Drivers often ask questions when the cooling fan turns on on a cold engine. The problem mainly occurs due to certain malfunctions in the cooling system. For example, many cannot understand the reason when the fan starts to turn on on a cold unit.

Timely prevention will help avoid more serious problems. Since if you do not pay special attention and do not repair the fan, then in the future, you can cause the motor to overheat. In frequent cases, the use of an adapter is required to carry out a thorough diagnosis.

By eliminating the main cause, fan short circuits can be avoided. Many experts believe that the process is quite easy, so every person can determine the malfunction of the device in his own garage. This common question plagues many people who are faced with an unpleasant problem. But first, you need to understand the principle of operation of a system that gradually fails.

It is worth noting that the fan is connected using a sensor. This important element is located at the bottom of the radiator. More modern models are equipped with special triggers, which, in turn, pass through the unit control unit.

However, this occurs in rare situations. Therefore, let's consider another option. Complete heating of the coolant reaches at least one hundred degrees. Accordingly, the circuit closes, after which the fan itself turns on. In such a case, you need to look for the cause in breakdowns. Because when the cooling system deteriorates, more serious problems may arise in the future.

Diagnosis and common causes of cooling system problems

Of course, any on-board computer error related to the cooling system will not be eliminated; after eliminating the malfunction, reset the errors from the on-board computer by disconnecting the power terminals from the battery for about 10-15 seconds.

Closing contacts

One of the most common causes of this breakdown is a banal short circuit of the contacts of the coolant temperature sensor. In this case, when the ignition is turned on, the cooling fan turns on, since electric current is constantly supplied to the fan due to a short circuit. The consequence of such a malfunction may be, perhaps, accelerated discharge of the car battery.

We recommend reading an article on the topic: how to extend the life of a car battery. This article talks about the reasons for the short life of the battery, how to actually extend it, as well as the main signs of battery failure.

To diagnose this malfunction, you should disconnect the sensor and use an ohmmeter to measure the resistance at its contacts. If the sensor is working normally, then the resistance will be extremely high (the readings are only nines, which is analogous to “infinite” resistance). If the resistance is low, then the contacts are closed and the sensor must be replaced.

Also similar symptoms include a short circuit of the fan terminals to ground, in which case it will also work constantly as soon as the ignition is turned on. Since the voltage is supplied directly from the battery.

Small amount of antifreeze

Another common problem is too little coolant. It is to its temperature that the DTOZH reacts. With a small amount of antifreeze, the liquid warms up much faster than the engine itself warms up, as a result the fan turns on too early. Add fluid to the required level and, just in case, check for leaks in the cooling system.

Thermostat and its sensors

On some modern cars, the cooling system is equipped with thermostats with sensors that regulate the operation of the cooling system more efficiently. However, this design is more complex in structure than a conventional one, and due to its complexity it is susceptible to various problems. If the operation of a specific sensor that is connected to the thermostat is disrupted. Or the cooling control system does not receive data from the thermostat sensors, then, as a rule, it “goes into protection”, turning on the fan for constant operation. Checking these sensors is, in principle, similar to checking the contacts of a conventional DTOZH. We measure the resistance, and if it is low, then the sensor should be changed.

Oxidation of contacts

It is worth noting that the ECU can also “go into protection” in cases where the fan is controlled through the on-board computer itself. The reason for this may be problems with contacts. As a rule, contacts tend to oxidize over time, which greatly complicates the transmission of signals from sensors to the ECU. And if the required signal does not pass through at all, then in this case the control unit forcibly turns on the cooling fan, regardless of the engine temperature.

To eliminate it, you just need to clean the contacts and coat them with insulating grease to prevent the spread of corrosion. By the way, this procedure is recommended to be carried out 2 times a year to avoid unpleasant situations at the most inopportune moment.

Let's watch the video, the reason for the periodic switching on of the fan on a cold engine (Mazda 6 car):

Problems with the air conditioning system

On some vehicles, the air conditioning radiator is directly connected to the engine cooling system. And when the radiator of the air conditioning system becomes clogged, the operation of two systems at once is disrupted. Although the fan does not turn on immediately in this case, this problem can lead to much more serious consequences, including engine overheating.

To fix it, you need to clean the radiator, or preferably two at once. For more productive operation of these two interconnected systems.

That's all we wanted to say on this issue. In fact, this is not the worst malfunction, but if ignored for a long time, it is fraught with certain consequences. Therefore, you shouldn’t delay repairs either, and if the engine cooling fan turns on when you turn on the ignition, it is recommended to carefully check the cooling system for problems and fix the breakdown as soon as possible.

