The automatic transmission control unit is one of the most important parts in a car. This is a complex electronic device, which, unfortunately, like all electronic parts, tends to fail over time. If the electronic control unit consisted of various transistors, and the principle of its operation was simple, then there would be no problems with its repair. However, it is not. The automatic transmission electronic control unit is a complex device, and the principle of its operation only becomes more complex every year. This is done in order to improve the performance of the automatic gearbox.

Control unit - appearance

TCM, CVT, DSG modules – automatic transmission control

Modern automatic transmission on-board computers operate in constant mode, analyzing information received from sensors every second and reacting by sending commands to the transmission actuators. The system is involved in almost all components of the car, and its brain center is the electronic transmission control unit . Like any microcircuit, the automatic transmission ECU can also fail and require repair.

- Mechanical impact: overheating, power surge, corrosion, “flooding” of the unit with technical fluids, constant vibration, shock during an accident;

- Software errors: Certain car models have "chronic" transmission computer problems. These faults can appear throughout the entire period of use of the car;

- Incorrect operation of the automatic transmission - frequent departures from the transmission characteristics declared by the manufacturer provoke increased wear of the circuit board;

If the gearbox starts operating exclusively in third gear mode without the possibility of changing the position, with 95% probability it can be said that a failure that cannot be corrected by standard means has occurred and the automatic transmission has switched to an “emergency” operating mode, allowing you to get to the nearest service station.

This usually happens when the electronic transmission control module stops receiving input from a sensor or loses communication with the slave solenoid. In this case, it is recommended to immediately diagnose and repair the transmission ECU and related systems. If there is no suitable service station nearby, it is better to call special equipment to transport the car.

We repair any electronic transmission units ourselves in our own equipped laboratory, which eliminates the markup of intermediaries and increased repair time.

Location of the automatic transmission control unit in the Volkswagen Bora

Automatic transmission models that were installed:

- VAG 01M;

- Jatco JF506E;

- Aisin TF-61SN.

The VAG 01M model showed itself best during operation. It was developed by designers and designers of the Volkswagen concern. During its operation, from 1999 to 2008, it underwent a considerable number of changes. Some car models still have this particular automatic transmission model installed.

But no matter how high-quality the automatic transmission is, breakdowns still occur. And the electronic transmission control unit is responsible for most of the problems in the gearbox.

The operating principle of this complex digital device is to read data and operating parameters of sensors and microcircuits, which are then analyzed, and special control signals are sent to devices mechanically dependent on the automatic transmission ECU. However, the electronic control unit can also fail, and accordingly it requires repair and service.

Automatic transmission control unit "Volkswagen Bora"

To analyze the operation of the automatic transmission ECU, it must be found and removed. And to do this, you need to find out in which part of the car the Volkswagen Bora automatic transmission control unit is located. The system ECU of the automatic transmission in the Volkswagen Bora is located between the windshield and the hood, right under the frill.

To remove it, you need to do several operations:

- First you need to open the hood of the car.

- Then remove the wipers.

- Remove the plastic cover - frill.

- Disconnect the two connectors from the electronic control unit by pulling the special lever.

- Remove the control unit.

After the operations have been completed, you can already inspect the control unit and analyze the cause of the breakdown.

Automatic transmission ECU: structure and principle of operation

An automatic transmission is a complex unit that consists of a whole complex of mechanical, hydraulic and electronic devices.

At the same time, the most important element in an automatic transmission, regardless of the type of automatic transmission itself, is the electronic transmission control unit. Next, we will look at how the electronic automatic transmission control unit is structured and works, what malfunctions of the automatic transmission unit may occur during operation, as well as what methods exist for troubleshooting problems associated with the automatic transmission ECU.

You are here » Nissan Teana Club » I: Electrical, Light, Tuning » Where is the automatic transmission selector control unit located? Help is needed.

Share114.01.2013 16:53:13

- Author: Admaevs

- Pro

- From: Krasnodar

- Posts: 740

- Respect: +36

- Gender: Male

- Car: Nissan Teana 2004 VQ23DE

- Trim Level: AXIS

- Last visit: 09.11.2017 15:45:31

Good afternoon, colleagues!

