01/19/2021 4,076 ECU

Author: Ivan Baranov

The electronic engine control unit is the “brains” of the vehicle. With its help, the main processes that ensure the normal operation of the power unit are carried out and controlled. You can learn more about how to diagnose and repair an engine control unit at home from this material.

[Hide]

Our recommendation:

Vehicle owners will eventually need to replace a faulty ECM. The device may work initially, but over time there may be deterioration in vehicle performance, including poor fuel economy and efficiency, automatic transmission problems, and jerking or stalling while driving. The electrician will perform a diagnostic check on the vehicle's system and let the owner know which parts need replacing based on the code given by the ECM.

The mechanic will also check the transmission fluid to make sure there is no problem with the transmission. Some other problem areas that cause ECM failure include a faulty fuel solenoid, poor battery grounding, and wiring corrosion caused by moisture, among other causes. By regularly checking key vehicle components, owners can keep their vehicles in optimal operating condition, avoiding many of these problems. If the Check Engine Light remains on after resetting it, the ECM may need to be replaced.

Unlocking the immobilizer on Lada cars

Lada Kalina, Priora, Granta, Niva Chevrolet cars are equipped with a standard APS 6 immobilizer. The problem of engine start blocking may arise due to its malfunction.

If the immobilizer is faulty, then, as mentioned above, 6 seconds after an attempt to start the engine, a flashing indicator in the form of a car will appear on the instrument panel for 20 seconds and groups of signals will be heard.

A group of signals can contain from one to four sounds, each of which indicates a specific malfunction:

One signal (duplicated after 6 seconds) - the code in the key chip cannot be read due to a failed transponder or communication coil.

To check the immobilizer coil, you need to measure its resistance, which should be in the range from 6 to 8 ohms. To do this, remove the decorative casing around the steering column.

There, find a block with white and blue wires and measure the resistance on them with a multimeter.

If everything is in order with the coil, then you need to ring the circuit further from the ignition switch to the APS 6 control unit. To do this, we place a plug between the contacts of the white and blue wires.

We remove the main block from the immobilizer unit (to do this you will have to disassemble the front panel) and use a multimeter to test the circuit through pins 1 and 11.

If you suspect a transponder chip in the key, then disassemble it and make sure that the chip is present and the integrity of all elements, including contacts.

How important is this problem?

If car owners do not replace a faulty ECM, they can expect the vehicle to perform poorly, gradually deteriorating until the vehicle no longer starts or drives at all. Vehicle owners need to replace the ECM immediately to avoid this. When the ECM plays such an important role in the overall proper functioning of the vehicle, owners should have their vehicle checked as soon as they notice any problems while operating the vehicle. If identified early enough and replaced, a faulty ECM will cause virtually no subsequent problems.

Source

Replacing the engine control unit

As you know, a modern injection engine is completely controlled using a developed ECM. The system includes controller units, sensors and electronic-mechanical actuators. In this case, different control units are used for different engines.

Although these units are fairly reliable devices, their breakdown cannot be ruled out. Problems that are directly related to the ECU can be caused by a short circuit, mechanical damage to the unit, moisture getting inside the controller, etc. One way or another, incorrect operation of the control unit will not allow the internal combustion engine to operate normally.

In such a situation, the “brains” are replaced with a suitable analogue, after which the engine control unit is reflashed. In this article we will talk about how to replace the ECU with an engine with your own hands.

Automatic transmission ECU - how the controller works and works

Let's start with the fact that the automatic transmission ECU is a complex electronic device, which is actually a set of electronic microcircuits and chips, and also has a processor.

The automatic transmission electronic control unit analyzes numerous and constantly changing parameters in real time. The control unit receives signals from sensors, after which the signals are processed and control pulses are generated, which are then sent to the actuators.

It is important to understand that the automatic transmission unit of the latest generations operates according to so-called “floating” algorithms, that is, the logic of its operation is more complex compared to the engine ECU. This complication is necessary in order for the automatic transmission to function smoothly, harmoniously and clearly taking into account constantly changing conditions and loads. If we talk about the device, the unit has a memory module where special programs (software) are registered. Also, in the automatic transmission ECU, there should be a microprocessor that processes the information received from the sensors

If we talk about the device, the block has a memory module where special programs (software) are registered. Also, in the automatic transmission ECU, there should be a microprocessor that processes the information received from the sensors.

