April 10, 2017 Lada.Online 155 107 9

Currently, all LADA models (Lada XRAY, Vesta, Largus, Granta, Kalina, Priora, Niva 4×4) without exception are equipped with ABS (anti-lock braking system). During the operation of the car, many owners notice that the ABS and ESC lamps (if this system is available) light up on the instrument panel. Let's figure out how to solve this problem and improve the design.

How ABC works

The anti-lock braking system was developed when it became clear that when the wheels suddenly jam, the car loses stability and is difficult to control. Moreover, the quality of braking did not improve, and the car was pretty much carried off the road. Therefore, a system was developed that, by regulating the pressure in the brake system pipes, allows the wheels to turn slightly. This significantly improves vehicle dynamics, allowing the driver to control the vehicle more confidently. But despite its apparent simplicity, this is a rather complex process that requires the coordinated operation of many mechanisms included in the anti-lock braking system. If any of the components fails, a warning lamp lights up on the instrument panel.

You can often hear the question from drivers: “Why is the ABS sensor on?” It is important to know that when the warning light comes on, it does not necessarily indicate a faulty wheel sensor.

Cuvette test Lada Vesta with and without ESP

The winter road promises many hidden dangers. Often the right side of the roadside looks like a snow-covered, flat surface. However, a very large number of motorists who, for one reason or another, have to drive onto it, annoyedly (and, alas, belatedly) end up in a real ditch, covered with a seemingly horizontal layer of snow.

Our new test of the Lada Vesta is designed to find out what advantages the ESP system provides, specifically designed to control the distribution of vehicle forces in difficult situations. For greater clarity, we decided to drive into a ditch and try to get out of it, first without the exchange rate stabilization system, and then using it.

Let's say right away that the car had to work hard. Almost in a dangling state, its two wheels balanced on the edges of the ditch - in this case, as a rule, it is almost impossible to do without outside help. But we dare to assure you that the factory electronics did not let us down. The on-board “brains” accurately dosed the injection of gasoline, allowing not only to let the car stand up straight, but also to climb onto the opposite side of the ditch, returning to the roadway.

Let us remind you that we performed all the above maneuvers with the ESP system engaged.

Next we disabled ESP. In this case, no attempts or tricks to move the car from an awkward position were successful. The wheels of the front axle only bit into the snow and ice harder and harder. In such a situation, leaving the ditch is possible only with great luck or with outside help.

The test results revealed a clear benefit provided by the ESP system on the Lada Vesta. This applies to both smooth road surfaces and roads with poor traffic. In general, the presence of an electronic stability control system will be an excellent help for both beginners and experienced drivers - after all, when they want to help you, is it worth refusing?

How to check the abs sensor with a multimeter

How ABC works on Lada Priora

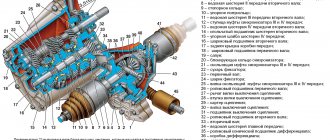

Like most modern car systems, ABS is computer controlled. But in addition to the electronic control unit, it also includes several sensors and actuators. The entire system consists of several elements. 1

.

Electronic control unit (ECU). 2

.

Sensors on wheel hubs 4 pcs. 3

.

Brake fluid pressure valves in the system 4 pcs. 4

.

EVN (Electric Return Pump). 5

. Warning light on the instrument panel. Despite all its apparent simplicity, this is a rather complex, high-tech system. Each sensor transmits data on the rotation speed of the Priora wheel to the electronic control unit. Based on the data received, the control unit sends a signal to the brake system valve, which, when you press the brake pedal, releasing pressure, prevents the wheels from completely locking and starting an uncontrolled skid of the car.

Options for self-diagnosis of the system if ABS lights up on the instrument panel

Experienced diagnosticians recommend starting your own troubleshooting in the ABS system with a visit to a car wash for high-quality and complete cleaning of wheel rims and hubs. As a result of this, it is possible to clean the system sensors as much as possible, for further correct operation of the system. If after this the ABS lights up, then proceed to the steps described below.

