Checking the functionality of the mechanisms

At the repair stage or during a preventative check of windshield wipers, problems in the device can be identified in several ways. The quality of the mechanism is primarily determined by the function of the brush and its position in the brush holder. The cleaning elements must move freely and easily at the specified speed. The electric motor itself is checked by a tester. In particular, such diagnostics makes it possible to detect irregularities in contacts and connections. When disassembled, the device allows you to evaluate the condition of the gearbox gear - in particular, the mentioned teeth and threads on the rollers are checked. The remaining components can be checked with the naked eye, even with a superficial inspection.

Symptoms of a malfunctioning windshield wiper: When turned on, the windshield wiper does not work

| Cause of windshield wiper malfunction | Remedy |

| Lack of electrical contact in the connecting blocks | Make sure connections are secure and troubleshoot |

| Switch damaged | Check, repair or replace |

| Sticking brushes or dust contamination of the motor armature commutator | Eliminate the cause of the brushes hanging, clean the commutator (with a soft student eraser) and clean the grooves between the commutator plates (from graphite-copper dust) |

| The fuse has blown (possible reasons: jamming of the drive levers, faulty gearbox or electric motor) | Determine the cause of the malfunction, eliminate it, replace the fuse link |

| Wear of the worm gear of the windshield wiper drive gearbox | Replace worn parts |

Features of the operation of automobile windshield wipers

To ensure long-term and effective operation of the wipers, you must follow a few simple but effective rules. If you run out of washer fluid, do not turn on the wipers on dry glass. Do not forget about wiping the windshield from inside the cabin, since poor visibility on the street side is not always the cause. It is recommended to periodically wipe the windshield with non-aggressive detergents.

The bending areas of the brush holder lead need to be lubricated from time to time, which ensures normal pressing of the element to the glass. The water supply nozzles must be adjusted so that the maximum pressure is directed strictly into the area of movement of the brushes. In winter, you should not turn on the wipers until the glass thaws. Cleaners will not help clear it of ice, but the brushes will wear out more actively.

Electrics

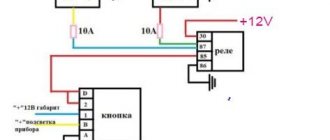

First you need to decide whether the problem is electrical or mechanical in nature. You need to start from the first, of course, if you have already sufficiently cleared the brushes themselves of snow and ice. First of all, make sure that the “dead” windshield wipers are not simply the result of a blown fuse. Open the appropriate compartment, which is usually located to the left of the steering column and inspect the required fuse. For the purity of the experiment, you can swap identical fuses that are responsible for different on-board systems of the car. Did not help? Then listen to whether the corresponding relay clicks in the depths of the dashboard when the wipers are turned on. If not, then perhaps it was this that gave up its life, but if there is a click, we move on to the mechanical part.

Foto-1

There are many fragile parts in a modern car, which are difficult to remove without the necessary skills. You should not, for example, without consulting anyone, try to disconnect electrical connectors, “boldly” (that is, at the risk of uprooting) separate the lights and many other parts from the car. This also applies, for example, to the turn signal repeater on Lada models, which they say “snaps easily.” Where are these latches and what do they look like? If you use a screwdriver blindly, you will probably damage something, scratch the paint on the wing or break the retainer. The best remover is a plastic card, preferably without raised markings. Use it to quickly feel the elastic tendril of the latch, press it and, pulling the flashlight towards you, easily separate it from the body.

Read also: Installing a child seat in the back seat

OH YES THE GERMANS.

P. GERASIMENKO, Krasnodar region

My Volkswagen Passat B3 with a manual transmission, released in 1993, has already covered about 400,000 km. For some time now I have begun to notice that gears are being shifted with increased resistance. In search of the cause, I removed the gear selection mechanism. It turned out that no lubricant was supplied to it from the unit at all - the parts were completely dry, which does not look like the technical solutions of the neat Germans! Naturally, I thoroughly washed the mechanism parts and lubricated them with transmission oil. And, obviously, he did it on time. After my intervention, the mechanics began to work absolutely flawlessly.

But here’s something else that seemed extremely interesting. During my “research,” I discovered a hole on the top of the mechanism body that was closed with a plug. I couldn't find any information about it in the old Passat manual. But it’s not difficult to periodically lubricate the mechanism through it, without disassembling anything for this. Adding 20–30 ml of gear oil here is a matter of minutes. I've been doing this ever since.

DOUBTING THOMAS

L. KANASH, Moscow

As life shows, getting a car dirty with bitumen or something similar is a piece of cake, and not only in the summer, during the busy season of repairs. Having discovered unsightly stains, many people go to the store for a special cleaner. I don't believe in advertising promises and miracle cures. And I remove such stains with an ordinary degreaser, bought at a nearby store for ridiculous money. I have never noticed that this chemical worked worse than the branded one, left any marks or stains or damaged the paint.

Relay failure

Another reason why the windshield wiper does not work may be the relay. First of all, remove it from its seat in the mounting block and insert it back. Often the problem lies in banal oxidation of contacts. If this does not help, we leave it in the mounting block and go to the salon.

The windshield wiper relay is only responsible for its operation in intermittent mode, therefore, it is not involved in fast and very fast modes. Turn on the ignition and move the wiper mode switch knob to the uppermost position. Did the wipers work? We change the relay. By the way, its catalog number for the “fourteenth” is 52.3747 or 525.3747, and it costs about 150 rubles. An adjustable wiper relay will cost a little more (about 250 rubles), which will allow you to adjust the duration of the pause between their sweeps.

The delay is adjusted by moving the mode switching knob from the “On” position. to the second position, in which the windshield wipers operate intermittently. At the same time, they begin to move in normal mode, with a shutter speed of about 4 seconds. Next, the knob is moved to the “Off” position, and the time countdown for the programmable pause begins. The next time you turn on the wipers in intermittent mode, the interval you have maintained will be observed.

How the device works

Despite the simple functionality of the cleaning system, it is necessary to understand how windshield wipers work. Key details you need to know:

- The electromagnetic relay receives the control command and sets the operating mode of the brushes. Depending on the vehicle, the wipers may operate intermittently at short intervals of 3-5 seconds, continuously move at a set speed, or enter wash mode with the washer on.

- The windshield wiper motor receives power from the on-board electrical system. The exact connection diagram depends on the car model.

- The windshield wiper arms, and along with them the glass cleaning brushes, are driven by an electric motor with a worm gear and a lever drive (trapezoid). The trapezoid transmits and converts rotational motion from the electric motor to brushes, which, pressing tightly against the working surface, remove dirt and moisture from the glass.

