Recommendations

Comments 21

It’s the same for me. I turn on the second one with force, but I don’t see the point in turning on the first one on the go. The engine runs fine at low speeds.

Synchronizers 1 and 2 are covered, I also turn on the first one at low speed - neutral - gas - clutch, the first one is like on a truck. and from 3rd to 2nd with transfer (but not on the clutch, but through the neutral gearbox!).

Was 3110 2000. Same behavior of the box. Only the second one is more or less normal. turned on. The first one did not turn on at all while driving. Now 31105 2004 The gears turn on normally. The first one turns on tighter while moving.

My father has the same problem on the Volga. Gas 24, the box is plugged in from 31st 5st. So the first one turns on only when the car is stationary; if you start moving, you can’t turn on the first one. The second one sticks in sooo hard, you have to sweat, nothing crunches, it just fits in very tight. The rest of the gears are like clockwork, and second and first cannot be engaged either. This is a CAT disease, and specifically stage 5. With 4speed this is not observed, everything turns on like clockwork)

When the speed of the car begins to turn on heavily, it not only causes an unpleasant feeling, but also makes the operation of the car unsafe. In this article we will analyze the reasons why gears are difficult to engage or do not shift at all, which is usually associated with this.

The gearbox is a complex mechanism that requires constant maintenance. Including regular diagnostics and gearbox oil changes. Ignoring these measures often leads to problems with gear shifting.

Clutch faults

Simply put, a clutch is a mechanism that transmits torque from the engine to the transmission and separates the engine and transmission so that gears can be changed. Damage to individual components of this unit may prevent accurate gear shifting while the engine is running.

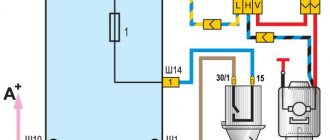

Brake fluid leaks

Many modern cars are designed so that the brake fluid must be in the clutch. If there is not enough fluid in the hydraulic system, the clutch will not engage fully.

In this case, the gears will shift poorly or not shift at all. During the first inspection, check the fluid level in the reservoir. If the level is low, check for leaks, repair and bleed the clutch.

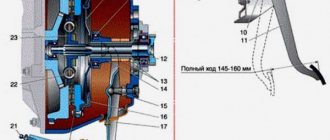

Release bearing

The gears may not engage or engage completely if the problem is in the clutch basket. The cause may also be the release bearing. If this bearing does not move freely on the main shaft or becomes stuck, it will need to be replaced.

Separately, it should be added that the main sign of problems with the clutch drum is the appearance of a rustling or pronounced rumble when the car is moving. Noises only occur when the clutch pedal is pressed to the floor. These sounds can be heard in both a cold and warm car. The noise should disappear when the clutch pedal is released. A stuck clutch disc will not engage, making it difficult to shift gears and can cause rapid wear and damage to other clutch components. grab

Clutch basket and disc

Separator malfunction is often associated with critical wear of the knives. Wear means that the basket stops functioning as it heats up. An increase in temperature means that the pressure plate cannot be fully retracted through the clutch basket. This results in very difficult gear shifting after the engine has warmed up a bit.

Once you remove it from the box, check the basket for deformation, signs of overheating, or other damage. If found, the element must be replaced.

After disassembly, check the friction linings on the disk. They should not be heavily worn, burned or damaged, and the plate should not be deformed. Additionally, when checking the clutch, check the diaphragm springs. After replacing damaged clutch components, the gearbox must be properly adjusted and the clutch must be bled during reassembly.

What are the reasons for poor gear shifting?

Difficulty shifting gears can occur as a result of improper operation of the gearbox, or due to operation of the vehicle on bad roads. Problems with the gearbox sooner or later occur in used cars.

If you have difficulties when trying to switch to another gear, you cannot shift or it takes a lot of effort, then there is clearly a malfunction. Most often, car owners turn to a car service center when they have difficulty engaging first gear or reverse gear . A fairly common problem on VAZ and Ford Focus cars.

Let's look at the faults that lead to difficult gear shifting:

- Clutch malfunction. In this situation, the gears will engage either poorly or not completely. A common occurrence in VAZ cars that have fur cables. the clutch is moving away from the mount.

