The engine coolant temperature sensor (ECT) is a temperature sensor in a car engine that detects and measures the engine temperature. The information received from the coolant temperature sensor is then used to regulate the vehicle's engine temperature.

The principle of operation of the sensor is as follows. The coolant temperature (ECT) sensor is often located near the vehicle's engine thermostat so that it can operate at its optimal level. The tip of the coolant temperature sensor is usually located near the engine coolant.

This temperature sensor works by measuring the temperature that the thermostat or coolant emits. The temperature that the sensor reads is then sent to the on-board computer or engine management system as a signal. The engine management system then uses the information received from the coolant temperature sensor to operate or adjust certain engine functions so that it operates at its optimal level.

In addition to regulating engine temperature by turning the cooling fan on and off, information received from the temperature sensor is also used to determine if the engine needs a richer fuel mixture to override the oxygen sensor rich/lean feedback signal to open EGR or limit the progress of the spark during ejection.

Checking the coolant temperature sensor

A common test is done to check if the coolant temperature is working accurately. For diagnostics, the ignition is turned off and the coolant temperature sensor connector is disconnected. An ohmmeter (an electrical instrument for measuring electrical resistance) is connected to the sensor terminal.

The sensor can also be completely removed from the engine and immersed together with the thermometer in a container filled with water. When heating water in a container, the sensor will exhibit particular resistance to temperature changes. It is recommended to replace the sensor if it does not show some resistance to changing temperatures.

Another approach to measuring the coolant temperature sensor is to remove the radiator cap (part of the vehicle's cooling system) and insert a thermometer into the radiator and then start the engine. When the engine is running, the coolant begins to heat up, and as soon as the temperature reaches 97 ° C, the fan starts working. If the fan still does not turn on, the sensor requires a full check. To check the sensor:

- coolant is drained from the engine,

- the ignition coil is removed,

- the electrical connector is disconnected from the sensor and then the sensor is immersed along with a thermometer in a container (connected to an ohmmeter) to measure the electrical resistance of that sensor at various temperature levels (as discussed earlier).

Measuring the change in resistance is one method of determining the specificity of the coolant temperature sensor. It is also possible to measure the voltage drop across the sensor terminals while the engine is running.

Where installed

The sensor is screwed into one of the channels of the cooling system and immersed in coolant.

Many cars have more than one coolant temperature sensor. In most vehicles, the primary DTS (ECT sensor 1) is installed next to the thermostat in the cylinder head, block or on the thermostat housing. The second sensor can be installed in another part of the engine or in the radiator.

Some vehicles use a cylinder head temperature sensor or CHT sensor instead of or in addition to the DTS. The CHT sensor works the same way, but it measures the metal temperature of the cylinder head and is not immersed in coolant.

This allows the CHT sensor to correctly measure engine temperature even when coolant is lost. This may help prevent overheating.

What to do when the temperature sensor does not work

As with any other component in your vehicle, the sensor can fail over time. This can cause a number of problems, including engine overheating.

If you know where the engine sensor is and what it looks like, you can do a visual inspection to determine if it is cracked. While this visual check can be helpful, it will not help you diagnose every possible problem, as some sensor faults may not be visually confirmed.

Generally speaking, if your sensor isn't working, it will send a signal to the computer and the Check Engine light will come on. If you see the check engine light illuminated, it is best to contact vehicle service immediately.

Replacing the coolant temperature sensor

The coolant temperature sensor can age and deteriorate over time, so it is important to know how to replace a faulty temperature sensor. CTS replacement is often recommended when rebuilding an engine or when it has suffered engine damage.

The engine must cool before replacing the sensor. The coolant in the cooling system must be drained before replacing the coolant temperature sensor. However, do not drain the radiator. It is enough to drain only a little coolant. Open the valve to drain the antifreeze.

After draining the coolant, replace the old sensor with a new coolant temperature sensor. It is important to remember to fill the radiator with coolant.

You can watch the video in more detail:

Do I need to change the DTOZ when replacing the thermostat?

No, this is not necessary. However, there are intermittent faults related to engine temperature control, and it is difficult to determine whether the cause is the thermostat or the coolant temperature sensor.

In this case, usually both are replaced at the same time. In some vehicles, the control unit must be reprogrammed in the event of a malfunction related to engine temperature control.

Previous post Canister purge valve - how it works, problems, symptoms, check

Next entry Crankshaft position sensor - how it works, problems, symptoms, check

Where is the temperature sensor located?

The engine coolant temperature sensor is located primarily in the coolant passage of a liquid-cooled engine; usually near the thermostat valve. The engine temperature sensor connects to either the temperature gauge or the temperature indicator on the dashboard. In modern cars, you will notice that there is no separate engine temperature sensor. Instead, there is a tiny "light" to symbolize engine temperature; which is integrated with an rpm meter.

After turning on the ignition, the letter “C” also lights up along with the temperature symbol; indicating that the engine is cold. This should automatically disappear; after the engine warms up to the optimal temperature (usually within 2-3 kilometers from the start of movement).

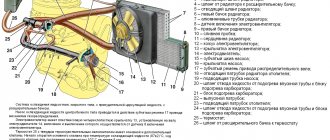

Temperature sensor connection diagram

How does the engine temperature sensor work?