The fan runs on a cold motor: causes, diagnosis, repair

Let's start with the fact that this problem can clearly indicate both a malfunction of the liquid cooling system and a malfunction of the fan itself. In any case, we are talking about a breakdown that cannot be ignored, since the risk of overheating of the internal combustion engine significantly increases.

For a better understanding, it is necessary to superficially consider the principle of operation of the fan on most modern cars. The airflow is activated by a special sensor located at the bottom of the radiator. Also, many cars use a separate engine cooling fan control unit. There are also models in which the ECU itself is responsible for turning on the fan, but this design is rarely used.

So, after heating the coolant to an average temperature of about 100 degrees Celsius, the sensor or control unit closes the electrical circuit. After this, the fan turns on, improving engine cooling. When the coolant temperature drops to the required value, the circuit opens and the blowing stops.

As you can see, the fan should not work on a cold engine. So, to determine why the fan turns on early, for injection cars with an OBD II diagnostic connector, it is recommended to start with computer diagnostics of the car. The fact is that the ability to read error codes from the ECU allows you to more accurately determine the cause of the malfunction.

We also note that in cases where the control unit detects errors in the cooling system, the fan can spin immediately after turning on the ignition, even on a cold internal combustion engine. This feature is found only on some models and is, in fact, protection against overheating of the power unit, since a constantly running fan reduces the temperature.

After repair, in this case you will also need to reset the errors. To erase an error from the ECU, on some models it is enough to remove the terminal from the battery for a couple of minutes, while on others the reset is carried out using diagnostic equipment.

Common cooling fan problems

Now let's look at common problems that are associated with the cooling system and the fan itself.

- First of all, in many cases the contacts of the air system sensor short-circuit. In this case, the air blower is activated immediately after the ignition is turned on.

During the diagnostic process, the resistance at the outputs is measured on a cold sensor using a multimeter. Deviations from the norm will indicate the need to replace the element.

- There is not enough coolant in the liquid system. In this case, the fan is triggered due to the fact that a small amount of antifreeze or antifreeze heats up very quickly. In other words, the fan is working properly and starts naturally.

As a rule, leaks or decreased coolant levels in the expansion tank are the main cause. Please note that antifreeze is a mixture of concentrate and water. Water gradually evaporates from the system, causing the level to drop. For this reason, it is recommended to periodically check and add fluid according to special marks.

If there is little coolant in the system, heating occurs quickly. It is also noteworthy that the actual temperature of the liquid is very different from the temperature of the internal combustion engine. It often happens that a cold engine is started, the temperature arrow on the dashboard has not yet risen, but the fan is already working because the liquid is too hot. To solve the problem, it will be enough to fill in antifreeze and remove air plugs from the cooling system.

- The fan shorts to ground because the wire may not be screwed securely enough, the contact point has been damaged, etc.

In this case, the fan can short-circuit to the battery and run non-stop. In such a situation, you need to check all contacts, wiring and other elements. Wires must be securely insulated and properly connected.

- The fan sensor, which is integrated into the thermostat housing, has failed. Quite a lot of modern cars are designed with a thermostat, which is combined with a fan control sensor.

This solution allows for flexible control of the engine cooling system. However, if there is a problem with the temperature sensor in the thermostat housing, the fan may start running without turning off. The fact is that the control unit begins to receive incorrect signals about how the thermostat works. As a result, the emergency mode is activated, the fan turns on and runs constantly.

In such a situation, you need to check the sensor with a multimeter. Normally, on a cold engine its resistance is infinite, in other cases the indicator should be 100 - 500 Ohms. Deviations in the readings from the norm will indicate that the sensor needs to be replaced with a new one or a known good one.

- The outside air temperature sensor has failed. This problem occurs on some cars that are equipped with ambient temperature sensors. If the temperature is above the permissible limit, then these sensors will turn on the fan.

This solution allows for more efficient cooling of the power unit, especially on cars that have a powerful forced-internal combustion engine and several radiators. On such units, the fan can be turned on in the warm season even on a cold internal combustion engine to protect against engine overheating.

- After turning on the car air conditioner, the fan is constantly running. Note that on some models this fan operation is normal.

If we talk about malfunctions, on most modern cars the cooling system is closely connected with the air conditioning system. It is for this reason that contamination of the air conditioner radiator can cause the engine cooling fan to constantly operate at maximum speed.

