AvtoVAZ engineers developed the 21213 engine in 1994 for installation on the updated Niva. Despite its obsolescence, the motor is still produced. Drivers are satisfied with cross-country ability, fuel consumption, the possibility of tuning and the cost of the unit. Let's see why the carburetor internal combustion engine is so common, and what shortcomings can be forgiven.

Technical characteristics of engine 21213

VAZ 21213 is a 1.7 liter petrol 4-cylinder 8-valve carburetor engine. The engine was created on the basis of 2121 and taking into account the developments of the VAZ 2107 unit. Engineers partially changed the original design to achieve better ergonomic characteristics of the Niva’s internal combustion engine:

- increasing power from 73 to 78.9 hp. and torque from 116 to 126 Nm;

- reducing fuel consumption to 12 liters per 100 km.

In addition to increasing the cylinder diameter to 82 mm, VAZ developed new pistons and a crankshaft for the 21213 engine. We replaced the outdated Ozone carburetor with the Solers, the most popular and successful model in the early 90s. Improved ignition and cooling systems.

To lubricate the 21213 engine, oil is selected depending on the climate:

- from -25℃ to +35℃ viscosity 10W-40 is recommended;

- from -2℃5 to +45℃ - 15W-30;

- from -30℃ to +20℃ - 5W-30, etc.

The manufacturer indicates the preferred brands of oils: Lukoil, ESSO, Rexol, Yar-Marka, Norsi, Shell, etc.

| Technical characteristics of the VAZ 21213 engine | Meaning |

| Number of cylinders/valves | 4/8 |

| Cylinder diameter/piston stroke, mm | 82/80 |

| Compression ratio | 9,3 |

| Cylinder volume, l | 1,69 |

| Crankshaft power, hp, at 5200 rpm | 78,9 |

| Torque , Nm, at 3000 rpm | 126 |

| Idle speed, rpm | 750 — 800 |

| Oil volume, l | 3,75 |

| Oil consumption , l/1000 km | 0,7 |

| Gasoline consumption, l/100 km, combined | 10,5 |

| Fuel type | AI-93 |

| Fuel tank volume, l | 42 |

| Dry weight , kg | 117 |

| Declared engine resource , thousand km | 80 |

Despite the factory-specified service life of engine 21213 being 80 thousand km, in practice the engine lasts 150 thousand km before overhaul, provided that high-quality fuels and lubricants are used and moderate operation.

Based on the 21213 engine, the 21214 unit with an injector was developed. The technical characteristics of the motors are identical. The designs differ in the power supply system, timing drive and the presence of hydraulic compensators. According to environmental requirements, the injection version meets the Euro-3 standard.

Similar article The principle of operation of a hybrid car engine

Tuning

There are several ways to increase the power of a Niva engine. We will tell you in more detail about these methods of tuning the VAZ 21213.

- Deep engineering tuning of the Niva engine with crankshaft replacement and cylinder boring. This kind of work allows you to increase the working volume of this engine to 1.95-2.1 liters. Accordingly, when adjusting the injector, the VAZ 21213 engine receives power of about 100 horsepower.

- Chip tuning of the Niva engine allows you to get about 10 additional horsepower at minimal cost. In this case, the work does not pose any difficulty. You just need to select the appropriate chip tuning and reprogram the engine control unit. The advantage of this option is the complete preservation of engine life.

- Installation of turbines and compressors on VAZ 21213 engines. In this case, we can recommend that you use compact turbines with a pressure of no more than 0.5 bar. At the same time, the injector is reconfigured and the oil and fuel pumps are replaced. It is necessary to understand that such work should only be performed by a specialist who knows the features of the VAZ 21213 engine.

Also interesting: Creaking pads: How to fix whistling when braking

Note that installing a turbine and boring the Niva engine invariably negatively affects its service life. Therefore, the car owner needs to weigh the pros and cons, and only after that perform tuning of the Niva engine.

Description of the motor device 21213

The basis of the VAZ 21213 engine includes:

- cast iron cylinder block (BC) 21213-1002011;

- block head 21213-100301*;

- crankshaft 21213-1005015;

- connecting rod and piston group 21213-10040*.

The main difference between the 21213 engine and its predecessors was the increased cylinder diameter - 82 mm versus 76 and 79 mm. The center-to-center distance of 95 mm remains the same, and allows the block to be bored to a diameter of 82.8 mm. The design of the water jacket has changed. The working volume has increased by 100 cm3, but the engine dimensions have remained the same.

