Body replacement 2121

Buying a VAZ body is a great chance to save money on expensive major repairs or buying a new car. It has long been proven that it is more desirable to immediately send a decrepit body for scrap than to periodically repair it in services where they charge quite a lot of money for services of this kind. A new body for the most popular Russian SUV is an opportunity for a radical update. On the other hand, if you understand the specifics of body repair, you can carry out the repair yourself.

Body replacement

In Russia, several companies are engaged in the sale of metal bodies for domestic cars, either assembled or in separate parts. Having familiarized yourself with the assortment of these products, you can see that such stores offer a wide range of colors, which allows the car owner to quickly choose the appropriate option.

As a rule, bodies intended for Niva cars, equipped with three doors, were painted at the factory in several standard colors. All of them are listed below:

- Snow white (factory code 202).

- Nessie (factory code 368).

- Jasper (factory code 140).

- Baltika (factory code 420).

- Glacial (factory code 221).

The VAZ-2121 car with five doors was painted at the factory in three color options:

- Nice (paint serial number - 328).

- Snow Queen (paint serial number – 690).

- Quartz (paint serial number – 630).

- White cloud (paint serial number – 240).

Getting to know the VAZ 2121

One of the best creations of AvtoVAZ, the 2121 autocar, with virtually no design changes, will soon pass the 40-year mark on the assembly line. All over the world there are only two such record holders. In a word, the Niva today is the most popular SUV on the used market, and this is not without reason.

The 77th year of the last century was marked by the appearance of a new machine at the Volzhsky plant, which almost caused a revolution. There were practically no similar models all over the world, since the Niva was equipped with an advanced spring suspension, all-wheel drive and a monocoque body instead of the supposed frame one, which was rare at that time.

Surprisingly, the SUV turned out to be cheap and very practical. Not a single model produced at the factory, and in general, if we add comfort and convenience, then not a single vehicle in the world with a 4x4 formula could boast of such a set of qualities. Most of the all-terrain vehicles of those years were outdated vehicles with a military past. The only real competitor to the Niva was the Range Rover, which came out 6 years earlier.

Getting rid of scratches

Minor rust and blistered paint that appears on a car is not a reason to completely replace the body. In this case, the operation to restore the Niva can be easily carried out independently, while saving a decent amount of your own funds.

For example, scratches can be removed by polishing the paintwork. To carry out this operation, various grinding compounds and special materials are usually used. With their help, you can easily and quickly remove the top layer of paint, thereby smoothing out shabby areas on the body. Complete elimination of scratches is only possible if the outer layer of paintwork is not severely damaged. It is also not recommended to remove too much paint when restoring the Niva -2121 with your own hands.

Tuning the suspension of Niva 2121

Since the Niva is an all-wheel drive SUV, when tuning it is necessary to pay attention to the suspension. The first step is the Niva lift - increasing the ground clearance. This will create an impressive reserve for overcoming various obstacles. The concept of tuning the Niva 2121 chassis, as well as a suspension lift, includes:

- Installation of spacers between suspension elements. You can make them yourself or buy them in stores.

- Installation of shock absorbers "Rancho"

- Installation of springs VAZ 2104

- Strengthening the front and rear axles using steel boxes

The Niva 2121 suspension lift is a simple process from a technological point of view that can significantly increase the vehicle's cross-country ability. It must be remembered that lifting is directly dependent on the size of the wheels; the larger their diameter, the more significant modifications will be required. Therefore, it is necessary to maintain a balance so that tuning the Niva 2121 suspension with your own hands does not turn into a headache.

Tuning of the Niva 2121 transfer case is also necessary, although this process is largely a refinement. The main problem is the backlash of the front and rear axle shafts. It can be eliminated by installing new components:

- Bearings (it is better to install a double-row variety)

- Lids

- Valov

- Flanges

A good solution would be to strengthen the shaft support. To do this, instead of the original flange, install a modernized one, which has an additional bearing and oil seal.

The second common problem with transfer case is leaking seals. The solution here is extremely simple, you should correctly install high-quality oil seals and the childhood disease of the unit will be eliminated.

The third problem is the correct alignment of the transfer case in the horizontal and vertical plane. This is necessary to reduce vibration and, accordingly, wear of the moving parts of the unit. You can do the alignment manually, but it takes a lot of time, requires patience and the result does not always meet expectations. It is much easier to use a subframe - a special design that is attached to the bottom and greatly simplifies the alignment of the transfer case.

