The throttle sensor can act up in different ways. For some, the revs fluctuate at idle, while for others, the car revs up even while driving. But often, suspicion about the serviceability of the TPS arises precisely at floating speeds. But this does not always happen... (Weak contact between the “foot” of the sensor and the track can lead to a lean mixture, which will certainly lead to a loss of traction and the engine shaking at idle. This sensor works in conjunction with the idle speed regulator and the ignition timing depends on it Thus, a faulty throttle sensor can have a very significant impact on engine performance, and diagnostics do not always show a faulty TPS.

Characteristics of the throttle position sensor

The purpose of the sensor is to regulate the volume of air flow that enters the motor. This air is used to form a flammable mixture.

Where is the sensor located in the car?

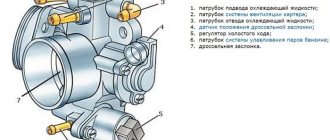

In order to diagnose the device if necessary, the car owner needs to know where the TPS is located. The controller is installed in the engine compartment. It can be seen on the side of the throttle line on the axis of the valve itself.

Controller location on the throttle

Device design

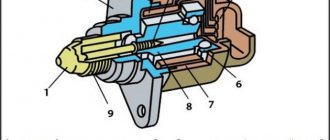

Structurally, the device includes the following:

- Controller housing. This component is made of heat-resistant fiberglass. The housing is equipped with two flanges, which are used to secure the controller to the throttle assembly.

- A connecting device equipped with three contacts. This component is integrated with the controller housing.

- A resistive device made of ceramic.

- Current collecting element. This component is designed to provide electrical contact with the resistive part.

- Collet clamp, equipped with a slot.

- Rubber gasket. Used to mount the controller on the axis of the throttle assembly.

Purpose of the throttle position sensor

The controller itself is responsible for correctly identifying the position of the valve on the throttle assembly. Its readings affect the operation of the fuel supply system. The power unit, in accordance with the device values, adjusts the volume of supplied gasoline under a certain operating mode. The TPS is used to convert the angular position of the throttle valve into DC voltage.

Features of the device:

- The data transmitted by the controller makes it possible to calculate the amount of damper opening. The information received by the control module ensures the calculation of the main control parameters of the power unit. Moreover, the data is determined taking into account the type of vehicle driving.

- The device itself is a potentiometer equipped with a current collector. The latter is used to move along a set sector radius, ranging from 0 to 80 degrees. When installing the device, the axis of this structural element must be connected to the drive of the throttle unit.

- The output resistance parameter of the potentiometer can change depending on the pressure on the gas pedal. Depending on its position, the degree of opening of the valve unit also changes.

- The controller is powered by supplying a stabilized voltage. The value comes from the control module and should be around 5 volts. A deviation of 0.1 V up or down is allowed.

Device technical parameters

Main technical properties of TPS controllers:

- The voltage to power the device is supplied to two pins - 1 and 2.

- The amount of resistance that forms between pins 1 and 2 ranges from 1.8 to 2 kOhm.

- The opening parameter for a fully closed node damper is from 0 to 2%.

- The voltage that is supplied to outputs numbered 3 and 2 when the damper is closed ranges from 0.25 to 0.65 volts.

- The valve opening value is more than 90 degrees.

- The voltage parameter supplied to pins 3 and 2 at full throttle ranges from 3.9 to 4.7 volts.

- The number of complete activation cycles of the device during its operation is at least one million.

- The calibration property of the dependence of the output voltage parameter on the rotation angle is linear. It is measured in the range from 0 to 100 degrees. The voltage ranges from 0.25 to 4.8 volts. The slope of the characteristic varies around 48 mV.

- The controller operating area parameter is in the linear range of the characteristic in the range from 10 to 90 degrees. This corresponds to the opening value of the unit damper at an angle from 0 to 100 degrees. The slope value varies around 39 mV.

Varieties

There are two main types of devices:

- Film-resistive sensors. This type of controller is usually installed standard during car production. The average service life of film-resistive devices is approximately 55 thousand km. But in fact, they fail more often.

- Contactless type of devices. Such TPS operate on the basis of a magnetic-resistive phenomenon, the Hall effect is used. The price of contactless sensors is higher, but their service life is long. These devices are more reliable and therefore rarely fail.

Andrey Seromolotov showed how a machine engine works with a contactless TPS.