To install the crankshaft in the BC there are 5 supports: one each on the front and rear walls, 3 more on the ebb. The crankshaft parameters provide a piston stroke of 80 mm. The crankshaft is cast from cast iron and consists of 4 connecting rods and 5 main journals. The connecting rod journals have oil channels. The necks are separated by cheeks with counterweights. In previous VAZ engines, balancing counterweights were found only in the outer and central cheeks. The axial movement of the shaft is limited by thrust half-rings.

The piston group for the 21213 engine was developed anew. Pistons 21213-1004015 are cast from aluminum and reduced to a single mass of 347 g. The piston class (A, B, C, D, E) is determined by the outer diameter in increments of 0.01 mm. The shape of the piston is conical in height and oval in cross section. The hole for the pin is 22 mm, offset by 1.2 mm from the piston axis. The finger is locked with rings. There are 3 rings installed on the piston skirt:

- upper compression barrel;

- medium oil scraper with expansion coil spring;

- lower compression scraper type.

The connecting rod 21213-1004045 is forged from steel and processed together with the cover. A steel-bronze bushing is pressed into the upper head of the connecting rod. To fasten the connecting rod, M9x1.0x56 bolts are used.

The aluminum BC head is designed for the VAZ 21213 engine and is designed for compression from 10 bar. Installing a head from other motors may cause it to break. Cast iron seats and guide bushings for 4 intake and 4 exhaust valves are pressed into the head. The valves operate from the camshaft cams. The gap between the valve stem and the cam is adjusted with a bolt.

Similar article Technical characteristics of the Toyota 2AR FE engine

timing belt

The camshaft 21213-1006010 is made of cast iron and rests on 5 journals. The jaws are bleached to increase wear resistance. Axial movement of the shaft is limited by a thrust flange.

The timing belt is driven by a double-row bush-roller chain. In addition to the camshaft, the chain drives the oil pump. The drive is regulated by a semi-automatic tensioner with a shoe and damper. To prevent the chain from falling off when removing the camshaft sprocket, a limiter is provided next to the crankshaft drive sprocket.

Systems

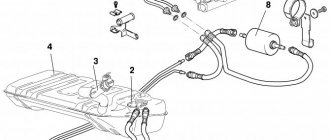

The power supply system in the Niva 21213 engine is a 21073 Solers carburetor. The carburetor unit is two-chamber, the throttle valves operate sequentially. When the first chamber is 2/3 open, the throttle of the second chamber is engaged. At idle, the economizer turns on. The carburetor device includes:

- float chamber;

- 2 dosing systems;

- crankcase gas suction system;

- heating the throttle zone of the first chamber;

- blocking the second camera;

- economizer;

- econostat;

- diaphragm accelerator pump.

The ignition system in the 21213 engine is non-contact. The system is controlled by a switch using distributor signals. In general, the system is classic, without any special features.

Cooling of the motor occurs according to a typical scheme: liquid circulates through the water jacket in the BC and the block head. The pressure is created by a centrifugal pump connected by a belt drive to the crankshaft and generator. The radiator fan impeller works on suction, so in winter the radiator has to be covered with cardboard.

Peculiarities

To ensure long-term and trouble-free operation of the power unit, it must be very carefully and properly maintained. It is also recommended not to allow the engine to operate in extreme modes.

And also interesting: Chevrolet Niva (2123) 1.7 5 doors. SUV, 80 hp, 5 manual transmission, 2002 – 2009. - high engine oil consumption

First, let's look at the VAZ-2123 engine, it is a modified version of the power unit installed on the “classic Niva”. The main differences are as follows.

- There are additional fasteners for installing additional equipment.

- The oil filter is not screwed directly into the block, which was typical for all VAZ engines, but has an intermediate insert. This insert is called the oil pump bracket. The power steering pump is also attached to it.

- The cylinder head has been slightly modified. It is designed for the use of INA hydraulic supports.

- A new pump was used, it is marked 2123. The main difference is the use of a roller bearing instead of a ball bearing.

- The pan has been modified; the front axle gearbox is no longer attached to it.

- The fuel rail used is 2123-1144010-11.

The Z18XE engine was widely used in various car models. There are several modifications of the power unit. Installed on the Chevrolet Niva, it had the following features.

