What is a naturally aspirated engine

Not all car owners understand what a naturally aspirated car engine means. These are gasoline engines of a classic design that pump air from the surrounding space using carburetor pistons. When oxygen is uniformly mixed with atomized gasoline particles, fuel mixtures are formed. They are used for combustion in the combustion chamber of a gasoline engine.

Operating principle of an atmospheric engine:

- Suction of air from the atmosphere.

- Mixing with gasoline vapors in the following proportions: gasoline - 1 part, oxygen - 14.

- Supplying the mixture to the combustion chamber.

- Volume expansion.

- Pressure on the piston.

- Transmission of rotation to the crankshaft.

The effect of suction of air masses occurs due to the creation of a rarefied atmosphere in the cavity of the intake manifold.

Principle of operation

The basic principle of any internal combustion engine is to ignite fuel in special chambers, due to which the pistons are driven, and then subsequent components of the car. The flammable liquid is often gasoline of various brands or diesel, but fuel also means a mixture of gasoline or diesel with air. This is the main condition for ignition in the engine, since without a sufficient amount of oxygen this process is impossible. The most optimal ratio for successful combustion is considered to be a mixture of 1:14 (flammable liquid: air). To solve this problem, any internal combustion engine has a special unit responsible for the mixture of fuel and air. In most modern cars, automatic air compressors or turbines (injector, carburetor) take on this task. That is why they are often called turbocharged. But in “aspirated” everything goes by gravity. Thanks to natural atmospheric pressure, air tries to fill any free space, on the basis of which the principle of an atmospheric engine is built. However, this is often not enough to achieve an air-fuel mixture, so a mechanical air supply system is created in “aspirated” engines. The engine pistons act as an air pump that draws the required amount of air into the combustion chamber. To do this, naturally aspirated engines are equipped with a special air duct that ensures an uninterrupted supply of oxygen from outside. Did you know? The first drawings of the car belong to the famous Italian artist and scientist Leonardo da Vinci. Thus, the main difference between a turbocharged engine and a naturally aspirated one is the automatic air blower, which is not present in “aspirated” engines. In addition, we should not forget that in turbocharged engines the air-fuel mixture is formed forcibly (due to the formation of increased pressure from 1.5 to 3 atmospheres).

Types of combustion chambers of diesel engines

The vast majority of naturally aspirated diesel engines differ only in the design of the combustion chamber. Classic diesel engines use an undivided combustion chamber - fuel is supplied to the space above the piston. Until recently, this type of combustion chamber was used mainly on low-speed, large-volume engines for trucks, since these diesel engines are characterized by high levels of noise and vibration. However, in our time, with the advent of electronically controlled high-pressure fuel pumps (HPF), two-stage fuel injection and stabilization of the combustion process of the fuel-air mixture, these problems on automobile diesel engines have practically been eliminated.

The most common in passenger cars today are diesel engines with a separate combustion chamber - swirl chamber and prechamber. In them, fuel is injected not directly into the cylinder, but into an additional chamber connected to it in the cylinder head. The vortex chamber is connected to the cylinder by one channel in such a way that when air enters it, it swirls intensively. This improves the process of mixture formation and self-ignition. In this case, the fuel-air mixture ignites in two stages - the process begins in the vortex chamber and goes into the combustion chamber. Thus, the pressure in the cylinder increases more smoothly, which results in reduced noise and increased maximum speed. Vortex chamber engines currently make up about 90% of power units of this type in passenger cars and SUVs. More complex, and therefore less common, are prechamber diesel engines. The combustion of the fuel-air mixture occurs in a special insert pre-chamber connected to the cylinder by several channels of small cross-section. Their shape and diameter are selected so that a pressure difference occurs between the cylinder and the prechamber, increasing the gas flow rate. This technology allows for a long service life, additional reduction in noise and toxicity levels, as well as the smoothest torque dynamics.

Pros and cons of naturally aspirated engines

With the advent of power units equipped with a turbocharger, many drivers began to prefer turbocharged vehicles. However, there are many motorists who, when asked which engine is better, naturally aspirated or turbocharged, choose the usual classic option, based on the following advantages:

“Atmospheric” is distinguished by the following advantages:

- good resource;

- reliability in operation;

- durability;

- ease of use;

- relative ease of carrying out preventive and repair work;

- unpretentiousness regarding fuel quality.

The reliability of the naturally aspirated engine is eloquently demonstrated by the numbers. High-quality engines allow the car to travel up to 500 thousand kilometers. In the history of the development of the automotive industry, there are cases when the engine was moved from an outdated car to a new one, and it continued to work properly for many more years.

Atmospheric internal combustion engines have the longest mileage. There are known cases when cars with installed aspirated engines operate without major repairs along the way, more than 500 thousand kilometers. The only condition is timely care and regular replacement of engine oil and filters. Their parts and components are wear-resistant. The reliable naturally aspirated engine has an increased service life and continues to work even after repeated replacements of the car body.

Thanks to the trouble-free operation of the naturally aspirated engine and the ease of its operation, it is unpretentious to the quality of fuel and lubricants. With regular use of gasoline of reduced quality, such engines, even if they fail, quickly restore their performance. The main requirement for motor oil is to ensure the required level. The lubricant should be replaced every 15 - 20,000 km. When choosing the most suitable brand of motor oil for a naturally aspirated engine, it is recommended to give preference to synthetic or semi-synthetic.

Interesting: Unlike a turbocharged engine, you can also use mineral oils here if you were unable to purchase better lubricants.

The design of the “aspirated” engine is such that not only a professional, but also a competent car enthusiast can handle its repair or maintenance

. The unit can be disassembled down to the last detail and put back together - the design allows you to do this without much expense. There are often cases when, when repairing a unit, “non-original” parts and components produced by other manufacturers are used. Accordingly, the cost of repairing such an engine is cheaper.