Self-check functionality

In most cases, when problems arise with the TPS, the “check engine” error is displayed. By connecting a diagnostic device, you can identify its code and causes of the error. It happens that for some reason the “check” does not light up, in which case you cannot do without using a multimeter for diagnostics.

The first step is to make sure that power is supplied to the sensor itself. To do this, you need to disconnect the chip with wires from the device and measure the contacts with the ignition on. If power is supplied, then the device itself is inspected.

Visual inspection of the sensor. In this case, we are talking about checking the internal components of the product. Most often, the slider loses contact with the resistive layer.

As mentioned above, if the causes of malfunctions in the sensor are identified, it must be replaced.

Replacement and repair of the VAZ 2114 throttle position sensor

How to understand that the VAZ 2114 TPS is broken?

Signs of a malfunction may overlap with the breakdown of other sensors responsible for creating the fuel mixture:

- high idle speed;

- deterioration of the car's response: you can easily stall when starting off;

- reduction in power: a loaded car practically does not pull;

- when you gradually add gas, the engine jerks and the thrust “fails”;

- unstable idle speed;

- When changing gears, the engine may stall.

A broken VAZ 2114 (2115) sensor can produce three types of distorted information:

- complete lack of information;

- the damper is unlocked;

- the damper is blocked.

Depending on this, the symptoms of the malfunction may vary.

Symptoms of a problem

A disruption in the synchronization of the operation of the entire throttle system and the engine as a whole occurs even with the most minor disturbances in the operation of the throttle sensor of the VAZ 2110 car. Signs of a malfunction are sometimes difficult to determine because there are no symptoms that are 100% related to the breakdown of this part.

Malfunctions, the cause of which can presumably be attributed to the throttle sensor, are as follows:

- The engine stalls when changing speeds.

- A drop in power when you press the gas pedal sharply.

- Jerking during intense acceleration.

- Changing indicators in idle mode.

Even a complete breakdown of this device will not lead to global consequences. Its functions will be partially filled by another element of the system, the mass air flow sensor. Although this does not mean that such a situation can be left for a long period.

Symptoms of a Malfunctioning Throttle Sensor

The following symptoms may indicate a malfunctioning throttle sensor:

- Unstable operation of the internal combustion engine at idle speed.

- The engine stalls when shifting the gearbox or when engaging neutral gear after other speeds.

- The car stalls at idle.

- When driving in different gears, there are jerks or dips in traction (most often such symptoms are felt when accelerating.

- Traction drops and acceleration of the car deteriorates (at the start, when driving uphill, when the car is fully loaded or when driving with a trailer).

- The Check Engine light on the dashboard lights up. If you connect scanning equipment in such a situation, you will receive error p0120 or with another code indicating a malfunction of the sensor in question.

- Failure of the throttle sensor leads to increasing fuel consumption by the car.

Please note that the listed symptoms can also be caused by a malfunction of other internal combustion engine components, for example, a breakdown of the damper itself. But despite this, you should start by checking the sensor.

Causes of malfunction

Improper operation of the throttle sensor may be caused by wear. It should be noted that the wear of various elements of this unit has different effects on the operation of the system.

If the coating on the conductor is worn off, the sensor will not be able to detect current readings.

Exceeding the design life of the moving parts of the sensor. If the gap between the sensor and the axle conductor exceeds a certain value, contact is lost between these parts. In this case, the malfunction indicator on the instrument panel will not light up. Such a breakdown can be assumed by the presence of interruptions in the operation of the motor in various modes.

Oxidation, contamination or corrosion of sensor contacts.

If such a malfunction is detected, to restore normal operation of the unit, it will be necessary to replace it. Non-contact sensors are considered more reliable, since their design does not contain rubbing elements.

Opinions of car enthusiasts about the malfunction of the damper sensor

1. PDZ sensor - works the same as the simplest volume controls in older TV models...

“This device is an analogue of the simplest volume control that is found in old televisions. The sensor has the following problems - “rustling” during operation. If in the case of a TV the regulator is not used so often, then in a car the throttle sensor works constantly. Its “rustling” is far from the speed that can be expected in accordance with the logic of movement. This is precisely what causes difficulties with engine speed freezing by 1.5-2 thousand revolutions or more. It is worth noting that the ECU will definitely detect a malfunction of the throttle sensor, as a result of which a “check” will light up on the dashboard. Usually the code for such an error is deciphered as “High level of TPS”.

