Category: KAMAZ

- The concept of KamAZ ignition

- Reasons for adjusting the ignition on KamAZ

- Install the ignition on KamAZ

- Ignition installation for KamAZ Euro-2

- Ignition installation KamAZ Euro-3 fuel injection pump Bosch

- Installation of ignition on KamAZ fuel injection pump BOSCH

- Is the injection angle adjusted correctly?

If unforeseen situations arise with the operation of the truck, sometimes it becomes necessary to independently set the ignition on the KamAZ to solve the problems that have arisen. When problems arise with starting the engine, this may be due to the ignition system. An experienced truck driver will say that there is no concept of KamAZ ignition, although other drivers can rightfully use such a phrase. And now the car does not want to drive and you suspect a malfunction in the fuel injection pump. How to correctly set the ignition on a KamAZ. To do this, let's figure out how the ignition system works and what causes the problems that appear.

The concept of KamAZ ignition

Passenger cars with a gasoline engine begin their movement due to the appearance of an electric spark in the candles. Most heavy vehicles have diesel engines. For cars with a diesel engine, the ignition system is carried out by creating pressure (compression) and heating a flammable substance. For trucks, motorists call the “injection moment” the familiar concept of “ignition”, which came from the owners of cars with a gasoline engine, in which a spark ignites in the spark plug at the moment the engine starts.

In conclusion

Despite the fact that the diesel power unit has a simple and understandable design, the elements of its fuel system are considered high-precision devices. In this regard, the installation of a high-pressure fuel pump requires special attention and optimal determination of the angle of injection of diesel fuel through the nozzle into the working cylinder at the compression stage.

Even an error of just one degree can lead to engine failure, which will require an emergency overhaul. Reliable KamAZ Euro trucks are popular in various areas. How to set the ignition on different modifications is discussed above. Knowing the features of this procedure, it is quite possible to adjust the timing of fuel injection on your own with minimal investment of time and equipment.

Similar articles:

- How to correctly set the ignition on a VAZ 2106, adjust the advance angle, order of operation of the cylinders, instructions with video and photos

- Adjusting the contact and electronic ignition of a VAZ 2107 injector and carburetor checking high-voltage wires how to correctly set the marks instructions with video and photos

- Repair and installation of distributor on 402 engine, ignition adjustment: video on how to install the drive

- Oka ignition system coil distributor lock how to set installation and adjustment video

Reasons for adjusting the ignition on KamAZ

The stage of supplying a flammable substance, which is carried out by the piston, is ignition. As the piston approaches top dead center, an increase in pressure occurs, this is due to air compression. It is at this moment that fuel needs to be injected. If the injection advance angle is incorrect, problems arise with the KamAZ ignition.

There are early and late injections.

Early injection is characterized by advanced ignition of the fuel, which occurs before the piston reaches top dead center. As a result, there is an increase in energy consumption to lift the valve.

Features of injection timing adjustment

On diesel cars, it is more correct to call ignition the injection moment.

It represents the beginning of the fuel supply when the piston approaches top dead center (the intake and exhaust valves are closed). Maximum pressure is created in the working chamber, at which point fuel is supplied. How to set the ignition on a KamAZ? It would seem that it is worth adjusting it once at the factory when the car is released and not worry about it. However, not all so simple. The fact is that each power unit has a specific injection moment, due to the characteristics of the engine components. In addition, this indicator is influenced by the quality and type of fuel.

With early ignition, the piston does not have time to reach the top point, and fuel already begins to enter the working chamber. The main signs of this moment:

- Rough motor operation.

- When you actively press the gas pedal, a characteristic ringing sound is heard, which intensifies as the temperature of the power unit rises.

- White smoke may appear from the exhaust pipe.

- There is poor traction.

- Fuel consumption increases.

The design of the ignition system of diesel trucks is somewhat different from their gasoline counterparts, where the task of igniting the mixture of gasoline and air is assigned to spark plugs. For a diesel engine, the term “injection timing” is more appropriate. In order for the power unit to start working, it is necessary to create high pressure in the chamber. After this, the fuel supply is turned on. The system begins to work when the piston approaches the top “dead” point.

If the system parameters are set incorrectly, engine parts may malfunction or overheat. It all depends on how the fuel mixture ignites - late or advanced.

If the piston has not reached the top position, but fuel is already flowing in, the mixture begins to burn ahead of schedule. This leads to unnecessary energy consumption, since the piston must reach the end, and the combustion gases and the mixture itself prevent this. This situation can be judged by the following symptoms:

- the engine becomes rough;

- when the accelerator is activated, a ringing sound occurs;

- the exhaust looks like white smoke;

- fuel consumption increases.

Late ignition is characterized by the flow of fuel when the piston leaves the upper position. In this case, the main signs of a malfunction are:

- a significant amount of whitish smoke from the exhaust pipe;

- decreased cravings;

- engine heating;

- increased fuel consumption;

- incorrect speed dial;

- vibration of the unit at medium speeds.

If any of the symptoms are observed, the KamAZ ignition must be adjusted as quickly as possible.