- Electronic throttle. This made it possible to more effectively manage the fuel supply.

- Two lambda probes were built into the new intake manifold.

The result was an original motor with interesting settings. Thanks to the settings, it is possible to achieve some variation in power and throttle response.

The VAZ 21213 four-cylinder eight-valve petrol engine has a displacement of 1.7 liters. The power of the power unit is 81 horsepower with a torque of 125 Nm.

Engines 21213 in their latest generation were equipped with an injector and ran on high-octane 93 gasoline. The cast iron cylinder block ensured maximum strength for this power unit.

The use of numerous automatic engine control systems made it possible not only to change the traction performance of this engine, but also significantly improved fuel efficiency. Niva in suburban mode consumes 8.3 liters of gasoline per 100 kilometers when driving at cruising speed.

Starting from 2014, Niva cars with a diesel engine are also offered to customers.

The Niva engine with an overhead camshaft is equipped with a chain drive, which significantly simplifies the service of this power unit. The chain drive does not require replacement of the tensioner or any adjustment during operation of the motor. We also note the presence of hydraulic compensators, which relieves the car owner of the need to carry out the procedure for adjusting the valve clearance. All maintenance work on this engine can be performed by the car owner himself, without contacting branded service stations.

Also interesting: Engine jerking at idle: causes of malfunction

What cars was the power unit installed on?

Tolyatti engineers designed the 21213 internal combustion engine to replace the 2121 for all-wheel drive off-road vehicles. The engine is found in AvtoVAZ SUVs and minivans:

- "Lada Niva" 21213 in the body of a 3-door station wagon;

- "Lada Niva" 2131 in an extended 5-door body;

- "Nadezhda" 2120 is a 4-door minivan.

Engine 21213 was installed on the export right-hand drive model Niva 21216.

VAZ 21214 engine modifications and their differences

| Motor modification | Availability of power steering | An exhaust manifold | EURO environmental class |

| 21214-41 | + | welded from stainless steel become | 3 |

| 21214-34 | _ | cast iron | |

| 21214-33 | + | ||

| 21214-32* | |||

| 21214-31 | welded from stainless steel become | 4 | |

| 21214-30 | — |

*21214-32 – has fuel pipes with quick connectors, a flywheel for the clutch of 215 mm (200 mm on other models).

The geometry of the cylinder block 21214 and 21213 is the same. There are no liners in the cylinders. Due to the use of an ejector, the configuration of the front engine cover has been changed to accommodate the installation of a crankshaft position sensor. To mount the power steering, a hole is made on the block for installing a bracket; in addition, there is a threaded hole for installing a knock sensor, as well as threaded holes with studs for mounting the ignition module bracket.

The most common engine failures

ICE 21213 has typical problems of VAZ engines:

- increased oil consumption due to carbon deposits on valves and cylinders;

- the appearance of vibrations at a speed of 90 km/h. The cause is a damaged head gasket or an unadjusted carburetor;

- when the timing chain is pulled, the valve bends;

- Excessive noise due to a broken timing chain tensioner or timing chain tensioner shoe, pump bearing creaking, or unadjusted thermal clearances;

- Overheating of the unit is caused by a faulty thermostat, a clogged radiator, or prolonged operation at high speeds. Due to the design features of the BC, the thickness of the coolant layer does not provide sufficient cooling, so it is necessary to operate the unit moderately. Increased engine temperature leads to cracking of the cylinder head.

Similar article Technical characteristics and reviews of the 2AZ FE engine

The disadvantages of the 21213 engine include repair features. If the wear of the cylinders exceeds 0.15 mm, then boring is permissible only for the repair dimensions of the pistons, increased by 0.4 and 0.8 mm from the nominal value. Exhausting the limit threatens to completely replace the pistons and cylinders.

Regrinding of the crankshaft journals is possible with a diameter reduction of 0.25; 0.5; 0.75 and 1 mm. The limitation is due to the repair dimensions of the liners. If the axial clearance of the crankshaft increases by more than 0.35 mm, the part must be replaced.

Gasoline engine on Chevrolet Niva

Not only imported engines are suitable for the Niva. Domestic production is also quite suitable. For example, a sixteen-valve power unit from VAZ can be easily installed without modification. It has lower fuel consumption than diesel engines and more power.

Car owners of such an engine are advised to change the camshafts for traction. There is no need to replace the gearbox. Engines from foreign cars require improvement. The next block will show which gasoline power units are suitable for swapping a Niva engine.