- Problems in the drive of the switching mechanism. Broken traction leads to difficult engagement of 1st and reverse gears.

- The jet thrust is faulty.

- Wear of plastic parts in the box control drive.

- The slide is incorrectly positioned. A weighty element, incorrect adjustment leads to malfunctions.

- Bearing wear. This is a fairly rare occurrence; anyone can experience this, especially when you have a manual transmission. In such a situation, it is usually difficult to engage first gear.

- The box shaft is faulty. By itself, it is not subject to heavy loads, which could lead to wear. A factory defect may cause the entire unit to be replaced.

- Clutch failure. Often found among owners of cars with an automatic transmission. The malfunction is eliminated by replacing the clutches.

- Faulty synchronizers are the most common problem among gearbox breakdowns. They are made of brass, and this metal itself is quite soft. During use, it wears out and wears out. The breakdown is usually accompanied by a grinding noise when switching to another speed.

If you have a mechanic

Gears shift poorly in a car with a manual transmission for three reasons. The first of these is a malfunction of the clutch when it does not completely disengage (drive). The first sign of this malfunction is that the reverse gear is engaged with a characteristic crash. The rear one reacts to this anomaly more noticeably than other gears, because it is the only one not equipped with a synchronizer.

The second reason is a defect in the gear selection mechanism of the gearbox. And finally, the third is excessive wear of the gearbox synchronizers.

There are also several clutch malfunctions in which manual transmission gears shift poorly:

- Air in the clutch release hydraulic drive or fluid leakage from it. The malfunction is eliminated by replacing failed components of the hydraulic system and pumping it.

- Worn or broken clutch release fork. The part requires replacement or repair.

- Warping (runout greater than 0.5 mm) or too thick new driven disk.

- Failure of the basket (temperature deformation of the pressure plate or its distortion).

- Loss of mobility of the support bearing of the gearbox input shaft (at the end of the crankshaft to which the flywheel is attached).

- Jamming of the clutch driven disc hub on the splines of the gearbox input shaft. To eliminate the defect, clean the splines of the gearbox hub and input shaft. It wouldn’t hurt to lubricate them a little with lithol.

There is too much free play in the clutch release fork. Its value needs to be clarified with the manufacturer, since it is slightly different for different cars. Until you find out the value of this parameter for your car, set it from 5 to 8 mm. Too little free play of the fork is also undesirable, as it leads to clutch slipping and increased wear of the release bearing.

Excessive wear of synchronizers mainly occurs in those gears that are engaged more often: these are usually first, second and third. The rear one is not included in this list because it does not have a synchronizer. When your gear shifts poorly, and you assume that the reason for this is wear of the synchronizers, firstly, you should only have difficulties with this while driving. Secondly, in this case it switches better if you use double squeeze.

Read more: Skirt for bumper Ford Focus 2

For those who don’t know what double squeeze is. To shift to a higher gear: depress the clutch, engage neutral, release and depress the clutch again, engage the gear.

Backlash in the so-called “helicopter” is one of the reasons for unclear gear shifting

To switch to a lower gear: double squeezing must be combined with re-engaging, that is, when the clutch pedal is released and the gearbox is in neutral, you need to press and release the accelerator pedal. This is how gears are changed in cars that do not have synchronizers. If the gearbox shifts easier using double squeezing, then the culprit for poor gear shifting is most likely worn synchronizers.

If the gears shift poorly when the car is standing still with the engine turned off, the fault may only be in the gear selection mechanism of the gearbox.

Look for damage or check that it is adjusted correctly. Don't even think about the clutch and synchronizers.

Why is it difficult to engage manual transmission gears?

manual gear shifting

- The most common problem is clutch failure. In such a situation, reverse gear turns on with a bang. This happens because the gear overlaps the tooth. Reverse speed is the only gear in the box that does not have synchronizers. For this reason, clutch failure is so obvious on it.

- The second reason is a defect in the mechanism responsible for selecting the gear. This breakdown occurs when the car is stationary and you try to shift into gear.

