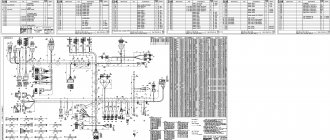

The ZMZ-40906 microprocessor engine control system is used to ensure optimal engine operation in all modes, taking into account fuel efficiency, exhaust gas toxicity, starting and driving qualities of the vehicle. As well as automated monitoring of the technical condition of the engine and control system elements responsible for compliance with toxicity standards, as well as external diagnostics in accordance with the requirements of EOBD (European On-board Diagnostics).

Fuel supply system and microprocessor engine control system ZMZ-40906, purpose, general structure, possible malfunctions.

Fuel supply is carried out through distributed fuel injection into the intake channels of the cylinder head in the area of the intake valves using electromagnetic injectors operating according to a signal from the microprocessor control unit. The control unit, depending on the engine operating mode, changes the duration of opening of the fuel injectors.

Schematic diagram of the microprocessor engine control system ZMZ-40906.

In order to reduce fuel evaporation, there is no fuel drain line from the engine fuel rail into the fuel tank. Maintaining constant fuel pressure in the line to ensure guaranteed fuel supply to the injectors in all engine operating modes is ensured by a pressure regulator, which maintains a fuel pressure of 38010 kPa.

The fuel pressure regulator together with the fuel level sensor are part of the submersible fuel pump module located in the fuel tank. Due to the absence of a phase sensor, the compression stroke in the first cylinder is determined by the control unit according to a special algorithm embedded in it.

Maintenance of the fuel supply system with the ZMZ-40906 engine.

Do not disconnect the fuel supply line while the engine is running. Before disconnecting the fuel line with the engine not running, it is necessary to eliminate the fuel pressure in the fuel line by draining fuel from the line by running the engine with the electric fuel pump turned off until the engine stops running.

A prerequisite for reliable operation of the fuel supply system of the ZMZ-40906 engine. is the cleanliness of its instruments and components. The components and parts of the fuel supply system on a UAZ Patriot with a ZMZ-40906 engine are discussed in more detail in a separate material.

The fuel line with the engine running is under a pressure of 3.8 kgf/cm2. The tightness of the fuel line connections should be carefully checked. This check should be done with good lighting and the engine idling. Leaking fuel creates a fire hazard. Leaks in threaded connections are eliminated by tightening bolts, nuts and fittings using a wrench with moderate force to ensure tightness.

Maintenance of the integrated microprocessor engine control system ZMZ-40906.

During operation, it is recommended to monitor the cleanliness of the components of the ZMZ-40906 engine control system and periodically check the reliability of the contact connections of the sensors and actuators of the control system. When carrying out periodic maintenance, it is necessary to diagnose the engine management system and replace the spark plugs.

To prevent rupture of the silicone tip of the ignition coil when removing it due to sticking to the spark plug insulator, apply silicone grease of the Penta-221 type, TU 2257-156-40245042-2006, to the inner surface of the tip with a brush before installing the ignition coil.

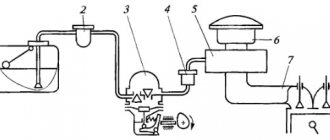

Fuel supply diagram

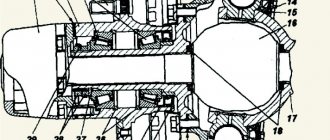

An electric pump takes fuel from the tank, which is pumped under pressure through the filter cavity. The blower motor is cooled by the flow of gasoline. Vehicle operating rules prohibit turning on the ignition when the right tank is empty. The design of the old-style fuel system includes a jet pump.

Gasoline is supplied to the ramp, which is equipped with nozzles inserted into the cavity of the intake manifold through rubber O-rings. The design of the injectors includes sprayers equipped with electromechanical valves that meter the amount of fuel supplied. When a pulse is transmitted from the controller, a needle valve is activated, opening the supply of gasoline to the spray head. Engines of cars manufactured before 2007 have an additional idle air valve that supplies air bypassing the throttle assembly.