Geometry restoration

If the body is severely damaged as a result of a vehicle collision, craftsmen have to restore the car to its former geometry. Metal deformation also occurs as a result of sudden temperature changes or obsolescence of the structure.

Active operation, as well as the use of a car in harsh natural conditions, will inevitably lead to rapid wear and tear of the body of personal transport. Poor quality road surfaces often lead to excessive tearing of bolted and welded joints, reducing the life of the vehicle.

If it is necessary to restore an old Niva and eliminate severe damage to its body, it will be necessary to diagnose and restore the geometry of the car using high-tech equipment in a car service center. It is impossible to perform such an operation correctly on your own in a garage.

Major malfunction of the rear body of the car

In the rear part of the body, the transverse link mounting bracket, popularly called the “soldier”, suffers more. Its correct position ensures the exact location of the rear axle relative to the front wheels. When the car moves along a deep rut at a decent speed, this bracket experiences shock load from the lateral rod. Constant exposure leads to fatigue and the metal weakens. The time comes when a good blow is enough for the “soldier” to change his position. As a result, the running parameters are violated.

In addition to the above reasons, the side members may weaken as a result of an accident. Despite the fact that the geometric parameters are restored, the places where they were deformed acquire “memory”. Subsequently, they can bend in these places from a slight load.

Off-road enthusiasts also strengthen the Niva's side members. They strengthen the body for the installation of non-standard chassis and additional equipment. For example, a winch.

Types of body repair

If after diagnostics it turns out that only some parts of the body have been deformed, the Niva is restored by tapping or squeezing out the damaged parts of the car. This work is carried out in several ways:

- No painting. In this case, the repair is based on such a property of steel as the tendency to straighten to its original position after deformation. At the same time, car service workers use special tools and technologies to squeeze out dents. If necessary, the restored part is polished. Typically, this method is used if the car's paintwork is not damaged.

- The second method is to straighten the part by tapping it with a wooden or rubber hammer. Strong blows to the part can damage the material being repaired, therefore, to carry out such an operation, considerable experience will be required.

- In some cases, repairmen will cut out the damaged body part. This is done in cases where the sheet steel is completely damaged and cannot be restored. To replace the removed part of the body, a new one is made and welded. Then the repair area must be painted.

- If the above methods for restoring a Niva after an accident do not bring success, a mechanic will replace the entire body parts.

Body care

To extend the life of the car body and avoid costly repairs, a responsible vehicle owner carries out a number of preventative measures. Such do-it-yourself Niva restoration measures include:

- removing any rust with sandpaper;

- treating rust spots with a rust converter;

- painting of treated body parts;

- covering newly painted parts of the car with protective varnish;

- anti-gravel treatment of car thresholds with special means;

- reinforcement of the body with a frame.

Tuning the instrument panel of Niva 2121

Traditionally, domestic designers developed the Niva not as a luxury, but as a means of transportation, and equipped it with an instrument panel that looks dull and sad. There are many tips on how to bring it to mind with your own hands. In this case, it will be transformed, but its functionality will remain at the same level. Therefore, the best tuning of the Niva 2121 panel is its complete replacement.

Why should the body be strengthened?

The procedure for restoring a Niva-Chevrolet, like other car models, is not an easy task for a beginner in this matter. Such work takes a lot of time and effort, but the result will extend the life of the car for several years, keeping your personal vehicle in good condition.

First of all, to restore the Niva’s body, as well as to modernize it, the side members on an old car are strengthened. To do this, steel sheets up to 5 mm thick are welded onto them. At the same time as this work, the suspension elements are being strengthened. It is especially important to strengthen the front side members in the following cases:

- It is planned to install stiffer shock absorbers on the car.

- Large diameter wheels are used.

- The Niva is equipped with power metal bumpers and winches.

How to strengthen the spars

First of all, to restore the Niva-2121, the side members are strengthened. To carry out such an operation? you should prepare, namely:

- Provide free access to the spar. To do this, the car should be driven onto an overpass or raised on a lift, and then the wheels should be removed from the vehicle.

- Then you need to remove the caliper. To do this, you must first unscrew the special lock from the top of the support.

- Next, use a hammer to knock out the fastening unit.

- After this, you need to loosen the shock absorber fasteners on the top and bottom sides.

- The cylinder, which is part of the brake system, is hung on the hoses.

- The upper arm must be completely removed from the vehicle.

- It is also necessary to remove the cup and bump stop.