How does a trapezoid work?

The windshield wiper trapezoid consists of a system of rods and levers that convert the rotational movement from the gearbox into the reciprocating movement of the leads with brushes. A standard device should perform the following functions:

- movement of the brushes when the windshield wiper motor is running;

- ensuring the required amplitude and speed of cleaning;

- Windshield wiper arms with two or more blades must move synchronously.

Windshield wiper trapezium

The trapezoid, like the electric motor, is an important component of the system. In case of any malfunctions (the appearance of backlashes) in its operation, the efficiency and quality of glass cleaning deteriorates.

For greater reliability, the trapezoid elements are made of sheet steel, which is resistant to aggressive environments and also has high bending rigidity.

Wiper motor

The windshield wiper motor has a basic design regardless of the car model. The main elements include the electric motor itself and the gearbox (usually a worm gear), which increases the force from the electric motor several times. Modern devices can be equipped with additional elements, including fuses for protection against heavy loads, heating elements for operation at low temperatures, and much more.

Windshield wiper motor for VAZ 2110

The windshield wiper gear motor is the most important element of the system, which ensures its performance. The brushes must fit tightly to the glass and move freely along it, otherwise there will be an increased load on the electric motor.

How to choose wiper blades

The first is the length of the brush

, which must meet the requirements of the vehicle manufacturer. If the brush is shorter than it should be, the glass cleaning area will be reduced, which will lead to a decrease in the viewing angle of the road. In the case of a longer length, the pressure per unit length of the rubber band will decrease and the force of the driver spring may become insufficient to push through the layer of water with the working edge of the rubber band and the glass may not remain sufficiently transparent after the brush passes.

Next you need to check if the adapter

, installed on the purchased brush or the presence of additional adapters in the kit for the leashes of your car. The most common type of fastening of wipers to a leash is a “hook”. Usually all brushes are equipped with an adapter for it.

The third criterion is the quality of the tape

. On its surfaces, especially on the working surface, burrs and irregularities are not allowed. The tape should be elastic, uniform in texture and color. The working edge must have a right angle along the entire length of the tape. The same requirements for the tape are imposed when purchasing it for the restoration of a brush. The tapes in expensive wipers are made of silicone, graphite-silicone and Teflon; they are more resistant to wear, since they have a reduced coefficient of friction, but their price is several times higher than rubber tapes.

It remains to check the frame and the free movement of the tape in the rocker arm supports. The rocker arms at the articulation points must have plastic liners and there must be no play, but there must be freedom of movement of the rocker arms relative to each other. The tape should move freely in the supports without play, except for the outer one that fixes it. This can be easily done by pulling the wiper blade strip away from the frame.

This three-story video shows how to test in practice the freedom of movement of the wiper blade in the supports. In the first plot, the tape is excessively clamped in the rocker arm supports or dirt has accumulated in the supports; such a brush requires repair or replacement. The second and third plots, respectively, show the response of a correctly secured rubber band in the rocker arm of a short and long brush. The vibrations of the rubber band show that the necessary freedom of movement of the band in the supports is available.

There is a lot of controversy about the manufacturers of windshield wiper blades, but in any case, all blades are made in China. Only branded ones are produced under the supervision of well-known companies. It is difficult for a non-professional to recognize whether it is a fake or not. Therefore, you have to rely more on external inspection. If a wiper blade or repair tape meets the above requirements and pleases your eyes with its appearance, then we can most likely assume that it is of high quality and will last a long time. This is the brush you should buy for your car.

Car wipers are an inexpensive and fairly simple accessory that every car owner can easily replace on their own. Despite its simplicity, it performs a very important function, namely, it cleans the windshield of the car, through which the driver receives the maximum amount of information about the situation on the road. To keep your car windshield clean in all weather conditions, you need to monitor the condition of your wipers. Their squeaking on the windshield indicates a problem that needs to be fixed as soon as possible.

As noted above, wipers are a very simple accessory that does not require much maintenance. Based on this, we can conclude that the squeaking of windshield wipers on the windshield can be observed for one (or several) of the following reasons:

The cause of the squeak may be poor-quality manufacturing of the wiper, for example, poorly selected materials for cleaning the windshield; Problems with installing the wiper. Creaking can occur if the wiper is not securely fastened or was installed in dirty grooves, dust and debris in which do not allow it to fit tightly to the glass; Incorrect angle of the wiper cleaning surface

Please note that it is tilted exactly 90 degrees; any deviation from this value can lead to squeaks and knocks as the wiper moves across the glass; Creaking of the wiper movement mechanism due to poor quality of the accessory or due to mechanical damage; "Old age" of wipers. If the cleaning surface of the accessories is worn out, it may make unpleasant sounds when moving across the glass.

Very rarely, a wiper squeaking during operation can be associated with microcracks and scratches on the glass, due to which the part cannot “move” smoothly and do its job.

Purifier management

The windshield cleaning system can be controlled in two ways - electronic and electrical. The last option involves manually changing operating modes. Under the steering wheel there is a special control lever that allows you to turn on the device, adjust the pause in the wipers and change the cleaning modes. But this option requires constant driver participation.

Understeering's shifter

The electronic control system is completely autonomous and does not require human intervention. The car is equipped with a special electronic unit and a rain sensor, which analyzes the cleanliness of the glass and weather conditions. Electronic control provides a range of functions:

- automatic switching on and off;

- changing the operating parameters of the purifier;

- blocking the motor in the presence of obstacles on the windshield;

- additional cleaning with windshield washer;

- preventing brushes from freezing when the engine is off.

Actions in case of faulty steering column switches

Nowadays, in most cars, windshield wipers are activated by turning on the steering wheel stalks. The latter must be reliable, perform efficiently and provide the necessary signals to turn on the windshield wipers. Most often, the handle breaks, the switch does not transmit signals, and this is precisely the reason why the wipers do not work.

But this failure can be eliminated by the following steps:

Often the cause of the malfunction is that the wires that need to be put in place are simply disconnected from the terminals of the steering column switch. Most likely, after studying and conducting a complete analysis of the causes of electrical failures, you will be able to quickly diagnose problems and easily bring the system into working order. No special abilities or highly specialized devices are required. All you have to do is to properly restore the operation of simple windshield wiper systems.

We recommend

There are three types of wind wipers:

- Holder device without frame

- Holder device with frame

- A holder for a hybrid brush, the structure of which is similar to the others.