We also note that the memory of the automatic transmission electronic control unit at the initial stage was a ROM (read-only memory). In such blocks it was not possible to make any changes to the firmware. For this reason, later developers began to use storage devices with the ability to reprogram them.

To change the algorithms (logic) of the automatic transmission, it is enough to connect special equipment (programmer), which allows for a more flexible adaptation of the automatic transmission.

Numerous sensors automatically send signals to the ECU, which allow the unit to receive accurate information about the state of various mechanisms. Based on the received data, an action is selected according to the program recorded in the block’s memory. The operation of the automatic transmission is controlled primarily using solenoids, which are actuators.

Also, the automatic transmission unit works in close connection with the engine ECU; these units actively exchange information. In some cases, the engine ECU and automatic transmission can even be combined, but this applies more to older models with a simple hydromechanical automatic transmission.

Cars of recent years are equipped with complex and technologically advanced automatic transmissions (for example, DSG), which have a large number of additional modes (sports, economical, winter, manual gear shift function Tiptronic, etc.), and are also adaptive gearboxes.

It is not difficult to guess that the operating algorithms of modern automatic transmissions have become too complex. This required the integration of a completely separate electronic control unit for the automatic transmission.

Main functions of the internal combustion engine control unit

Let's start with the fact that if the control unit fails, this device must be replaced, since repair is often impractical. Taking into account the high cost of the device, it is often practiced to replace it with a used control unit; less often, a new ECU is purchased.

In this case, for replacement, special attention should be paid to the selection of the control module. The control unit must not only be suitable for the model, but also correspond to a particular type of engine. In other words, most often the ECU only fits from a similar car model with exactly the same internal combustion engine.

The electronic unit monitors the operation of the ignition system, fuel injection, evaluates the composition of exhaust gases, etc. Each car model has an individual on-board computer for a specific type of vehicle.

DIY troubleshooting instructions

Before removing the control unit and disassembling it, inspect the device connector; it may be damaged.

The repair procedure is described using the example of a BMW ECU:

- Using a screwdriver, you need to bend the petals on the cover of the device, and then simply remove it.

- After this, on the back side of the structure, unscrew the bolts securing the housing.

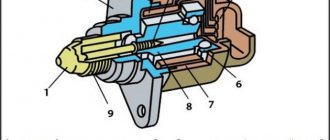

- Having disassembled the case, you can see a diagram of the device with soldered pins.

- As practice shows, one of the most common causes of brain failure is cold soldering of radio component contacts. In other words, all the contacts are soldered, but around them there may be a small crack in the solder itself. That is, there seems to be soldering, but in fact there is none. For diagnosis you will need a magnifying glass. If during inspection you notice poorly soldered leads, you will need a soldering iron.

- Next, you need to pay attention to diagnosing transistors and microcircuits; these components may have burnout. If there is burnout, these components will need to be replaced.

- If there are no burns or damage on the device board, then you will have to look for failed device components. Namely, we are talking about Darlington transistors. This component is a composite transistor, which in turn consists of two transistors. If you have any doubts about its performance, this board element also needs to be replaced.

- The last thing you should pay attention to is the quartz resonator, which is also mounted on the scarf. As a result of vibration, this element may fail, which, in turn, may lead to failure of the fixed frequency generator device.

1. Inspect the ECU connector for damage.

2. Using a magnifying glass, carefully inspect the entire board.

3. Inspect the quartz resonator, if necessary, replace it.

Why the controller needs to be changed and how to replace the ECU with an engine

As mentioned above, the need to replace the engine control unit may arise for various reasons. In most cases, malfunctions in the control unit do not allow the car to operate normally; as a result, the ECU needs to be replaced.

Taking into account the fact that the engine control unit is an electronic device, its high sensitivity to voltage drops in the on-board network and short circuits is noted. Also, moisture must not enter the ECU housing. The unit may also fail due to increased vibrations, shocks, etc.