- At the final stage, it remains to dismantle the gearbox and steering pendulum.

Free access to the spar is guaranteed!

During the restoration of the Niva, it would be useful to check the condition of the places intended for the installation of shock absorbers. If there are no signs of corrosion on them, they should be pulled out. If difficulties arise, you can drill the welds with a metal drill using a drill bit number 10. You can see all the welds only if you thoroughly clean the metal from rust and contamination.

Next, the spar is thoroughly cleaned to check for various defects. After this, sheet metal is mounted on the clean part, through welding, bolted connections and clamps, to strengthen the structure.

Technological features of strengthening Niva side members

Most often, the appearance of cracks, tears or rust on the side members is a consequence of a vehicle accident. However, such defects can occur due to the significant age of the car and wear of parts. Minor cracks and damage to body parts are most often repaired by welding the damaged areas. However, if the product bursts, then its complete replacement is necessary, since it is the main link to which the suspension elements are attached. Most often, when parts are replaced, the side members on the Niva-2121 are also strengthened in parallel to increase their service life and resistance to loads under aggressive operation.

To strengthen an element of the Niva’s body, ready-made linings are most often purchased, or reinforcing parts are made independently by the owners of the car according to drawings. They can be found on the Internet, however, if you have all the technical documentation for the car, then the drawing can be found in the documentation set.

Preparatory stage for the modernization of the Niva's front side members

Work on strengthening the Niva's side members must begin by studying the current situation. To do this, you need to open access to the body element. The car must be driven into a pit or overpass, the wheel and caliper must be removed and the ball nut must be unscrewed. It takes longer to disassemble the front suspension components, remove the shock absorbers and the upper arm. After this, you need to unscrew the brace that secures the beam and spar, and the shock absorber house is dismantled.

All elements are cleaned with a grinder to remove rust and deteriorated metal. This procedure is labor-intensive, however, proper cleaning subsequently guarantees high quality welding work. The next step will be the manufacture of a lining to strengthen the body element.

Manufacturing technology of the spar amplifier

To make the spar reinforcement, experts advise using steel sheets three or four millimeters thick. Initially, according to the drawings, it is necessary to make a model of the product from thick cardboard. It is important to very accurately transfer all the mounting holes onto the cardboard and the exact location of the bolts.

If the chassis was previously modified, the configuration of the fasteners was changed, then it is necessary to supplement the layout with modified elements. Everything is transferred from the template to the sheet of metal. The overlay is cut using a grinder and an electric jigsaw. Next you need to drill the mounting holes. You will also need to drill small holes on the plate in a chaotic manner that will simulate spot welding.

Reinforcement of front side members

Before starting welding work, it is necessary to check the condition of the spar itself. If it needs to be replaced, then it must be dismantled by cutting it behind the beam and separating the part from the body. It is necessary to install a new product in place of the old element and tighten all fasteners. Additionally, the fastening points of the old spar are cleaned. Then you can proceed directly to the installation of the Niva body element amplifier.

The prepared lining must be tightly attached to the spar using bolts. It is better to carry out welding semi-automatically. The product is scalded in a circle, and the holes prepared for spot welding are welded. Next, the shock absorber house is installed and welded. It is important to set it strictly perpendicular to avoid problems with silent blocks in the future.

Manufacturing of the spar amplifier

In order to correctly carry out the restoration process of the Niva 21213, an amplifier for the spar should be made. To do this, you first need to cut out a pattern from thick cardboard. Next, you need to mark the points on the paper where the bolts and clamps will be screwed in. After this, you need to cut a three-millimeter sheet of steel according to the layout using a grinder.

Next, you need to drill holes to attach the new part to the car body. During fastening, you should make sure that the piece of metal fits tightly to the spar; only after that can it be secured with bolted connections and welding around the entire perimeter of the part.

After completely assembling the car, it is necessary to coat all cleaned metal parts of your VAZ-2121 with anticorrosive. As a rule, such a coating dries within 24 hours. After this operation, the machine is ready for further operation.

Final works

In order for the result of the work to please you for many years, it is necessary to protect the welding areas from corrosion and impacts from stones flying from under the wheels.

For this purpose, rubber-bitumen mastic is used, to which polymer chips are added. It is applied with a brush or a special sprayer connected to a compressor. Before applying the composition, the bare metal should be coated with primer. It must contain phosphoric acid, which will protect the part from corrosion.