2. Lean mixture is a consequence of problems with the throttle sensor

“If I understand correctly, when driving at a constant speed the car jerks, and when the accelerator is abruptly released, a dip is felt and the engine may stall. If the throttle is more than half open, does the car drive pretty well?

If all the symptoms converge, then:

- Was the mixture composition measured at a car service?

- the symptoms indicate a possible lean mixture, so I would first check the lambda probe and then the air flow sensor. Of course, you should also check all sorts of places where excess air is leaking, but not the throttle sensor.

- disconnect the lambda probe and drive without it; if the car drives normally at average values, then you need to change the lambda.

This is what my opinion looks like at this moment. If it’s wrong, we’ll think further.”

3. Why does the engine stall?

“The car may stall due to a faulty throttle sensor. When my car's engine stalled, I adjusted the TPS and the stalling disappeared!!! This measure was enough for about 5-7 km (I tested the engine in different modes, turning it off and starting it up, but it ran smoothly), but the car suddenly “started up” and no other throttle sensor settings helped. At the same time, at the service station they told me that the reason for the unstable operation of the motor was not the remote control sensor. I just don't believe them! At first they claimed that the thermostat was “to blame,” but not the one that controls the cooling of the engine, but the one located near the throttle valve (I didn’t even know about that). There is an antifreeze stain in this area, and the mechanics decided that the problem was caused by this thermostat. Then they thought some more and switched to the valve in the motor, then to the wiring, etc.

After an unsuccessful search, the service station called me, apologized and said that they did not know what the reason was. I note that the composition of the drops on the thermostat is not similar to coolant, but to ordinary water. I removed the sensor - it was dry inside, which means no water got in there, but the drops were right on the throttle sensor chip! When I started to blow through the TPS, small splashes flew out of it.”

4. Incorrect sensor settings

“Due to errors in setting the throttle sensor, the wrong signal is sent to the ECU. Incorrect information about the throttle opening level is supplied, which means the dosage of the fuel mixture is disrupted. Of course, the lambda probe can adjust the mixture. I would correct the settings myself. I understand that this is simple and short-lived, but “there is nothing more permanent than temporary.”

What are the effects of TPS malfunctions?

If signs of a malfunction of the throttle sensor appear, then, first of all, this may affect the operation of the engine when the gear is in neutral. Injection engines do not have a system that controls the engine at neutral speed, as is provided in carburetor units. The electronics regulate the number of revolutions of the power unit solely based on data from the damper sensor. Thus, incorrect operation of the TPS leads to unstable operation of the internal combustion engine.

Increased fuel consumption. The TPS produces an incorrect signal, which the motor control electronics interprets as a closed damper position, but in fact it is open. It turns out that the engine operates stably in normal mode, but spends more fuel mixture.

- When accelerating, you feel dips and the car jerks violently.

- The position of the gas pedal does not change, but the engine jerks, and after the gas is released, it stalls.

- You feel a loss of traction (the car “does not pull”).

- The indicator lights up to indicate a breakdown.

- P2135 – error in throttle position sensor

In addition to the above error, the diagnostic scanner can also show other codes indicating incorrect operation of the remote control or its sensor: P0120, 0122, 0123, 0220, 0223, 0222, 01578.

To diagnose, it is necessary to measure the pulse voltage from the sensor, the wiring resistance, and also check the ground pin on the control unit.

Causes of problems with the damper sensor:

- Poor ground contact. To eliminate the malfunction, you need to clean the contacts or eliminate existing breaks.

- Relay failure. To eliminate the malfunction, you need to install a new part (to replace it, it is better to choose a relay from a reliable manufacturer with a current of 40 A).

- Poor condition of the sensor's electrical outputs. Sometimes you need to bend them in the connector to fix the problem.

- There is a short circuit between 1 and 2 contacts of the VTA. To identify the problem, it is necessary to measure the voltages in this area.

- Malfunction of the electromechanical throttle mechanism (EMDU). Repair in this case consists of replacing the unit.

We recommend

“How to wash car windows: options for solving the problem” Read more

Error P2135 appears due to improper operation of the throttle sensor as a result of severe wear of parts, poor pin contact or short circuit. In this case, you need to replace the spare part. On Russian-made machines that use wiring from the Tolyatti plant, the cause of such an error is often poor-quality insulation.