From time to time, I cannot remove the selector from parking; the solenoid that opens the selector does not work when the ignition is turned on and the brake is pressed.

I checked everything: the frog works clearly (the brakes are on). I disassembled the console and found out that there is a constant positive going to the solenoid, but it is controlled by the negative. So the minus does not come.

Sometimes I drive for a week, everything works. Then, for some reason, the solenoid does not work and you have to use SHIFT to turn on the gears. In a day, everything might work again.

In general, I read on the forums that sometimes the diode in the solenoid control unit malfunctions, but I couldn’t find where to find this control unit. It seems that there is also some kind of automatic transmission selector control unit, but I suspect that it is one and the same. At the march, he seems to be standing somewhere behind a tape recorder, but I don’t know what he looks like, I never found a photo of him.

Anyone who knows anything about electrics can tell me where to look for it. I want to check these diodes.

I don’t want to go through the trouble of removing the solenoid and selector lock. MUST BE SURE THAT EVERYTHING WORKS AS SUPPOSED.

Share218.01.2013 13:54:06

- Author: Takashi_61

- Driver

- From: Rostov-on-Don

- Posts: 17

- Respect: 0

- Gender: Male

- Car: nissan teana

- Trim Level: 230jm

- Last visit: 03/19/2013 15:45:34

Hello. The control unit for the automatic transmission itself is located under the glove box (an aluminum box with two chips, the size of two packs of cigarettes), maybe it contains the selector control, but I’m not sure.

Share318.01.2013 17:26:46

- Author: Admaevs

- Pro

- From: Krasnodar

- Posts: 740

- Respect: +36

- Gender: Male

- Car: Nissan Teana 2004 VQ23DE

- Trim Level: AXIS

- Last visit: 09.11.2017 15:45:31

No, he's definitely not there. I think I found it on other forums. He's standing somewhere behind the tape recorder. Now everything works and there is no point in looking for it. I assume that there is a diode in it, but for now I will not calculate it. When the selector stops working again, then I will look for it. If I find a problem, I will definitely post a photo report on the repair. The sore is not uncommon for Tean, as I understand it. Maybe it will be useful to someone in the future.

Share402.02.2013 13:16:05

- Author: Stepanych

- Driver

- From: Peter

- Posts: 12

- Respect: 0

- Gender: Male

- Car: Teana 2.3 2006

- Trim Level: JM

- Last visit: 12/15/2013 12:33:58

I encountered exactly the same problem. Do not move it to the R position, but through Shift everything works fine.

Electronic automatic transmission selector lock

I encountered this problem back in the summer. It was impossible to move the automatic transmission selector to the R position... Here and there, oh, everything is ok, I thought it was some kind of glitch, and I gave up. Here the other day, I start to turn around on a narrow road, there is a stream of cars, I turn left, I twist the steering wheel, I want to stick the rear one in, but that’s not the case! There’s no way... What should I do, there’s already a traffic jam around me, I press the SHIFT button and only then, with the button pressed, I was able to turn on R... And that’s it, from that day on everything switches normally, then you press the brake, you pull the selector, but it doesn’t wants, only through the SHIFT button. To be honest, it started to piss me off a little... I came to visit my friends at the dealer. Their answer: “In the entire history of the existence of the J31 with left-hand drive, yours is the second car that came to us with this problem.” The solenoid is covered there. Simply put, an automatic transmission lock. It was possible to remove it altogether, but then the key would be pulled out in any position of the automatic transmission; you could buy a used selector. By the way, among Qashqais this is generally a disease, with a mileage of 80 thousand km and above. And on a Qashqai, the selector assembly is changed - 23,000 rubles, not sour, right?! And naaaaaaaas =))) And here this crap can be changed separately =) I spent the evening reading the manual. I ordered a bracket with solenoid assembly. I waited a week. And then he came =)

Common ECU malfunctions and their causes

The electronic control system can fail for various reasons. One way or another, the car owner in this case will be faced with the need to carry out diagnostics in order to accurately determine the malfunction of the unit, since in most cases these devices cannot be repaired. As practice shows, even specialists usually do not undertake to repair the device, but simply replace it with a new one. But in any case, before you say goodbye to the ECU, you need to carefully understand the reasons why it failed.