Also, as part of diagnostics, it is very important to determine the very reason that led to the failure of the controller. Please note that if the cause is not found, then replacing the motor control unit may again result in a breakdown of the recently installed device.

As for the unit itself, at the initial stage the voltage at the ECU is checked. Then diagnostic equipment is connected to the unit, performance is tested, and input and output signals are tested. Only tests carried out as a whole allow us to conclude that the control unit is inoperative and needs to be replaced.

Typical unit malfunctions

Repair of vehicle control units must be carried out if a malfunction is detected.

Before removing and disconnecting the faulty ECU, let's look at the main causes of breakdowns:

- Repair of the engine ECU can be carried out in case of mechanical damage. The “brains” of the car can be subject to vibrations and shocks, which can result in cracks forming on the device body and circuit board.

- The cause of a car ECU malfunction can also be temperature changes, which contributes to overheating of the device.

- Corrosion and exposure to aggressive environments on the device.

- Moisture - if it gets into the housing, it may require replacing the vehicle's ECU. Often it is not possible to make repairs after moisture gets inside the structure. The reason for moisture getting into the device may be depressurization of the housing elements.

- As experts note, quite often the need for repairs arises as a result of interference in the work of the “brains” of inexperienced repairmen.

- Lighting the battery from a car with the engine running.

- Replacing the engine control unit may be necessary if the “+” and “-” terminals were reversed when connecting the battery.

- Another reason is that the starter is turned on when the power bus is not connected (video author - Ramil Abdullin).

We will also consider the signs of a malfunction of the car ECU, which will help determine the breakdown of the device:

- The engine does not start, smokes, detonation is possible.

- Mistakes during engine operation.

- Dips, when you press the gas pedal, the car may not respond.

- There is no connection with the “brains”.

- The engine control system malfunction indicator light is on. This may be the Check Engine light, but some cars use a separate unit performance indicator.

- The cooling system fan turns on randomly.

- Safety elements regularly burn out.

- Controllers and sensors stop sending signals.

Replacing the electronic engine control unit

Now let's move on to the replacement itself. Please note that replacing the engine control unit can be a difficult task if you do not have the necessary skills. Typically, the ECU must first be detected. In other words, you should know where the engine control unit is located on the car, depending on the make and model of the vehicle.

In the second case, the main task is to make it difficult to access the device so that the thief does not have an easy opportunity to replace the block, bypass the immobilizer, etc. It is quite obvious that the ECU can be located both in the engine compartment and in the cabin. To find the controller, you may need to partially disassemble the interior, remove attachments from the engine, etc.

After this, you need to check the operation of the ECU, and only then reassemble the interior in the reverse order. If attachments have been removed from the engine, you must first install all the parts and elements back, and only then check the functionality of the new unit.

By the way, on many cars the unit needs adaptation. In practice, especially if we are talking about a car with a significant mileage, this means “self-adjustment” of the controller taking into account wear of the internal combustion engine, reduced performance of the fuel pump, injectors, etc. It turns out that after replacing the ECU, the engine will not reach optimal performance immediately, but some time after the vehicle starts operating.

Video “Replacing the ECU using the example of a Mitsubishi Pajero”

How to replace the engine control unit with your own hands - see the video below (the author of the video is Sergey Kitaev).

The ECU on the Priora is located under the instrument panel on the right side. To get to the engine control unit, you need to remove the plastic floor tunnel plug at the front passenger's feet. The controller is located behind it, which can be clearly seen in the photo below.

In order to replace (remove) the brains on a Priora, you will need the following tool:

- 10 mm head

- extension

- ratchet or wrench

Tips and tricks

Although electronic units from many manufacturers are officially unrepairable, specialists often quite successfully restore these devices. This means that the possibility of repairing the ECU should not be completely ruled out. If the unit is very expensive or rare, then the possibility of repairing the ECU may be a way out of this situation.

If all the work is done correctly, additional tuning of the ECU allows you to improve individual technical characteristics of the engine on a particular car. As a rule, the engine begins to “pull” better at low speeds, dips disappear when you sharply press the gas pedal, the engine operates more elastically in different modes, etc.