Once the faulty throttle sensor has been replaced, you will need to reset the error code using your diagnostic computer. In some cases, to erase the error, it is enough to disconnect the negative terminal of the battery, wait 10 minutes and install it back.

Characteristics of the throttle position sensor

The purpose of the sensor is to regulate the volume of air flow that enters the motor. This air is used to form a flammable mixture.

Where is the sensor located in the car?

In order to diagnose the device if necessary, the car owner needs to know where the TPS is located. The controller is installed in the engine compartment. It can be seen on the side of the throttle line on the axis of the valve itself.

Controller location on the throttle

Device design

Structurally, the device includes the following:

- Controller housing. This component is made of heat-resistant fiberglass. The housing is equipped with two flanges, which are used to secure the controller to the throttle assembly.

- A connecting device equipped with three contacts. This component is integrated with the controller housing.

- A resistive device made of ceramic.

- Current collecting element. This component is designed to provide electrical contact with the resistive part.

- Collet clamp, equipped with a slot.

- Rubber gasket. Used to mount the controller on the axis of the throttle assembly.

Purpose of the throttle position sensor

The controller itself is responsible for correctly identifying the position of the valve on the throttle assembly. Its readings affect the operation of the fuel supply system. The power unit, in accordance with the device values, adjusts the volume of supplied gasoline under a certain operating mode. The TPS is used to convert the angular position of the throttle valve into DC voltage.

Features of the device:

- The data transmitted by the controller makes it possible to calculate the amount of damper opening. The information received by the control module ensures the calculation of the main control parameters of the power unit. Moreover, the data is determined taking into account the type of vehicle driving.

- The device itself is a potentiometer equipped with a current collector. The latter is used to move along a set sector radius, ranging from 0 to 80 degrees. When installing the device, the axis of this structural element must be connected to the drive of the throttle unit.

- The output resistance parameter of the potentiometer can change depending on the pressure on the gas pedal. Depending on its position, the degree of opening of the valve unit also changes.

- The controller is powered by supplying a stabilized voltage. The value comes from the control module and should be around 5 volts. A deviation of 0.1 V up or down is allowed.

Schematic principle of the controller

Device technical parameters

Main technical properties of TPS controllers:

- The voltage to power the device is supplied to two pins - 1 and 2.

- The amount of resistance that forms between pins 1 and 2 ranges from 1.8 to 2 kOhm.

- The opening parameter for a fully closed node damper is from 0 to 2%.

- The voltage that is supplied to outputs numbered 3 and 2 when the damper is closed ranges from 0.25 to 0.65 volts.

- The valve opening value is more than 90 degrees.

- The voltage parameter supplied to pins 3 and 2 at full throttle ranges from 3.9 to 4.7 volts.

- The number of complete activation cycles of the device during its operation is at least one million.

- The calibration property of the dependence of the output voltage parameter on the rotation angle is linear. It is measured in the range from 0 to 100 degrees. The voltage ranges from 0.25 to 4.8 volts. The slope of the characteristic varies around 48 mV.

- The controller operating area parameter is in the linear range of the characteristic in the range from 10 to 90 degrees. This corresponds to the opening value of the unit damper at an angle from 0 to 100 degrees. The slope value varies around 39 mV.

Varieties

There are two main types of devices:

- Film-resistive sensors. This type of controller is usually installed standard during car production. The average service life of film-resistive devices is approximately 55 thousand km. But in fact, they fail more often.

- Contactless type of devices. Such TPS operate on the basis of a magnetic-resistive phenomenon, the Hall effect is used. The price of contactless sensors is higher, but their service life is long. These devices are more reliable and therefore rarely fail.

Andrey Seromolotov showed how a machine engine works with a contactless TPS.

Algorithm for self-testing of the throttle sensor

Now let's look at the practical use of the information described above to inspect the sensor on our own. Before purchasing a part, you need to determine exactly what malfunctions of the throttle position sensor occur in your case. Only after identifying the causes of the problem can you decide whether to change the TPS.

How to determine a faulty throttle sensor? The procedure is as follows:

- Determine the location of the part you are looking for and make sure there is voltage on it.

- Connect one output of the multimeter to the TPS connector, and the other to the damper axis to measure the voltage in different positions of the DPS. If the voltmeter readings change, then the device is normal. If the voltage indicator remains unchanged, then there is a malfunction of the TPS.

- At the same time, the condition of the tracks should be checked. If there are any defects in the coating, the part must be replaced.

