In the conditions of modern Russian reality, switching to gas seems quite reasonable. It is much cheaper than gasoline, for which prices are rising, no matter what happens in the country.

Gas is much cheaper than gasoline, prices for which are constantly rising

Converting a car to gas and installing gas equipment is a rather serious step, but completely justified. Especially against the backdrop of rumors that owners of gas-powered cars may be exempt from paying taxes. Gas equipment is installed with some intervention in the car, but, fortunately, without major alterations. Each kilometer traveled on gas will cost one third less than gasoline.

Lovato gas-cylinder equipment quickly pays for itself with runs over 2 thousand kilometers per month, the injector or carburetor does not matter. Payback for Lovato usually occurs in six months to a year. The scheme is quite simple, and the price of equipment and installation is low.

Why is it worth installing gas equipment?

- The price of gas is significantly lower and does not change so dramatically depending on the situation on the global economic market.

- Propane, butane and methane are cleaner than gasoline.

- The gas burns almost completely and leaves no harmful emissions behind.

- The octane number of the gas is higher, detonation does not occur when using it, and the load on the engine is less.

- When the fuel tanks are fully filled, the car will be able to travel 200-500 kilometers more.

After installing LPG, the car will be able to travel 200-500 kilometers more - Engine power will increase.

- The design of the car will not change. The weight will increase slightly, the weight distribution will not change.

- Gas equipment can be installed on any engine, even those equipped with a turbine. Injector or carburetor, it doesn't matter.

- Installing a gas system will not affect the safety of the machine.

- HBO is very reliable and there is nothing to break there.

- Does not reduce engine life.

Installation and configuration of HBO

GBO installation is carried out by specialized workshops. They are certified, have trained specialists and the necessary equipment and tools for installation. These same workshops sell equipment of various configurations, repair and service it.

You can install the 1st generation kit on a carburetor or injection machine and connect it yourself, but it is better to contact specialists; installation and adjustment will not be expensive. But there will be all the documents necessary for registration, since this is making changes to the design of the car. Failure to note this in the documents will result in a fine of 500 rubles for the first violation. In addition, installers' warranties will come in handy.

Disadvantages of gas equipment

- The system requires maintenance, draining condensate and checking the filter.

- HBO takes away useful space in the car.

- You will still need to fill in gasoline; it is recommended to warm up the engine using gasoline.

- There are fewer gas stations.

- It is necessary to periodically check the tightness of the system.

- At high speeds, a gas engine will overheat, and there will be no savings.

Failure to comply with installation requirements or vehicle malfunction may result in a fire. But this applies to those cars that are simply dangerous to drive.

- If the gas is installed on the carburetor, then adjustment will be needed.

Video

LPG: myths and realityReal experience in using LPG, or what will happen if you drive a GAZIn detail: LPG 4th generation

The first generation of gas equipment was developed for use on carburetor and injection engines without a catalytic converter and lambda probe.

The system is configured mechanically.

This article will discuss all the features of gas installations of this type, their advantages and disadvantages, as well as the key components and operating principle of this equipment. You will also find out whether the first version of gas equipment is still found in our time, when there is already data on the 5th and even 6th generations of installations. Please note! Gas equipment of the 1st generation is distinguished by a minimal number of electronic parts, so it is easy to understand even for a beginner.

The GBO-1 package includes:

- vacuum reducer-evaporator;

- control controller (button) for switching between fuel types “gas/gasoline”;

- mixer (mixer);

- mechanical gas quantity dispenser;

- high pressure pipeline;

- balloon;

- multivalve;

- remote filling device (VZU);

- gas solenoid valve;

- gasoline solenoid valve.

Good to know Read more information about the differences between different versions of gas equipment in a special section of the site - gas equipment generations.

Gas equipment for carburetor

HBO of the first generations was intended for carburetor cars.

1st generation LPG was intended for carburetor cars

Last century? No, considering that 50 percent of the vehicle fleet in Russia consists of vehicles older than 10 years. More than 30 percent are cars produced by the Lada concern, plus a certain percentage of GAZ, UAZ, KAMAZ, and so on. And VAZ stopped producing carburetor models just 10 years ago.

For carburetor engines, gas cylinder equipment is the simplest. No electronics or sensors, just like the carburetor engines themselves. If you remove all the sensors and bells and whistles from fourth-generation gas equipment, you will get the first. The only negative is that if you install it on a carburetor, it needs adjustment periodically.

The carburetor engine or Otto power unit was popular in the world for a very long time until it was supplanted by a more economical and environmentally friendly injector. The injector was controlled by a computer; the adjustment of all systems and engine modes was entrusted to it. The carburetor was much simpler and more reliable than the injector. The carburetor of Hemi and other brands works quietly and after 50 years of operation, there is nothing special to break. An old American classic car with a huge multi-liter engine and a consumption of over 20 in quiet mode will come in handy with gas equipment.

An old American classic car will come in handy with gas equipment

The carburetor did not have any electronic control systems, much less the injector. The carburetor regulates all the work with two holes and adjusting bolts, with the help of which the adjustment was made.

In the first generation, the dispenser is manual; it requires adjustment, just like the carburetor.

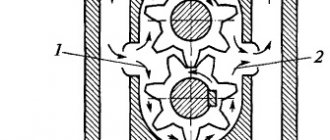

Diagram of gas cylinder equipment for a carburetor car

- Balloon. Usually mounted under the bottom of the car or in the trunk. And unfortunately, it takes up useful space.