You can also determine the cause of the ABS system malfunction signal by performing a simple test: you need to accelerate the vehicle, and at a speed of about 100 km/h, turn off the car radio and close the windows. If, as a result of this manipulation, you can hear extraneous noise in the area of the front or rear wheels, most likely, one of the bearings of the hubs has critical wear and needs to be replaced. Additionally, you can perform the following manipulations:

- Check the safety block, and if faulty elements responsible for the ABS system are found in it, replace them.

- If possible, try to determine the error code, which will help identify the faulty system element.

- Consult with an experienced auto mechanic, describing to him in detail the essence of the problem, and based on his consultation, try to independently restore the system’s functionality.

- Check the condition of the brake control system sensors and clean them of dirt and corrosion. To access the sensors, simply jack up the car and remove the wheels.

- Inspect and test the electronic control system of vehicle components.

- Carry out diagnostics of the ABS system at a specialized service center.

Naturally, the last item on the list will be completely justified, but also the most costly, since this is the only way to correctly identify the source of the problem, determine the subsequent tactics and budget for repair activities. Specialists will test all car systems using a special scanner and detect any errors. Thus, in a short period of time, all important information about the state of the vehicle components is collected, possible errors are identified, which will help determine the malfunction as accurately as possible.

ABC control unit on Priora

Structurally, on the Priora, the ABS ECU is mounted together with the EWH and valves that regulate the pressure into a single unit - the hydraulic unit.

It is located on the front left side member of the vehicle. The hydraulic unit is connected to the entire system by a common wiring harness. It includes pipes for supplying brake fluid to the working cylinders. An EWH is also installed here, increasing the pressure in the system. This unit does not understand handicraft conditions. Usually replaced entirely with a new one.

ABS sensor on the hub

The sensors that supply wheel speed data to the control unit are made on the principle of a Hall sensor. By the way, most rotation sensors use exactly this principle: changing the voltage on the semiconductor of the sensor, depending on the passage of a control point on the rotating disk near it. It is in correlation with the signals from the ABS sensors that the control unit manipulates the valves.

Electronics

This is a failure of components associated with electronics:

• breaks in the electrical wiring harness; • failure of rotation speed sensors; • break or short circuit of the control valve activation coil; • failure of the return pump electric motor; • valve activation relay failure; • program failure, or failure of the ABS control unit.

ABS FAULTS IN THE FIELD OF HYDROMECHANICS

In this case, the most typical failures are leakage of oil seals in various connections and assemblies. Deterioration of working surfaces on disks, and as a result, a change in the distance between the sensor and the readable surface. System valves jamming. Clogging of hydraulic drive pipes and breakdown of the working part of the return pump.

DETERMINING ABS MALFUNCTION

The serviceability of the ABS system in the Priora, like in any car, is a very important issue. It is very convenient that the slightest malfunction in its operation will immediately be reflected on the dashboard. The ABS warning light will come on or it will not go out after the required time after turning on the ignition.

There's no need to think twice about it. You urgently need to go for computer diagnostics to a decent service station. Modern Priora ABS ECUs have access to a diagnostic connector. They are perfectly diagnosed by both portable portable scanners and stationary motor testers. Since all ABS electronics are very closely connected with the mechanical part, most breakdowns in this area can be determined by an experienced diagnostician by scanning the ECU. For example, the operating valve is jammed in one of the directions. What happens: the coil, figuratively speaking, tries to influence him, but he doesn’t move. The computer, noticing a load violation in the circuit, will immediately give a signal. The “ABS sensor” will light up. When connected, the technician will see the direction that needs to be looked at and quickly fix the problem.

FEATURES OF ABS PRIOR DIAGNOSTICS

Some scanners that read faults recorded in the ECU produce only alphanumeric codes, so for particularly meticulous car enthusiasts it makes sense to have on hand the decoding of these codes for the VAZ Priora: C0035 - malfunction of the left front sensor; C0040 – the same for the front right; C0045 – rear left malfunction; C0050 – the same for the right rear; C0060 – failure of the left front exhaust valve; C0065 – front left intake valve failure; C0070 – malfunction of the front right exhaust valve; C0075 – malfunction of the front right intake valve; C0080 – rear left exhaust; C0085 – rear left inlet; C0090 – rear right exhaust; C0095 – rear right intake valve; C0110 – return pump circuit malfunction; C0121 – failure in the relay circuit for turning on the supply voltage of the valves; C0161 – malfunction in the brake light circuit; C0245 – incorrect reading of rotation speed; C0550 - ECU malfunction; C0800 - voltage mismatch in the ABS network. This list allows you to find a fault, even if a simple scanner for a Priora produces only codes, and find out why the “ABS sensor came on.” Still, it is worth remembering that it will be more pleasant for the technician to hear the correct wording - the anti-lock system malfunction lamp is on.