Pressure plates help connect the base to the body. In the diagram, they are made in the form of strips made of a springy alloy, with cuts along the edges that ensure fixation of the holder to the base. The base holders are inserted into special side grooves.

Then the elastic band with inserted springs is secured to the holder itself. In the case of frame fasteners, a design is used that consists of bent rocker arms - the body. Such a scheme has a main rocker arm, where there is a fastener for fixing it to the lever. At the edges of the movable rocker arms there are clamps that help hold the base with springs.

The tape of frameless fasteners is installed and secured in the clamps of an even elastic spring in the shape of an arc. This spring presses the rubber band to the surface of the glass, and an adapter is used to install it on the lever in the elastic spring. As for hybrid wipers, they have a frame hidden in a plastic housing.

Frameless brush device

Frameless wiper blades are rarely used and this is due to their high cost and narrow applicability. Each brush is produced for a specific narrow range of car models. They are not universal.

Frameless brushes differ from frame ones in that instead of a rocker arm system, a flat, wide, spring-loaded metal plate is used, on which the wiper tape holders are secured with rivets.

The shape of the generating plate is made in accordance with the shape of the windshield of a particular car. Therefore they do not fit any model. This wide tape is covered with a rubber casing glued to it, thereby eliminating cases of disruption of the hinges, like with a frame brush. The design of the rubber band and the principle of its operation when cleaning glass does not differ from work in a frame wiper. In frameless wipers, it is also possible to replace the rubber band when worn, as in a frame wiper.

Drainage

The water from the windshield simply has to drain somewhere, and this, of course, should have been foreseen by the engineers. Of course, the compartment in which the trapezoid operates has its own drain hole, but sometimes during operation the car’s drainage becomes clogged, and this fact can backfire, especially with our winters. Inside, there may be autumn leaves, spring dirt, summer dust and winter salty sand that clog the drain hole. Because of this, the water simply does not go anywhere, and at sub-zero temperatures it freezes, hindering the movement of the windshield wipers. To prevent troubles with dead wipers from happening again, we strongly recommend checking the cleanliness of the drainage hole. Otherwise, despite your best efforts, your windshield wipers will turn into real estate again the next cold night.

The wipers on the VAZ work poorly and slowly, we are improving it

| With the onset of spring, puddles and dirt appear on the road, which force the windshield wiper blades to work more often than usual. The main problem that owners of VAZ cars face during this period is the slow operation of the wipers. Let's look at a few ways to make your windshield wiper blades work faster! |

The wipers are slow, it's all about lubrication

Why are the wipers slow? Most often, the reason is that the lubricant in the gearmotor has dried out. You will need to remove the trapezoid and disassemble the wiper motor by removing several screws. Lubricate all rubbing areas of the gearmotor and windshield wiper trapezoids. Slow operation of the brushes can also be associated with litol lubricant, which hardens in the cold. It is better to use “softer” winter lubricants that behave better at sub-zero temperatures.

Swapping wiper speeds

Everyone knows that the VAZ 2110 windshield wiper blades have two speeds (slow and fast). The improvement is to swap them. To do this, you should rearrange the wires in contacts 53 and 53b in the steering column switch. Standard operating modes of the wipers:

- Intermittent mode, slow.

- Constant mode, slow.

- Constant mode, fast.

- Washer - constant mode, slow.

Operating modes of windshield wiper blades after modification:

- Intermittent mode, fast.

- Constant mode, fast.

- Constant mode, slow.

- Washer - constant mode, fast.

You can forget about slow wipers! The result of the first speed in the video:

Wipers do not work well due to lack of power

Another way to get rid of the slow operation of the windshield wiper is to replace the motor with a more powerful one, for example, from a foreign car (the standard motor of a VAZ 2110 is 7.5 watts, and from a Volkswagen Transporter is 40 watts). The modifications presented in the article are also suitable for owners of VAZ 2109, 2114-15, etc. What methods of increasing the speed of brushes do you know? Let us remind you that the site also presents other improvements to the wipers that will solve problems associated with poor glass cleaning (for example, an increased size of the brushes or a cleaning area). Also work on improving the washer performance.

Procedure for replacing windshield wiper rubbers

Inexperienced and, in some cases, negligent drivers often make the stupid mistake of throwing out virtually new wipers when they no longer clean the glass as effectively. In fact, the problem that has arisen can be solved in just ten minutes by simply replacing the rubber bands. When choosing new parts, give preference to rubber structures.

According to experts, their advantages are as follows:

- clean glass silently;

- function properly at a fairly wide temperature range;

- Features a durable graphite coating;

- There is a wide range of different brush sizes available;

- have a reasonable price.

The purchase has been made and it’s time to start replacing the part. The procedure is absolutely not complicated. Most men and even women can cope with it. Here is an approximate sequence of your actions:

- We dismantle the wipers and move them to a warm place;

- Using a screwdriver, remove the plugs located at the edges of the windshield wipers;

- squeeze out the so-called burr that secures the brush;

- we remove the old rubber bands, install new ones in their place and return the burr to its original position;

- The final stage is putting on the plugs and installing the windshield wipers on the car.

When installation is complete, make sure that the windshield wipers are firmly in place. In this case, the brushes should fit tightly to the surface of the windshield. Weakly fixed rubber bands and loose attachment of the blades are the reasons why windshield wiper blades may not clean the surface of the windshield well.

What and how to clean the wipers on your car?

As a result of prolonged use, windshield wiper blades may become stiffer and not adhere so tightly to the glass. Of course, in such a situation, you shouldn’t count on the wipers to clean the glass efficiently. Do you think there is only one way out - a complete replacement of the structure? We hasten to please you. The problem can be solved by thoroughly cleaning the rubber bands. We'll tell you how to clean your car's wipers at home:

- remove the rubber bands, dip them in gasoline for a few minutes, and then rinse thoroughly with soapy water;

- after an “invigorating shower”, lubricate the elastic bands with a special silicone lubricant, which is sold as a spray or gel in a tube;

- Another cleaning method is to moisten a piece of cloth with white spirit solvent and gently wipe the wiper blades with it;

- A very simple and cheap way is to use a hot bath for the rubber bands, which helps destroy deposits and contaminants from their surface.

Having tested at least one of the above methods, you will certainly see a difference in the operation of the mechanism before and after the cleaning procedure. For example, wipers who previously stubbornly did not clean the middle of the glass will correct themselves and will delight you with a perfectly clean surface.