- Check and clean parts, devices - contacts, wires and connections. Broken pins must be soldered and treated with varnish.

Separately, it is worth emphasizing that the throttle sensor is a significant part in the car’s main computer system. The sensor transmits to the on-board electronic system the indicators of the opening/closing angle of the damper at a specific moment.

Whatever signs of malfunction of the throttle position sensor you find when analyzing the operation of the engine and other units, they cannot be left without any attention. Identifying problematic issues in the operation of the unit in question will allow you to avoid more expensive repairs.

Regular diagnostic measures and prevention of breakdowns of the throttle sensor are an important condition for comfortable driving and safe vehicle operation.

Regulator condition: check on VAZ-2110

So how do you test your throttle sensor? This process is necessary, as it makes it possible to understand whether the malfunction is actually due to its cause or the problem is due to the failure of other parts of your “ten”.

Sometimes new car owners make hasty conclusions based on the primary signs of damage. This entails extra spending of money and time on repairs.

To check the current TPS position, you will need to do the following:

- measure the voltage at the output of the slider, while turning on the ignition, open the idle contacts;

- during the test it showed a voltage above 0.7 V - which means the controller is faulty;

- open the throttle valve completely (in normal position the voltage values are a maximum of 4 V);

- measure the variable resistor for resistance;

- connect an ohmmeter/multimeter to the power supply and output;

- slowly turn the valve;

- track readings on the device;

- if the resistance changes smoothly as the damper opens, then the device is functioning properly.

If during the inspection you notice that the TPS itself is damaged, it will need to be replaced. Repair will not help here. An important point is the selection of this element. In the 2110th VAZ model, 2 analogues of TPS are installed:

- Film resistive. This type is equipped by the manufacturer; The sensor is designed for 55 thousand km.

- Contactless. A Hall sensor is used here. Such a device has no restrictions regarding its service life. The cost of such a sensor is more expensive.

The resistive layer, where the slider moves, wears out over time when exposed to friction. For this reason, the regulator produces incorrect data, the properties of the supplied mixture change, and engine performance decreases.

Types of TPS faults

Problems with the operation of the throttle sensor are associated with its design design, and are generally characteristic of most variable resistors. Car enthusiasts identify three main problems:

- Wear of the moving contact or film resistance.

- Backlash of fastenings.

- Oxidation of active contacts.

During the operation of the moving contact and interaction with the film resistance, constant friction arises, which, with prolonged exposure, wears out both the resistive layer and the surface of the active contact itself. Practice shows that the degree of wear directly depends on driving style and manifests itself extremely unevenly. Because of this, only in some places places are formed where the active contact does not reach the resistive layer, causing the voltage to disappear at the output of the throttle position sensor.

Oxidation of working contacts occurs exclusively under conditions of high humidity under the hood. As a result, the resistance may increase and the electrical contact may be completely broken.

How to replace the throttle position sensor on a VAZ 2110-VAZ 2112?

Removal: 1. First, simply press out the latch that holds the wire block and then disconnect the block (see photo 1), insert the key into the ignition and turn it until all the devices light up, then turn on the device, namely the Voltmeter function and from device, place the minus probe (it usually comes in black) to ground (the ground can be the car body or engine), and connect the plus probe to terminal A of the wire block (All terminals on the block are marked, look carefully) and the device should give a reading of approximately 5 Volts, but in no case less, if this is the case, then everything is in order with the wiring and most likely the sensor itself is to blame, if the voltage is less, then either the controller is faulty or there is a problem with the wiring, after the operation, turn off the ignition don’t forget, and when the wiring is checked, you can start replacing the sensor with a new one, for which unscrew the two screws that secure it to the throttle body body and then remove the sensor, under it there will be a foam ring that must be replaced.

Note! If you are going to change the sensor, do not forget to remove the minus terminal from the battery, how to do this, read the article: “Replacing the battery on VAZ cars”, point 1!

Installation: The sensor is installed in the reverse order of removal; when installing, its leads should be directed towards the engine shield. To make sure that the sensor will be installed correctly, lean it against the throttle assembly and make sure that the holes for the screws in the sensor coincide with the threaded holes in body and then fully open the throttle valve using the sector (or the gas pedal, let an assistant gently and slowly press it all the way), if everything goes well, the throttle valve will open completely and you can then tighten the sensor mounting screws until they stop.