FakeHeader

Comments 12

That's it, guys, the problem is solved. There was condensation in the oil receiver, and this condensate froze. We drained the oil, removed the filler, warmed up the oil receiver, filled in oil, started the engine, heated the engine to 80 and drained the oil, then poured in new oil. Now everything seems to be fine.

Drain the oil, my sump and change the oil receiver, a friend did this on a viburnum and the machine came to life.

I don’t think it’s anything serious, maybe the oil is frozen. Another option is to check the wire that goes to the sensor with a tester; if the light does not light, it means there is an open circuit, this happens in cold weather

I had this happen with a couple of Kalinovodovs as well. Condensation. It appears if you go on short trips in winter. Then it freezes in the car along with the oil in severe frost. I warmed up the pan and changed the oil. I switched to 5v40 Mobile. Before this, the owner supposedly had zero .Thank God this didn’t happen again!

It is no secret that the engine is the main component of a car, for the normal functioning of which a number of conditions must be met. One of them is maintaining optimal engine oil pressure. Reducing this parameter can lead to a number of problems - increased wear on the engine, a decrease in its power, disruption of the functioning of some components, and so on. But more about everything.

Functions of motor oil

Let's remember what tasks are assigned to motor oil. There are several of them:

- Reducing friction between the main elements of the engine, as well as increasing their service life.

- Formation of the required pressure level in all systems and components equipped with a hydraulic drive.

- Effective heat removal from the piston system, bearings and other rubbing elements of the system.

- Reliable protection of all engine components from corrosion.

- Prevention of various deposits and the appearance of soot on the walls of the motor.

- Protection of the engine from the action of acids that may form during combustion of the air-fuel mixture.

- Elimination of any form of sediment in the main components (oil pipeline or engine crankcase).

Main reasons for lack of oil pressure

Before checking the oil pressure in the system, you must clearly understand the reasons for this phenomenon. There are several of them:

Reduced oil level in the power unit. To avoid this problem, you should check the oil level from time to time under the following basic conditions - the engine should be stopped and cool. If the level drops, it is necessary to top up using oil of the same type, brand and viscosity. After this, check the pressure again. Increased oil filter resistance. Often, novice car enthusiasts make a mistake in choosing this unit and install a filter of the wrong type (intended for a different model). In such a situation, the throughput of the newly installed filter may not correspond to normal engine operating parameters. Oil pump failure. A malfunction of this unit is a very common pressure issue. Its malfunction can be caused by simple contamination and the presence of significant deposits on the internal filter elements. To fix this problem, you may need to replace the pump. As a rule, car enthusiasts do this work with their own hands, without going to a service station. Increasing the gaps between the main elements of the power unit. The main reason is wear and tear. There are times when, even if all the problems listed above are eliminated, the pressure in the system remains at an extremely low level. In such a situation, disassembling the engine and checking the main clearances can help out.

In particular, special attention must be paid to the distances between the bearings and the connecting rod journals. Coolant or fuel getting into the engine oil. A similar problem can occur for a number of reasons - burnout of the cylinder head gasket, wear of the rings, failure of one of the cylinders, and so on.

In the event of such a malfunction, it is no longer possible to do without changing the oil and repairing the engine. The oil pressure sensor is broken. If after diagnostics (we will look at its essence below) it turns out that the oil pressure in the systems is normal, but the sensor still gives a signal to the contrary, then the only way out is to replace the sensor. The wiring has failed. In domestic cars, this reason is one of the most common. The emergency oil pressure light may light up due to damage to the switching conductors.