Dzhiper89 › Blog › How to make wheel alignment with your own hands

You can adjust the wheel alignment angles of your car with your own hands using available tools and simple devices. In this material we will talk about how to do wheel alignment yourself at home, and what difficulties are most often encountered when adjusting wheel alignment angles.

Incorrect alignment adjustment can cause, for example, rapid wear of tires, or the fact that when driving in a straight line, the car will pull to the left or to the right.

At the end of this article you will find a video that explains and shows in detail everything you need to know about wheel alignment.

First, let's look at the theory: wheel alignment - what is it? What are the wheel alignment angles and how does the car’s behavior on the road depend on them?

Wheel alignment - what is it?

Camber is the angle between the vertical and the plane of the wheel. It ensures reliable contact of the tire with the road (see picture above).

Toe is the angle between the direction of travel and the plane of rotation of the wheel. The stability of the car in corners and tire wear depend on it.

On rear-wheel drive cars, the wheels should be slightly turned towards each other - this is called positive toe. When moving, they move apart and become parallel. For front-wheel drive vehicles, on the contrary, the toe-in should be negative (see the diagram below). Caster is the longitudinal inclination angle of the king pin. This parameter very rarely needs adjustment, only on a newly assembled front suspension from new parts, so we will not consider its adjustment.

Repairing the suspension or steering (replacing the same shock absorbers or steering joint) leads to a significant change in the wheel alignment angles. Daily use of the car also makes adjustments to these parameters over time, so the need to adjust the wheel alignment periodically arises.

It is best to adjust wheel alignment twice a year, during seasonal tire changes. During this time, you will fall into a hole more than once or run over a curb, causing the chassis to become loose and the angles to change. Timely alignment adjustment will cost much less than a set of new tires.

In 1955, American engineer Lee Hunter developed the first wheel alignment stand. Sensors mounted on the wheels sent focused beams of light and accurately measured angles. That's why the stand was called optical. But already in 1969 it was connected to a computer, and in 1995, 3D technology was first used to measure and adjust angles.

How to make negative camber?

Let's now dig a little deeper and find out how to make negative camber yourself. Before making direct adjustments, you need to find out whether your car model will accept such a camber and whether lateral and vertical stability will be within normal limits.

The last two indicators can be artificially increased. To increase lateral stability, it is necessary to install a special stabilizer in the front suspension, but for the vertical one, replace the shock-absorbing springs with new ones that will be more rigid. And in order to eliminate the possibility of skidding when turning at speed, reduce the number of turns in the rear suspension springs. Then the car will press against the outer side of the wheel while turning, which means the rear axle will not drift.

Now let's move on to the adjustment process itself. To do this, you will definitely need special plates, which can be purchased at any auto store. Be sure to consider what angle you want when purchasing a plate because they come in different sizes. The algorithm of actions is identical for almost all brands and models of cars.

The car must be installed on a hard and level surface, then jacked up and the wheel removed. After this, the brake drum is removed along with the pads, and even the hub. Now you can put on the camber plate and assemble the dismantled elements back in the opposite order (hub-drum with pads-wheel). The same manipulations must be done with the second wheel, after which the work will be completed.

The work is actually very easy, but if you do not have the necessary equipment and desire, contact the service center, they provide such a service. With high-quality negative camber of the rear wheels, you will immediately notice that the car has become much more stable when turning.

Adjusting the wheel alignment of a VAZ-2109 car

In order to ensure good handling and stability of the car, the wheels are installed at a certain angle relative to the car body. To set these angles there are three options:

Front wheel toe-in under load 320 kgf, mm - 0±1

Front wheel camber under load 320 kgf, deg – 0±30′

Longitudinal angle of inclination of the wheel rotation axis under a load of 320 kgf - 1°30'±30'

Checking and adjusting wheel alignment angles is carried out on special stands according to the instructions for the stand.

Checking the wheel alignment angles is mandatory if suspension parts are being replaced or repaired, which may result in a change in the wheel alignment angles.