To solve the problem, external cleaning of the air conditioner radiator and cooling system radiator may be required. The fact is that these radiators are located next to each other, dirt, dust and fluff accumulate between them. Removing such a “coat” allows you to normalize the operation of the air conditioning and engine cooling system, get rid of frequent fan starts and increased noise during its operation.

- Problems with wiring and electrical contacts. Regardless of how the fan is controlled, contacts are a common cause of problems.

Oxidation of contacts or damage to wiring, insufficient fixation at connections and other defects lead to short circuits, transmission of incorrect signals to control units, etc. As a result, the overheating protection mode is activated by constantly rotating the fan, etc.

In order to avoid such a situation, experienced drivers recommend cleaning contacts before the onset of winter and summer for preventive purposes. Treatment with special lubricants and protective compounds is also actively practiced.

DVV

Sensors turn on

The fan switching sensor (FSW) occupies not the last place in the internal combustion engine cooling system. He is responsible for engaging the fans installed on the radiator and activated when the coolant temperature increases and standard cooling for the engine is clearly not enough.

If the DVV is connected directly to the ignition, and not to the relay, then it is recommended to carry out a different circuit by replacing the sensor. A sensor connected directly to the ignition may not work correctly. On some car models it is integrated with a relay, which looks noticeably more reliable.

The diagram looks like this in this case:

- The minus of the fan is connected directly from the battery, the plus - from the battery through a relay (it is also possible to connect the plus directly from the ignition);

- The sensor is also integrated with the relay on one side, and with the ground (any part of the car body) on the other.

Obviously, if the sensor is responsible for turning on the fan on the car, then untimely activation of the system may well be caused by damage to the element. Let's look at what the sensor consists of.

Both fans turn on when the ignition is turned on

Its device is simple. A bimetallic strip is installed at the bottom of the sensor. It is made so that when the coolant temperature increases, it deforms and thereby affects the contacts of the device.

Regarding the sensor connection circuit:

- Until the coolant heats up, the sensor plate is level and does not move;

- As soon as the coolant temperature increases (reaches a certain level), the plate is deformed and the contacts close.

It is noteworthy that on different car models the DVVs are set to one or another activation temperature.

There are two types of DVVs: those designed for 1 rotation speed and models designed for 2 rotation speeds.

The fan runs when the ignition is turned on.

As a rule, all modern cars are equipped with DVV with a 1-speed activation system, although 2-speed sensors are not uncommon. It will be interesting to note that on such a DVV, when a certain degree level is reached, the fan turns on to the first rotation speed. The second speed is activated and the fan speed increases accordingly when the coolant temperature continues to rise.

Damage to the engine is not only problems when turning on the ignition, but also overheating of the engine and other unpleasant moments. For this reason, first of all, if the fan turns on when you turn on the ignition, you should test the functionality of the sensor.

You can test the functioning of the DVV yourself. To do this, you need to hang the removed sensor over a pan filled with water. Connect the DVV in advance with two wires to a continuity tester (multimeter).

Attention. The metal part of the DVV should be immersed in water. In addition, the sensor should not come into direct contact with the pan.

The DVV should be triggered when the water in the pan heats up. It is recommended to study the technical specifications of the DVV in advance in order to properly test the sensor. For example, some of them are designed to turn on after 93 degrees Celsius, others - after 100 degrees, etc.

Cooling fan VAZ 2107

In the power plants of the first "sevens" the radiator fan was installed directly on the water pump shaft. Like the pump, it was driven by a belt drive from the crankshaft pulley. This design was also used on other cars at that time. It almost never failed, and it was impossible to overheat the engine with it. However, she had one drawback. The constantly cooled power unit warmed up very slowly. That is why AvtoVAZ designers changed the principle of forced airflow, replacing the mechanical fan with an electric one, and with automatic activation.

Early modifications of the VAZ 2107 had a mechanically driven fan

Why do you need an electric fan?

The fan is designed for forced airflow of the cooling radiator. During operation of the power plant, liquid coolant enters the radiator through the opened thermostat. Passing through its tubes equipped with thin plates (lamellas), the refrigerant cools due to the heat exchange process.

Later modifications of the Sevens were equipped with electric cooling fans

When a car moves at speed, heat transfer is facilitated by the oncoming air flow, but if the car sits for a long time or drives slowly, the coolant does not have time to cool. At such moments, it is the electric fan that saves the engine from overheating.