- The third is severe wear of the gearbox synchronizers. Mostly, breakdowns occur with those that are most often used. These are first, second and third gear. Severe wear of the synchronizers only appears when switching while driving.

To prevent possible gearbox malfunctions, perform regular maintenance, change the oil on time, and in case of minor failures, rush for diagnostics . This will save you time and money in the future.

Watch the video for what not to do with a manual transmission:

What to do if it is difficult to engage reverse gear?

If you have difficulty engaging reverse gear, do one of the following :

- When you feel that the gear has not reached the end, release the clutch slightly, and the gear will be inserted all the way.

- Fully depress the clutch and only after a few seconds engage reverse gear.

- Depress the clutch, set the gear to neutral and release the clutch. After this, press down and engage reverse gear.

- Shift into reverse through another gear. For example, first engage 4th and then shift to reverse.

How to properly engage reverse gear on a Hyundai Solaris, watch the video:

It's hard to engage first gear

Many drivers who encounter this situation try to force the gearbox selector to engage 1st speed. But this is fundamentally wrong and should not be done this way.

In this situation, it is necessary to use the regas method . Its essence is as follows:

- While driving in second gear, depress the clutch and set it to neutral and then release the clutch.

- After this, you need to press the gas pedal, increasing the speed to 2.5 thousand.

- The next step is to engage the clutch again by pressing the pedal all the way and turn on the first gear on the gearbox. If you still have difficulties with this, then you need to repeat it, because... You gave too little gas, there were too few revolutions.

- If all the steps are performed correctly, the first speed will turn on without any difficulties or sounds.

However, this method should not be used on an ongoing basis when it is difficult to engage 1st gear. This method is temporary in order to at least get to the service station without any problems. In any case, the box will have to be repaired.

For those with automatic

If your car has an automatic transmission. It will not hurt you to know the modes in which your machine can operate:

- P – For parking and starting the engine. Switching to this mode is possible only after the machine has completely stopped.

- R – To move backwards. Switching to this mode is also possible only after stopping the car and with the brake pedal pressed.

- N – Neutral. When the engine is completely disconnected from the gearbox.

- D – Moving forward without restrictions on gear shifting (the most commonly used operating mode of the automatic transmission).

- D3(S) – Low gears for climbing and braking engines on descents.

- D2 – Mode for difficult conditions (slippery or mountainous roads). Gears above second are not shifted, that is, only first and second gears are engaged.

- D1(L) - Movement occurs only in 1st gear, used off-road on mud, snow or ice, where you need to drive without changing the throttle, and also to overcome steep climbs.

The automatic transmission also has a button on the mode shift lever with the inscription O/D OFF. When it is turned on, the inclusion is prohibited, increasing the gears of the analogue of the 5th gear of the manual transmission. That is, if your automatic machine has 4 gears for moving forward, then for more dynamic acceleration it will use only three lower gears.

About a faulty automatic transmission, an automatic transmission is much more complex than those encountered with a manual transmission, and the chances of repairing it in your garage are slim. But despite this, you still need to know something about it, if only in order not to harm it through improper use.

An automatic transmission is much more demanding in terms of accuracy in maintaining the oil level in it than a manual transmission. Both too low and too high oil levels are very harmful to her. Both of these can lead to serious damage. In both cases, oil foaming occurs. When there is a lack of oil due to the fact that the oil pump begins to capture air along with the oil. When there is excess oil, it foams on the rotating parts, which in this case are immersed in it. Foamed oil compresses better and has low thermal conductivity. Therefore, if you operate a machine with such oil, the pressure in its control systems will be low. Which will lead to slipping of the clutches and their intensive wear. Deteriorated thermal conductivity will not allow all excess heat to be removed. Which, together with low pressure, will lead to the machine failing and requiring serious repairs.

Read more: Where is the fuel filter located on Renault Logan

Foamed oil has more volume. Therefore, checking the oil will show the level is too high. If you find that the oil level has risen for no apparent reason, you need to turn off the engine and let the oil settle. After this, check the level again. If it turns out to be low, you need to safely add the required amount and repeat the test.

The oil level in the machine is checked using a dipstick or through a control hole closed with a plug.

