When is it necessary to flush the engine when replacing antifreeze?

The engine cooling system must be flushed before replacing antifreeze:

- when changing the class of coolant, for example, they decided to replace G12 antifreeze with G13, or it is not known at all what kind of liquid is in the cooling system;

- if contamination of the coolant in the expansion tank of the cooling system is visually determined;

- if the drained coolant contains rust particles and other contaminants;

- if additional compounds were poured into the cooling system to eliminate leaks.

How to flush the engine cooling system when replacing antifreeze

Washing is carried out with clean water, preferably distilled. It is advisable to fill not with water, but to prepare a solution containing 80% water and 20% antifreeze (which will be poured after washing).

This solution is relatively cheap, allows you to thoroughly flush the cooling system; the chemical elements of the new antifreeze will react with the elements of the cooling system and form a protective film.

If you use distilled water and antifreeze concentrate for pouring not ready-made antifreeze, the addition of the concentrate to the washing solution is reduced by 5 times the norm. If distilled water is not available, then it is permissible to use boiled water for rinsing (boil for 25–30 minutes).

Recently, a new product for flushing the cooling system has appeared on the market. It does not have a strong acid or alkaline reaction, its pH is neutral. This drug does not destroy the elements of the cooling system and is a “soft flush” option.

It is added to the expansion tank of the cooling system 1–2 thousand km before the planned replacement of the coolant. When using such preparations, it is advisable to then flush the cooling system with a solution of antifreeze and distilled water.

The use of various special compositions based on acids and alkalis is not recommended. After flushing with such compounds, leaks may form in the cooling system. In addition, it will not be possible to completely drain the coolant or flushing fluid; the remaining volume may have a bad effect on the composition of the new antifreeze.

WASHING THE SYSTEM WHEN REPLACING THE COOLANT: HOW TO DO THIS AND WHAT TO USE?

Flushing the cooling system is a necessary step when replacing antifreeze. It is especially relevant when the drained liquid is contaminated with slag, oils, rust, silicate gel and other compounds. This operation can be omitted only if the drained antifreeze is clean and the replacement poured in is of exactly the same type and brand.

Why is flushing necessary? It solves two problems at once. The first is cleaning the system from contaminants that have arisen during operation and interfere with heat removal and fluid circulation. The second task appears when you decide to change the brand or type of antifreeze, and is to remove the remnants of the previous composition. This is necessary so that the two liquids (“old” and “new”) do not enter into a chemical reaction, which can significantly reduce the anti-corrosion properties of the filled antifreeze.

If you neglect flushing, rust and other contaminants will be washed away by the new coolant - and all these sediments will remain in it, further creating the threat of clogging of the radiator channels and pipes.

In the photo below you can see the “damaged” pipe located in the bus cooling system. The system was not washed, but antifreeze was immediately poured into it, as a result of which the silicate components included in the previous fluid, coupled with rust, accumulated in the pipe and blocked it. The result was that the heating system was not working (and this was at the beginning of winter), as a result of which the antifreeze had to be replaced again, this time with flushing.

Washing methods

Soft rinsing. This method is the simplest and does not require any tricks. You simply fill the cooling system with water (necessarily clean!) and start the engine at 10-15 to idle. If you add about 10% concentrate or 20% new coolant to this water, the flushing efficiency will increase significantly. This technique allows you to remove the remnants of the previous antifreeze (silicates in particular), as well as partially coat the metal with new antifreeze.

The argument in favor of this method is that it poses a much lower risk of leaks, while strong agents can cause holes to form in places where the metal is already corroded.

20% of new antifreeze added to the flushing water also increases the service life of the new fluid. As is known, in the first minutes of operation, a significant amount of additives leaves the solution, settling in the foci of metal corrosion, as a result of which the pH of the antifreeze decreases by 1-1.5 units. Thanks to gentle washing, a kind of “primer” appears on the walls, which helps to retain more additives in the antifreeze and keep its pH at the same level.