Device design

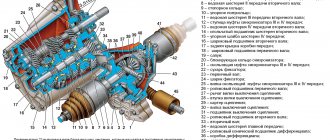

The radiator fan consists of three main elements:

- DC motor;

- impellers;

- framework. The fan consists of an electric motor, impeller and frame

The electric motor rotor is equipped with a plastic impeller. It is she who, rotating, creates a directed air flow. The engine of the device is installed in a metal frame, with which it is attached to the radiator housing.

How does an electric fan turn on and work?

The process of turning on the fan for carburetor and injection “sevens” is different. For the former, its activation is controlled by a mechanical temperature sensor mounted in the lower part of the right cooling radiator tank. When the engine is cold, the sensor contacts are open. When the temperature of the refrigerant rises to a certain level, its contacts close and voltage begins to be supplied to the brushes of the electric motor. The fan will continue to operate until the coolant cools down and the sensor contacts open.

The device circuit is closed via a sensor that responds to changes in refrigerant temperature

In injection “sevens” the electric fan switching circuit is different. Everything here is controlled by an electronic control unit. The initial signal for the ECU is information coming from a sensor installed in the pipe leaving the engine (near the thermostat). Having received such a signal, the electronic unit processes it and sends a command to the relay responsible for turning on the fan motor. It completes the circuit and supplies electricity to the electric motor. The device will continue to operate until the refrigerant temperature drops.

In injection "sevens" the fan is turned on by command from the ECU

In both carburetor and injection "sevens", the electric fan circuit is protected using a separate fuse.

What to do if the cooling fan operates on a cold engine

Drivers often ask questions when the cooling fan turns on on a cold engine. The problem mainly occurs due to certain malfunctions in the cooling system. For example, many cannot understand the reason when the fan starts to turn on on a cold unit.

Timely prevention will help avoid more serious problems. Since if you do not pay special attention and do not repair the fan, then in the future, you can cause the motor to overheat. In frequent cases, the use of an adapter is required to carry out a thorough diagnosis.

By eliminating the main cause, fan short circuits can be avoided. Many experts believe that the process is quite easy, so every person can determine the malfunction of the device in his own garage. This common question plagues many people who are faced with an unpleasant problem. But first, you need to understand the principle of operation of a system that gradually fails.

It is worth noting that the fan is connected using a sensor. This important element is located at the bottom of the radiator. More modern models are equipped with special triggers, which, in turn, pass through the unit control unit.

However, this occurs in rare situations. Therefore, let's consider another option. Complete heating of the coolant reaches at least one hundred degrees. Accordingly, the circuit closes, after which the fan itself turns on. In such a case, you need to look for the cause in breakdowns. Because when the cooling system deteriorates, more serious problems may arise in the future.

What to do if the radiator cooling fan runs constantly

Another problem that can arise with the radiator cooling fan is its constant operation. If the electric motor does not turn off or turns on too early, when the coolant temperature is still far from the critical zone, it is necessary to determine the cause of such a malfunction and eliminate it.

Running the radiator cooling fan without stopping may be associated with the following problems:

It is worth noting that constant operation of the cooling fan is not as dangerous as its complete failure, but not in a situation where the problem is associated with a stuck thermostat and overheating of the engine.

Cooling fan

Before we talk about troubleshooting, we should say a few words about the cooling fan itself. It serves to create a flow of air directed towards the radiator and serves to cool the latter. The fan turns on automatically when the temperature sensor located under the radiator is triggered.

When the coolant reaches a temperature of 100-105 C, the sensor closes and starts the rotation of the fan, which blows over the radiator and cools it. As you can see from this, normal fan activation is only possible when the engine is fully warmed up, and starting it when the engine is cold indicates obvious problems in the system.

Operation of the VAZ 2114 cooling system

Why is the cooling fan constantly running?

If the engine fan runs constantly, there may be 7 reasons for this.

Coolant temperature sensor

- Failure of the coolant temperature sensor or damage to its wiring . If incorrect information is sent from the sensor to the ECU (high or low signal, its absence, short circuit), then errors are generated in the ECU, as a result of which the control unit puts the engine into emergency mode, in which the fan “threshes” constantly to prevent overheating engine. You can tell that this is the problem by the difficulty of starting the engine when it is not yet warmed up.

- Shorting the wires to ground . Often the fan runs constantly if its negative wire is frayed. Depending on the engine design, this may be in different places. If the design of the engine provides for two DTOZH, then if the “minus” of the first sensor breaks, the fan will “thresh” when the ignition is on. If the insulation of the wires of the second DTOZH is damaged, the fan runs constantly when the engine is running.