Russian-made electronic engine control system controller

According to many electricians with whom we consulted when writing this material, the main reason for unit failure is voltage surges in the on-board network . Overvoltage usually occurs as a result of a short circuit in one or more solenoids.

But this is only one of the most common reasons; in fact, there are many more:

- Failure of the device can occur as a result of its mechanical damage. For example, it could be a strong impact or large vibrations, due to which a crack appeared at the module removal. Also, cracks and damage can form in places where elements or contacts are soldered.

- The ECM has overheated, a problem that usually occurs as a result of temperature changes. In practice, there are cases when, at low subzero temperatures, drivers started the engines at high speeds, trying to ensure accurate starting of the power unit. At this moment, overheating could occur.

- Exposure of the ECM to corrosion. The formation of corrosion on the module structure can be caused by changes in air humidity in the cabin, as well as the accumulation of condensation or moisture entering the engine compartment of the vehicle.

- Violation of the sealing of the device. Such a problem will lead to the cause of the malfunction described above - in particular, water entering the module structure.

- If there is no connection with the ECU, then such a malfunction could be caused by interference of outsiders in the control system, which could contribute to a violation of the integrity of the structure. For example, if they tried to “smoke” another car from the battery of a car, while the engine of the first one was running, the terminals of the battery could also be disconnected while the engine was running. In addition, the problem could arise as a result of the fact that when connecting the battery, its polarity was reversed, that is, the terminals were connected incorrectly. In some cases, a malfunction may appear after turning on the starter unit to which the power bus was not connected.

Electronic unit board removed

In any case, for whatever reason the device fails, repairs or replacement must be carried out after a complete diagnosis of the module has been performed. It must also be remembered that the nature of the breakdown may indicate possible malfunctions present in the operation of other systems. If these faults are not corrected, this will lead to the fact that the new device will also fail.

If there is no connection with the ECU and the device refuses for some reason, the car owner can notice this by the following symptoms:

- The Check Engine icon, which appears when a malfunction in the engine is detected, does not light up on the dashboard. Or the icon may blink or may not appear immediately. If the indicator blinks, you need to make sure that the problem is not in the light bulb itself, and then check the unit itself.

- When you tried to connect the ECU with your own hands to the diagnostic connector, the scanner began to produce incorrect data that raises your doubts. That is, the information may be radically different from what it should be. If there is no connection with the computer, the scanner may not recognize this device at all.

- The power unit of the car malfunctions, troits, it may not start or starts every once in a while, and it may even smoke. However, there are no reasons for this behavior, including overheating.

- The car's ignition began to misfire.

- The engine cooling fan can turn on randomly, without a command from the control unit.

- Safety elements in the car begin to fail, and they burn out repeatedly, but there are no apparent reasons for this. If fuses blow, this is usually due to overvoltage in the on-board network or in a certain section of the electrical circuit, but diagnostics do not detect voltage surges.

- Pulses are not received from various sensors or are received but irregularly.

- In addition, another symptom may be incorrect operation of the gas pedal. When the driver presses the pedal, it may respond slowly or very slowly. This sign is the most accurate, especially if the pedal previously worked in normal mode.

- Traces of damage may also be visible on the device body. For example, these could be burnt contacts or traces of burning on the wires.

- Another sign is the absence of control signals for the ignition system or fuel pump, idle air control and other devices whose operation is controlled by the ECU (the author of the video about self-diagnosis is Vladimir Chumakov).

Composition of the electronic control system

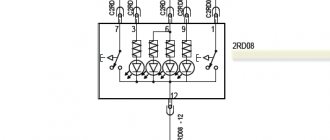

The electronic automatic transmission control unit consists of the following components:

- Memory in which the logic of the gearbox operation is stored.