Before adjusting wheel alignment, check:

– air pressure in tires;

– radial and axial runout of wheel disks: it should not exceed 1 mm for axial, 0.7 mm for radial;

– free play of the steering wheel;

– free play (play) in the bearings of the front wheel hubs;

– technical condition of suspension parts and assemblies (absence of deformation, destruction and wear of rubber-metal hinges, unacceptable settlement of the upper support of the suspension strut).

Correct any defects you notice.

After installing the car on the stand, immediately before checking the corners, “press” the car’s suspension, applying a force of 392–490 N (40–50 kgf) 2–3 times, directed from top to bottom, first on the rear bumper, and then on the front.

In this case, the wheels of the car must be parallel to the longitudinal axis of the car.

When checking and adjusting wheel alignment, first check and adjust the caster angle, then the camber angle, and lastly, the wheel toe.

Angle of longitudinal inclination of the axis of rotation

If the angle value does not correspond to the data given above, change the number of adjusting washers 23 installed on both ends of the suspension braces 29.

To increase the caster angle of the steering axis, reduce the number of washers on the extension in the front or rear part.

And, conversely, to reduce the angle, add a number of washers, but only in the rear part of the stretcher, since this is not always possible from the front due to the short threaded part of the stretcher.

When changing the number of washers on the brace, make sure that the chamfers on the washers are facing towards the thrust end of the brace.

Observe the same rule when installing the internal thrust washer of the rubber-metal hinge when the adjusting washers are completely removed.

Failure to comply with these requirements may result in loosening of the nuts securing the guy wires.

The number of adjusting washers on the extension should not be more than two at the front, four at the rear.

To ensure that the position of the brace 29 relative to the suspension arm 22 does not change when adjusting the longitudinal inclination of the steering axis, use a special device that fixes the brace relative to the lever, that is, it does not allow the brace to rotate under the influence of forces when tightening the nut securing the brace to the lever.

This requirement must be observed in order to prevent premature wear of the rubber-metal hinge and rubber cushion on which the ends of the extension rest.

When installing or removing one shim, the caster angle of the steering axis changes by approximately 19′.

Front camber angle

If the camber angle is different from the norm, then adjust it. To do this, loosen the nuts of the upper and lower bolts and, by turning the upper adjusting bolt 11, set the required camber angle.

After completing the adjustment, tighten the nuts to a torque of 88.2 Nm (9 kgf m).

Front wheel alignment

If the toe-in value does not correspond to the standard, loosen the nuts 4 and, by rotating the rods 5, set the required toe-in.

Then make sure that the plane “ A ” of the ball joint 2 is parallel to the plane “ B ” of the supporting surface of the swing arm 3, then tighten the nuts 4 to a torque of 121–150 Nm (12.3–15 kgf·m).

Front wheel camber of VAZ 2109

Wheel alignment angles and their influence on vehicle handling

- camber, caster and toe - on the behavior of your car.

Possibly the easiest parameter of the three to understand.

Camber is the angle of the wheels relative to the road surface when looking at the car from the front. If you draw an imaginary line through the center of the wheel perpendicular to the road, then this will be zero camber.

If the top side of the wheels is directed inward (“house”), this is a negative camber angle.

If the top side of the wheels is directed outward, this is a positive camber angle.

INFLUENCE OF CAMBER ON VEHICLE BEHAVIOR

Camber values for sports cars are usually within

What are the advantages of this:

— When turning, the car body rolls, thereby creating positive camber and reducing the area of contact between the wheel and the road. Negative camber values compensate for this effect. As a result, more grip and more stability in corners.

— Negative camber on both wheels creates additional stability on a straight line, because a wheel with negative camber tends to roll inward (like a cone rolling in a circle around its apex)

— When turning, the inner wheel is unloaded and even sometimes rises completely, thereby allowing the support wheel to move the car even further into the turn.

Negative camber also has its disadvantages:

— Increased wear on the inner edge of the tire when driving in a straight line.