Additional video: Visually watch the process of replacing the TPS in the video below:

Checking TPS

There are different types of throttle position sensors. If you notice one of the above signs of a sensor malfunction, we advise you to check this engine element. Remember that improper operation of the TPS can lead to poor throttle performance, sudden engine stalling and other problems. As an example, we will give a method for diagnosing a potentiometric TPS. For this we need a voltmeter.

- Disconnect the wiring connector from the throttle sensor.

- Open the throttle valve fully by hand and check for changes in resistance between terminals 1 and 2.

- Check the resistance in three different accelerator pedal positions.

- You can get about 10 ohms of resistance when you press the accelerator fully, from 2 to 10 ohms when you press the throttle partially, and 2 ohms when you release the throttle.

- Check your car's repair manual or read specialized forums to get specific numbers that can tell you whether you need to think about replacing the TPS or whether the results obtained correspond to the normal values set by the manufacturer.

For more information about a detailed check of the TPS and the wiring leading to it, read our article.

Cleaning

So, the part has been removed. Now you need to assess the condition of the gasket. If cleaning is being done for the first time, the gasket should be replaced. Cleaning is carried out using a pre-prepared product, cotton swabs and a toothbrush. We need to clean all cavities, hidden channels

The damper itself and the landing sites must be given special attention

The photo shows the cleaning process using a special liquid.

As a result, the remote control must be completely cleaned of grease and dust. Before installation, it is worth cleaning the crankcase ventilation duct. Here you will need a foot pump. It is better to perform purging with the same product.

The photo clearly shows what a cleaned unit should look like.

Evidence of pollution

Let's look at the signs that indicate a malfunctioning throttle valve:

- Revolutions. You sharply release the gas pedal, but the engine is in no hurry to switch to idle speeds from high speeds. Instead of a smooth reset and acceleration, the engine begins to shake, it either stalls completely, or with great difficulty restores the required speed;

- Launch. Your VAZ has difficulty starting cold, and sometimes you cannot quickly start even a hot engine. There may be other reasons for this phenomenon, but the fact that the throttle valve is to blame may be indicated by the fact that after several throttle applications (short-term presses on the gas), the engine usually starts;

- The starter spins for a long time before starting, and the smell of gasoline is heard from the exhaust pipe;

- The engine may run for a couple of minutes after starting.

Dirty throttle valve VAZ 2110

Which to choose?

Please note that the VAZ-2114 throttle position sensors cannot be repaired. This element is changed entirely on the car

There are several:

- "Schetmash"

- "Autoelectrics".

- "Omega".

The latter is installed on the Lada from the factory. It lasts long enough

When choosing, you need to pay attention to contactless elements. They cost about 600-900 rubles

Why is it needed?

The throttle position sensor is responsible for determining the current throttle position. Depending on this, the fuel supply system changes the amount of fuel supplied under one or another operating mode of the power unit.

If problems arise with it, you can contact a service station so as not to waste your energy and nerves. But in practice, changing the TPS yourself is quite simple, plus you will save a decent amount of money.

The desired regulator is located on the side of the throttle pipe on the throttle valve axis.

Regulator location

Features of work

The TPS is essentially a variable resistor, one output of which is supplied with 5 Volt power. The second contact is connected to ground, and the third is connected to the controller.

When you press the gas pedal, the voltage changes. The sensor monitors the output voltage on the controller, thereby regulating and monitoring the quality of the supplied air-fuel mixture. This directly depends on the opening angle of the damper itself.

If for some reason this regulator fails, a catastrophe will not occur, since another sensor, the mass air flow sensor, will temporarily take over its functions.

This does not mean at all that the TPS can not be changed. Each regulator has its own functions, so there is no point in transferring the tasks of the TPS to the MAF.

What should I do if I have problems with idle speed after adjusting the sensor?

If adjusting the throttle position sensor led to jumps in idle speed, you need to perform a procedure to familiarize the electronic unit with the characteristics of the new TPS.

The task is performed like this:

- The terminals from the battery are disconnected. The clamps are loosened with a wrench, after which you need to wait about 20 minutes.

- Then the terminals are connected back. Before the next step, you need to make sure that the valve of the unit is closed.

- The key is inserted into the lock and the ignition is activated for approximately 15 seconds. The power unit does not start. After this, the ignition is turned off.

- Then you need to wait about 20 more seconds. During this time, the microprocessor module will be able to remember the characteristics of the new TPS in its memory.