An engine temperature sensor provides early warning of engine overheating, allowing the driver to stop and turn off the vehicle before damage occurs due to overheating. In very cold weather, the temperature sensor can also tell you if the engine has not yet warmed up, and driving an unheated engine is also very harmful for it.

The sensors show the current engine temperature using a special indicator that gradually rises when you turn on the ignition. The sensor unit allows the current to change its value depending on the engine temperature due to the heating coil inside the sensor. A bimetallic strip inside the coil rotates by an amount depending on the amount of current and deflects the pointer along a calibrated dial to give the driver a relatively accurate reading of engine temperature.

A temperature measurement system typically consists of two elements: the sensor itself and the sensor unit, which controls the sensor by connecting to it with a wire.

Types of temperature sensors

There are two main types of engine temperature sensor mechanisms:

- magnetic sensors

- bimetallic sensors

We have selected something even more interesting for you: Where is the temperature sensor located and how does it work?

You can tell which type of the two is in your car by how it reacts when you turn on the ignition. In the case of magnetic sensors, the pointer immediately gives temperature readings, but bimetallic sensors slowly push the needle to read after turning on the ignition.

Engine temperature sensors are built into the vehicle's dashboard housing. The sensor block, however, may be in one of the following several locations:

- thermostat housing,

- cylinder head

- upper radiator hose.

In some cases, the sensor may be in other places, but in all cases the sensor is located on the coolant flow line at the engine outlet.

Magnetic sensors

Magnetic gauges, also called moving gauges, are a pair of coils, one on each side of the rotary iron armature, that hold and control the indicator needle. The coils are connected directly to the car's electrical network - one of them is in direct contact with the engine body, and the other is supplied with current from a sensor, the resistance of which changes depending on the engine temperature. The current flowing through the coils creates a magnetic field that moves the pointer in one direction or another. The amount of movement depends on the difference in the magnetic fields created by the two coils. This difference, in turn, depends on the amount of current passing through the sensor unit.

Bimetallic sensors

In bimetallic sensors, the main role is played by a metal strip and a wire wound around it, through which current passes. If you have read the article about how speedometers work, then you already know this system of bimetallic sensors. Its essence is that the higher the engine temperature, the more current comes from the sensor, which heats the winding around the plate. Heating causes the plate to stretch and bend slightly, moving the engine temperature gauge needle to the desired calibrated amount.

In this type of sensor, in order to avoid errors caused by changes in the vehicle supply voltage due to electrical load and generator speed, a voltage stabilizer is included in the sensor circuit. The voltage stabilizer operates on the principle of a bimetallic strip and maintains the voltage in a constant range from 8 to 10 Volts.

Signs of a broken coolant temperature sensor

A faulty coolant temperature sensor can cause a lot of problems for the engine, so it is important to always keep the sensor in good condition. Typically, searching for the sensor itself will help determine if the part is faulty. However, this will only detect visual damage that can be seen, such as a crack, leak or corrosion in the sensor.

A digital voltmeter (DVOM) can also be used to measure the internal resistance of the sensor. The reading can be compared with the usual characteristics. If the readings are within specification but the problem is still apparent, then the problem is in the wiring.

One of the best ways to determine if the coolant temperature sensor is bad or faulty is to check if the check engine light is on. If the temperature sensor is not working properly, the computer in the vehicle's engine will send a signal. This data is then used to provide a trouble code that turns on the check engine light.

Methods for checking the coolant temperature sensor

Because the tip of the sensor must be immersed in coolant, low coolant levels or air bubbles within the cooling system may cause an incorrect signal from the sensor.

The coolant level should always be checked first when solving problems with the cooling system. The coolant temperature sensor connector should be checked for damage or corrosion.

There are several ways to check the DTOZH. The correct method can be found in the service manual.

Checking the sensor resistance

One method is to measure the sensor resistance at various engine temperatures and compare the readings to the specifications in the service manual. A multimeter is used to check the resistance.

The resistance of the sensor can only be measured when it is disconnected from the circuit. The reason is that if you measure the resistance of any electrical device that is connected to a circuit, the measurement will be inaccurate.

Checking the sensor voltage

Another way to check the sensor is to measure the voltage at the sensor terminals with the ignition on.

The sensor is connected to the engine control unit. The ECU supplies a reference voltage (usually 5 volts), the second wire is the sensor ground. The reference voltage and ground should be checked first.

Since the sensor resistance decreases as the engine warms up, the voltage also drops. When the car is cold, you can measure about 3-4 volts. When the engine is fully warmed up, the voltage drops to 1 volt.

With the sensor disconnected, the multimeter will show 5 volts. If there is no voltage, you know that the circuit is either open or shorted to ground. For example, one of the wires in the sensor harness may break or rub against the housing and short out.

Compare DTOZ readings with other temperature sensors

An example of another sensor that measures temperature is the Intake Air Temperature (IAT) sensor.

If the car has been sitting overnight, the engine and Intake Temperature (IAT) sensor temperatures should be very close. This can be checked using a diagnostic scanner or an ELM327 adapter with Torque software.

As you can see in the photo, the intake sensor reads 32°F inside the air intake and the DTOH reads 30.2°F. The slight difference in measurement is due to the air warming up faster than the engine. If the difference were much greater, it would mean that one of the sensors is measuring the temperature incorrectly.