How to check the oil level using a dipstick

- Warm up the oil to operating temperature (to do this you need to drive about 15 km).

Select a flat horizontal area for measurement. Put the car on the handbrake.

- Move the lever to select the operating mode of the box through all positions, holding in each position for 3 to 5 seconds, until the machine operates.

- Leave the mode selector in position P, and in this position determine the oil level.

- Without turning off the engine, remove the oil dipstick, wipe it dry and reinsert it into the tube until it stops, then pull it out and read the readings. The upper limit of oil traces on a dry dipstick should be at the mark with the inscription “hot” or in an area with intersecting notches.

If the level is insufficient, you can add oil through the tube into which the dipstick is inserted. Do not forget that the automatic transmission is afraid of dirt, so add only clean new oil. Wipe the dipstick with a clean cloth from which the threads do not fall out.

When checking the oil level, pay attention to its appearance. Dark liquid with a burning smell indicates that not everything is in order in the unit. First, try changing the oil and filter in the automatic transmission. The milky color of ATF indicates that coolant has entered the box. The coolant softens and swells the material from which the clutches are made. Do not hesitate to change such oil, having first eliminated the cause of antifreeze getting into the box, otherwise significant damage will be caused to the machine. Coolant may enter the box due to a leak in the oil section in the radiator of the cooling system. In this case, the emulsion will be observed both in the box and in the engine cooling system.

The most common machine malfunctions

- The car does not move forward or reverse normally. Possible reasons: wear of the forward clutch clutches, a defect in the piston of this clutch, breakage of the rings of the same clutch, jamming of the valve body valves.

- There is no reverse speed, forward there are only 1 and 2. Probable causes: wear of the reverse clutch clutches, a malfunction of the piston of this clutch, damage to the spline joint in the drum body, another defect of this drum.

- There is no rear, everything works forward. Reasons: wear of the brake band, malfunction of the piston of this band or breakage of its rod, defects in the braking package.

- There is no movement either forward or backward when you turn on any mode, there is a shift push, but the car stands still. Causes: torque converter malfunction, lack of oil, clogged filter.

- Only reverse, 1st and 2nd gears are engaged. Reasons: valve jamming in the valve body, low oil level, general wear of pistons and clutch clutches that do not engage.

Problems with automatic shifting

An automatic transmission is very demanding in maintaining the oil level and its condition, unlike a manual transmission. Too high or low oil level can lead to machine malfunction. In addition, due to a lack or excess of oil, difficulties may arise in switching gears.

The most common automatic transmission faults:

- Forward gears do not engage.

- There is no reverse gear, forward there is only 1st and 2nd.

- All speeds are engaged except reverse.

- The gears don't engage at all.

The oil level in the automatic transmission is checked using a dipstick. If the oil level is low, add.

Poor activation due to the slider

First, let's look at why first gear doesn't engage well and the problem is with the transmission.

Often the problem with turning on the speed lies in the latch and slider. The appearance of a burr near the groove for the retainer on the slide can easily prevent the ball retainer from entering the groove. When moving the slider, the latch rests on this burr and cannot overcome it without significant effort from the driver. In this case, the gears come very close to each other, but do not engage, and the teeth of one gear hit the other.

Theory of gearbox operation

At the moment, all modern gearboxes are equipped with synchronizers, which are important elements of the gearbox. The essence of how synchronizers work is that they equalize the operation of the gearbox shafts.

Every driver, when switching from second to first gear, has encountered a situation where some kind of obstacle was felt. What prevents you from engaging first gear while driving. This is the synchronizer.

If you have a fairly new transmission, then when switching from an upshift to a downshift you will not find yourself in such a situation. Switching will be carried out without problems. This manifests itself as the components of the unit are used and worn out.

If you have problems with switching, come to Ankara for diagnostics and repair of transmissions of Mitsubishi, Toyota, Lexus, Land Rover, Jaguar, Infiniti, Mercedes, BMW, Audi and other brands.