When the ignition is turned off, the fuel system does not communicate with the atmosphere. Fuel vapors flow from the right tank to the left, and then accumulate in the adsorber. After turning on the ignition, the system becomes leaky; gasoline vapors are supplied to the intake manifold.

The adsorber contains a valve through which atmospheric air enters to equalize the pressure in the tanks (a vacuum in the tanks occurs as fuel is consumed).

For what reasons do problems arise with pumping between tanks?

The causes of the problems are:

- damage to the housing of gasoline storage tanks when driving off-road;

- incorrect connection of the ejector pump (on Euro-2 machines);

- incorrect connection of the gasoline supply and vapor exhaust lines after repair or maintenance;

- Damage or collapse of pipelines (for example, due to incorrect installation of parts or as a result of contact with obstacles on the road).

An additional reason for poor gasoline circulation is a loose or damaged plug in the right tank. If the seal is broken, fuel may leak out of the container while the engine is running. Clogged filters in the fuel system reduce the flow of fuel supplied from the ramp to the jet pump. The device operates with reduced performance, which is not enough to compensate for the volume of gasoline in the right tank.

When replacing an electric pump, performance and operating pressure must be taken into account. As the unit wears out, the parameters decrease, impairing the supply of gasoline from the left tank to the right tank. On Patriot machines that comply with Euro-3 standards, it is recommended to use Bosch equipment (catalog number 0580454001). You should not purchase analogues from Siemens, since the equipment differs in mounting points and plug configuration.

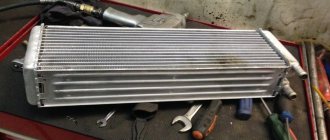

Fuel filter UAZ Patriot.

Replacing the element is necessary if a loss of traction is felt and the car begins to move jerkily. But at the same time, the on-board computer will not generate errors.

To change the element, you first need to disconnect it from the fuel line. Before this, it is necessary to remove the pressure in the system. You need to start the engine and pull out the fuel pump relay. Now we wait for the engine to stall itself and get to work. The filter is located under the bottom of the car and is secured with two 10mm bolts. The hoses are held in place with special quick releases. Installing a new one occurs strictly in the reverse order.

Replacing the fuel pump.

Before starting work, the right seat is removed. To do this, use a 17 key to unscrew 4 bolts. After this, unscrew the cover on the bottom to gain access to the pump and fuel pipes. It is necessary to remove them and the power supply.

We unscrew the 10 nuts around the circumference of the pump, after which it can be removed from the seat. You need to pull out the part carefully so as not to tear off the float. It is best to tilt the bulb towards the rear of the car.

During further work, it is necessary to close the hole for the pump so that dirt does not get inside the tank.

One of the problems when removing a part can be the corrugated hose mounted on the pipe. It is made of heat shrink material, so heat is required to release it. It is important to remember that you should not use open fire sources for this, since gasoline vapors may remain in the system. It is best to use a hair dryer.

Causes of failure

If the plastic mesh is dirty or the pressure regulator ring mesh is clogged, then:

- Fuel pumping may be disrupted.

- There will be an overflow of liquid through the adsorber.

- The car will begin to twitch during sudden acceleration.

Auto mechanics include the following reasons for such problems:

- jammed bins;

- incorrect installation of the jet pump (on UAZ Patriot 2006-2007);

- the pumping and steam hoses are mixed up (this mistake is often made in car repair shops);

- the steam removal and pumping hoses are pinched or clogged with debris.

The main disadvantage of the system

It is worth noting that the UAZ Patriot fuel tank is not without its shortcomings. Due to the pumping of fuel from one container to another, if the right element is damaged, fuel loss will occur at an increased rate.

Perhaps in the future, manufacturers will add a button that will allow you to turn on and off the replenishment of the right tank, but for now there is no such option. Perhaps this is the main disadvantage of the fuel system of a domestic SUV.