- Multivalve. A special device located on the valve. Through it, liquefied gas enters the system.

- Refilling mechanism. Since the fuel is not liquid and is under pressure, it will not be possible to “pour” it into the neck. For these purposes, a special mechanism is used to safely connect the cylinder and the filling station.

- High pressure gas line. It's just a pipe through which gas flows.

- Gas filter. The gas is fairly clean, but it could contain debris.

- Gas valve. Locks or unlocks the gas supply.

- Reducer-evaporator. It is here that the gas returns to its normal state.

- Dispenser. They make the adjustments.

- Mixer. If it was not installed directly into the engine.

Gasoline valve - Gasoline valve. Locks or unlocks the gasoline supply.

- Fuel switch. It is installed in the cabin and serves to switch the type of fuel.

Accessories

The first generation of HBO (the first by European standards) is a generation with a minimum of electronics. The 1st generation of HBO includes:

- vacuum type gearbox,

- fuel type selection button,

- mechanical dispenser,

- mixer,

- lines (refueling and consumable),

- multivalve,

- filling valve,

- gas solenoid valve,

- gasoline solenoid valve,

- gas cylinder.

How does a gas car work?

After filling the gas cylinder, the gas in it is in a liquefied state. After opening the multivalve, liquid gas enters the main line, where it passes through the filter and is cleaned. The mode selection occurs immediately. One of the clear advantages of internal combustion engines and Diesel engines is the ability to run them on gas without any problems.

And gas does not wear out the engine at all; on the contrary, it is much easier for it to work. Oil is not washed out from the cylinder walls, due to the high octane number, detonation does not occur, and so on. Cars with gas installations can easily travel half a million kilometers. But this is only if the equipment was purchased from the manufacturer and installed by a specialist, otherwise everything, of course, may break.

When running on gasoline, the high pressure line is closed. The mode switch is installed inside the car, usually on the dashboard. The system is equipped with a mode indication. Switching is possible without stopping the car.

The gas-gasoline mode switch is installed in the car interior

If the valve is open, the gas enters the reducer-evaporator, where it finally returns to atmospheric pressure and becomes a gas. In the process of turning back into a gas state, butane or propane greatly cools this part of the system, so it is connected to the cooling system and is constantly heated to avoid freezing. This is where condensation forms, which must be disposed of every second refill. This is one of the disadvantages of driving on gas. Next, the gas enters the dispenser and then into the mixer, directly inside the carburetor, between its flaps. Sometimes this part of the system is made as a cut-in directly into the carburetor.

Which system should you choose?

There are several leading LPG manufacturers in the world, one of which is Lovato. The equipment has a fairly high build quality, as well as high performance indicators. A particular advantage is the electronic control unit, which calculates all readings with excellent accuracy and very rarely fails. You can also note the compactness of this installation, in comparison, for example, with BRC equipment. It is worth choosing LPG for a specific type of gas, that is, either for liquefied propane or for compressed compressed methane. By the way, when using propane, gasoline injectors can be used, since the density and consistency of the gas is close to gasoline. When working with compressed gas, it is necessary to use special gas injectors.

Adjustment process

The Lovato gas regulator itself is presented in the form of a screw compressing a spring. In order to install it, you should consider:

- when tightening, the gas supply will be reduced by the reducer;

- when unscrewing, it will grow.

Sometimes screws are found with left-hand threads, most often they are right-hand threads. This moment depends on the designer’s imagination of the manufacturer. To simplify this task slightly, it is necessary to take into account: with any rotation it is characterized by the above characteristics of changes in gas pressure.

Adjusting the idle speed on vehicles is explained by the degree of engine shaking. His calm work indicates that the gearbox repair was carried out competently and efficiently.

So, start the engine and hold the throttle open. Then we smoothly release it and slow down until the power unit stalls. At the same time, do not forget the condition: the gas reducer of the car engine must continue to work. For “dummies”, an explanation: the engine will not stall completely if you start twisting the throttle valve in an arbitrary direction. If worse motor performance is observed, you will have to change the direction of rotation of the gearbox and restore its stable operation.

The truth about generations

If we exaggerate, there are only three generations or stages of HBO, they have fundamental differences, but in fairness, it is worth noting that between them there are so-called hybrid (intermediate) versions, which also represent generations, although this is not entirely correct.

All the differences between the “versions” of HBO are hidden in the power system. It's no secret that the car's standard power supply system is gasoline. When installing gas equipment, it is changed or modified to consume gas.

With the development of the internal combustion engine, power systems also evolve , that is, the principle of supplying fuel to the cylinders of the power unit changes. The replacement of one fuel with another, that is, gasoline with gas, is also evolving - each such “turn” can be called a generation.

As you and I know, the fuel supply system of an internal combustion engine has only three main generations. This is injection through a carburetor (also mechanical), then distributed injection, and direct fuel injection. It is these stages that the main three changes in HBO systems are equated to. Although, as I already wrote above, there are also transitional versions. I will try to tell you about all types, from the very first to the last sixth.

Although once again I want to emphasize that there are only THREE main generations (if you can count it that way)! Remember this, due to the evolution of fuel injection systems in gasoline engines, the rest are simply intermediate versions.