- A huge number of sensors whose task is to transmit information about the state of the automatic transmission to the processor.

- The ECU also contains many mechanisms that perform the programmed work.

The heart of the ECU is the processor, which is responsible for the operation of both the unit itself and the gearbox.

Internals of the control unit

Control unit design

The automatic transmission ECU consists of the following elements:

- memory, which, like on a computer hard drive, stores all the information collected during the operation of the machine. Automatic transmission errors are also stored here. Experienced mechanics can make changes to it or clean it completely;

- RAM. It responds by quickly processing all data that comes from sensors and sending responses to them given by the processor;

- processor or main chip on which the entire operation of the electronic module depends. Executes or issues specific commands. A car owner can often find that the processor and RAM of the control units are connected into one chip;

- sensors that are located in the valve body and any other place in the automatic transmission to collect information and transmit it to the electronic gearbox module.

Control units from different manufacturers differ in the amount of filling and other parameters. The automatic transmission ECU is the most important and most fragile part in the car. Any shock or overheating, or short circuit of the electrical circuit can lead to its failure and the fall of the entire car or automatic transmission into emergency mode.

Have you already repaired the control module yourself?

Causes of failure of the automatic transmission electronic control unit

As practice shows, the automatic transmission electronic control unit can fail due to a wide variety of external and internal influences:

- Mechanical damage.

- Penetration of moisture into the block.

- Factory defects in both the unit itself and its components. This reason is the most common among all failures of the electronic control unit.

As a rule, the third, most common reason manifests itself after the car’s warranty period has come to an end. And if we take into account the fact that used foreign cars are popular in our country, every ninth owner of a car with an automatic transmission faces this problem. Due to the complexity of the ECU, it is impossible to carry out repairs on your own without certain skills. Therefore, you have to contact a car repair shop that specializes in repairing electronic vehicle control systems.

Burnt out automatic transmission control unit

Tips and tricks

Before attempting to repair an automatic transmission ECU, it is advisable to first pay attention to the cost of both new and used control units.

In some cases, it is easier, more reliable and faster to replace the unit in order to qualitatively solve existing problems in the operation of the automatic transmission.

It is strongly recommended not to carry out such repairs at a low cost in a makeshift environment, entrusting work with the ECU to craftsmen who repair and service automatic transmissions in a garage. In this case, there is a high probability that the restoration will be performed poorly and without any guarantees. In this case, the unit itself may fail completely.

Problems that may arise when repairing the electronic transmission control unit

When repairing an automatic transmission ECU, certain difficulties may arise:

- The first and, unfortunately, the most common problem is the unavailability of the necessary parts and microcircuits for the ECU. This may happen if you have a car equipped with an automatic transmission, which is not popular in our country. In this case, spare parts will have to be ordered from the country of the car manufacturer. Not only will you have to wait a very long time for them to arrive, but the cost for them will be many times higher than for similar spare parts for popular models. In addition, if the car brand is outdated, it will be almost impossible to find spare parts via the Internet.

- The second important problem is that it is not possible to repair the transmission ECU in every city due to the lack of experienced technicians. It often happens that a car service center has all the necessary equipment, but the master can at most remove errors from the ECU memory.

- It often happens that the problem with the operation of the ECU is micro-breaks in the wires. Because of this, information does not constantly enter the processor. As a result, errors occur that interfere with the correct operation of the automatic transmission. As a rule, when conducting diagnostics, the technician sees the error itself, which he deletes, but does not notice the very essence of the problem. Having eliminated the error, he considers that the work was done efficiently. But after some time the problem arises again. Finding a microtear (fault) is very problematic. This takes a huge amount of effort and time. And in the case of a car owner - also money.

If you have a problem with the electronic transmission control unit, to solve it you need to contact large specialized car services that provide a guarantee for all the work they carry out. If the service does not issue a guarantee for repairs, you may encounter the problem that comes third in the list above.