However, we should not forget about the disadvantages of chip tuning. If a program from an unknown manufacturer is installed, specialists have not “tested” the firmware on the go, etc., then the engine life may be noticeably reduced, problems with mixture formation may arise, the revs may begin to fluctuate, the engine will become “stupid”, responsiveness to pressing the accelerator pedal will disappear, under under load the internal combustion engine stalls, etc.

How to independently replace an electronic engine control unit (ECU, ECM, controller)

The electronic engine control system detects failures associated with wire breaks, short circuits to each other or to ground. With poor contact quality in the connectors. And also with a malfunction of the sensors themselves. However, there are malfunctions in the power and ignition systems that have external signs (which are noticed by the driver), but no fault codes are recorded in the memory of the electronic unit.

Main symptoms of malfunctions:

If, when starting the engine, the battery voltage drops to eight volts (determined by the voltmeter on the instrument panel), then these are poor starting conditions (low ambient temperature) or the battery capacity is less than nominal. Quite often, a voltage drop is associated with oxidation of the battery terminals. Also, starting the engine will be difficult at low temperatures and high oil viscosity.

– jerks or failures in engine operation.

When you press the gas pedal, there is no expected acceleration. A well-warmed-up engine should, when you sharply press the gas pedal, increase the crankshaft speed from low (800-900 rpm) to high (5000 rpm) in no more than 0.75 seconds.

– insufficient throttle response (power).

When the car is moving, downshifts are often used. The speed is picking up slowly. There is a feeling that the engine “does not pull, it’s dull.”

The following elements of the electronic system may be associated with the appearance of this symptom: mass air flow sensor, oxygen sensor, clogged injectors, unbalanced injectors, lack of required fuel pressure due to a malfunction of the fuel pump or pressure regulator. You should check whether the throttle valve opens fully and whether the exhaust system is clogged.

– frequent detonation.

A sharp metallic knock is heard, changing when the throttle valve is opened. The main factors contributing to the occurrence of detonation are temperature and pressure in the combustion chamber. As well as the ignition timing.

The following elements of the electronic system may be associated with the appearance of this symptom: mass air flow sensor, coolant temperature sensor, oxygen sensor, knock sensor, lack of required fuel pressure due to a malfunction of the fuel pump or pressure regulator.

The air filter should be replaced. If the filter is heavily contaminated, the correspondence between the action on the gas pedal and the signal from the mass air flow sensor sent to the control unit is disrupted.

– delays, twitching, failures.

This is most noticeable when starting off.

When you press the gas pedal, the engine does not immediately respond by increasing the crankshaft speed. Such delays can occur at all vehicle speeds.

The following elements of the electronic system may be associated with the appearance of this symptom: mass air flow sensor, throttle position sensor, injector imbalance, lack of required fuel pressure due to a malfunction of the fuel pump or pressure regulator, malfunctions in the ignition module (high-voltage wires, spark plug tips, etc.) the spark plugs themselves are faulty, the high-voltage terminals of the ignition coils are heavily oxidized).

– interruptions in engine operation.

Uneven engine operation. When the crankshaft rotation speed changes, jerking begins, especially when the load increases. There is a constant popping noise in the muffler at idle.

The correct operation of the same sensor can be disrupted by magnetization of the toothed synchronization disk (checked with a thin steel plate).

The following elements of the electronic system may be associated with the appearance of this symptom: imbalance of injectors, lack of required fuel pressure due to a malfunction of the fuel pump or pressure regulator.

– increased fuel consumption.

Tire pressure is below normal, a malfunction of the brake system (braking of one or more wheels), an aggressive driving style, all malfunctions in the engine, power and ignition systems, malfunctions in the cooling system.

– Unstable engine operation, stopping at idle.

Air leaks behind the mass air flow sensor, improper operation of the idle air control.

– pungent smell of gasoline in the exhaust system.

This phenomenon usually occurs when the working mixture is very rich, and the enrichment is associated with a misfire. It is also not recommended to idle the engine for long periods of time.

– self-ignition of the fuel mixture.

After turning off the ignition, the engine continues to run unevenly. This type of engine operation is associated with increased temperature in the combustion chamber and the presence of fuel in it. When this symptom appears, you should check the tightness of the injectors.