- Faulty fan relay . For most cars, the fan power supply consists of “plus” from the relay and “minus” from the ECU according to the temperature from the DTOZH. “Plus” is supplied constantly, and “minus” is supplied when the antifreeze operating temperature is reached.

- "Glitches" of the electronic control unit . In turn, incorrect operation of the ECU can be caused by a failure in its software (for example, after flashing) or when moisture gets inside its housing. The moisture could be banal antifreeze that got into the ECU (relevant for Chevrolet Cruze cars, when antifreeze gets into the ECU through a torn throttle valve heating tube, it is located near the ECU).

- Dirty radiator . This applies to both the main radiator and the air conditioner radiator. In this case, the fan often runs constantly when the air conditioner is on.

- Freon pressure sensor in the air conditioner . If it fails and if there is a refrigerant leak, the system “sees” that the radiator is overheating and tries to cool it using a constantly turned on fan. Some car enthusiasts have a cooling fan that constantly runs when the air conditioner is turned on. In fact, this should not be the case, since this indicates either a clogged (dirty) radiator or a problem with the freon pressure sensor (freon leak).

- Low efficiency of the cooling system . Failures may be associated with a low coolant level, a coolant leak, a faulty thermostat, a pump failure, or a depressurized radiator cap or expansion tank. With this problem, the fan may not work constantly, but for a long time or turn on frequently.

Why does the cooling fan turn on?

HomeVAZ 2110Why the cooling fan turns on

The cooling system is extremely important for stable engine operation. Antifreeze circulates through its tubes, which takes part of the heat and, when passing a large or small circle, releases it into the atmosphere.

A LITTLE ABOUT THE ENGINE COOLING SYSTEM

To understand the role of the fan in the engine cooling system, it is necessary to consider in detail how this system works. It consists of many interconnected elements, such as a radiator, thermostat, expansion tank, and so on. But the main role in the overall structure, of course, is played by the coolant jacket. Imagine that there are small grooves on the sides of car cylinders. They contain antifreeze. It absorbs most of the heat as the piston rises and falls. So that the engine cooling process does not stop for a moment while driving, antifreeze constantly circulates through the system. If its temperature is below 80 degrees, then it goes in the inner circle, but as soon as this temperature line is crossed, everything changes radically. The coolant is directed to a large circle through a valve, which is also a thermostat. When passing a large circle, the coolant enters the honeycomb radiators. It is opposite this part that the engine cooling system fan is installed. As soon as the need arises, it is activated and helps the heat dissipate into the atmosphere. Important! The honeycombs are also blown with a counter flow of air. After the antifreeze passes through the honeycomb radiators cooled by the engine fan, it will again enter the cylinder grooves, but its temperature will be much lower. This process is not interrupted for a single moment while the car is moving.

WHAT ARE THE FANS?

The automotive industry is constantly evolving. Scientists are inventing new technologies that make it possible to achieve much greater productivity. It is not surprising that there are many fans that are installed in engine cooling systems. However, in a fiercely competitive environment, only the strongest of hundreds of possible types survive. After more than a hundred years of continuous competition, only two of the most productive designs remain: mechanical and electrical. The first type of engine cooling fans is driven by torque, which is transmitted from the crankshaft through a pulley. This is the design that has dominated the market for the last 20 years. But recently she has had a serious competitor.

An electrically driven cooling fan is superior to its mechanical opponent in many respects. It consists of a control unit and a motor, which operates from the vehicle’s on-board network.

Attention! The electric cooling fan is activated by the command of the temperature sensor, or more precisely, by its readings. Before we begin to explain the operating principle of the engine cooling fan, it is necessary to delve a little deeper into the typification. Of course, all fans are divided into mechanical and electrical, but they can also be classified depending on the control system. Naturally, this affects the operating principle in a certain way. Cooling system fans are divided into the following types:

- with thermal switch,

- with viscous coupling,

- with control unit.

Nowadays, there are practically no cooling systems left in automobiles in which one could find a fan with a viscous coupling. Nevertheless, such structures are still installed on SUVs. This is explained by the longitudinal arrangement of the engine, but not only. The main advantage of a viscous coupling is its tightness. As a result, a car with such cooling can cross rivers and small bodies of water without the slightest difficulty.

Attention! Conventional electric cooling fans in engines immediately break down upon contact with water.