If you notice any problems with the operation of the windshield wipers, do not wait to visit a service station. You need to take care of the health of your car no less than your own. Only in this case will your iron friend serve you faithfully for the maximum possible number of years.

https://youtube.com/watch?v=Jj69K_8KhoQ

How to extend the life of your wipers

Before moving on to a review of the reasons why wipers do not clean the windshield well, we suggest considering the factors on which their quality work depends. So, dear car enthusiasts, remember, or better yet, write down the following recommendations:

- never turn on the wipers on dry glass, since the resulting frictional force will significantly reduce the service life of the soft rubber bands of the windshield wipers;

- if the windshield is heavily soiled, do not be lazy to clean it manually using a special, non-aggressive automotive glass liquid;

- before starting to drive in the winter, do not forget to clear the windshield wipers of snow and ice crust that has formed, since such build-ups are difficult to clean on the wiper blades;

- It is better to wipe off the moisture formed on the windshield as a result of melting snow, this way you will protect the rubber bands of the brushes from serious damage;

- replace your windshield wipers twice a year: in the summer you will need a summer set, in the winter you will need a more durable winter set;

- Another nuance that many motorists forget about is regular preventative cleaning of wiper blades from plaque.

As you can see, the recommendations are quite simple. Their implementation will take a few minutes, and the result of the manipulations will significantly improve the quality of the windshield wipers.

Common reasons for poor wiper performance

Even the most thrifty driver sooner or later windshield wiper blades begin to clean poorly, lose their properties and fail. How quickly this happens depends on a number of factors.

Firstly, due to improper use, untimely replacement of windshield wipers with summer and winter modifications, the brushes lose their elasticity, become rougher and are no longer as effective as in their original form.

Many drivers believe that locking their wipers in a standing position when the car is parked or in a garage will benefit them. The opinion is wrong! In fact, this position of the windshield wipers leads to stretching of the spring, weakening of the driver and, as a result, the pressing density of the cleaning surface of the brushes weakens.

If the driver systematically forgets to clear the wipers of snow and ice build-up, then at one “wonderful” moment the frame of the structure becomes clogged with ice, practically does not adhere to the glass, and the blades simply do not clean the windshield or rear window. Solving the problem is quite simple - heat the wipers and remove ice using your fingers.

Winter comes unexpectedly, as always. You will find out what to do if the washer fluid in your car is frozen here.

It’s trite, but ineffective operation of windshield wipers can be caused by incorrect sizing. Always consider this point when purchasing.

And at the end of this section, let us once again remind you of the importance of regularly cleaning glass with special liquids. Exhausts, smoke from a car moving in front, wax, and oil particles falling on the glass reduce the quality of wiper operation.

New wipers do not clean well: causes of malfunction

In some cases, after replacing windshield wipers with new ones, the motorist will get an unpleasant surprise. The updated, by no means cheap design refuses to work, driving the car owner into a stupor. Don't be so quick to blame your problems on the part seller or, worse, throw it in the trash right away. There is an explanation for everything. What are the reasons that new wipers do not clean dirt on the windshield well?

Not a common, but quite common reason - incorrectly selected size

To avoid this, always pay attention to what car the windshield wipers you choose are intended for, do not hesitate to contact the seller for advice

And yet, most of the problems are related to existing malfunctions of the vehicle’s cleaning system itself.

If you ask a specialist why the wipers are poorly cleaned, he will most likely draw your attention to the following problems:

- malfunction of the motor gearbox, oxidized power wires;

- contaminated collector (in some cases it may burn);

- deformation of the so-called wiper rods, resulting in their friction against body parts;

- entry of a foreign object into the structure of the device;

- wiring burnout at the level of the windshield wiper relay;

- malfunction of gear motor gears.

Only a specialist can troubleshoot problems, as well as identify a specific problem in your case.

Windshield wiper design elements

Design features depend on the type of device and the type of fastening elements. The standard windshield wiper circuit consists of the following parts:

- lever drive (trapezoid);

- leashes;

- relay for controlling operating modes;

- electronic control unit (if equipped);

- electric motor with gearbox;

- hinged fastenings;

- brushes

Design of windshield wipers Additionally, control devices are provided. For example, for manual control, a steering column switch for windshield wiper operation modes is used, and for automatic mode, a special electronic control unit and a sensor for analyzing glass contamination (rain sensor) are installed in the vehicle.

History of the creation of wipers

A windshield wiper is a mechanism that removes drops of rain or dirt from the windows of a car (windshield, and sometimes rear). In the modern world, windshield wipers, or windshield wipers as they are popularly called, are usually installed on every car, train, plane or ship.

Rain, mud and snow caused a lot of trouble for drivers back in the early 20th century. The very first cars did not have windshield wipers. When the pollution was severe, the cars stopped, and the drivers themselves worked as “windshield wipers,” manually wiping the windows to improve visibility. In this case, various cleaning compounds were used.

For a very long time, the most convenient way to clean glass was to use a special scraper with a strip of rubber, with which the driver could remove dirt directly from his seat without leaving the car. At this point, it's pretty clear that this isn't the best way to improve visibility, although people had a different opinion in the early 20th century.

The patent for the first windshield wiper was received in 1903 by American Mary Anderson. She came up with this idea while moving from Alabama to New York. While traveling on a tram on a frosty day, she noticed that the driver was driving with the windshields open, as it was impossible to clean them due to heavy snowfall. She came back to Alabama and arranged with a designer and a local company to make a working device.

Her idea was to use a rubber scraper with special rods and a return spring, which made it possible to control its movements from inside the car. Using a special lever, the invented mechanism pressed a scraper with an elastic band against the glass, the device described an arc, clearing the glass of rain, snow or dirt, and returned to its original position. Similar mechanisms had been proposed before, but Mary Anderson came up with the first truly effective cleaning device.

Unfortunately, Mary Anderson's invention was not properly appreciated by her contemporaries. In 1903, the number of cars was very small; Mary Anderson's idea did not arouse enthusiasm among both car manufacturers and their buyers.

Critics did not take it seriously and believed that activating the windshield wipers would distract drivers' attention from the road. Their attitude changed dramatically in 1908, when Henry Ford built his first car.

By 1913, most machines were equipped with an invented cleaning mechanism.

Time passed, and Mary Anderson's patent ceased to be valid. As is usually the case, Mary Anderson did not make any profit from her idea. However, it is noteworthy that it was also a female inventor, Charlotte Bridgwood, who came up with the idea of automating the windshield wiper. She managed the Bridgwood Manufacturing Company in New York. In 1917, Charlotte Bridgwood received a patent for the first electric roller wiper. She called it Storm Windshield Cleaner.

