Few drivers know what to do if valves or hydraulic compensators on a VAZ 2112 16 valves are knocking. This is a fairly common situation. But most people do not know the reasons for such phenomena and are afraid of them. In fact, this may be quite common and should not be a cause for concern. Depending on the characteristics of the knock, we can draw a conclusion about its nature and danger to the engine. Some types of knocking are quite harmless. You can ride with them, but this problem may lead to others. Therefore, it is still better to eliminate the cause immediately. Moreover, in most cases this does not require any special costs.

How to understand that the hydraulic compensators of the VAZ 2112 are knocking?

It is very easy to check the hydraulic compensators: you need to remove the valve cover, bring the crankshaft to a position where the cams will not act on the compensators, and then press on the piston. If the hydraulics are working properly, the piston will move down, if not, it will stop!

This often happens due to insufficient oil. You can understand what exactly is knocking in the engine by the following characteristic signs:

- If the knocking noise disappears only at high speeds, it means that there is a faulty ball piston hidden somewhere, it must be detected and the failed compensator replaced

- When it starts knocking on a warm engine, this is a sure sign that the hydraulic valve has worn out and has completely exhausted its service life.

- If knocking occurs at high speeds, there is most likely excess oil in the system. The lubricant gets onto the cylinder head and disrupts the functioning of the compensators

Verification methods

Now the motorist is faced with the task of finding out whether the expansion joints on his car are working or not. What is the best thing to do in such a situation?

There are two verification options.

- The first option involves removing the valve cover. The method is more visual and allows you to almost certainly guarantee the correct diagnosis. But implementation is more difficult due to dismantling work;

- The second option does not require the elements to be dismantled. But here you need good hearing. To improve it, it is better to use a phonendoscope. By listening to the operation of the main engine in different modes, you can find the source of the problems.

Which option should I choose? It's up to you to decide.

Both verification methods have their strengths and weaknesses. For a beginner in such matters, I would recommend starting by listening to the hydraulic compensators. If wiretapping does not yield anything, then open the valve cover and more clearly examine the condition of the elements.

Wiretap check

The preparation for the procedure is extremely simple. You need to place the car on a flat surface, open the hood, start the engine and listen.

Even perfect hearing does not always allow one to clearly recognize a non-working compensator. It is better to take an auxiliary medical instrument to help. It's not difficult to find.

And here we will consider several situations. Depending on the result of the check, we will draw appropriate conclusions.

- After starting the engine, the noise appeared at first, but disappeared after a few seconds. Everything is fine with compensators. Lubricant just temporarily leaked out of the cavities of the main body. The engine turned over and filled them;

- The speed is idle, and the noise from the compensators is intermittent. As soon as you raise the speed, the noise goes away. There is a problem. It lies in the bushing or blockages;

- The engine is warm, the speed is idling, the noise is continuous. By increasing the speed, the noise disappears. This means that the gap has increased;

- The symptoms are similar to the previous point, only at low speeds there is no noise, but at high speeds there is. Here you are faced with foaming of the oil;

- One or several knocking noises occur at once, regardless of engine speed. Any of the above malfunctions are possible here.

By applying the wiretapping tool one by one to the area where each of the compensators is located, you can understand where exactly the problem is.

If the noise of one HA differs from the others, you have found the source of trouble. All that remains is to figure out the reasons and eliminate the malfunctions.

Disassembly check

To check these elements for their functionality, you can remove the valve cover. Next, you will have to rely on your own feelings when checking elasticity.

You will have to turn the crankshaft using the center nut to do this. This will set the shaft in motion.

When the pusher cam is directed in the direction opposite to the main body, check the elements one by one for their elasticity, whether there is free play.

You can use your hands or available tools. When the compensator is loose and moves too softly, it is faulty. Needs renovation.

How to eliminate knocking on a VAZ 2112?

The reasons for the appearance of knocking noise from hydraulic compensators are quite clear: natural wear, low-quality engine oil, lack or excess of lubricant in the system. Monitor the engine oil level; if necessary, top up, don’t skimp. Also, you don’t need to save on oil changes - it’s more expensive for yourself.

As practice shows, repairing expansion joints is a waste of nerves and time. It is also impractical and, in the end, unprofitable. Check all the elements again, most likely one of the hydraulic valves is knocking. Replacing hydraulic lifters is a simple job.