Types of automatic transmission electronic control units

There are two main types of electronic control units:

- Separately responsible for the operation of the automatic transmission. In this case, the device is assigned to control only the gearbox. The advantage is the lower price compared to combined blocks. It can be placed externally, for example, in the car interior or engine compartment, or be built inside the automatic transmission housing;

- Combined with engine ECU. Designed to reduce vehicle components and take into account the interaction of the engine and gearbox. All information is processed by a common processor, simultaneously issuing commands to the engine and gearbox. The result is more optimized operation of the power plant, since more external factors are taken into account when generating control signals.

When manufacturing an ECU together, it is almost impossible to use the placement of the device inside the gearbox, so the number of cables going to the control unit increases. This, in turn, does not have the best effect on the reliability of the system. The wires in the cable have a thin cross-section, which causes frequent damage.

External placement

In this case, the block is manufactured in a closed housing. It can be either a separate element or combined with the engine ECU. There are different locations of the module, for example, in the dashboard or engine compartment. An example of the brains of an automatic transmission is shown in the figure below.

External location in a closed housing

There are a large number of sensors inside the transmission. When the control module is moved outside the box body, it becomes necessary to lay a large number of wires. At the same time, it is important that the automatic transmission housing remains sealed and transmission fluid does not leak out.

The advantage of this solution is the ability to place the ECU anywhere. This protects electronics from exposure to high temperatures and aggressive environments. Finding a breakdown and making repairs is also easier when placed externally.

Operating principle of the control unit

The development of electronic brains has made it possible to make automation even more comfortable for the car owner. Their design contains memory blocks that have records of the necessary actions for a certain motor operation and speed. Another important task of the control unit is storing data about errors that have occurred, as well as diagnosing and monitoring the operation of the box.

Having such a system in the car can significantly simplify the search for errors and repair of automatic transmissions; quick identification of problems allows the technician to get to work faster and do it more accurately. Modern systems have floating algorithms, that is, they make the actions of the box smoother, clearer and more harmonious, so that it can adapt to changes in load and other conditions.

It is worth noting that, if necessary, you can change the logic of the brains; to do this, connect specialized equipment (programmer) to them and change the existing settings. In the very first models, this possibility was absent - the brains were equipped with a permanent storage device, and it was impossible to change anything in its operation.

The operation of the control unit is that the automatic transmission sensor supplies information to the microprocessor, which processes it. After this, a control pulse is generated, which is already executed by slave devices.

Location of the electronic control unit

Depending on the car model and gearbox, the brains may be located:

- Inside - in this case, the number of connecting wires going from the ECU to different sensors will be much smaller. The main disadvantage is that the part is affected by any temperature difference, and this can lead to malfunctions of the microcircuits. If repairs are necessary, you will have to twist many fasteners, which only complicates the process.

- Outside - if the brain of the automatic transmission is located outside of it, then many necessary wires come from it, which transmit a signal to the transmission. Despite this, the ability to choose an arbitrary location for its installation protects against temperature influences and humidity. Thus, you can significantly extend the operation of the unit and avoid repairs for a long time.

If problems arise with a block of any type, you need to act carefully, since if you try to debug it yourself, you can damage the system even more. Our company can fix problems in any region. We repair and diagnose used automatic transmissions and parts (valve blocks and ECUs), sending them after restoration to the desired city.

Causes of control unit failure

Most often, brain problems lead to complete inoperability of the entire transmission. The car may start, but the operating modes of the box will not change or function incorrectly. In this case, it is better to immediately seek help and not operate the box, as this can lead to serious consequences.

If it becomes obvious that the solenoid block does not perform the required commands, there is no need to forcefully try to force the control unit to work; it is better to leave the diagnostics to the technicians and go to service. Possible causes of brain damage or malfunction may include:

- consequences of strong mechanical shock or vibration;

- overheating after exposure to elevated temperatures;

- damage after exposure to water, moisture.