This is due to the operating characteristics of the engine cooling fan. The viscous coupling is sealed. Therefore, water cannot harm her. Electric fans become unusable during such tests.

OPERATING PRINCIPLE AND DEVICE

The viscous coupling is filled with silicone-based oil. Under the influence of temperature, its properties change. The greater the heating, the higher the rotation speed of the engine cooling fan. A viscous coupling consists of the following structural elements: The design of an electric fan is slightly different. Firstly, there is an electric motor that drives the device. Secondly, the engine cooling fan control unit is responsible for selecting the operating mode and rotation intensity. The design also includes elements such as a temperature sensor and a relay. Attention! The most modern electric engine cooling fans have several sensors.

One sensor is mounted in the thermostat housing. Some manufacturers install it in the pipe at the outlet of the engine. The second device is located on the pipe that comes out of the radiator. Based on the difference in readings, the control unit selects the intensity of the device.

In those days when electronics had not yet reached such a level of development, other methods were used to control the operation of the device. There were so-called thermal switches. They were the ones responsible for activation. The operating principle of devices that work with thermal switches is quite simple. The signal from the sensor is transmitted to a scale located in the cabin. It is on its readings that the mechanism is guided when it is necessary to change the rotation speed.

As soon as the antifreeze temperature exceeds the standards set by the manufacturer, the contacts inside the thermal switch close. They, in turn, have direct power supply to the unit. After this, voltage begins to flow to the electric motor. As a result, the impeller rotates.

Attention! When the liquid temperature normalizes, the contacts open and the device stops working.

WHY DOES THE FAN TURN ON WHEN THE ENGINE IS TURNED OFF AND OTHER PROBLEMS

Typically, such a defect indicates that the temperature sensor has stopped functioning. But in order to draw any specific conclusion, a more complete diagnosis will be needed. Attention! In most cases, if the cavities of the device rotate constantly. This means that the fault lies in the power sensor. But when diagnosing, you must take into account that the cause of the fan failure may lie in something else.

To carry out initial diagnostics, remove the plug connector. It is located on the temperature sensor. Then check the condition of the terminals by shorting them. For this you will need a piece of wire.

In a double temperature sensor, you first need to short-circuit the red-white and red cables, then the red and black ones. In the first case, the impeller will rotate slowly, and in the second, quickly. If nothing happens, the fan needs to be replaced.

RESULTS

The fan is an important device for ensuring normal operation of the motor. It helps the structure to cool efficiently even at maximum engine speeds. Devices with electronic control units are becoming increasingly popular.

Fan diagnostic method

Experts say that injection cars are considered the most practical. They can be diagnosed much faster than all others. It is advisable to use computer diagnostics to thoroughly investigate the cause of all malfunctions. Some models, when making errors, immediately show a constantly spinning fan. This helps protect against overheating.

To reset errors, you need to remove the terminal from the battery for a few seconds. After the system is cleaned, everything returns to normal.

DD or pressure sensor

You should be aware that on some cars where the air conditioning is turned on, 2 sensors are used in the fan activation circuit. One of them is the DVV, but it is more correct to call it a temperature sensor, because it turns on the fan based on the temperature readings.

The second sensor is a pressure regulator or pressure regulator. If the DVV is in front of the thermostat, then the DD is in the air conditioning system on the high pressure line. It operates and is activated exclusively by pressure up to 15 bar. Accordingly, if the pressure rises above this value, an additional car fan turns on.

Why does the fan turn on when the ignition is turned on?

Thus, if the air conditioner or fan turns on when you turn on the ignition, this may indicate a failure of the pressure sensor.

It is also likely that the chip was disconnected. This often happens by accident, due to the fact that in some cases the DD is placed near the battery, next to the filling channels.

Closes the sensor

In frequent cases, the fan operates immediately after the ignitor is turned on. This occurs during the process of closing the sensor contact. In this way, it is possible to ensure the constant operation of the blowing object. This method is considered the most harmless in the process of observing breakdowns. If the ignition is in the on mode, this will lead to battery discharge.

To carry out a thorough check, it is necessary to install a cold sensor and measure the resistance at the terminals. If the sensor is working properly, then the resistance indicator will show the process progressing to infinity. With less resistance, the contacts close.

Accordingly, to ensure performance, you will need to change the product. A thorough diagnosis will immediately indicate the presence of breakdowns using a special code. That is, when the sensor turns on, it is possible to determine the indicator.

