very difficult to find.

Some workshops got out of this situation thanks to the independent production of working parts of devices produced by various foreign manufacturers, the main of which in this market are BOSCH DENSO

,

WALBRO

,

PIERBURG

,

AC

,

VDO

.

Having carried out a spectral analysis of the material from which the parts of gasoline pumps are made, they learned how to make similar units of no worse quality, which made it possible to repair them much cheaper.

Thanks to this, you can even completely restore a failed device that was previously planned to be replaced.

But there are only a few such workshops and you need to know where they are.

How does an electric fuel pump work?

To constantly maintain the correct pressure in the fuel rail, the electric fuel pump must always operate when the ignition is turned on. The uninterrupted supply of fuel to the combustion chambers of the engine depends on it.

As soon as you get into the car and turn the key in the ignition, this unit immediately starts working - even before the starter starts cranking. When you turn off the engine, the fuel pump also turns off - this ensures safety in emergency situations and in case of an accident. Excess fuel is released back into the tank through a special bypass valve.

Having a given pressure in the fuel rail, it is easy to dose the fuel supply to each specific cylinder: at the right moment, the “brains” of the car send a command to one or another injector, its solenoid valve opens for a few milliseconds, and the fuel flows by gravity into the combustion chamber through tiny holes. All the car's ECU needs is to calculate the time during which the injector valve should remain open. When the pressure in the rail drops, the fuel supply is disrupted, which leads to numerous problems, which we will discuss below.

The design and principle of operation of the fuel pump and its malfunctions

Any car engine has a power system that ensures mixing of the components of the combustible mixture and supplying them to the combustion chambers.

The design of the power system depends on what fuel the power plant runs on. But the most common is a gasoline-powered unit. In order for the power system to mix the components of the mixture, it must also receive them from the container in which the gasoline is located - the fuel tank. And for this purpose, the design includes a pump that supplies gasoline. And it seems that this component is not the most important, but without its work the engine simply will not start, since gasoline will not flow into the cylinders.

Basic fuel pump malfunctions

Video: When the fuel pump is sick

All gasoline pumps have a fairly long service life due to their relatively simple design.

Problems are very rare in mechanical components. They most often occur due to rupture of the membrane or wear of the drive elements. In the first case, the pump stops pumping fuel altogether, and in the second, it supplies it in insufficient quantities.

Checking such a fuel pump is not difficult; just remove the top cover and assess the condition of the membrane. You can also disconnect the fuel line coming from the carburetor, lower it into a container and start the engine. For a serviceable element, fuel is supplied in uniform portions with a fairly powerful jet.

In injection engines, a malfunction of the electric fuel pump has certain symptoms - the car does not start well, there is a noticeable drop in power, and interruptions in engine operation are possible.

Of course, such signs can indicate malfunctions in different systems, so additional diagnostics will be required in which the performance of the pump is checked by measuring pressure.

But the list of faults due to which this unit does not work correctly is not so many. Thus, the pump may stop working due to severe and systematic overheating. This happens due to the habit of pouring small portions of gasoline into the tank, because the fuel acts as a coolant for this unit.

Refueling with low-quality fuel can easily lead to malfunctions. The impurities and foreign particles present in such gasoline, getting inside the unit, lead to increased wear of its components.

Problems can also arise through the electrical part. Wiring oxidation and damage can result in insufficient power being supplied to the pump.

Note that most malfunctions that occur due to damage or wear of the components of the fuel pump are difficult to eliminate, so often if its performance is impaired, it is simply replaced.

Fuel pump for injection engine

Forced injection of fuel into the cylinders requires high pressure in the fuel system. The use of an additional pump for this would lead to a significant complication of the vehicle design. Therefore, it was necessary to completely change the existing one, while adhering to the following requirements:

- The pressure generated by the pump must be sufficient to operate the injectors.

- The need to operate in accordance with the commands of the electronic control unit.

- The pump must have high performance.

To meet all the requirements, we had to make the fuel pump electric. This allowed us to solve some of the problems. For greater efficiency, we had to change the location.

The fuel pump of an injection engine consists of the following elements:

- frame;

- stator winding;

- rotor with impeller;

- check and pressure relief valves;

- outlet fitting.

When describing the fuel pump, it is necessary to mention the coarse filter, the so-called mesh, which protects its components from the ingress of foreign particles.

