The chassis can easily be considered the most important part of the entire car. The only one who can argue with him is the engine, without which there will be no movement.

But the entire chassis consists, in turn, of individual chains, among which there are pendants. The latter have such a seemingly insignificant detail as a suspension arm, but in reality this is not the case.

Today we will talk about the suspension arm, its role in a car, possible problems during operation and much more.

What is a control arm

For an ordinary car owner who only uses it as a vehicle, but does not understand the features of its design at all, the car is divided somewhat differently into different zones - interior, body, engine and chassis.

This is roughly how a person who is only vaguely familiar with its design sees a car. But the same chassis has a suspension that is divided into two parts - rear and front.

Moreover, the wheels themselves are not part of the suspension - they are a separate part, which, however, must have connection points with the entire structure.

This is where the front suspension arm comes into play. This part is used to attach the wheel to the frame or body.

Only from the front? What about the rear suspension, are there levers there? Yes, of course there is, and always. In addition to connecting, this lever is also responsible for the movement of the wheels along the spring along the vertical guides.

That is why the fastening is done on both sides - both from the wheel and from the body. However, suspension arms are different, and we will talk about this further.

What levers are installed on Passat B5

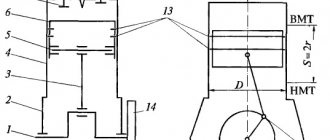

The front suspension of the Passat B5 is equipped with four arms that are placed transversely. They effectively reduce vibrations transmitted to the body. The shock absorber strut is attached to the suspension bracket, and its lower part is attached to the transverse arm.

Important! You should know that welding and straightening are strongly not recommended on this part.

A lot of talk is connected with one feature of the Passat B5 suspension arms - all parts are made of aluminum alloy. It cannot be said that it can be used on our domestic roads due to the excessively softness of the metal. Statistics show that many problems are associated specifically with the front suspension. In extremely rare cases, car enthusiasts manage to drive 70,000 kilometers; usually the levers “die” at around 45,000 kilometers.

How to choose a new spare part

If you are thinking about replacing wishbones for a VW Passat, then you should look at the manufacturers: HDE, Lemforder, Kraft, Baw, Teknorot and TRW - it is about them that car owners leave positive reviews. But it’s worth thinking about buying MOOG, FEBI and Stellox, weighing all the pros and cons, since according to consumer reviews they are not enough for a long time.

Original, analogue, used

You can buy Volkswagen Passat levers on contract - they will last you much longer. In order to save money, you can also consider analogues or used ones. A lot here depends on the availability of the required amount for the purchase of spare parts, the availability of parts for the Passat in the region, as well as on the wishes of car enthusiasts.

Important! When choosing non-original spare parts for the B5, you will subsequently have to perform precise alignment and camber.

According to certain data, the upper rear is the first to fail, and the lower front also begins to creak. The developer is already aware of this, and has recently begun producing improved upper rear control arms.

Read also: Characteristics and features of replacing an automatic transmission in a Polo sedan

The cost of the kit for the Passat is on average from ten to fourteen thousand rubles.

Types of suspension arms

Suspension arms are different, and the division is not arbitrary, but quite reasonable. If you look at different photos of the suspension arm, you will notice that they may differ in the number of attachment points.

At the same time, their placement also plays an important role, which is compared with the direction of movement of the entire machine. Depending on this, there is another division - into transverse suspension arms and longitudinal ones.

In addition, levers can be rod, triangular and diagonal. They are installed not just in different classes of cars - cars and trucks, for example, but even simply in different model ranges, which also depends on the manufacturer.

An important role when choosing a suspension arm is played by the type of suspension itself. For example, for an independent suspension, the manufacturer usually chooses wishbones that have two attachment points.

But the levers can still be different, because they have no connection with each other.

Another thing is dependent suspension, in which all the wheels of the car are connected to each other by a rigid beam. In this case, replacing the suspension arm may require an integrated approach, because they will also be connected to each other.

Signs of faulty suspension arms

Symptoms of faulty suspension arms of a passenger car:

- The car loses directional stability.

- Rapid tire wear.

- Uncomfortable driving conditions when driving on uneven surfaces: it catches every bump or hole.

If the listed malfunctions are detected, you must contact a car service. These defects cannot be ignored - the safety of road users depends on it.

Purpose of the suspension arm

If you have problems with the suspension arm, or it has simply become unusable, then you need to think about replacing it. Before you start looking for a place to buy a control arm, it's worth first understanding what it does in your car.

You already know that levers can be of different types. Depending on the design features, the required type of lever is selected.

If you make repairs yourself, then you should not change the type of lever when replacing it, especially if you do not know what consequences this may bring.

First, let's look at the upper control arm. What is his task? First of all, all suspension arms must ensure that the wheel is held in the desired condition.

The upper arm is usually found only in the front suspension, because only here are the drive wheels installed. The upper lever is responsible for ensuring that the wheel does not turn willfully while the car is moving.

As you can see, the failure of this part can not only cause discomfort, but also become a threat to your life. On the other hand, we have lower control arms, what do they do?

In fact, his work is not much different from the top one, because he is also responsible for ensuring that the wheel does not move to the side.

The difference is that the lower arms also control the lower strut, which without this influence will begin to swing, which is extremely undesirable.

The rear suspension arms are only needed to connect the wheel to the overall structure, and given the fact that they are already in a fixed state, you don’t have to worry about them turning.

Typical unit malfunctions

Most often, drivers encounter the following problems:

- the suspension “breaks” even on minor irregularities;

- the car is not able to maintain the set course, it is constantly pulled to one side;

- significant tire wear (the rubber is worn down to the cord threads).

All of the above signs may indicate problems with the front suspension arms. For example, in the first case, the cause of deviations in the operation of the car may be the notorious kink of the lever. When even one of the three levers in the A- or H-block bursts, the suspension will immediately lose its energy capacity. It is also worth additionally checking the integrity of the springs.

If the car is drifting and the driver is forced to steer all the time, then it is necessary to inspect the integrity of the front suspension arms. The metal rod could be deformed during operation.

Particular care should be taken to inspect the junction of the lever with other suspension components.

Regarding quickly wearing tires: it is obvious that in this case the correct wheel alignment angle is off. The vertical position of the wheels is off, so the rubber begins to “eat up”. If you can’t get the “healthy” wheel alignment back, then you need to look for a defect in the place where the front suspension components are attached to the steering knuckle. Fastening elements or seals may be deformed there.

Operation and repair

Knowing how and for what purpose suspension arms are used, you yourself should already understand that they are constantly subject to a fairly heavy load, which only increases while moving.

In fact, these should be very durable and reliable parts that you should never skimp on. But even very high-quality suspension arms can become unusable, and usually there are only two reasons for this - time and a careless owner.

In the first case, everything is clear, because nothing is insured against wear and tear, but the conditions in which you place the car already depend on you, the owner.