Sensor short circuit

Often, the fan starts to operate simultaneously with the ignition being turned on, this is due to the closure of the sensor contacts. Which leads to constant operation of the blower. Perhaps this is the most harmless type of breakdown. The only thing that threatens you is the battery draining if you leave the ignition on for a while.

To check, you need to measure the resistance at the terminals on a cold sensor. On a working sensor, the resistance should tend to infinity. If the multimeter shows the presence of less resistance, then this is definitely a shorted contact. Feel free to change it. When conducting diagnostics, this breakdown is always marked with a separate code.

Lack of fluid in the unit

The sensor partially fails with the smallest amount of liquid. Even in the presence of antifreeze, the sensor immediately warms up. This process can disrupt the entire function of the system and cause many problems. Such a malfunction is characterized by a banal oversight.

With careful monitoring, you can get rid of serious problems and breakdowns. To do this, you need to check the amount of liquid. Since during evaporation there is no liquid in the radiator

If there is a small amount of liquid, the temperature reaches the unit temperature. For example, if you start the engine, it will not be completely heated, but the fan will immediately cool down. This process occurs due to the fact that the liquid heats up very quickly in the unit. Problems can be resolved in the simplest way. By adding a little antifreeze, you can avoid air locks in the system.

When is it advisable to repair it yourself and in the service?

If your car has problems with the electric fan of the cooling system, you can fix the problem in the sequence described above. Almost any repair can be done by yourself. Since the main problems come down to faulty sensors, replacing them will not be difficult. It is enough to dismantle the faulty part and install a new one in its place. If the problem lies in bad contacts, then they can be cleaned or, as a last resort, the connectors can be replaced. If you are not confident in your abilities, then in order to avoid new problems it is better to contact the service.

Video: solving the problem of a constantly running fan

To decide whether to carry out independent repairs in case of problems with the cooling fan or seek outside help, you can familiarize yourself with the approximate prices for a particular operation.

Table: cost of repairing the cooling system with your own hands and in the service

Constant rotation of the cooling fan on a cold engine is not normal. Therefore, you should deal with the malfunction that has arisen, find and eliminate the cause of its occurrence in order to prevent rapid wear of the device. Diagnostics consists of checking the coolant level, as well as the elements responsible for the operation of the electric fan, which every car owner can do.

Cooling Fan VAZ 2107 Injector Doesn't Work

Wiring diagram VAZ 2107 - injector: conversion from classics

The cars of the VAZ family have served their owners for many years. But, during use, there is rarely an option to provide the car with unique spare parts, since the automaker has modified that other unit.

And the owners are required to disassemble and install new components in the car without the help of others.

- Wiring 2107 with carburetor power system

- Namely, the carburetor version has not been produced for several years - the Gorky Automobile Plant has switched to producing cars equipped with a fuel injection system (injector).

- There is an option to make a replacement yourself, but with all this you need to stock up on new parts, the cost of which is not very high.

For reference: injector

(from English - injection) is a system of nozzles that mix fuel with air according to signals from the electrical controller of the engine control system (ECM).

What is required for modernization

Modern injection systems

fuel pumps operate according to a pre-programmed operating method:

- The electrical system takes into account the readings of numerous sensors;

- Based on them, it selects the best mode;

- Provides separate signals to each injector.

Engine compartment wiring diagram for VAZ 2107 with injector

Fan VAZ 2110 injector 8 does not work

Why, when converting a traditional VAZ 2107 car yourself, you will need to purchase new parts.

- New crankshaft pulley;

- Front motor cover with casting for sensor installation;

- Antifreeze temperature and crankshaft position sensors;

- 2107

wiring for the injector; - Specifically the injector

; - Electric

cooling

fan

. _

The cooling system fan does not turn on on a fuel-injected car. What is the reason

How to find the right video. about it here Support the project! MAP.

For reference: there are special marks on the pulley for reading by the sensor. And forced airflow of the radiator after replacing the pulley will be impossible - so an electric fan is installed instead.

In addition, you will also need a visual aid to carry out work on converting a car to a fuel injection system.

Tip: On auto forums dedicated to car modifications, photo and video materials are available, which it is advisable to view before starting work.

What to do

In fact, the car conversion work will take you no more than 3-4 hours.

The algorithm will be as follows:

- Dismantling of old equipment;

- Sub-assembly of components before installation;

- Direct installation and debugging of the injection system.