With modification

Niva is suitable for an engine from a BMW M42, M43 or Toyota, but gasoline. You will need to buy some parts for the swap, but changing the engine to one of these will give results that will surprise you. The car will become more maneuverable and will respond better to the accelerator pedal.

The fuel consumption of these power units is low. Therefore, you won’t have to spend money on them if you only follow the technical inspection rules and visit service centers on time.

Similar article Reasons if the engine stalls and the check engine light blinks

No modifications

Many engines that are suitable without modifications for the Chevrolet Niva do not differ from the power unit that left the factory with the vehicle. Therefore, experienced mechanics advise installing an additional turbine if you want to increase engine power. The choice of gasoline engines is much higher than that of diesel engines.

A budget engine that will successfully fit into a Chevrolet Niva is Toyota’s 3S. There is no need to make major changes when installing this power unit. You can install a transmission from this car and a transfer case. Then Niva will become more powerful.

Attention! When swapping a power unit, do not forget that the controllability of the car changes along with the engine. For example, if a more powerful motor is installed, then controllability deteriorates somewhat.

Price of new and contract engine 21213

Drivers of Niva with engine 21213 note the affordable price of spare parts and the car as a whole as one of their selection criteria. A new fully equipped engine with a factory warranty will cost 70,000 rubles. For comparison, the price of the injection 21214 is from 85,000 rubles.

A used engine costs 2 times less: 30 - 45,000 rubles. There are models for 10-15,000 rubles, but their condition, as a rule, requires repair.

Which modification is better

It is impossible to say unequivocally which engine is more reliable and better. A lot depends on how you use the car. For urban conditions, the Z18XE is better suited; it is more effective on asphalt. The VAZ-2123 has lower revs, which is very good off-road.

If we take reliability into account, both cars break down. But the Z18XE has much fewer minor faults that ruin the lives of car enthusiasts. At the same time, the VAZ-2123 is well known for minor problems with leaks, sensor failures and other shortcomings.

Tired of paying fines? There is an exit!

Forget about fines from cameras! An absolutely legal new product - Traffic Police Camera Jammer, hides your license plates from the cameras that are installed in all cities.

More details at the link.

- Absolutely legal (Article 12.2);

- Hides from photo and video recording;

- Suitable for all cars;

- Works through the cigarette lighter connector;

- Does not cause interference to radios and cell phones.

Read news about the new Niva

- Engine VAZ 2123 Niva Chevrolet

- The modernized Lada Niva Legend (4x4) 2021 was shown on the Internet

- Lada 4×4 Bronto - sales stopped, new details » Lada.Online - all the most interesting and useful about LADA cars

- Description of the instrument panel Lada 4×4 (VAZ 2121, 2131) » Lada.Online - all the most interesting and useful about LADA cars

- LADA Niva – Operating manual – Official LADA website

- Chevrolet Niva gasoline consumption per 100 km

- Buy LADA (VAZ) 2131 (4×4) 2021 in Rostov-on-Don, low price for Lada 2131 (4×4) 2021 on the Avto.ru website

- Fuses Niva 21214 injector «

Weaknesses of the VAZ 21214 engine

In addition to the weak points of the base 21213, the motor has the following weak points:

Cylinder block. This weak point appears on various models of Nivov engines, including the previously discussed 21213. Due to insufficient quality control, the assembly unit is manufactured with a high percentage of factory defects. In short, the drilling depth of the intake manifold stud holes is not maintained, causing the holes to meet the camshaft stud holes. In this way, L-shaped through channels are obtained. After installing the studs at the factory, the connections remain sealed for some time and the problem is not identified when the quality control department employees accept engine tests. After the sale of new cars with low mileage, during sharp braking, oil begins to seep through the studs onto the hot intake manifold, so much so that smoke from the oil burning in the manifold pours out from under the hood, and accordingly, there is nothing to breathe in the cabin. It would seem that there is a manufacturing defect and it should be fixed free of charge or the cars should be recalled altogether to eliminate the defect, but that was not the case. In service centers they pretended to know nothing until the very end...

The most interesting thing is that AvtoVAZ knows about this problem and, in response to questions in correspondence with car owners, advises eliminating it according to the following technical specifications:

A sketch for the technical specifications for eliminating oil leaks from under the exhaust manifold studs.