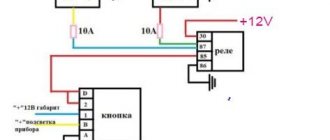

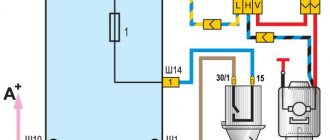

For normal operation, hydraulic compensators require an uninterrupted supply of oil, which is supplied under pressure. The supply occurs through a special channel with a check ball valve, which prevents oil from draining from the channel after the engine is stopped. In addition, there are channels located on the lower plane of the bearing housing, which supply oil to the camshaft journals.

Hydraulic compensator design:

To enlarge the image click on the image!

The disadvantage of hydraulic compensators is their excessive sensitivity to the quality and purity of the oil. The presence of mechanical inclusions and other foreign elements in the oil leads to rapid failure of the hydraulic compensator plunger pair. This malfunction is most often accompanied by increased noise emission and intense wear of the camshaft cams.

Replacement

Experienced car enthusiasts advise replacing hydraulic compensators as a set. They wear about the same. Therefore, if one fails, the other will soon fail. To replace the hydraulic valves, you will have to remove the camshafts, as well as some other engine parts. In principle, the work is not difficult and does not take much time. This should only be done on a completely cooled engine.

For greater reliability, you need to change the engine oil at the same time. When you first start the engine, do not be alarmed; you may still hear the same knocking noise. It will end after half a minute, as soon as the required amount of oil is filled into the hydraulic compensator. If replaced correctly, the motor will run quietly for a long time.

Conclusion

. The engine on the “two-wheeler” has a lot of advantages; it is quite resourceful, and at the same time not gluttonous. But it has one drawback, valve knocking. Therefore, novice drivers often ask what to do if valves or hydraulic compensators on a VAZ 2112 16 valves are knocking. Before answering this question, it is necessary to find out the exact reason for this phenomenon. After which, it can be eliminated.

Let's summarize. Hydraulic lifters are knocking - reasons

- Hydraulic lifters can knock due to problems with oil, including the fault of a faulty oil system, as well as as a result of a mechanical malfunction of the hydraulic compensator itself.

- If hydraulic compensators knock when cold , but the knock disappears when hot, then, according to experienced mechanics, there is nothing wrong with this; this phenomenon occurs in most car owners.

- If the hydraulic compensators knock when hot , that is, after the engine has warmed up to operating temperature, this is a clear sign of a malfunction that must be eliminated immediately.

Everything about hydraulic compensators for Lada Priora 16 valves

Some users of Lada 2170 cars in the 16-valve version encounter a suspicious knocking sound inside the internal combustion engine. This may be caused by a small part called a hydraulic compensator.

Why are hydraulic compensators needed on the VAZ 2170 Priora

A design element of a modern engine is designed to automatically adjust the valve position. The part allows you to eliminate the manual calibration procedure every 10,000 km, which makes car maintenance easier and helps increase the power of the power plant.

The design and principle of operation of hydraulic compensators on the Lada Priora

Structurally, the hydraulic compensator on Priora looks like a metal cylinder with a spring and a shut-off valve. Inside the part there are two smaller sleeves. The operating principle of the system is based on oil pressure in the plunger. When the pusher cam leaves, the cavity inside the hydraulic valve is filled with oil. At the end of the cycle, the container is completely filled and the cam begins to push the entire structure down (open the valve). In this case, the main valve pusher rests on the part and lowers it. The opening depth is adjusted by changing the pressure of the liquid entering under the plunger mechanism.

Why are hydraulic compensators knocking on a Priora with 16 valves?

A knocking sound during operation of parts appears when the supply of emulsion to the plunger is reduced and the pusher does not move evenly. The causes of the characteristic sound can be the following factors:

- Wear or low quality lubricant. The correct operation of the mechanism depends on engine oil. The technical clearances in the plunger are minimal, which requires the use of a high-quality consumable.

- Clogged fluid lines.

- Natural aging of parts. Main engines are designed for 100,000 km. Moreover, if the machine is operated in difficult conditions, the service life is reduced by 15-20%.

Why do hydraulic compensators knock on a Priora when it’s cold?

The reasons for knocking parts on a cold engine can be several factors:

- The viscosity of the lubricant is incorrectly selected. Thick oil does not pass through small channels, which causes dry friction.

- Worn or contaminated lubricant. The presence of solid impurities, soot or soot makes it difficult for the mixture to flow freely.