Dismantling work

Perform operations in strict sequence:

- Disconnect the battery and remove it from the car;

- Drain the coolant from the system;

- Disconnect the fuel hose from the carburetor and turn it off, preventing gasoline from leaking out;

- Disconnect the air filter housing;

- We dismantle the carburetor;

- Loosen the exhaust pipe clamp and unscrew the exhaust manifold;

- Remove the intake manifold;

- We unscrew the front cover of the engine, freeing access to the crankshaft pulley;

- Remove the radiator fan.

Sub-assembly work

At this stage, the electrical wiring of the VAZ 2107 to the injector will be affected, since we have to:

- Secure the ECM;

- Add new wires with connection terminals to the standard wiring;

- Route the wiring to the cooling radiator;

- Route the wiring to the electric fuel pump.

Tip: wiring 2107 for injection modifications is sold separately. Those. you can purchase either all the wiring for the car, or the missing elements to connect the injection system.

Instructions for the stages of subassembly of the main components of the injection injection system

VAZ 2107 injector cooling fan does not work

- Connect the controller using terminal blocks;

- Connect the wires to the injectors;

- Connect the wiring to the electric fan;

- Install and connect the battery.

conclusions

Converting a car from a carburetor power system to an injection system is available to most car owners who have experience in servicing the power unit

It is only important to comply with safety requirements, since you have to work with gasoline and electricity

Confinement of mass

The functioning of the fan depends on different methods, as you have already seen from reading this article. There is another reason that disables the fan's performance. For example, if the corresponding wires are poorly screwed to the body, the fan is connected directly to the battery. It should be noted that in this case, it is necessary to take timely measures to avoid serious problems.

With this option, you can expect the car to catch fire. If a strong short circuit occurs, then all the wires will heat up accordingly. To avoid serious consequences, you should check the connections and wires that have access to the sensor. Reliable fastening of wires and intact insulation reduces the risk of serious consequences.

Thermostat problem

Every modern car is equipped with a thermostat with a sensor. This invention promotes efficient control of a cooling system. However, there are certain disadvantages here. If a malfunction is observed in the thermostat, the fan will function without fail.

The device can be checked using special equipment. When the unit is cold, the resistance should show infinity.

Now, you know why problems occur in the engine and how to properly diagnose it to ensure that the device operates in the correct mode.

Source

What to do when turning on the cooling fan on a cold engine

Sometimes car owners are faced with a situation when the cooling system fan turns on and starts working when the engine is cold. Although, under normal operating conditions of this element, it must be activated only when the temperature of the internal combustion engine reaches certain values.

There are many reasons why this situation occurs on modern cars. Some of them can lead to serious negative consequences if measures are not taken in time to eliminate the causes and provoking factors.

To understand the situation, you need to find out the reasons for turning on the fan, understand its operation and find the best methods to solve the problem.

Turning on the fan on a cold engine.

- Log in to reply to this topic

#1 EKU

- Users

- 1,696 messages

- From: Khanty-Mansi Autonomous Okrug, Nefteyugansk

- Car: was: Peugeot 508 1.6 THP 150 hp. Active White (Blanc Banquise), now: MAZDA CX-5 2.5 SkyActiv 194 hp AWD 6AT Supreme Eternal Blue

- Top

#2 Konstantin

Dear Chairman of KOLHOZa

- From: Moscow, North-Eastern Administrative District

- Car: Peugeot 508 2.0 HDi Allure – Brun Guaranja

EKU said:

American forum: You ask a question, then they answer you. Israeli forum: You ask a question, then they ask you a question. Russian forum: You ask a question, then they tell you for a long time what a #assass you are.

- Top

#3 EKU

- From: Khanty-Mansi Autonomous Okrug, Nefteyugansk

- Car: was: Peugeot 508 1.6 THP 150 hp. Active White (Blanc Banquise), now: MAZDA CX-5 2.5 SkyActiv 194 hp AWD 6AT Supreme Eternal Blue

Konstantin (05 January 2014 - 17:40) wrote:

- Top

#4 Watch

- From: Perm city

- Car: Peugeot 508 Allure 1.6 THP

EKU (05 January 2014 - 16:36) wrote:

- Top

#5 Walkman

- From: KHMAO

- Car: 508 alloy, 1.6 petrol

- Top

#6 Walkman

- From: KHMAO

- Car: 508 alloy, 1.6 petrol

- Top

#7 valery

Wisdom is when you understand everything, but are no longer upset.

- From: Moscow

- Car: no

Post edited by valery: 08 January 2014 - 09:33

- Top

#8 Listik

- From: Kyiv

- Car: 1.6 THP

- Top