Strengthening other areas of the car

The metal body of the Niva car has several more places that need strengthening over time, since they can no longer withstand increased loads during operation of this vehicle. All of them are listed below:

- Subframe for transfer case. Over time, owners of Niva VAZ-2121 cars are faced with the problem of loosening the fastening of the gearbox and transfer case, which leads to increased vibration during engine operation. You can get rid of this problem by installing a subframe under the transfer case of a passenger vehicle. As a result of this procedure, the working unit of the car receives additional reliable support and protection from damage while driving.

- Strengthening or replacing the front suspension beam. Some craftsmen install, instead of the old spare part, a reinforced front suspension beam with modernized lower control arm bushings. This design can securely fix the axes, preventing them from bending.

- Replacement factory ball joints are more durable.

- Removing the suspension springs and installing stiffer parts instead. Springs from the Volga are often installed on the Niva, after cutting the spare part by 1.5 turns.

- Strengthening the connection between the rod and the body.

- Dismantling factory thresholds and making new, stronger ones. It also wouldn’t hurt to install thick moldings on the reinforced thresholds. The thresholds must be firmly welded to the side members of the vehicle.

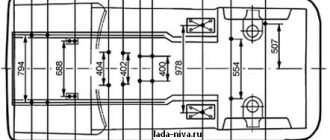

Body 2121 with its parts

| 1 hood | 14 floor and side panel connector | 27 floor mat holder | 40 lower sliding window seal |

| 2 upper bulkhead reinforcement | 15 front wing | 28 door sill trim | 41 seal frame |

| 3 right side | 16 front fender mudguard | 29 rear floor mat | 42 door seal |

| 4 wind window frame | 17 front panel | 30 front floor mat | 43 door sliding glass seal |

| 5 roof panel | 18 radiator trim panel | 31 front side panel upholstery | 44 tailgate seal |

| 6 rear floor panel | 19 upholstery holder | 32 side trim | 45 tailgate glass seal |

| 7 side rear stand | 20 upper door trim holder | 33 connector | 46 side glass seal |

| 8 roof reinforcement | 21 door trim | 34 fastening bolt | 47 rubber plug |

| 9 outer door panel | 22 arch and side trims | 35 bracket | 48 wind window frame seal |

| 10 inner tailgate panel | 23 roof lining | 36 bumper beam | 49 windshield seal |

| 11 outer side door panel | 24 roof liner | 37 pad holder | 50 hood seal |

| 12 inner side door panel | 25 anti-squeak bushing | 38 rubber pad | 51 air supply box seal |

| 13 left side | 26 upholstery fastening nut | 39 rotary window seal | 52 front bumper connector seal |

Is it worth changing the body to a new one?

The body of the VAZ-2121 is the most expensive part of this domestic car. You should take good care of it and carry out cosmetic repairs. You should also cover the thresholds with anti-gravel protection, promptly remove rust from the metal, and wash the car as often as possible, especially in the winter, because that is when reagents are actively used on the roads, corroding car body parts and rubber seals.

If the body has fallen into disrepair, is heavily rusted, or has large holes formed on it that cannot be repaired, the easiest way is to replace it with a new one. However, remember that a radical replacement of the body can result in problems when meeting with traffic police officers. You should come to the registration point in advance and register the changes made to your car.

If the body of the VAZ-2121 has undergone minor corrosion, the best option for the owner would be local cosmetic repairs of metal parts, as well as strengthening of some components of the car.

Tuning headlights of Niva 2121

Tuning the optics of the Niva 2121 sets the tone for the overall modernization concept. For example, installing headlights from Mercedes Gelandewagen will create the ambience of a powerful, aggressive SUV. Sports modifications of the headlights will add dynamics to the appearance and emphasize the streamlined shape. High power LED headlights can be installed to increase visibility. Another good option is to install lensed, crystal or bi-xenon headlights.

The standard models have virtually no potential for modernization, so it is better to replace them with new ones.

Tuning the rear lights of the Niva 2121 is carried out according to the same scheme as upgrading the optics. It is easier and more efficient to replace standard lights with new modifications.

Buying a VAZ body is a great chance to save money on expensive major repairs or buying a new car. It has long been proven that it is more desirable to immediately send a decrepit body for scrap than to periodically repair it in services where they charge quite a lot of money for services of this kind. A new body for the most popular Russian SUV is an opportunity for a radical update. On the other hand, if you understand the specifics of body repair, you can carry out the repair yourself.