If the contamination of the system is quite severe (this is indicated by the state of the drained liquid), it is worth re-flushing. Attention: do not pour cold water into a hot motor, let it cool down - otherwise the engine may simply crack.

In addition, different automakers have their own methods for flushing the cooling system. Companies that produce trucks approach this issue especially scrupulously. Let's give a few examples from practice.

Thus, Caterpillar insists on flushing before replacing coolant, especially if we are talking about replacing the conventional composition with the company’s proprietary antifreeze - Cat ELC. The washing itself occurs as follows. The first stage is rinsing with water, the second is with a specialized cleaning composition Caterpillar Standard Cooling System Cleaner, the third is water again. If severe contamination occurs, the pipes are removed and cleaned separately. Next, you need to continue washing with water while simultaneously starting the engine and warming it up to 50-60°C. Flushing can only be stopped when the water flowing out of the system is spotlessly clean.

A slightly different approach is practiced by specialists at MAN service centers. The first flushing is carried out using a 60% solution of new coolant concentrate and the engine is started for about 20 minutes (no more). After this, the antifreeze is drained again, carrying out a similar flushing, but now the concentrate content is only 10%. The third stage is pouring new antifreeze diluted with water in a ratio of 50:50.

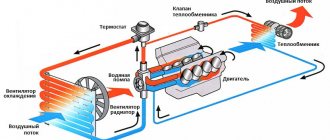

And finally, the last example is Cummins. According to the requirements of its specialists, washing is carried out in this way. First, even before draining the old antifreeze, start the engine for half an hour. This is necessary to open the thermostat and freely circulate fluid through the radiator, cabin heater and additional heat exchangers. After this, you should drain the old antifreeze as soon as possible, before all the contaminants contained in it have time to settle on the walls again.

Next, the system should be washed with a specialized cleaning agent. The engine runs at idle, again for half an hour, and the fluid temperature is at least 85°C. The next step is to fill the system with water and flush for 15 minutes, still at idle. If oil residues are found in the drained liquid, the flushing must be repeated - with a cleaning agent, then again with water. The pipes are removed and cleaned separately.

The cleaning agent should be selected according to the table, focusing on the content of acids or alkalis in it, as well as on the effectiveness of use for certain types of contaminants.

| Type of pollution | Alkaline cleaner (such as Fleetguard Restore) | Acidic cleaner (such as Fleetguard Restore Plus) |

| Silicate gel | Excellent | Bad |

| Oil, grease or fuel | Excellent | good |

| Scale | Bad | Excellent |

| Rust | Bad | good |

| Solder slag | Bad | good |

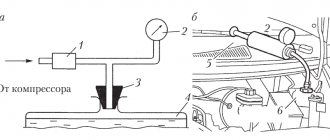

Cooling system flushing process

The flushing procedure is not much different from replacing the coolant. It is carried out on a lift or using a pit, although if desired, on many car models, this work can be performed simply on a flat platform. All necessary tools and containers for drained liquid are prepared.

The procedure for flushing and replacing the coolant should be carried out on a cold engine, since when the engine is running, the coolant temperature reaches 78–115 °C. Hot fluid may be under increased pressure in the cooling system and pose a danger to humans.

How to flush the engine cooling system when replacing antifreeze:

- Visually inspect the cooling system hoses. If there are cracks, purchase new hoses and steel clamps to secure them.

- Remove the cap from the cooling system expansion tank.

- Place a container to collect the liquid under the drain hole in the radiator housing.

- Open the drain hole in the radiator housing (usually located at the bottom of the radiator).

- Open the filler hole in the radiator housing (usually located on top of the radiator).

- Allow the liquid to drain completely.

- Close the drain hole at the bottom of the radiator.

- Pour the flushing solution into the radiator up to the neck and then tightly close the filler hole with the cap.

- Pour the flushing solution into the expansion tank of the cooling system to the maximum level mark. Do not tighten the cap, just place it on top of the neck of the tank to avoid splashes.

- Start the engine, turn on the heater. Warm up the engine until the electric forced cooling fan (located next to the radiator of the cooling system) turns on. At the same time, monitor the fluid level in the expansion tank. Top up periodically. If necessary, squeeze the cooling system hoses with your hand to remove air bubbles more completely, using protective gloves, since the surface temperature of the hoses can be high.