Watch a video about the design and operating principle of the gearbox:

Owners of cars with a manual transmission often encounter the problem of poor gear engagement, which occurs after starting and warming up the engine, that is, “on hot”. In this case, engaging one or more gears may not only be difficult, but also be accompanied by extraneous noise or unnecessary vibrations.

In this case, the gearbox shifts normally when the engine is turned off. Next, we will look at the common reasons why this malfunction occurs, as well as what to do if the gears are difficult to engage when heating.

Read in this article

Gears are difficult to engage when hot: the main causes of manual transmission malfunctions

The manual transmission is designed to transmit torque from the internal combustion engine to the drive wheels of the car, as well as stepwise change the gear ratio. In a manual transmission, gears (steps) are changed manually by the driver, who also selects the optimal gear ratio, ensuring the best operating mode of the internal combustion engine while the vehicle is moving.

In the case when problems switching speeds occur when the internal combustion engine is warm, the main symptoms can be identified:

- Reverse gear is difficult to engage;

- shifting gears from high speed to low speed and vice versa is accompanied by extraneous noise, grinding or crackling;

- complete lack of ability to change gears;

The main causes of manual transmission malfunctions:

- low oil level in the box;

- the link is poorly adjusted or damaged;

- problems with the clutch mechanism;

- destruction or deformation of gears;

- wear of shaft bearings;

- failure of synchronizers.

So, often when heated, gears are difficult to engage due to low oil level in the manual transmission. Taking into account the decrease in the level of lubricating fluid, the coefficient of friction between the rubbing parts increases, which leads to difficult and unclear gear shifting.

- Often the reverse gear is not engaged “in hot” mode due to a malfunction of the linkage. This is a common cause of problems with reverse gear engagement, which occurs when the rocker mechanism is incorrectly adjusted or worn. In fact, a tolerance shift occurs when the gear shift mechanism moves (as a result of wear of the rocker joints or adjustment failure).

Gears engage with effort: gearbox malfunctions

In cars with a manual transmission, gear shifting is done by the driver himself. Using a lever from the interior, it acts on the rocker and then on the entire gearbox mechanism. Simply put, the driver moves the gears on the shafts.

Since the shafts rotate at high speeds, cooling is required. This is done using special gear oil. Oil also protects the surfaces of rubbing parts from premature wear. The lubricant must be changed on time. On average, this is done after every 40-50 thousand kilometers.

As for the reasons for tight gear engagement, there may be several of them. However, most often they are associated with problems in the clutch or the gearbox itself. If you study the list of the most common breakdowns, then you can highlight the following:

- the link is poorly adjusted. In particularly difficult cases, it may be necessary to replace the plastic bushings. This procedure, like adjustment, can be done on your own;

- hydraulic drive failure. If it leaks, you may not be able to engage the gear at all, since it is impossible to disengage the clutch;

- the clutch cable has broken or fallen off (in a cable clutch);

- The clutch basket has failed.

The exception is reverse gear, since it does not have synchronizers; By the way, when the reverse gear is difficult to engage, extraneous noises, clanging, and crunching often occur. Such phenomena directly indicate wear of the gear teeth.

Read more: Automatic transmission Peugeot 408 reviews

What's the result?

As you can see, there are several main reasons why gears don’t engage well when hot. However, none of the above reasons can be indirect or secondary.

The main thing is to promptly correct the slightest problems, prevent leaks, monitor the oil level in the box, adjust the rocker, change the clutch when signs of wear appear, etc.

Why gears on a manual transmission are difficult to engage: the main reasons for difficulty engaging manual transmission gears. Clutch and transmission failures.

Manual transmission gears (speeds) do not engage after replacing the clutch: main reasons, settings and adjustments. Diagnosis of problems, useful tips.

Types of clutch drive. If the clutch pedal falls, the clutch has become soft, problems have arisen with the clutch: causes and repair of major faults.

Reasons for difficulty shifting gears with the engine running. Transmission oil and level in the gearbox, wear of synchronizers and gearbox gears, clutch.

Manual transmission: manual transmission diagnostics, repair of a car's manual transmission. What to look for during diagnosis, recommendations.

The automatic transmission does not change gears: the car does not move forward or backward, the automatic transmission does not switch to individual gears, reasons.