Come on, get moving: why the wipers stop working and how to fix a trapeze

Probably, many owners of not very new cars are familiar with the situation in which the windshield wiper blades suddenly start working slower than usual, and then stop completely. Sometimes - right halfway through the move, in the middle of the glass. Unfortunately, it is not a cheap fuse that is to blame for this. It's all the trapezoid's fault.

Just about simple things

The trapezoid of the wipers is the same mechanism due to which the rotational movement of the brush drive motor is converted into their translational movement. At first glance, there is nothing complicated about the trapezoid: several rods, articulated joints and bushings. Moreover, it is not clear what could break there. Usually nothing breaks, it’s just that over time the connections become clogged with dirt, corrode and lose mobility. And in the case of such arthritis in the trapezius, the wipers first walk more slowly, then they simply stand up.

There is another scenario: the engine is on fire. It’s better not to wait for this, but to start repairing. Depending on their greed, the services ask for different amounts of money for this work. Some are ready to do it for five hundred rubles (which is rare), others – for one and a half thousand (which is more common). Not robbery, of course, but many will most likely want to tinker with their favorite car themselves. Therefore, we will tell you how to do this. At the end there will be a bonus for those who read the instructions after they have already broken everything.

The work has one significant advantage: it does not require complex “devices”, torque wrenches, a lift or a synchrophasotron. For example, we did everything with an ordinary set of tools from a well-known store for 600 rubles. In addition to a screwdriver, keys, hammer and Torx, you will also need graphite lubricant and some kind of liquid wrench like WD40, Valera, Runway or any other - everything is up to your taste.

Almost all trapezoids are constructed the same way and sour in the same place. We will take the Ford Focus as an example, the trapezoid of which has stubbornly turned sour at the most inopportune moment for three generations in a row. Stability, damn it. There is also a whole list of cars in which the trapezoid sours more often than we would like: from the Mercedes W204 to the Hyundai Elantra IV and any Kia Ceed. The principle will be the same everywhere. Therefore, we will tell you how to do everything on a Ford, and if you are lucky enough to buy another car, just carefully project this guide onto your car.

Bolts, latches and flexible pins

First, remove the wiper arms. Everything is simple here: remove the protective caps, unscrew the nuts and pull them off their axles. There is nothing complicated here.

Then we move on to dismantling the plastic frill. Focus has two parts – upper and lower. The top half is attached with simple latches that can be easily moved with a screwdriver. The main thing is to hold them tightly with your fingers, because at the last moment the latch may fly somewhere into the engine compartment. We put the removed latches together with the nuts and washers from the wiper arms, pull out the rubber seal from the groove and remove half of the frill. And again, all this is not difficult to do.

At this stage, the trapezoid is already clearly visible. Some people are already stopping here and taking her out of the car. To be honest, this is not very easy, so let's work with the screwdriver a little more and disassemble the car a little more. It is enough to unscrew just two bolts with Torx heads to remove the lower part of the frill. But access to the trapezoid will be downright chic. Therefore, we spend a couple more minutes and remove this part.

You just have to do this carefully: Ford engineers (damn them for just one hood lock!) for some reason made the windshield heating two-zone, so the connectors for heating the glass halves are visible on the right and left under the frill. If you swing the removed plastic like Taras Bulba with a saber, you can damage the cables.

So now we can see the trapezoid in its entirety.

In our case, the trapezoid is secured with three bolts, which we unscrew. Now you can pull it out, but again, very carefully. There is nothing surprising in the fact that there are wires that connect to the trapezoid motor, which do not need to be torn. You need to remove the terminal, but this is easier to do if you slightly pull the entire trapezoid into the light of day. The length of the wires allows this, and Ford engineers (let them be empty for all the electrics!) placed the connector latch at the bottom. So it is very, very difficult to hold it in place. Therefore, we pull the trapezoid out a little, then remove the terminal.

That's it, the trapeze is in our hands. You can breathe out. But not much, because the most difficult thing awaits us ahead.

A little strength and a lot of skill

Trapezium hinge joints are usually made from polyformaldehyde. It is such a durable material with very low friction. For example, recently mediators for guitarists have often been made from it. And for machines - these are the connections where the friction force should be minimal and wear resistance should be high. It also does not rust, which is also good. Due to all these factors, we can say that it is almost pointless to disassemble the hinges: nothing will turn sour there, and breaking the connection for the sake of curiosity is harmful. Well, if you do take it apart, you can remove the dirt from there. This will not be superfluous.

Now let's move on to our main enemy. The trapezoid sours precisely in these places: these are the bushings with the axles of the leads. No matter how much they try to protect them with all sorts of caps and rings, water still gets inside and does its dirty deed.

The axles must be pulled out of the bushings. To do this, first remove the protective cap and retaining ring. I won’t warn you about the meanness of the latter: everyone knows that it can fly anywhere. But with some skill it is not difficult to remove.

And now the dancing with the tambourine begins. More precisely, with a hammer, a Vedashka and swear words. If the trapezoid has not yet completely soured and the wipers are at least moving somehow, it will be much easier to knock out the axles. Otherwise it will be difficult. In addition, you will have to knock with a hammer on the end on which the thread is cut for the wipers themselves. If you do this with fanaticism, then you won’t be able to put the wiper in its place. And without fanaticism, it is difficult to knock the axle out of the bushing.

Liquid keys will help here (but this is not certain). For those who have not used them before, I will give one piece of advice: it is useless to spray on the axle and hit it with a hammer at the same time. First you need to splash the soured compound, then wait five to ten minutes, then you can knock with a hammer. If the axis has moved even slightly, the procedure should be repeated. There is no such thing as an extra “Vedashka”.

So, let's say that we managed to knock out the axle. All that remains is to lubricate it. Many people mistakenly believe that the same WD-40 softens corrosion so well, removes moisture and works other miracles. And also - that the parts on which it fell never rust. This is wrong. As long as this miracle liquid has not dried, the axle will even rotate quite well in its bushing due to the small amount of oil in the “wheel drive”. But it won’t last long, as is the case with any other “liquid key”. They are poor lubricants, so as soon as the axle dries, it needs to be lubricated. Graphite grease is best. Well, when the axis is generously lubricated, everything can be assembled in reverse order. Anyone who has taken it apart once can always put it back together.

Only one point is important: before installation, it is advisable to place the trapezoid in the position in which it once soured. Otherwise, there is a non-illusory chance that after the first turn on, the revived mechanism will grind both the wipers and itself.