Checking the operation of the fuel pump of injection engines

After turning the ignition key, the main ECM relay and the fuel pump relay are turned on. The characteristic sound of a running pump can be the first sign that it is working. If you can’t hear the pump (extraneous sounds are disturbing, the pump is running quietly, etc.), open the back seat and get to the gas tank flap - in this place you are guaranteed to hear the pump running.

| rice. 1 |

Of course, the easiest way to check the operation of the pump is by the result of its operation - measure the fuel pressure in the fuel rail, for example, using an MTL-2 pressure gauge, but you may not have a pressure gauge at hand. Remove the cap from the fitting on the fuel rail to connect the pressure gauge. Press the shut-off valve. The presence of fuel in the rail under pressure is confirmed by the characteristic release of fuel when the pump is running. When the pump is turned off, the pressure quickly drops and fuel stops flowing from under the valve. Relieve pressure in the rail, turn the ignition key again. The pump will turn on if the ignition has been turned off for 10 seconds. Repeat the procedure with the valve. If there is fuel in the tank and the pump is running, pressure should appear in the ramp.

If there is no fuel pressure in the rail, you need to understand the functioning of the pump and pressure regulator installed on the fuel rail. Malfunctions of fuel pipelines (kinked hoses and tubes), clogged fuel filter, fuel leakage may occur, but the likelihood of these defects is low. Moreover, these malfunctions are either determined by visual inspection, or appear gradually, making themselves known in advance by deteriorating driving performance, increased fuel consumption, fuel smell, etc.

Purpose and principle of operation of the fuel pump

The fuel pump is designed to pump fuel from one point to another. In a car, the role of the first point is played by a fuel reservoir - the tank, and the second - by the engine, where the pumping takes place. This process occurs at a certain pressure, which is maintained by the pump reducer, which is a very important point.

Fuel pump diagram

Fuel pumps are divided into 2 types according to the type of drive: electric and mechanical. Inside the first there is an electric motor with a mini-pump, which operates from the mains and uninterruptedly pumps fuel into the engine. The second type is becoming increasingly rare, as it is installed on carburetor cars, and operates due to the reciprocating movement of the lever.

Fuel pump diagram

Classification

The most commonly used classification of fuel pumps - by engine type - was given above. However, other signs are also used that make it possible to divide the mechanism under consideration into types. For example, based on their location in the car, a distinction is made between submersible pumps, which are installed directly in the fuel tank, and pumps, mounted directly to the engine power unit.

Based on the type of drive, fuel pumps are divided into mechanical and electric. The first type is used in carburetor engines and older models of diesel units. An alternative option is used much more often today and is installed both in injection gasoline engines and in modern diesel power plants.

The operating principle of a modern electric pump

The pump receives the command from the ECU. Before starting, pressure is built up in the fuel system. This is facilitated by an impulse that is supplied electronically to the relay after the ignition is turned on. The control unit not only controls the entire operation of the electric pump, but also takes a direct part in the formation of the fuel assembly (fuel-air mixture). In addition, the electronics control the throttle valve, regulate the content of exhaust gases, etc.

On some car models, the pump turns on when the driver's door is opened.

Control circuit

The electric fuel pump pushes fuel into the engine. The speed of its operation depends on the standards set for the motor. But the operating speed of a mechanical type pump is constant.

You should know that electric fuel pumps are designed to work under pressure, as a result of which their design is thought out differently. They are prone to heating up quickly and making noise. The operating principle of a modern pump depends on the functioning of the engine. If the latter does not work, then the pump does not work.

There may be element malfunctions related more to the mechanical part. Electrical breakdowns also happen, but they are extremely rare. It is mainly the fuel pump supercharger that wears out, because it is subject to a large load.

It is noteworthy that the electric pump is controlled directly by the ECU and is activated even before the starter is activated. It is not worth writing about the fact that the fuel pump is one of the most important elements of the internal combustion engine power system. Its malfunction easily leads to interruptions in engine operation, failures when pressing the accelerator pedal and difficulties with starting.

Share with friends on social networks:

Basic fuel pump malfunctions

Thanks to their simple design, electric pump models have a long service life. And mechanical ones practically do not break. Most often, the membrane or spring located under it fails.

Here are the main malfunctions of electric fuel pumps:

- Overheating of the electric motor due to frequent driving with a low fuel level in the tank.

- Oxidation of contacts or damage to electrical wiring.

- Clogged filter.

- Wear of moving parts.

The serviceability of fuel pumps is checked as follows.

- Mechanical. The top cover is removed and the condition of the diaphragm is checked. To test it in action, you need to disconnect the hose from the carburetor and start the engine. If the stream is supplied evenly and with good pressure, it means it is working correctly.