— Instability during acceleration and braking in a straight line (because the contact patch area is small)

The ideal would be to have the wheels mounted perpendicular to the road under all conditions. But, compared to racing cars, this is more difficult to achieve on ordinary civilian cars due to the softer suspension with longer travel, which creates greater roll when cornering. Tire wear also plays a big role - for a regular car it should be economical, and racers can afford to buy tires more often (at least I would like it to be so

Source

general information

Before looking at the advantages and disadvantages of negative camber, let's figure out what wheel alignment is and what it is like. So to speak, let’s conduct a small educational program for novice drivers.

Camber - this concept refers to the location of the car’s wheels at a certain angle to the plane, i.e. to the road surface. Wheel alignment has a direct impact on vehicle handling, driving safety and tire wear rate. In the vastness of the country you can see cars of different brands and models, which means their designs are different. Therefore, each car model has its own optimal camber angle.

The camber value can be like this:

A wheel has zero camber when it is positioned strictly perpendicular to the road surface. If the top of the wheel is directed towards the body, then this is a negative wheel alignment. Well, if the top of the wheel is directed away from the body, then it is called positive.

Please note that during operation of the car, the wheel alignment is under constant tension, and therefore its readings change over time. Moreover, the camber values on the front and rear wheels will not match, so periodically stop by a service station and do camber on two axles at once.

If the car's wheel alignment is optimal, then the car becomes more maneuverable and more stable on the road. Be careful, a change in camber of 2 degrees can seriously affect the stability of the car and the life of the tire.

Checking and adjusting the wheel alignment angles of the VAZ-2109

You can adjust the wheel alignment angles of your car with your own hands using available tools and simple devices. In this material we will talk about how to do wheel alignment yourself at home, and what difficulties are most often encountered when adjusting wheel alignment angles.

Incorrect alignment adjustment can cause, for example, rapid wear of tires, or the fact that when driving in a straight line, the car will pull to the left or to the right.

At the end of this article you will find a video that explains and shows in detail everything you need to know about wheel alignment.

How to make a wheel alignment with your own hands on a VAZ-2109

Almost every owner of a business-class car, when adjusting such a parameter as wheel alignment in the car, will prefer to entrust the matter to a specialist so that he can do everything quickly and correctly. However, those motorists who drive, for example, a VAZ-2109, often resolve this issue on their own. Today, car enthusiasts are increasingly trying to repair their own cars on their own. After all, if we are talking about a domestic brand, then there is nothing complicated or impossible. It is worth remembering that the life of a car directly depends on how carefully the owner treats it. It is important that vehicle repair work is carried out on time. Car alignment should be done every 10-15 thousand kilometers. These manipulations do not require a lot of effort and energy, but they can protect you from negative consequences and extend the service life of the machine.

Wheel alignment - what is it?

First, let's look at the theory: wheel alignment - what is it? What are the wheel alignment angles, and how does the car’s behavior on the road depend on them?

Camber is the angle between the vertical and the plane of the wheel. It ensures reliable contact of the tire with the road (see picture above).

Toe is the angle between the direction of travel and the plane of rotation of the wheel. The stability of the car in corners and tire wear depend on it.

Caster is the longitudinal inclination angle of the king pin. This parameter very rarely needs adjustment, only on a newly assembled front suspension from new parts, so we will not consider its adjustment.

Repairing the suspension or steering (replacing the same shock absorbers or steering joint) leads to a significant change in the wheel alignment angles. Daily use of the car also makes adjustments to these parameters over time, so the need to adjust the wheel alignment periodically arises.

It is best to adjust wheel alignment twice a year, during seasonal tire changes. During this time, you will fall into a hole more than once or run over a curb, causing the chassis to become loose and the angles to change. Timely alignment adjustment will cost much less than a set of new tires.

In 1955, American engineer Lee Hunter developed the first wheel alignment stand. Sensors mounted on the wheels sent focused beams of light and accurately measured angles. That's why the stand was called optical. But already in 1969 it was connected to a computer, and in 1995, 3D technology was first used to measure and adjust angles.

True, Soviet car enthusiasts managed without any stands or computers - using wrenches, calipers, thread and a plumb line, they adjusted the camber and toe angles with their own hands.