Since the design of electronic brains is complex and fragile, normal diagnostics can only be done with the help of special technical equipment. Most often, it turns out that a microcircuit or memory board has failed; after replacing them, the gearbox works as usual for a long time.

But there are often cases when it is more profitable to completely replace a faulty control unit. By contacting us, you can find an electronic system and other automatic transmission spare parts for any car model. Even if the required part is not in stock, you can quickly arrange its delivery to the desired region.

Reasons for failure of the automatic transmission ECU

In most cases, malfunctions of the automatic transmission control unit lead to complete immobilization of the car. In some cases, gear shifting occurs incorrectly, or the gearbox can only operate in emergency mode. The cause of breakdowns of the automatic transmission control unit can be:

- onboard voltage surges. especially in the direction of exceeding the nominal value;

- mechanical damage due to impact;

- parasitic vibration that appeared due to a malfunction of any vehicle system, for example, the brake system;

- excess operating temperature;

- factory defects in both software and module circuitry, which is especially important for domestic cars;

- influence of an aggressive external environment.

Damage to the electronic control unit board

The reason why control information is not processed may be burnout of any element on the board. Depending on the damaged element, a method for solving the problem is selected. For example, the capacitor can be replaced with a new one. Resoldering a processor is a labor-intensive process, so when it burns out, the board is replaced with a new one.

Internal layout

The internal location of the automatic transmission module provides a minimum number of wires. But at the same time, the risk of the ECU being overheated due to high temperatures of the gearbox increases. Although such control units are protected by the manufacturer from overheating by making them from high-quality, temperature-resistant metal, constant heating still negatively affects the electronic chip and microcircuits.

Subtleties of automatic transmission ECU repair

It is better not to repair the control unit in an automatic transmission yourself. Since it will be necessary to replace boards and microcircuits. If you have never disassembled microcircuits and soldered them, then it is better not to bother.

And chips and microcircuits for many cars, especially exclusive or top-end ones, for example, Land Cruiser 200, Volvo, Jaguar, are not readily available. At the same time, components for the ECUs of automatic transmissions and mass-produced vehicles can be found.

Another problem will be the pinout of the contacts. For example, one brand of car may have several modifications of the module. Each will have a different pinout. Therefore, it is difficult to choose here.

Repairing the control unit in an automatic transmission is considered expensive. It will cost about half the price of a used but working ECU. And independent diagnostics and repair of the module are not able to correct the situation and give an excellent result.

Types of blocks and their location

It is the use of such fully electronic control units that has significantly improved the usability of a car with an automatic transmission. The design of the automatic transmission electronic control unit consists of memory blocks in which the logic of action under certain engine operating conditions and vehicle speed is recorded. The control unit is also responsible for diagnosing, adjusting the operation of the box and storing errors. The presence of such an electronic control unit can significantly simplify the diagnosis of errors in the operation of an automatic transmission, which allows you to quickly eliminate gearbox breakdowns.

Electronic control unit closed

Like any other complex element, the gearbox control unit can fail and break. It should be noted that due to its structural complexity, repairing an automatic transmission ECU is very difficult. In some cases, it is necessary to completely replace it, which leads to significant costs for the car owner. Only a professional specialist can determine the exact breakdown and the cost of its elimination when performing transmission diagnostics.

The electronic transmission control unit can be located either directly inside the transmission or outside the gearbox housing. Each of these options for the location of control units has both its advantages and disadvantages.

Types of ECU

There are three most popular types of control units.

- Separate. Such an ECU can be located inside the car, and also in rare cases in the engine compartment.

- Combined. It is combined with the engine control unit. Just like a separate one, it can be located under the hood or inside the car.

The third type of automatic transmission ECU is a relatively recent invention. It is also combined, but not with the engine ECU, but with the transmission valve body. A striking example of such a design can be the new models of Mercedes, BMW and Nissan.