Promised bonus

Unfortunately, for very strong and stubborn people, repairing a trapezoid often ends in its complete destruction with the help of a hammer and their own stupidity. The platform on which the motor stands is often made of a rather fragile alloy that does not withstand the tenacity of the hammer owner. It breaks, and in this case no miracles like Suprotec, blue electrical tape and dimexide will help. There is only one way out - buy another trapeze. New, original, analogue, disassembled, Chinese - a matter of money, preference or religion, the choice is yours. The main thing is that free work will result in spending on new spare parts and unnecessary actions associated with rearranging the engine. You can, of course, buy it assembled, but it will be noticeably more expensive.

And when buying a trapezoid from disassembly, you need to check it thoroughly. In the best case, it will also be sour, and it will have to be disassembled and lubricated in the same way. At worst, it can be broken: over time, the polyformaldehyde connections wear out and begin to play. And it is no longer possible to fight this.

Source

Motor malfunctions and solutions

Let's look at what to do if the windshield wiper motor does not work, and what can cause such problems. There are several options:

1. The electric motor does not work, the bimetallic fuse is inactive, and the fusible insert responsible for powering the wipers is intact. In this case, you need to check the serviceability of the wiring, the quality of connections of all contacts, determine any existing damage and eliminate them.

If everything is fine with the wiring, then you should check the wiper switch. If it acts up, just replace it. The engine itself may not work - this often happens when brushes stick or contact connections burn.

In this case, you need to repair the windshield wiper motor - inspect it, replace faulty elements, clean dirty components

It is important to check the integrity of the wiring that connects the electric motor and the block

The rear wiper stopped working - what's the problem?

Rear wipers are usually installed on hatchbacks and station wagons. These elements allow you to avoid total contamination of the rear window, which plays a huge role in the overall view from the car. Manufacturers often provide a washer system to the rear wiper. And unpleasant breakdowns may also occur in this system. If the rear wiper does not work, you should urgently fix the problem, since a variety of troubles in the form of accidents due to poor visibility are quite possible.

So, the main breakdowns in this case are as follows:

It is not always possible to determine the problem yourself. The design of rear wipers on modern cars is quite complex and cannot always boast of quality. Also, many manufacturers began to make rear wipers not universal, but individual. This will force you to spend a lot more money on replacing the rear window wiper if you need to perform such a procedure.

We offer a short video on how to deal with the problem if the wipers suddenly stop working:

How to repair wiper blades

The method of repairing car windshield wiper blades must be chosen taking into account the reason for their poor performance:

- If you want to make the rubber bands of the brushes softer and more elastic, dip them in gasoline. After this, wash them carefully with warm soapy water. In addition, you can lubricate the wiper blades of your car with silicone grease. This product is sold in a tube or as a spray.

- To degrease windshield wiper blades, wipe them with a rag soaked in white spirit. This is a light oily liquid that perfectly removes grease and dirt from the surface of brushes. Do not forget that white spirit must be handled with extreme care. White Spirit

Before starting work, put on personal protective equipment. Treat car wiper blades in a well-ventilated room. In addition, you can degrease the wiper blades in another way - simply keep them in hot water for thirty minutes. High temperature water will destroy the surface layer of fat, which will improve the ability of the brushes to clean glass. Of course, this method revives the car's windshield wiper tools only for a while.

If the wiper does not clean the car window due to wear on the working surface of the blade, correct it using a plate of rigid material and sandpaper. Fine-grain sandpaper and multi-layer plywood are ideal for this work. Please note that the longer the plate, the better the edge will be. Glue sandpaper to the plywood and carefully shape the rubber edge of the brush into a rectangular shape. As you work, try to correct the shape of the tape evenly. If you make mistakes, the turned on car wiper will leave wide stripes on the windshield.

Trouble-shooting

Poor quality of glass cleaning is usually associated with wear of the cleaning tape, as well as contamination of the hinges in the frame brushes and limited mobility of the rocker arms. The easiest way to solve this problem is:

- In frame brushes, the cleaning tape is changed. The brushes must first be dismantled, the worn element removed, a new one installed in its place, secured with steel plates and the brush secured to the lever.

- Frameless brushes are replaced entirely.

Sometimes the tape is in good condition, but the brushes leave streaks because the grooves that hold the tape are clogged. In this case, they should simply be cleaned. If the metal frame is covered with rust and the rocker arms have lost their mobility, it is better to replace the brushes entirely.

Cleaning tape is inexpensive, but some motorists are in no hurry to change it. You can restore the elasticity of the tape by dipping it in gasoline and washing it with a warm soapy solution; after this procedure, it is useful to coat the tape with silicone grease. Traces of grease are easily removed with white spirit. A worn, rounded edge can be smoothed out using fine-grit sandpaper glued to a hard base.

Slow movement of the wipers may be due to:

- With wear of the gear motor. It must be disassembled, cleaned, lubricated, and if critical wear occurs, replaced.

- With corrosion, contamination, insufficient lubrication of moving joints. The entire mechanical part is dismantled, disassembled, cleaned, and lubricated.

- With an error made during the installation process that needs to be identified and corrected.

Incorrect assembly can also cause the wipers to not return to the park position. Another reason for this problem is wear or breakage of the drive splines, in which case they need to be replaced.

Problems in the operation of the electric motor can be associated with both its breakdown and mechanical problems. If the gearmotor itself is damaged, it is best to replace it entirely. But if the problem can be fixed by replacing the damaged gear, cleaning the dirty manifold, and adjusting the limit switch, replacement can be avoided.

If the engine does not turn on, you need to inspect the power wires, winding wires, commutator, brushes, as well as the steering column switch, which includes a wiper switch.

- Damaged power wires are replaced with intact ones, oxidized tips are cleaned.

- A failed switch is replaced.

- A dirty collector can be cleaned, the internal cavities can be blown out and the surface can be sanded.

- If the collector burns out, it is better to replace the gearmotor.

- Replacing the gearmotor is also recommended if the winding wires are broken, although only the armature can be replaced.

The engine shutdown due to the fuse tripping may be caused by a short circuit in the winding; in this case, the gearmotor must be replaced. But quite often, an emergency shutdown is associated with the locking of the brushes due to their freezing to the glass, deformation of the levers, or the entry of a foreign object into the mechanism. In this case, the cause must be eliminated. Frozen brushes are carefully separated from the glass using a scraper so as not to damage the cleaning edge, but it is better to wait until it thaws. The mechanism is cleaned of dirt and foreign objects that hinder its operation. Deformed drive elements are leveled, and if the deformation is severe, they are replaced with new ones. After eliminating the cause of the fuse tripping, the blown disposable fuse is replaced with a new one, and the thermobimetallic fuse can be used again.