Preparation and procedure for adjusting wheel alignment angles of VAZ 2107

Having a level area, balanced equal-sized wheels and tires with the required pressure are far from the only requirements. It is equally important to remove the decorative caps before starting the adjustment and ensure:

It is advisable to check and adjust the chassis by first placing 70 kg on each seat and 40 kg in the trunk. However, adjustments can also be made on an empty car. With the steering wheel in the direction of straight-line motion, you should remove all the play in the suspension by shaking each of the four bumpers several times.

Instructions for adjusting wheel alignment yourself

Before you begin adjusting the camber and toe angles, it is imperative to check the vehicle's chassis. If repairs are needed, then doing a wheel alignment is pointless. The steering and suspension must be in perfect order.

Pay attention to three points on which the wheel alignment angles on a car greatly depend:

Be sure to check the tire pressure before adjusting the wheel alignment and make sure that you haven’t accidentally forgotten a couple of bags of potatoes or cement in the trunk

As an example, we will describe how to do a wheel alignment with your own hands on a VAZ 2109 car.

To avoid unnecessary camber and toe adjustments after chassis repairs, before disassembling the suspension, all disconnected connections should be marked relative to each other. This is best done with a chisel, core or paint. It is also necessary to count the number of revolutions when turning the ends out of the tie rods.

When is it recommended to carry out alignment - VAZ 2109

Various sources recommend adjustments at approximately 12-15 thousand kilometers, or once a year. Sometimes there are cases when it is necessary to perform such an operation ahead of schedule. The reason for this in most cases is the condition of our roads. It is enough to “catch” a good pothole once to require checking and adjusting the camber and toe of the front wheels.

Carrying out work on adjusting the front wheels of a VAZ 2109

If the owner plans to use his car for a long time without any problems, then it is not worth saving on this operation. After each replacement of ball joints, silent blocks, steering rods, shock absorbers, it is necessary to check and adjust the camber and toe of the wheels.

Tire wear due to incorrect camber of VAZ 2109

Performing this operation today is quite simple. You just need to go to a service center that performs such an operation, and specialists will quickly and efficiently complete this work. But there are times when such work must be done independently in a garage.

How and what to measure

Caster angle cannot be measured. Decreasing it leads to the inability to take a turn at speed, and increasing it leads to a “heavier” steering wheel. Usually 2-3 degrees is considered a “sporty” option. This is what we need to build on.

To measure toe and camber angles, it is enough to place a thread and a weight. Zero camber corresponds to the fact that the values of A and B are equal (Fig. 52).

Measuring with a thread

“Zero toe” is also easy to check: measure distance B (Fig. 51), knowing that the track of the front and rear wheels differs by 30 mm. The rear wheel is “recessed” inward compared to the front.

To accurately measure the toe angle, you will need equipment: a sliding ruler or a chain with a dynamometer. Only one thing is used.

Measuring the toe angle

The “measuring device” itself is brought in front and behind, then the obtained values are compared. For zero degrees, the two digits should not be different.

The car must be placed on a surface whose inclination angle is zero! In practice, to take measurements, plates are placed under the wheels. The steering wheel must be turned to the “0 degrees” position - this is also important.

everything useful is here

Adjusting the front wheel alignment angles

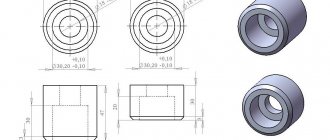

Rice. 1. Casting angle of the wheel axis

Rice. 2. Wheel camber angle

Rice. 3. Wheel alignment

To ensure good stability and controllability of the car, the front wheels are installed at certain angles relative to the body and suspension elements. Three parameters are adjusted: toe-in, wheel camber angle, and the longitudinal inclination of the steering axis.

Camber - alignment - why is the procedure needed?

Before I give you step-by-step instructions, let's figure out what kind of wheel alignment procedure this is, what are the wheel alignment angles of the VAZ 2109 and how does the car's behavior on the road depend on them?

To ensure good stability and controllability of the car, the front wheels are installed at certain angles relative to the body and suspension elements. Three parameters are adjusted: toe-in, wheel camber angle, and the longitudinal inclination of the steering axis.