Automotive diagnostics forum Autodata.ru

Car diagnostics and repair » DIESEL cars » UAZ Patriot F1A 2008

UAZ Patriot F1A 2008

Involuntarily stalled, the “EDC” lamp came on, and as a result, no start

From: Russia Chelyabinsk Total posts: 58 Link

Hello everybody! UAZ, with an IVECO F1A engine, complains of involuntary engine stopping, and notes that this happens more often during acceleration and turning. Before this, the “EDC” lamp flashes. I haven't worked on diesels before. I check with a scanmatic, the ECU “complains” about high pressure, high voltage of the pressure sensor (P0151, P0152) and an incorrect signal from the brake pedal sensor. I don’t find any defects in the operation of the brake pedal sensor, although there are some oddities. The sensor has two pairs of contacts, one is closed, the other is open. But the scanmatic shows only one parameter, and when the pedal is not pressed, it marks “ON”, and when the pedal is pressed, “OFF”. That is, information about only one pair of contacts is presented. At the same time, in terms of clutch it represents the opposite, and in my opinion it is more adequate. That is, when the pedal is released, “OFF”, and when pressed, “ON”. I discovered that the brake lights were not working. I fixed it, it turned out to be a fuse, and although the diagram did not show the connection between the ECU and the brake light, I fixed the defect just in case. I connected a pressure gauge in front of the fine filter and went on a test trip. The car stalls, the fuel pressure drops to zero and it is not clear what comes first. Not knowing the power system diagram at that time, we filled the right tank and the problem went away. It would seem that everything and the whole problem. But questions remained in my head. The pressure dropped and errors occurred due to a large signal from the pressure sensor. How to understand? Well, let’s say the required pressure increases when there is actually a lack of pressure, but the actual pressure should not increase. But since the defect disappeared, we stopped there. But. Not so. A couple of days later we got the car, same problem. But at the same time the tank is filled (left) and the low pressure does not drop, equal to 5 atm. But the worst was yet to come. The car started confidently and clearly. While they were checking. We rode around and recorded the parameters and noticed a deterioration in the launch, while it became somewhat protracted, but still without problems. We decided to inspect the high pressure control valve, unscrewed two screws? then another car pulled up for diagnostics, I decided to start the UAZ in order to drive it out of the box (I left the pressure regulator on one bolt, not taking into account that the pressure is not multi-point injection). There was no startup, I hear diesel fuel leaking, I inspect it - it’s leaking from under the regulator. I tighten another fastening bolt, but I couldn’t start it. I turned the starter again to see the parameters - there was no high pressure. I rolled it out of the box in my hands and, as soon as I was free, started it up with difficulty, after pumping the fine filter and squeezing the return line with pliers. I changed the coarse filter (I changed the fine filter earlier). Launched it again. I also pinched the return line and couldn’t start it again that day. High pressure is only 110 atmospheres. I put the syringes on the return line - the result is the following: during cranking with the starter (about 8 seconds): two of them contain 4 ml, one 8 ml, and one 12 ml.) Result: a frighteningly catastrophic deterioration of the situation. I would ask the public to comment on the situation, and would be grateful for any help. 1. Why don’t I see in the parameters (when the car started up confidently) the reasons for the lamp to light up. in the recording, the nominal pressure is at a maximum of 158.2 and the actual pressure is 158.1 MPa (the injectors may be dirty. They do not operate stably and the system, trying to compensate for this, raises the pressure above the permissible level)

2. What could have happened so suddenly to the pump? 3. At this point, it becomes clear that the two injectors should be changed, but if it’s chips. What to do with the pump and why do they change the ramp because it cannot be washed?

Dimensions of elements

As already mentioned, the total volume of UAZ Patriot tanks reaches 76 liters. Both elements are identical. Thus, after simple calculations, it becomes clear that the volume of one UAZ Patriot fuel tank reaches 38 liters.

It will also be interesting to read: Fuel consumption of Chevrolet Niva 1.7-1.8: real reviews from owners

At the same time, the system has a fairly large neck that goes to the plug. As a result, the volume of each tank increases by an additional 5 liters. Thus, 86 liters of fuel can be filled into a completely empty system (the volume of UAZ Patriot tanks is 43 liters each). In principle, the increase is quite substantial, especially if you are planning a long trip.

It is worth noting that the volume of the UAZ Patriot fuel tank may differ in a number of modifications. There are also models with the following parameters:

- 68 l (pickup 2nd restyling 2021, suv 2nd restyling 2016);

- 72 l (suv until 2021, pickups until 2014).