Replacement

In fact, changing this sensor is insanely easy. So don't rush to send your car to a service station. Everything can be done with your own hands, the quality will not suffer from this.

To remove the throttle position sensor, you first need to find it. As we have already noted, the desired unit is located on the side of the throttle pipe on the throttle valve axis. Having found the element, pick up a shaped screwdriver. Using this simple tool, unscrew a couple of bolts that hold the device. Pay special attention to the gasket that is available under the old regulator. We do not recommend using it again; it is better to immediately buy a new one

Often the gasket is already included with the throttle sensor itself. After removing the old sensor, you can slightly clean the place where it is installed if there is dirt there. Next, a new sensor is installed along with a new foam gasket and the bolts are tightened. Try to tighten the fasteners as far as possible, otherwise the new throttle sensor will quickly lose its effectiveness. The work will have to be done again. There is no need to make any adjustments after replacement. The zero mark on the controller will determine that the throttle is completely closed.

Foam pad

What to choose?

When replacing, many more or less experienced car owners have a question about which regulator is better to install. After all, there are two types.

| Sensor type | Peculiarities |

| Film-resistive | These sensors are usually factory installed. The service life of such a throttle position sensor is stated to be about 55 thousand kilometers, but in practice it has to be changed more often |

| Contactless | The operation of such a device is based on the magnetic-resistive phenomenon; a Hall element is used. The cost is noticeably higher than the first option, but it is unlikely to have to be changed. Huge resource, high reliability |

In pursuit of savings, many forget about the importance of quality. But it should be in the first place when choosing spare parts when repairing a car

TPS is an important, but easy to replace device. The repair operation will take you no more than an hour, even if you are just beginning to learn the joys of repairing your car yourself.

But under no circumstances delay repairing the sensor, otherwise this may negatively affect the operation of the engine, its service life and the cost of fuel, which you will overuse due to incorrect data from the sensor to the ECU.

Loading …

TPS design

The throttle position sensor can be of two types:

- film;

- magnetic or contactless.

In its design, it resembles an air valve - in the open position the pressure corresponds to atmospheric pressure, in the closed position it drops to a vacuum state. The TPS includes DC and AC resistors (each resistance is 8 ohms). The process of opening and closing the damper is monitored by the controller, with subsequent adjustment of the fuel supply.

If at least one symptom of a malfunction occurs in the functioning system of this sensor, then fuel may be supplied to the engine either in excess or in deficiency. Such malfunctions in engine operation are reflected in the engine of the VAZ-2110 car and on its gearbox.

Cleaning the throttle valve on a Priora

Welcome! Throttle valve - this is what people say, in fact, the unit that we will talk about today is called a throttle assembly, and the valve is only a small but very important part of the assembly, which is responsible for supplying air to the car engine, as you already know the engine a car can only work with the help of gasoline and air that is mixed with it, since gasoline without air simply cannot ignite and the car will not even start due to this, but the air that the car is powered by is not as clean as it seems, there is dust in it (Air is taken from the environment), what other dirt particles, etc. In general, it all depends on what kind of roads the car is driven on, if there is a lot of dust on a dirt road, then over time this dust and dirt settles on the throttle assembly and the car begins to work incorrectly, the very first symptom that a clogged unit will give is idle speed, namely they will float for you, just for no reason the speed can increase and you don’t even press the gas pedal and there will be some other symptoms, we have already indicated them a little lower and you will become familiar with them as you read this articles on cleaning the throttle body.

Note! To clean it, you will need: Carburetor cleaner (Sold in car dealerships in the form of a can), as well as a socket wrench and various types of screwdrivers!

Where is the throttle assembly located? In 16 valve cars and even in 8 valve cars, finding it will not be difficult, but the screen that covers the engine of the car will prevent you from finding the throttle assembly, so when removing it and in general to find it, you will need to remove this screen, for more details about For information on how to remove the screen from a car engine, read the article: “Replacing the engine screen on a car.” After removing it, you will see the entire engine of the car and the throttle assembly itself, respectively. For clarity, the unit is shown with a red arrow just below, and the blue arrow indicates the spacer rod, which It was not installed on cars at the factory, so you don’t have this unit and therefore don’t need to look for it.