Bosch electronic control unit

Causes of block failures and ways to fix problems

Electronic control units can fail for various reasons. As a rule, failures of the control unit result in complete inoperability of the transmission. That is, the car starts, but the transmission operating modes do not change or change incorrectly. It should be remembered that operating an automatic transmission with a faulty control unit is simply unsafe. Therefore, we recommend that when the first signs of a problem appear, you contact professional specialists, and if your transmission does not show signs of life, do not try to forcefully start the car, but transport it to a service center using a tow truck. The cause of a malfunction of the electronic control unit may be:

• Sudden change in voltage;

• Mechanical shock;

• Exposure to strong vibrations;

• Fever;

• Exposure to moisture;

All this can lead to failure of the control unit, which forces its expensive replacement or repair. Service centers will tell you how to check the automatic transmission control unit. Diagnosis of a breakdown is carried out using special equipment, which allows you to determine the nature of the breakdown, which in turn will allow you to eliminate it with the minimum possible financial costs. In most cases, repair of electronic transmission control units comes down to replacing failed boards and microcircuits. It must be said that this work is very difficult, since you have to unsolder microcircuits from printed circuit boards and replace burnt capacitors. In some cases, it is much easier to completely replace the control unit, which will completely solve existing problems in the operation of the gearbox.

Diagnostics and repair

In modern realities, car computer repair is the norm. Even 20 years ago, having heard such a request from a car owner, a car repairman would have taken him for a madman. Now in every major settlement there are specialized car services that carry out diagnostics and repairs of the automatic transmission electronic control unit and any other computer.

Determining the cause of a breakdown is a rather labor-intensive process.

The first step is to diagnose in detail the wiring that connects the ECU to the gearbox. Next, a detailed check of various electronic sensors located in the automatic transmission and engine is required.

A striking example of a control unit malfunction can be errors in solenoids. This type of error either cannot be completely removed from the memory of the electronic control unit, while the automatic transmission operates in pre-emergency mode (or does not work at all), or they occur periodically (as a rule, this happens after the automatic transmission heats up). The reasons for this situation may be a short circuit in the wiring of the automatic transmission, as well as a short circuit between the solenoid plugs.

Electronic control unit for automatic transmission

As a result of all of the above, overloads of the system that protects the output stages may occur, and the automatic transmission does not operate stably. The consequences of unstable operation are as follows:

- Jerks.

- Tremors.

- Hard loading, which can lead to complete failure of the automatic gearbox.

If similar symptoms begin to appear in the operation of your car, this means that the automatic transmission ECU requires immediate repair. Without the appropriate knowledge and experience in the relevant field, you should not attempt to carry out repairs yourself. This could end badly. It is best to seek qualified advice, diagnostics and, possibly, repairs at a specialized car service center. In most cases, the ECU can be repaired. And only some require its complete replacement.

Such diagnostics and repairs, as a rule, do not take much time. If you really turn to a professional in this field, the control unit will be repaired taking into account all the features, this will maximize the life of the automatic transmission.

Automatic transmission ECU diagnostics

Automatic transmission ECU malfunctions and repairs

Note that the control unit is responsible not only for regulating the operation of the box, but also for diagnosing the automatic transmission. The controller also records in memory errors that may occur during operation of the unit.

This means that the ECU can greatly simplify the diagnosis of an automatic transmission, quickly determine the cause of failures and breakdowns of the gearbox, etc. However, it also happens that the control unit itself fails.

In practice, problems with the automatic transmission ECU do not arise so often, but one cannot completely exclude the possibility of failures and malfunctions in the operation of the automatic transmission precisely because of a faulty controller. As a rule, the box itself can be fully functional in terms of mechanics and hydraulics, but ECU problems cause incorrect operation of the unit, errors, etc.

Typically, failure or malfunction of the ECU is caused by:

- mechanical damage to the block;

- controller overheating;

- short circuit;

- problems with wiring, contacts and connectors (due to moisture, oxidation, breaks, etc.);

- attempts to flash/repair/adapt the ECU in makeshift conditions;

In any case, the automatic transmission begins to work incorrectly, since it is errors in the algorithms that lead to various failures. Certain modes or gears may not turn on, the automatic transmission kicks, jerks, hits or dips, the automatic transmission slips, does not change gears, etc. Often the automatic transmission can also go into emergency mode; an automatic transmission fault signal lights up on the dashboard.