It must be said that the very large capacity of the UAZ Patriot fuel tank fully corresponds to the fuel consumption indicators of the vehicle. The car takes from 9 to 14 liters per 100 km, so this volume of the UAZ Patriot 2021 fuel tank will be enough for a maximum of 550-800 kilometers of continuous driving.

Fuel pressure regulator malfunctions

Problems in the engine power system can vary. For this reason, during diagnosis it is necessary to look for certain signs of a malfunctioning fuel pressure regulator. Most often, the main symptoms are considered to be when the engine does not pick up speed and does not develop full power, and also stalls in different operating modes. In the list of main signs, experts note:

- unstable operation at idle, the unit stalls at idle;

- loss of power, noticeable increase in fuel consumption;

- slow reactions to pressing the gas pedal;

- jerks and dips during acceleration, at the moment of throttling;

- the car does not accelerate, does not gain momentum;

Note that the malfunction of the RTD on gasoline cars is similar in symptoms to common problems with the fuel pump or its strainer. For this reason, when determining faults in the power system, a mandatory check of the fuel pressure regulator is necessary.

In other words, if the car stalls at idle, the engine power is lost, dips appear, the car jerks during acceleration or when changing gears, significant fuel consumption is noted, then the problem may not only be in the fuel pump grid, the motor or its relay, but also in the fuel pressure regulator.

Regulator malfunctions usually come down to the fact that the spring loses the required force, as a result of which the fuel is prematurely drained into the “return”, and the engine simply does not have enough fuel when you press the gas and increase the speed, as well as in transient modes. It turns out that the pressure in the fuel rail when the fuel pressure regulator spring is faulty is low, as a result of which the engine runs unstably, engine power decreases, the ECU is not able to correctly adjust the mixture composition for different operating modes, etc.

Failures in the operation of the RTD are also possible when the pressure regulator in the fuel rail begins to jam at certain intervals. In such cases, pressure drops occur in the fuel supply system, and the car begins to twitch. Let us add that the most common reasons for regulator failure, which results in signs of malfunction of the fuel pressure regulator on a diesel or gasoline car, also include wear and tear of the materials inside the device, that is, the valve simply wears out its service life over time. The service life and condition of the regulator are affected by the quality of the fuel and the content of various impurities in it, long periods of vehicle downtime without starting the engine, etc.

Typical faults

As mentioned above, the fuel pump has a very certain operating capacity, which is enough for approximately 80,000 kilometers. Then various troubles may happen to him that need to be corrected. Most often, the following problems can occur in this node:

- The fuel level indicator in the car shows false information;

- The car cannot be started - fuel is not supplied to the cylinders;

- Also, short circuits often occur here when the positive wire, for one reason or another, shorts to ground;

- Fuse failure in the control circuit. This case can be corrected quite simply - by replacing the device with a new one. Getting to the fuse is not difficult, since it is located in a special mounting block;

- Damage to the fuel pump relay. It is determined mainly by the fact that the pump pumps, but the system as a whole does not work as it should.

These are just some typical breakdowns that periodically occur with the UAZ Patriot fuel pump. Fixing them is not that difficult, but it does require some experience and care. The most important problem is any damage to the fuel pump itself. They are usually very diverse and unpredictable. In this case, many experienced drivers advise simply installing a new unit, since the old one, most likely, has simply worn out its mileage.

Fuel system composition

The power supply system of the SUV engine consists of the following structural elements, without which the operation of the ZMZ-409 engine would be impossible. Below is a power supply diagram for the ZMZ-409 engine of the UAZ Patriot Euro-3 SUV.

The main structural elements of the engine power system include:

- Two fuel tanks. These tanks are designed with filler necks and drain plugs. Thus, you can refuel the SUV from both the left and right sides. To drain sediment from the tanks, there are drain plugs. The tanks do not have a switch tap, which prevents disruption of the fuel supply in case of untimely operation. The main tank is the right one, which, when empty, is automatically filled from the left. The supply of fuel from the left tank to the right is ensured by rarefaction of the air. The fuel plugs of the tanks are blind, which ensures the tightness of the structure and prevents gasoline evaporation or leakage.