Dismantling the glass cleaner for repairs should begin with the levers and brushes

Intermittent purifier problems are most often caused by a damaged relay or switch. If the brushes move intermittently without pauses, and everything is in order with the relay, the limit switch may not operate. In this case, you need to adjust it, bend the contacts or the spring plate, which the gear cam bends. It is also possible that the limit switch contacts are dirty and need cleaning.

When the brushes do not move when the engine is running, the problem lies in the gear motor gear; it is necessary to inspect the gear itself and the crank on its axis:

- if the gear teeth are broken, it needs to be replaced;

- If the crank fastening is loose, you need to tighten the nut to the limit.

The wipers stopped working: the most common reasons

Over time, every car owner is faced with the fact that the wipers suddenly stop functioning. Problems that arise reveal themselves either by a complete stop or by the appearance of extraneous sounds during operation (for example, creaking).

The mechanical part of the windshield wiper is usually very reliable. Therefore, usually wipers may not work for the following reasons:

- Excessive wear and tear on moving parts of the system or lack of lubrication in required areas. In order for the windshield wiper mechanism to work properly and not fail for unknown reasons, inspection and maintenance are required, albeit not too often.

- Improper use of wipers. As an example, in the winter season, before turning them on, you need to unfasten them from the glass (ideally, melt the ice on them). Failure to do this may result in fuse, motor, or drive rod failure during startup.

As a rule, the cause of windshield wiper failure is often a malfunction of the electrical part of the device:

- The hum of the motor is not heard, the wipers do not work (they do not move in any of the operating modes). In this case, the cause may be a malfunction of the following elements: wiring, connectors, switches or gear motor.

- The wipers work, but very slowly. Most likely, the reason is also in the gear motor. The drive mechanisms may have become oxidized and rusted. Usually they need to be cleaned and lubricated or checked for correct assembly of the mechanism.

- When the intermittent mode is on, the windshield wipers operate continuously. The reason is most likely a broken relay, which will have to be replaced since it is not repairable. If the wipers are working and the sound of the motor is heard, you can also diagnose a malfunction of the breaker relay.

- You can hear the engine running, but the wipers don't move. In this case, the reason is most likely a break in the rod or contact elements.

- The windshield wiper arm does not work. The cause of the malfunction may be oxidation or damage to the contact elements of the traction rod.

- The windshield wipers do not work correctly - they do not move to their original positions. The cause of the breakdown in this case may be improper installation, problems in the contact group of the gear motor, wear or shearing of the splines on the brush drives.

- The wipers do not work when the washer fluid is applied to the windows. The cause may be a broken steering column switch or defective wiring and electrical connections.

Reasons for mechanical windshield wiper failure include:

- Self-unscrewing (full or partial) of the nut connecting the crank to the gear axle. Such a defect is easy to determine when the wipers are on, since the gear motor is working, but the brushes do not move.

- The nut securing the wiper arm is loose or its thread has been stripped. The reason may be incorrect installation of the leash in the initial position. Avoiding this is quite simple - you need to tighten the nuts with the required torque, and before final tightening you need to put the windshield wipers in the desired position.

- The wipers do not clean the glass due to a poor fit. The simplest reason is wear of the brushes themselves. The brushes simply need to be replaced. The second most common reason is poor adherence of the brushes to the glass due to mechanical interference. An option to eliminate it is to clean the wiper of foreign objects that interfere with normal pressure. But if none are found, then it is necessary to inspect the wiper mechanism, disassemble it, find and replace parts with a lot of wear.

From the above it follows that the reason that the wipers do not work can be either a malfunction of the electric motor or wiring, or a failure of the mechanical component of the vehicle unit in question. The trapezoid, the mechanism for driving and moving the wipers, is very often prone to breakdowns. Read further in the article for what to do when your windshield wiper breaks or does not work.

Trapezoid - the mechanism for direct operation of the wipers

One of the most complex mechanisms in the wiper system kit is the trapezoid. Today, no car manufacturer has such a reliable wiper drive mechanism to guarantee long-term operation of the device. What can cause damage to the trapezium:

- banal jamming of brushes,

- excessive emphasis on glass,

- improper activation of the wipers,

- freezing to glass in winter.

Among the possibilities for restoring this mechanism, it is worth highlighting only a few possible steps:

- purchasing a new trapezoid is often the best step for domestic cars, in which the wiper mechanism costs about 1000-1500 rubles;

- for foreign cars, purchasing a new trapezoid will cost exorbitant amounts of money, so in this case, repairs should be made and broken parts restored;

- Often the bushings and tips in trapezoids fail, which are often plastic and are terribly resistant to frost, so they can simply be replaced;

- if it is not easy to find a repair kit for a trapezoid for your car, you can try installing bushings and other parts from other cars of a similar class;

- Direct replacement of the trapezoid is necessary if even repair work does not eliminate the problem, or after repair the mechanism begins to tap during operation.

Any sounds coming from the trapezoid may be a harbinger of its death. This is exactly the sign that indicates a possible failure of the entire device. However, you should not change the trapeze immediately after unpleasant sounds occur. Before replacing, you can wait until the device completely fails or try to eliminate the sound by tightening the components of the trapezoid using standard tools. It's not difficult and can be done right in your garage.

General provisions

It is necessary to regularly check the condition of the wiper rubber. If the product is of high quality, it will last about 2 years, although everything depends directly on the manufacturer. It’s better to change brushes once a year; their price tag is not so high that you can save on it.

It is also worth understanding that wipers come in several types:

- frameless;

- frame;

- hybrid.

The frameless design consists of a pressure plate and the brush itself. The disadvantage is that it is not universal. The fact is that to ensure the correct clamping force, it is necessary to select the right wipers. In the case of a frameless design, they are purchased for a specific car brand; you can’t buy these in every store. But here it is worth highlighting such an advantage as all-season use.

What to do with a faulty electric motor

First check if the electric motor is working properly. To do this, first make sure that the fuse responsible for its operation is serviceable. If the engine does not spin and the fuse is in good order, it makes sense to check the integrity of the electrical wiring and that there are no broken wires or short circuits.

Very often, the gear motor for the wiper drive stops working due to foreign parts or objects getting into it, such as keys or something similar. Car owners often keep a tool under the hood so that it is always at hand in case of any problems. If you determine that the cause of the malfunction is that the electric motor does not work, then there are only two options for further action - either replace it with a new one, or give it to an auto electrician for restoration.