- Low pressure inside the lines, pump malfunction.

- Jamming of the plunger mechanism due to sludge formation or misalignment of surfaces.

- Wear of the main body. Fatigue of the spring, shell on the check valve ball.

Problems in the oil system that can cause knocking in hydraulic compensators:

- Clogged oil channels (dirt in the channels, plaque);

- Airy oil system (air present in the system increases the compression ratio of the oil). Air in the oil can occur as a result of high or low oil levels;

- Clogged oil filter;

- The wrong oil has been filled in (does not match: viscosity, fluidity, quality, temperature characteristics);

- There may be interruptions in the operation of the oil pump;

- Overheating of the engine, as a result of which the oil burned, losing its viscous and lubricating properties.

How to check hydraulic compensators - video

Device

What to do if valves or hydraulic compensators on a VAZ 2112 16 valves are knocking? Before answering this question, it is necessary to understand the structure of the hydraulic compensator, which mechanics often abbreviate to “hydric”. It is from the peculiarities of its structure that the reason for some knocks follows.

The hydraulic compensator itself consists of a cylindrical piston, whose bottom receives the force from the camshaft pusher. There is a plunger located inside it. With its help, force is transmitted from the camshaft to the valve stem. The plunger moves quite freely in its seat. This is necessary to ensure a thermal gap. When the engine is running, the camshaft cam pushes the piston, which opens the valve through a plunger. The thermal gap is adjusted using oil supplied to the head under pressure. Accordingly, adjustment occurs by changing the pressure. To avoid oil leakage from the hydraulic valves during parking, a ball valve is used.

How to solve the problem of knocking hydraulic compensators?

- You can try changing the oil if it has been changed for a long time or looks bad (dark brown color, bad smell, etc.). As a rule, after replacement, the knocking of hydraulic compensators disappears. If the knocking does not disappear, you will have to take out the main battery and see what’s wrong.

- If adding oil did not lead to anything, and washing the engine did not give any result, you can try another way to solve the problem of knocking hydraulic valves. The principle is to remove the main hydraulic valves, perform a visual inspection of them, in case of insignificant wear and normal condition, you can disassemble and wash the hydraulic compensators. When removing, I recommend remembering or writing down where which hydraulic compensator was installed. After washing, everything is assembled and the operation of the engine is checked; if washing the hydraulic compensators does not lead to anything, the only way out is to replace the hydraulic compensators .

Troubleshooting methods

In specialized services, the cause of the knocking is determined using acoustic diagnostics. The same method allows you to identify a faulty hydraulic compensator, and there is always one. So is it possible to find it without resorting to the help of professionals?

It is possible if you disassemble the motor. Of course, it does not need to be completely disassembled. It is enough just to remove the valve cover and try to push through each device. When pressing on the working hydraulic compensator, you have to apply some force. The faulty piston is the one that retracts when pressed lightly. There is no other way to identify a knocking hydraulic compensator.

It should be noted that if extraneous noise appears while the engine is warming up, it is not recommended to operate the vehicle. In this case, it is necessary to entrust the iron horse to the caring hands of professionals. If this is not possible, you can try to fix the problem yourself.

To do this, perform the following operations:

- the oil and oil filter are changed;

- The channels are washed to remove old lubricating fluid.

Recommendations for choosing oil

The brand of motor oil must be selected following the recommendations of the plant where the car came off the assembly line. But the seasonality of operation must also be taken into account. When the engine heats up, the viscosity of the lubricant decreases. To ensure the same lubricant characteristics, a thicker liquid is poured in the warm season, and a thinner liquid in the cold season.

If the knocking does not stop after the engine warms up, you need to check the filter. Over time, the filter element becomes clogged with foreign particles, which prevent the lubricant from penetrating the hydraulic compensators. In this case, it is necessary to replace the filter.

Pistons can knock when cold if low-quality lubricant is used, which contributes to contamination of the channels. This problem can be eliminated by removing the expansion joints and washing them in gasoline. The devices must be removed one at a time and then installed in the same sequence.

How to replace an element

If all the previous methods have been applied, but the desired results are not achieved, the knocking hydraulic compensator must be replaced with a new one. To do this, remove the valve cover, the sprocket from the camshaft and check the tensioner. Then they remove the bed and take out the pushers, strictly observing the sequence. They take out the compensators and lay them out in the same way.