Atmospheric internal combustion engines have some disadvantages:

- Relatively heavy weight of the mechanism.

- Reduced power and developed torque compared to a motor equipped with a turbine.

- Aspirated engines are not designed to operate under heavy loads.

- Difficulties in operating at high altitudes in thin air conditions.

- When a naturally aspirated engine operates at low speeds, a sufficient amount of air is not always sucked in, which affects the stability of operation.

However, this is where the list of “cons” ends. Atmospheric internal combustion engines are reliable, simple and durable, but they are not designed for heavy loads and high speeds.

Advantages and disadvantages of naturally aspirated engines

Most users, when buying a car, do not know which unit to give preference to, whether to choose an atmospheric or turbocharged engine to drive the car. In such cases, the pros and cons are weighed, and they also determine what tasks will be performed by the purchased equipment. Looking ahead, we note that today the “palm of championship” belongs to the naturally aspirated gasoline engine.

Mechanical supercharger:

Advantages of naturally aspirated engines

- The positive aspects that have made naturally aspirated engines popular are the following:

- Operation and design are simpler;

- Increased service life;

- Reliability and reliability of units;

- Repairing does not require “special” skills or tools.

Since devices that increase air pressure are excluded from the operating circuit of the unit, the design of the device is simpler in comparison with turbocharged units. This feature eliminates expensive repairs, since fewer parts and spare parts are used; turbines, compressors and related parts and mechanisms are excluded. The unit is not sensitive to fuel and does not require high quality lubrication.

When operating atmospheric engines, processes take place inside the chambers that load parts and mechanisms less than those of their counterparts with a turbine. This feature affects the resource, increasing the indicator. The service life of “atmospheric” engines under normal conditions is 300,000-500,000 kilometers before major repairs. Turbocharged units run 200,000-250,000 kilometers.

Examples of vehicles with powerful naturally aspirated engines

The modern car market features naturally aspirated cars produced under well-known brands:

- Mercedes C 63 FMG Coupe Edition 507.

- Chevrolet Corvette C 7 Stingray.

- Jeep Grand Cherokee SRT.

- Audi RS 5.

- Audi RS 4 Avant.

- Chevrolet Camaro.

- Mercedes SLK 55 AMG.

- Porsche Cayenne GTS.

- Infiniti QX 70.

- Lexus LS 460.

- Mercedes-Benz OM 602.

- OM 612.

- OM 647.

- BMW engines of the M2x, M5x, M6x, N5x series.

The naturally aspirated engine operates predictably, which is a definite advantage for many motorists. You should decide for yourself which option is more suitable based on your own preferences. If reliability, ease of operation and maintenance are a priority, it is better to look at an atmospheric engine, but if dynamics indicators come first, then the choice is obvious. By the way, thanks to the efforts of craftsmen who practice tuning, turbines are also installed on atmospheric engines. This is not easy to do and requires special skills, but in practice it is quite applicable. Since the device is not stuck to the motor at random, calculations of the speed and volume of incoming air are required. It is better not to carry out such work on your own, because only virtuosos of their craft can successfully cope with the task.

Sources: drivertip.ru, auto.rambler.ru, fastmb.ru, motoran.ru.

Aspirated or turbocharged engine - the main differences

Example of an atmospheric BMW engine

To put it roughly, the presence of a turbine (compressor, supercharger) is the only thing that distinguishes an atmospheric engine from a turbocharged one. But today manufacturers are investing specifically in turbine units, so their number on the market is constantly growing, and technologies are actively changing.

The fundamental difference between these engines is that in an atmospheric unit, air is supplied under natural pressure through the intake valve. In a turbo engine, air is forced by a compressor under high pressure.

Example of a turbocharged engine

This gives rise to the following differences between an atmospheric engine and a turbocharged one:

- at the lower speed range, most engines operate in approximately the same mode;

- at higher speeds the turbine turns on, the power plant receives a significant increase in power;

- in the operating speed range, a turbo engine consumes less fuel as it operates more efficiently;

- acceleration of a modern unit with a supercharger is much more dynamic, and the maximum speed is often higher;

- The elasticity of operation of the motor with the compressor is better, since the turbine functions are controlled by a smart computer.

If previously a turbocharger could operate in two modes (to blow or not to blow), today the technology has become much smarter. The injection of air pressure is not felt in the form of sharp jolts or jerks, the engine simply gains excellent enthusiasm and dynamics.

This is the difference between a naturally aspirated and a turbocharged engine - the turbo unit better adapts to the driver’s wishes and can work more efficiently.

The main design features of a turbo engine

The turbine most often has a “snail” shape and is located in the front part of the unit. If you don't know how to distinguish a turbocharged engine from an atmospheric one, everything is simple here: look for the “snail” under the hood. Usually it is difficult not to notice it, since it stands out from the monolithic outlines of the unit itself.

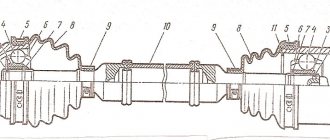

Turbocharger operation diagram

The standard design involves connecting the compressor to the exhaust system. The exhaust gases spin the device's impeller, which allows the compressor to pump higher air pressure into the system. This changes the characteristics of the fuel mixture and affects the operation of the ECU. This is how the engine changes its characteristics during the trip.

The problem is that the turbocharger is a very delicate part. Therefore, in any accident it breaks. Also, after 100-150 thousand km of operation, the turbine often needs to be replaced. Another trouble is the use of low-quality oils in the engine. In this case, the turbine is poorly lubricated and fails very quickly.