To replace the electric motor in the gear motor, you will only need a 12 key and a certain amount of time. It is important to pay attention to the strength of the electric motor fastening, since if it is not fastened tightly enough, it will very quickly break the trapezoid. This operation is not complicated; it is enough to put the trapezoid in the desired position so that the wipers stop in the required place.

If the wipers are not working well, the cause may be faulty electrical wiring. First, they check the fuses, which very often burn out and simply do not allow electric current to pass through. The fuse box is installed both under the hood and inside the vehicle, depending on the manufacturer and model.

Sometimes the cause of the malfunction is torn wires as a result of poor repairs. If, for example, after visiting a car service center your wipers do not work, then most likely the technicians cut the wiring and did not notice it.

It is necessary to check the electrical circuits of the windshield wipers, if possible. But it is best to take the car to a trusted auto repair shop and repair the damaged wiper power wires.

We recommend

Function and principle of operation of wipers

The key task of the windshield wiper mechanism is to clean the windshield from water during rain, as well as dirt that falls on its surface during movement. These wipers operate using special mechanisms.

Using the scheme of rods and hinges, the non-circular movement of special cones is ensured; they only provide translational-rotational action, after which they return. Almost every car has two wipers. The design of the rods and hinges is designed in such a way that the drive cones work synchronously, which facilitates the simultaneous movement of the wiper arms. This helps prevent them from touching.

Often a wiper is also installed on the rear. Its function is similar, but the circuit is a little simpler. An electric motor helps drive the rear window wiper, since these mechanisms work almost the same on all cars. Most often it is located close to the drive cone of the lever, but begins its movement with the help of a small gear reducer.

The design and principle of operation of the frame wiper brush

If the metal or rubber frame of the wiper does not have serious mechanical damage, then such a brush can easily be repaired with your own hands. In order to carry out repairs consciously, you should understand the structure and operating principle of the windshield wiper.

Wiper frame brush device

The main part of any car wiper is a rubber band, since the cleanliness of the car windshield in bad weather depends on its quality and technical condition.

To effectively remove water, the rubber band is made quite elastic and two elastic leaf springs are used to secure it in the wiper. The length of the plates is equal to the length of the rubber band and is inserted on its two sides into grooves specially provided for this in the rubber band.

Rectangular indentations are made at the ends of the elastic plates, and protrusions of the same shape are made at the base of the tape. This ensures that the plates are fixed in the rubber band, preventing them from moving.

The brush frame consists of several rocker arms pivotally connected to each other using axes. The number of rocker arms depends on the length of the brush and there are from three to seven pieces in the frame. The axles are fixed in the rocker arms with a rivet.

For better mobility when connecting the rocker arms, plastic inserts are inserted between them, which reduce wear on the rocker arms and eliminate squeaking when the wiper is operating. In the middle of the longest rocker arm there is a pressed-in axle for attaching a plastic adapter to it - a latch.

Adapters are necessary to be able to install a wiper blade on a windshield wiper arm (arm) of any car model. Typically, new blades are equipped with a set of the most popular adapters, suitable for almost any car windshield wipers. To fix the adapter on the rocker, just put it on the axle and press hard on it. The adapter will fit securely onto the rocker arm. Before installing a new adapter, you need to determine which of the kit will fit your windshield wiper. You can also use the old adapter by removing it from the old brush.

The length of the rubber band depends on the size of the wiper blade. But the profile of tapes for wipers of different lengths and designs, including frameless brushes, is almost the same. True, there are tapes that have additional sharp edges on the side surface, but having ruled that out, I have not seen them on sale.

The profile photo of the tape clearly shows three symmetrical grooves running along its entire length. The upper groove is designed to install elastic spring plates into it, which give the rubber band elasticity and shape. The claws of the rocker arm clamps, including the fixing one, are inserted into the middle groove. The lower groove forms the neck of the band and makes it possible to shift the working part of the rubber band when changing the direction of movement of the wiper while cleaning the car windshield from precipitation and dirt.

What are the features of using wipers?

In order for the operation of your wipers to be as effective and long-lasting as possible, you need to follow a few simple and very reasonable recommendations. In a situation where the special washer fluid runs out, you should not activate the wipers if the glass is dry. You should always remember to wipe the windshield, since poor visibility can be caused not only by external factors.

How to clean windshield wipers? It is recommended to periodically lubricate the holder arm in the bend area. This procedure helps to improve the tightness of pressing the structural element to the surface being cleaned. The fluid supply nozzles must be adjusted so that the point of maximum pressure is concentrated in the area where the brushes move. In winter, it is not recommended to activate the wipers until the snow has completely thawed. No cleaner will help get rid of the ice that has formed, and the decline in performance will be accelerated.

Causes of malfunction and their elimination

It often happens that the wipers do not respond to switching modes. If you turn on the wipers and when you switch the lever you do not hear the sounds of the electric motor or the clicks of the relay, the reason may be hidden in three places:

- switch;

- relay;

- fuse.

In such a situation, you first need to check the functionality of the fuse. It is located on the circuit board designated F5. You can check its working condition using a conventional tester. You also need to check the bimetallic fuse located in the purifier gearbox. If the wipers on a VAZ-2114 stop working in winter, there is most likely one reason - severe frost. The same fuse prevents the windshield wiper from turning on in case of overheating or freezing of the blades to the windshield.

Next, you need to check the relay (“short circuit” on the circuit board). You need to find it and temporarily replace it with a new breaker, and then check the operation of the wipers. If the windshield wiper does not function, we continue to look for the problem area. It is quite difficult to independently verify the operation of the switch. It consists of a complex structure, so it is easier to change it than to try to repair it. If the turn signal refuses to work together with the windshield wiper, the problem area is the switch located under the steering wheel.

What conclusions can be drawn?

So we looked at which rubber bands for wipers are better. In most cases, it is better to give preference to hybrid designs. They combine not only long service life, but also high performance properties. However, it is necessary to understand that even such wipers require regular, timely replacement.

If your budget does not allow you to choose hybrid brushes or they are not in stock, then you should pay attention to frameless silicone ones. If the rubber band for the wiper can be replaced, then even better

This way you can save a lot and install a quality product yourself. If graphite brushes creak or glide poorly on glass, it is recommended to lubricate them with silicone. Although the effect is temporary, it may help for the duration of your trip. In the future, of course, it is recommended to replace the brushes with silicone ones, preferably of a hybrid type.