When should you clean the throttle body? When clogged (Basically, the valve itself becomes clogged), the car’s idle speed first begins to fluctuate, the engine may also periodically stall and jerking will appear when driving (This is especially noticeable during sudden acceleration), in addition, the engine may take a little longer to start than usual , but the same symptoms are characteristic of various types of sensors, so it is possible to say that it is the unit that is clogged here, but it may not be the whole problem, in addition, the unit does not usually become clogged after long-term use of the car (After 40,000-60,000 thousand km.) and if you just recently bought a new node and you have these symptoms, then most likely the whole issue is not even in it and there is no point in even looking there.

Types of sensors

Modern car models are equipped with potentiometers - contact TPS or magnetoresistive sensors. Electronic devices differ in cost and service life. Depending on the installation method, they can be built into the throttle body or separately installed.

Contact sensor

Inside the housing there are several resistive tracks and a movable current-collecting element - a slider. It is rigidly connected to the throttle valve rod and moves when it closes (opens). During movement, it touches the resistive layer and, upon contact, changes the resistance:

- when the damper is closed, the slider is positioned at the very beginning of the track, this extreme position corresponds to the minimum values of resistance and voltage;

- when the gas pedal is pressed, the throttle valve opens and the slider moves, while the length of the resistive layer included in the circuit increases, which leads to an increase in resistance and voltage.

On a note!

There are 3 wires connected to the device. One supplies voltage to the resistive layer - 5 V, the other goes to ground, the third to the slider.

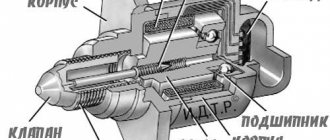

Non-contact TPS with Hall sensor

The operation of the device is based on the magnetoresistive Hall effect. There is no mechanical contact between its elements; there are two types:

- Hall Sensor;

- Permanent magnets performing the functions of a slider.

On a note!

Non-contact sensors are more expensive, but also last longer.

The magnetic sliders move when the throttle valve is turned, the magnetic field changes while driving, the sensors instantly record this and transmit a signal to the microcircuit, which sends information to the ECU. The elements of the device are separated by an air gap and therefore do not experience mechanical stress. The installation location of the board is the throttle body.

Inductive TPS

Inductive type devices, without physical contact of the elements, calculate the angle of rotation of the throttle valve. Diagram of such a sensor:

- a conductive rotor connected to the damper axis;

- stator – a board with coils (receiving, transmitting), a microcircuit responsible for transmitting data to the controller.

This type of device is designed for electronic throttle valves. They are installed on the body. The magnitude of the voltage on the stator depends on the angle of rotation of the rotor.

Causes of problems

The main cause of malfunction of the throttle sensor is burnt contacts or grinding of the resistive layer. Contact TPSs are more often damaged - they are also called resistive. The principle of their operation lies in the movement of a special slider along resistive tracks. The latter wear down sooner or later, and the regulator transmits false information. Thus, the reasons for damage to the contact type TPS are as follows:

- wear of the resistive layer, breakage of the tip or other damage to the mechanical property;

- abrasion of the base coating, which does not allow the current to increase;

- obsolescence of the slider drive gears and other moving parts of the regulator - contact may disappear if the gap between the TPS and the axle conductor increases;

- breakage of signal or power wiring;

- the relay has failed;

- breakdowns in the circuit;

- oxidation, contamination, corrosion of connections.

Oxidation and corrosion of the throttle sensor

Magnetic or non-contact regulators rarely fail, since they do not involve spraying. Therefore, problems are reduced only to damage to the terminals, connections and wires.

As was said, the engine is the first to react to a malfunction of the TPS. This happens especially often when the engine is idling. The fact is that in injection systems there is no carburetor that controls the unit in idle mode. All adjustments are performed by electronics, operating solely on the data sent by the sensor.

Replacing TPS

Replacing the auto sensor takes place in several stages, it is quite simple, even a novice car enthusiast can do it. First you need to turn off the ignition and disconnect the wire from the negative terminal on the battery. Then you should press the plastic latch and also disconnect the block with the existing wires from the sensor. To completely remove the device being replaced, unscrew the two bolts using a Phillips screwdriver.

Foam rubber is used as a seal between the throttle pipe and the sensor. It is a component and also needs to be replaced. When installing a purchased device, you need to carefully tighten the mounting screws until the ring is completely compressed.

After installing the sensor, you should connect the wires. Since no further adjustment is required, the work can be considered complete. The entire process of changing the device takes no more than a quarter of an hour.