- Electrical. Their serviceability is even easier to check. When you turn on the car's ignition (turn the key one position), the diagnostic lights come on. At this moment the fuel pump should start working. The driver should hear a soft buzzing sound for 1-1.5 seconds. If this sound is not heard, then something has happened to the pump.

Most often, breakdowns of fuel pumps are eliminated by completely replacing them. If the membrane fails in mechanical models, it can be replaced with a new one by purchasing a fuel pump repair kit at the store.

To learn how to install an electric fuel pump on a carburetor engine, watch the video:

Electric fuel pump for carburetor. Correct installation of HEP-02A

Fuel pump for injection car

The fuel pump of an injection car consists of a housing, an electric motor running on direct current, a rotor, rollers that act as working parts, a filter mesh, inlet and outlet pipes, and a one-way valve.

The operating principle of the device is very simple.

You start the car engine by turning the key in the ignition, and the computer sends a signal to the fuel pump electric motor and starts it. Under the action of the electric motor, fuel is pumped.

After two seconds, the computer waits for a confirmation signal from the electric motor that it is working. If there is no such signal, then the computer stops supplying direct current to the device. This is done to prevent the pump from burning out.

Through a filter mesh and a one-way valve, fuel enters the fuel filter, is cleaned and then enters the engine through a pipe system. As long as the car engine is running, the fuel pump is also running.

Fuel pump service life

The service life of a fuel pump depends on its design and the materials from which it is made. Depending on the model of the device, the fuel pump will work without interruption for a period of 100 to 200 thousand kilometers of the car.

The pump fails for two main reasons:

- untimely replacement of fuel filters. Moreover, some pay attention only to the fine cleaning element, but the cleanliness of the mesh, which is installed directly on the pump itself, deserves no less attention. When the pump tries to create pressure through a dirty filter, it gets hotter. Timely maintenance will extend the life of the pump;

- The fuel level in the gas tank is often low. Because of this, the device does not receive proper cooling, so the risk of overheating increases significantly.

Also pay attention to the video on how to restore some pumps:

Types of fuel pump breakdowns in injection cars

Types of electric fuel pumps

Today, the following types of electric pumps are distinguished.

- The gear pump operates by eccentric movement. Installed in the fuel line. The pump is equipped with two internal gears, which pump gasoline when rotating.

- Rotary roller. This type of pump is also installed in the fuel line. Its design includes an electric motor, on the rotor of which a disk with rollers is installed. A part of this type has two outlets: one for fuel to enter inside, the other for its exit.

- Turbine or centrifugal. This is the most popular type of pump, installed directly into the car tank. The fuel wire is connected to it already inside.

A submersible or turbine pump is used in most modern foreign cars. It is located in the tank, which minimizes fuel losses and better protects the pump from damage. In addition, the pump inside the tank is cooled better and does not overheat even after very long operation.

Vin submersible fuel pump

Cooling is carried out by flushing the pump housing with fuel. Thanks to this, a significant part of the heat is removed. It is for this reason that the recommendations for cars with submersible pumps prohibit driving with a half-empty tank, because this negatively affects the life of the fuel pump.

Troubleshooting after replacing the fuel pump

Some motorists are faced with the fact that after installing a new fuel pump, the car does not start. This phenomenon is explained by the fact that the new device takes some time to pump through the pressure that was removed before repair.

After installation, you need to start the ignition for 4-6 seconds. Then you need to crank the engine for 5-10 seconds. If after this procedure there is no effect, you need to wait about 1 minute and repeat it .

Connection diagram

The decent power of the electric motor does not allow the fuel pump to be powered from the electronic control unit (ECU). Therefore, the intermediate relay contacts are included in its circuit. Due to its high resistance, its winding can be connected directly to the control unit. Having activated its contacts, the relay closes the power supply circuit of the electric motor.

The fuel pump connection wires run through the entire interior of the car. Over time, their insulation may fray, which can lead to a short circuit. Therefore, the fuel pump circuit is protected by a fuse. To increase reliability, its rating is slightly overestimated. On domestic cars, the block where the fuel pump fuse is located is usually located separately from the general panel. This allows you to quickly find it in case of a malfunction.

see also

“Peter - AT” INN 780703320484 OGRNIP 313784720500453

Source

Electric fuel pump for a motor with a carburetor

So, an electric low-pressure fuel pump on fuel-injected cars is located in the gas tank and takes fuel from the fuel tank, after which it supplies it under a certain pressure to the injectors. As a result, the engine operates stably regardless of the load, and accurate and timely injection is also achieved.