The casting angle of the steering axis is the angle between the vertical and the line passing through the centers of rotation of the ball joint and the bearing of the telescopic strut support, in a plane parallel to the longitudinal axis of the vehicle. It helps stabilize the steered wheels in the direction of straight motion. This angle depends on the number of adjusting washers at the ends of the extension. To decrease the angle, washers are added, and to increase it, they are removed. When installing/removing one washer, the angle changes by approximately 19′. Symptoms of deviation of the angle from the norm: the car pulls to the side when driving, different forces on the steering wheel in left and right turns, one-sided tread wear.

Wheel camber angle is the angle between the plane of rotation of the wheel and the vertical. It promotes the correct position of the rolling wheel during suspension operation. The angle is adjusted by turning the top bolt securing the telescopic strut to the steering knuckle. If this angle deviates greatly from the norm, the vehicle may deviate from straight-line motion and cause one-sided wear of the tread.

Camber angle of VAZ 2109 wheels

Wheel toe is the angle between the plane of rotation of the wheel and the longitudinal axis of the car. Toe can also be defined as the difference in distances between the flanges of the rims, measured from the rear and front of the wheels at the level of their centers. Wheel toe ensures the correct position of the steered wheels at various vehicle speeds and turning angles.

Wheel alignment VAZ 2109

The toe-in is changed by rotating the adjusting couplings with the locknuts of the tie rod ends loosened. Before adjustment, the steering rack is set to the middle position (steering wheel spokes are horizontal). Signs of toe deviation from the norm: severe saw-tooth wear of tires in the transverse direction (even with small deviations), squealing of tires when cornering, increased fuel consumption due to high rolling resistance of the front wheels (the vehicle's run-out is much less than required).

Castor angle: measurement and adjustment

angle The angle between the vertical and the axis of rotation of the wheel when turning the steering wheel, which ensures automatic alignment of the tires due to movement, is 4º±30′ for a loaded car and 3º±30′ for an unloaded car.

The angle is measured using specialized templates. The parameter is adjusted by rearranging the washers on the bolts that fix the lower arm relative to its axis (located at the ends of the axis). The angle is increased by installing the washer on the bolt located closer to the interior.

Drift

This wheel alignment angle is especially relevant for drifting. The car grips the road better. For drift enthusiasts, the camber should be between -0.5 and -5.5 degrees.

Also, negative camber can be considered optimal for participants in circuit racing. In this case, the negative camber angle of the front axle should be greater than that of the rear axle. This ensures better traction, sharper and more responsive steering.

Adjustment

If the caster angle changes, self-locking nuts M12x1.25 will be needed. VAZ has a suitable article number - 16105011. If the angle is reduced, washers “2108-2904225” (part 24) are also needed. Installing one washer leads to a decrease in caster by 19 arc minutes.

Stretch (saber) and lever

To adjust any parameter, the wheel is hung up and removed. And when adjusting the caster, each of the two wheels is hung in turn. In general, the work ahead is long.

Caster angle

To add or remove washers, you need to remove the stretcher: use a flat 24 wrench to hold the stretcher itself, and use another wrench to unscrew the nut.

Removing suspension braces

Having unscrewed the nuts on both sides, the part cannot be removed immediately. You also need to unscrew the fastening of the lever to the stabilizer link (key “17”). To knock out the mounting pin, use an aluminum spacer.

The maximum number of washers is two in front and four in back (near the fist). Recommended tightening force – 43-52 N*m (stabilizer thrust), 160-176 N*m (stretch).

Camber angle

On all Tens, including the VAZ-2112, the camber is easily adjusted. The upper bolt, which holds the fist, is equipped with an eccentric. The nut on the bolt needs to be loosened and then rotated with a wrench - the camber angle will change.

Adjusting the right wheel camber

Mark the standard position of the adjusting screw cap (Fig. 1). Loosen the nut on the bottom screw. The same must be done with the top screw - do not unscrew the nut completely! After completing the adjustment, tighten the fastener. You need two keys “19” (Fig. 2).

The recommended torque when tightening the nuts is 78-96 N*m.