- Pressure regulator. This is a device in the form of a bypass valve, through which a constant differential pressure of the fuel is maintained between the nozzles and the pipeline.

- Fuel pump. It is an electrical mechanism through which fuel is supplied from the right tank to the engine. The fuel pump is equipped with a fine filter.

Fuel gauge and checking it

The fuel gauge operates in conjunction with a special sensor installed in the right tank. This sensor is a rheostat made of nichrome. Thanks to the float, which is equipped with a moving element, it moves along the rheostat. When there is less than 5 liters of gasoline left in the tank, the warning light comes on and the indicator shows zero.

Instructions for replacing the fuel pump on a Patriot

First, let's figure out where the fuel pump is located on the domestic UAZ Patriot. It was already written above that it is located on the right side of the tank, which means that you need to look for it under the front seat on the passenger side. To access it, you need to remove the seat by unscrewing all the mounting bolts and the bolt securing the seat belt. Please note that there is a mat under the chair that you just have to lift and there will be a fuel pump in front of you.

To remove the device you will need the following tools:

- Head at "17".

- Pliers.

- Keys for "10" and "17".

Step-by-step instructions for removing a faulty fuel pump:

- There are 3 hoses going to the pump that need to be disconnected; in this case, place unnecessary cloth under the hoses, since remaining fuel will certainly leak out of them.

- The pump is equipped with a special plastic power terminal, which also needs to be disconnected.

- At the next stage, unscrew the 8 nuts that hold the cover in a stationary state.

- And now, you can remove the pump and replace it with a new device.

It is likely that when replacing the pump, it will be necessary to replace such an element as the coarse fuel filter.

We assemble everything in the exact reverse order of extraction. When everything is installed, turn the ignition key and wait for the pump to pump fuel into the system, this usually takes 10-15 seconds. And only after this manipulation is it recommended to start the engine.

Diagnostics

The serviceability of the fuel pressure regulator is checked by measuring the pressure in the fuel rail. Let's consider the algorithm for checking the pressure regulator using the example of a VAZ-2110 car with an injection power system. This car uses an injector with fuel recirculation, so the RTD is located on the fuel rail. To do this, you will need a pressure gauge, as well as a piece of oil-resistant rubber tube and two clamps. The algorithm of actions is as follows:

- We produce fuel from the ramp (we remove the fuse responsible for powering the electric fuel pump, start the engine and wait for it to stop voluntarily).

- On the ramp we find a fitting designed to relieve pressure and remove the cap on it.

- We unscrew the spool valve from the fitting (carefully and slowly, since fuel may remain in the ramp).

- We pull the tube onto the fitting and secure it with a clamp.

- We connect a pressure gauge to the tube and also fix it.

- We put the fuse back and start the engine.

- We install it on the XX motor.

- We check the pressure gauge readings (on the VAZ-2110 this parameter is 2.8-3.2 Atm.).

- We find the pipe coming from the manifold on the regulator and disconnect it from the RTD. If the device is working properly, this action will lead to an increase in pressure by 0.3-0.7 Atm.

Inconsistencies in pressure gauge readings will indicate a problem with the regulator or other system components. To accurately identify the cause of the malfunction, you need to diagnose the operation of other components.

Features of the tank cover

The design features of the car require the presence of two filler holes (and, as a result, two covers). Such elements are hermetic structures with which you can lock the fuel tank capacity of the UAZ Patriot. The system is very reliable, thanks to which it effectively prevents fuel leakage and evaporation.

Such covers are equipped with special locks. In principle, such an element is not absolutely necessary, but its presence will not hurt (the lock increases the safety of the vehicle, since no one will be able to drain gasoline from the car).

Tuning options

It is worth noting that you can replace a damaged fuel tank with either an original or a tuned one. Particularly popular are the enlarged Bakor tanks with a volume of 53 liters (106 liters for two tanks).

True, in this case the load on the suspension also increases, which will negatively affect its service life, so think through the pros and cons of such an improvement. If you listen to the reviews, most owners are satisfied with the models from the Bakor brand, so you can safely buy them.