The following elements of the electronic system may be associated with the appearance of this symptom: mass air flow sensor, throttle position sensor, injector imbalance, lack of required fuel pressure due to a malfunction of the fuel pump or pressure regulator.

– Open the front passenger door.

– Unscrew the side fastenings from the console of the car’s instrument panel using a Phillips screwdriver.

– You get direct access to the engine control unit.

– Unscrew the 2 screws holding the controller.

– Take the block with one hand and gently pull it towards the front passenger door. At the same time, hold the wires with your other hand so that they do not rest against the carpet.

– Disconnect the unit from the wires. To do this, look for where the connector lock in the form of a bracket is located and pull it to the side.

– You receive a car without an ECU, ready to install new equipment.

Before installing a new engine control unit on a VAZ

, it is worth remembering that not all ECM models are suitable for this.

We recommend installing ECUs from Itelma and Avtel on your VAZ.

Among the advantages of such blocks it is worth highlighting:

– ease of installation;

– compatibility with almost all models of domestic cars, regardless of configuration;

– engine control units from these manufacturers already have standard firmware with the latest updates upon purchase.

You will succeed

The information will also be useful to you: Varieties of electronic engine control systems (ECM, controllers), which are installed on different models of the VAZ family car.

If you haven't found the answer you are looking for, then ask your question! We will respond shortly.

Don’t forget to share the information you find with your friends and acquaintances, as they may also need it - just click one of the social networking buttons.

Source

Engine control unit repair

A modern car is partly a computer on wheels, or, to be more precise, a computer that controls the movement of the wheels. Most of the mechanical parts of the car have long been supplanted, and if they remain, they are entirely controlled by the “electronic brain.” Of course, driving a computerized car is much easier, and designers think about the safety of such cars first and foremost.

However, no matter how perfect the design of electronic control units (ECUs) is, they can still fail. This is not the most pleasant situation, and due to the complexity of the device, there is no need to talk about self-repair (although there are such craftsmen). In today's article we will talk about what malfunctions can happen to the ECU, what can cause them and how to diagnose them correctly.

Reasons for ECU failure: what should you be prepared for?

First of all, a car's electronic control unit, or simply ECU, is very complex and important computer equipment. If this device malfunctions, all other vehicle systems may malfunction. In some cases, the car may stop working altogether, including failure of the transmission, chargers and control sensors.

Electronic units are different and can control different devices. At the same time, all systems still actively interact with each other and transmit important information to regulate all functions. The most basic of them is the car's engine ECU. Despite its design simplicity, it performs a lot of complex tasks:

1. Control of fuel injection into the combustion chamber of a car.

2. Adjusting the throttle (both while driving and while the engine is idling).

3. Controlling the operation of the ignition system.

4. Monitoring the composition of exhaust gases.

5. Valve timing control.

6. Coolant temperature control.

If we talk specifically about the engine ECU, then all the data it receives can also be taken into account when operating the anti-lock braking system, and when operating the passive safety system, and in the anti-theft system.

When is car engine control unit repair necessary?

Repair of the engine control unit, the price of which depends on the type of breakdown, will be needed in the following cases:

Algorithm for diagnosing the engine control unit with subsequent repair

Before deciding what type of manipulation the ECU needs (repair of the engine fan control unit or complete replacement), a thorough diagnosis should be carried out.

At the slightest suspicion of a technical “inadequacy” of the ECU, there is a strong desire to repair it yourself - but this cannot be done: at best, you will not change anything, at worst, you will significantly aggravate the problem. According to experts, the ECU (as the “intelligent” center of the machine) is the most complex implementation compartment, therefore the repair of electronic engine control units is trusted only to competent technicians at legal service stations.

The safety of your traffic depends on the efficiency and uninterrupted operation of the control unit, so listen to the opinion of experts and do not skimp on your own health and the lives of other road users.

Comprehensive repair of the engine control unit of cars and trucks: best prices, quality guarantee

So, the repair scheme for the engine control unit consists of the following steps:

They trust us with the whole range of activities for diagnosing, repairing and replacing ECUs, because the service from AvtoBloki is:

In the ECU repair sector, we are one of the best and you have a chance to see this.