In both the first and second cases, the pump supplies fuel to the metering systems (injectors or carburetor). It is quite obvious that if you install an electric pump instead of a mechanical pump, you can achieve trouble-free operation of the carburetor and a stable fuel supply.

However, it is important to understand that the electric fuel pump on the carburetor must operate at low pressure to avoid fuel overflow. As for the installation itself, in some cases the electric pump is installed under the hood, and not in the tank (as on an injector). Also quite common is the option when the pump section is integrated directly into the gas tank.

Installing an electric fuel pump on a carburetor

Let us immediately note that installing an electric fuel pump on a carburetor internal combustion engine is associated with a number of difficulties. Please note that without proper experience in carrying out such work, it is not recommended to carry out the specified modifications to the fuel system yourself.

Now let's look at a common installation method with an example. First of all, you need to select the most suitable electric fuel pump in terms of performance for the specific type of internal combustion engine and the carburetor installed on the car.

In addition to the pump, you should also prepare the following items:

- hose 5 meters long, internal diameter of the hose is about 8-9 mm;

- an additional relay will be required;

- you also need to have a 3 or 4 mm drill;

- you will also need a fuel filter from injection systems;

- fuel filter for carburetor systems;

- steel tube 7 mm with a wall of 0.8 mm and a length of 25 cm;

- fuel hose with an internal diameter of 12 mm;

- adapter fitting from 8 mm to 12 mm;

Having prepared everything you need, you can proceed to installation. First you will need to remove the fuel level sensor in the gas tank. Then a hole is drilled in the sensor cover, then a 7 mm tube is soldered into the hole with a soldering iron. It is important to bend the tip of the tube so as to drain the return as far as possible from the fuel intake.

Also, the upper end of the tube is bent parallel to the outlet of the fuel intake. Now a modified fuel level sensor with an intake and return should be installed in the tank. It should be taken into account that the rubber tube will need to be connected to the installed return fitting from the standard fuel line.

Now one end of a hose with a length of 5 meters is put on the fuel intake fitting. After the rubber fuel supply hose has been connected, the said hose is securely attached to the metal tube. This can be done by using clamps.

When installing, it is important to ensure that the pump is positioned correctly (fuel is sucked in from the side of the expansion tank, and the supply goes to the engine). Next, a fuel filter from the injection systems is installed on the rubber supply hose. A hose 5 cm long should be put on the second fitting. This hose is subsequently secured with clamps to the car body in a vertical position.

Signs and causes of malfunction

The design of the injection pump remains a mechanism that is difficult to diagnose in a garage environment. Detection of faults occurs at special stands. Among a large group of factors that confirm problems with a main or other type of injection pump is the presence of foreign media in the system - water, fuel and contaminants. In practice, problems with the pump are identified by increased fuel consumption, engine overheating, a drop in dynamics and power, and an increase in the amount of smoke in the exhaust gases. The lack of injector activation will be indicated by difficulty starting the engine, interruptions in idling and increased noise while driving.

Fuel injection pump

The fuel pump for injection engines can be located either directly in the fuel tank or outside the tank. Such remote pumps are slowly becoming an archaism and are found on relatively old cars. Now the manufacturer is trying to combine a fuel pump and fine and coarse filters, if not in the same housing, then arrange them structurally next to each other.

Video about replacing the fuel pump on a VAZ

On the one hand, this makes life easier for the manufacturer, since we can no longer change fuel filters separately from the pump. To do this, you have to dismantle the pump, which is buried in the depths of the gas tank, and only then try to change the filter. This discrepancy arose due to the fact that the manufacturer overestimated the quality of post-Soviet gasoline, which clogs filters exactly twice as fast as they need to be changed according to regulations. The owners have to unravel this conflict on their own. However, the location of the fuel pump in the fuel tank is also justified by the fact that gasoline serves as a coolant for the pump engine.

Why is an electric pump better than a mechanical one?

The efficiency of an electric pump is clearly visible on diesel cars, where diesel fuel is supplied under high pressure, and on gasoline cars with a direct injection system. Fuel is injected directly into the cylinders of the power unit. And in this case, a conventional mechanical pump simply will not be able to provide the required level of pressure.

Direct injection injectors use two pumps. The electric one is installed in the fuel tank, from where it pumps gasoline, and the second pump is the injection pump. The latter’s task is to increase the pressure of gasoline before it is directly supplied to the injectors.

Diagram of operation of a fuel pump on an injection engine

The electric pump is capable of pumping an average of 1-2 l/min. Crazy efficiency, which is only possible at a pressure of 3-4 atm. To equalize the operating pressure to the desired performance level, a special regulator is used in the fuel rail. It's called RDD.