- After the engine has completely warmed up, the air from the cabin heater is hot, let the engine run for 5-10 minutes and turn it off.

- Close the expansion tank tightly with the lid and let the car sit for several hours, or better yet a day, then drain the flushing fluid and add antifreeze.

Attention! An aqueous solution of antifreeze does not have sufficient frost resistance.

What happens if you change green antifreeze to red?

“I’m going to change the green antifreeze to red. Is it necessary to flush the cooling system, can there be any negative consequences, and if so, what are they?”

If all that is known about the old antifreeze is that it is green, flushing the cooling system before adding new antifreeze will definitely not be superfluous, because the problem lies not in the color of the coolant, but in its chemical composition.

It is indicated in the container in which the antifreeze was purchased. If the canister from the old antifreeze is lost, nothing can be said about whether the new red antifreeze will be compatible with the old green one, some of which will probably remain in the cooling system after draining.

All coolants consist of a base base and additives. The basis of most antifreeze is an aqueous solution of ethylene glycol, but there are also propylene glycol liquids.

The concentration of ethylene glycol or propylene glycol in water determines the freezing point of antifreeze.

Additives occupy only 3-7% of the volume of antifreeze, but the ability of the liquid to prevent corrosion and cavitation on engine parts in contact with antifreeze, its service life and other properties depend on them. By the nature of the additives, coolants are silicate and carboxylate, which are designated by the abbreviations SF (Silicate Free), OAT (Organic acid technology), SNF (Silicate Nitrite Free) or Organic coolant, as well as hybrid, often labeled Hybrid coolant or HOAT ( Hybrid organic acid technology), and Lobrid, which appeared about 7 years ago in response to the requirements of the VW TL 774-G (G 12++) specification. You can also mention nitrite antifreezes, but they are even more outdated than silicate ones, so it’s unlikely that any serious manufacturers continue to produce them.

So, the new antifreeze and the remains of the old product must be analogous both in glycol base and in the nature of additives. If antifreezes that are not similar are mixed, there is a risk of conflict between the bases and/or additives. For short-term use, provided that the mixture is drained at the end of the trip and the cooling system is flushed, mixing all antifreezes is allowed. This situation may arise on the road, when you need to bring the coolant level to normal and continue driving, but it is not possible to purchase the appropriate type of antifreeze. However, how the conflict of bases and additives will affect the long-term operation of a mixture of two different antifreezes depends on each specific case. As experts say, nothing good is expected almost always.

Unfortunately, color does not indicate what type of antifreeze it is. The base and additives are indicated not by color, but by the inscriptions on the product container. Why then are antifreezes painted? Without adding dye, all antifreezes are colorless. Coloring helps users see the fluid level in the expansion tank or storage container. This is its main purpose, but in addition there are production and marketing considerations. There are absolutely identical antifreezes produced by the same manufacturer, which are painted in different colors depending on where they go - for filling at car factories or for sale on the spare parts and consumables market. It is clear that such antifreezes can be mixed without any negative consequences.

But without knowing what antifreezes of different brands are in terms of chemical composition, even mixing coolants of the same color is unsafe. This makes intermediate flushing of the cooling system with water highly recommended when replacing antifreeze with an unknown formulation in order to more completely remove it.

Sergey BOYARSKIKH Photo by ABW.BY

You have questions? We have the answers. Topics that interest you will be expertly commented on by either specialists or our authors - you will see the results on the website abw.by. Send questions to [email protected] and follow the site

Recommendations

If the flushing procedure is carried out in winter in an unheated box, immediately after turning off the engine, drain the flushing fluid and add antifreeze.

Leaving flushing fluid at subzero outside temperatures can lead to defrosting of the cooling system, even leading to destruction of the radiator, water pump, and engine cooling jacket.

Defrosting the engine leads to a very expensive overhaul. The cooling system radiator is also not the cheapest spare part in a car.