Taking into account the fact that the list of possible automatic transmission problems is very wide, and the control unit itself interacts with a large number of sensors and actuators, diagnosing a malfunction can be very complicated.

For this reason, in difficult cases when standard diagnostic procedures do not allow identifying the malfunction, it is recommended to temporarily install a known-good and completely similar automatic transmission control unit on the vehicle.

Even taking into account the fact that the electronic transmission control unit can be located not only outside, but also inside the transmission (it is necessary to partially disassemble the automatic transmission), this approach often avoids carrying out a whole range of additional work to check individual sensors, actuators, etc. .

In fact, there are cases when a car service center does not know how to check the automatic transmission ECU and where it can be done. In this case, in order to determine the malfunction, the automatic transmission itself is often hastily removed and disassembled, the unit is troubleshooted, the gas turbine engine, mechatronics, valve body, etc. are checked.

However, after all the work has been carried out, it turns out that the problem element is the ECU box. For this reason, you must first accurately identify the faulty element.

- As for repairing the automatic transmission ECU, you need to understand that many units can be reflashed. However, if more serious problems arise (with chips, processor or memory modules), as a rule, control units are not initially repairable.

Taking into account the high cost of controllers, in some cases some specialized workshops still undertake repairs, but it is not always possible to achieve guaranteed quality.

Diagnostics of the control unit is carried out using special equipment to determine the nature of the malfunction. You can then determine the approximate cost of restoration. Often, repairing electronic transmission control units involves replacing boards and microcircuits.

This kind of work is difficult, since you need to unsolder microcircuits from printed circuit boards, replace burnt-out capacitors, etc. In other words, certain doubts arise about the subsequent reliability of the unit after repair.

At the same time, the cost of restoring the functionality of the ECU with an automatic transmission can be quite high (usually about 50-60% of the cost of a fully functional used device).

Automatic transmission ECU: how the controller works and works

Let's start with the fact that the automatic transmission ECU is a complex electronic device, which is actually a set of electronic microcircuits and chips, and also has a processor.

The automatic transmission electronic control unit analyzes numerous and constantly changing parameters in real time. The control unit receives signals from sensors, after which the signals are processed and control pulses are generated, which are then sent to the actuators.

It is important to understand that the automatic transmission unit of the latest generations operates according to so-called “floating” algorithms, that is, the logic of its operation is more complex compared to the engine ECU. This complication is necessary to ensure that the automatic transmission functions smoothly, smoothly and accurately, taking into account constantly changing conditions and loads.

- If we talk about the device, the block has a memory module where special programs (software) are registered. Also, in the automatic transmission ECU, there should be a microprocessor that processes the information received from the sensors.

We also note that the memory of the automatic transmission electronic control unit at the initial stage was a ROM (read-only memory). In such blocks it was not possible to make any changes to the firmware. For this reason, later developers began to use storage devices with the ability to reprogram them.

To change the algorithms (logic) of the automatic transmission, it is enough to connect special equipment (programmer), which allows for a more flexible adaptation of the automatic transmission.

Numerous sensors automatically send signals to the ECU, which allow the unit to receive accurate information about the state of various mechanisms. Based on the received data, an action is selected according to the program recorded in the block’s memory. The operation of the automatic transmission is controlled primarily using solenoids, which are actuators.

Also, the automatic transmission unit works in close connection with the engine ECU; these units actively exchange information. In some cases, the engine ECU and automatic transmission can even be combined, but this applies more to older models with a simple hydromechanical automatic transmission.

Cars of recent years are equipped with complex and technologically advanced automatic transmissions (for example, DSG), which have a large number of additional modes (sports, economical, winter, manual gear shift function Tiptronic, etc.), and are also adaptive gearboxes.

It is not difficult to guess that the operating algorithms of modern automatic transmissions have become too complex. This required the integration of a completely separate electronic control unit for the automatic transmission.