Adjustment procedure

The question of how to set the ignition on a KamAZ, it would seem, is not applicable to a unit that has just come off the assembly line. After all, the developers should have taken care of the correct installation of parts. In fact, each engine has its own characteristics. It depends on its purpose, configuration, adaptation to certain operating conditions. The type of fuel also matters a lot. Therefore, individual adjustment of injection timing is very important for the further use of the machine.

On each engine you can notice special marks or degrees. They are intended to guide the driver who is solving the problem of how to set the ignition on a KamAZ.

In order for the engine to operate in normal mode, it is necessary that the characteristics of both the injection pump, the fuel, and the unit itself meet the requirements of the regulations. It is the marks that help determine how to set the ignition on a KamAZ correctly.

On the machines of the Kama plant, the pump that supplies fuel under high pressure is installed using a key on the side of the box. The pump coupling can be secured in two positions, the difference being 180 degrees. When the screw holding the drive is at the top, the marks of the injection pump and the pump coupling should be found opposite.

So, to check the ignition system, you need to:

- install the elements according to the marks;

- fix all elements;

- start the engine.

If the above malfunctions are observed, it means that the components are placed incorrectly and the operation should be repeated: loosen the elements, check the installation at 180 degrees, secure the components and start the engine.

The coordinated operation of the engine is important for the functioning of the vehicle as a whole: the KamAZ gearbox shafts will not be able to perform their task if problems are observed in the operation of the unit itself.

Install the ignition on KamAZ

We will answer the question posed using the KamAZ 740 as an example. To do this, we will describe the ignition procedure of the KamAZ 740, which is similar to many models of this class.

Installation of the KamAZ 740 ignition is carried out in several stages:

- getting started we'll start by raising the truck cab

- we will fix the cabin on supports to protect the person’s work

- find the flywheel on which you will find the rod, it is located on the back of the flywheel on the top left side.

- lift the rod and rotate it ninety degrees, then return it to its original place

- find two bolts on the flywheel housing, unscrew them, you will need a seventeen mm wrench.

- To continue working, remove the mudguard

- through the slotted passage of the casing into the flywheel we insert a hard alloy rod 400 mm long and 10 mm in diameter

- perform rotational movements with the crankshaft until movement is blocked

- if the injection pump coupling is located with the scale up, you need to ensure that two marks coincide: zero with the mark on the fuel pump flange, secure with two bolts

- if the part is positioned in the opposite direction, lift the stopper and rotate the crankshaft one 360 degrees. After this, repeat the steps described above.

Gas distribution mechanism of the KamAZ-740 engine

The gas distribution mechanism of this engine consists of a camshaft 1 (Fig. 14) with a gear 17, pushers 2 with guides 3, rods 4, rocker arms 6 with adjusting screws 5 and locknuts 7, intake 14 and exhaust 15 valves with springs 10, 11 and parts their fastening, camshaft drive.

Fig. 14. Gas distribution mechanism

Pushrods transmit force from the camshaft cams to the rods. The cylindrical guide part of the pusher is hollow, it has two holes for draining oil from the internal cavity. This oil lubricates the side surface of the pushers and the camshaft cams. The inner surface of the pusher ends in a spherical socket where the lower end of the rod rests. The end surface of the pusher, coupled with the cam, is overlaid with bleached cast iron to increase wear resistance and has a disc-shaped shape.

The pushers are installed in cast iron guides attached to the cylinder block. When the engine is running, the pushers constantly rotate around their axes, which ensures their uniform wear. The rotation of the tappets is achieved due to the spherical surface of their plates and the beveled surfaces of the camshaft cams. The rods transmit force from the pushers to the rocker arms; they are made of steel, hollow, with insert tips. The lower tip has a convex spherical surface, the upper tip is made in the form of a spherical cup. To allow lubricant to pass through the rods, there are holes in the tips.

The rocker arms transmit forces from the rods to the valves and are made of steel. Each rocker arm is a two-arm lever, into the hole of which a bronze bushing is pressed. The nose of the long arm of the rocker is hardened to high hardness. An adjusting screw with a lock nut is screwed into the short arm of the rocker to adjust the gap between the rocker and the end of the valve stem.

The rocker arms of the intake and exhaust valves are installed on a common stand, secured to the cylinder head with two studs. The axial movement of the rocker arms is limited by a plate clamp installed under the rack. The rack has a hole for supplying oil to the rocker arms.

Valves are designed to open and close intake and exhaust valves. Each cylinder has one intake and one exhaust valve. Both valves are made of heat-resistant steel. The valve consists of a head and a stem; the head has a working chamfer, and the rod has an annular groove. The diameter of the intake valve head is larger than that of the exhaust valve, this improves the filling of the cylinder with air. The working chamfer of the exhaust valve head, operating at high temperatures, is reinforced with a wear-resistant and corrosion-resistant alloy called stelite.

The valves move in metal-transverse bushings pressed into the block head. For better running-in, valve stems are coated with graphite before assembly. A sealing collar is installed on the intake valve bushing to limit the flow of oil into the gap between the valve stem and the bushing. These parts are coated with oil flowing from the rocker-axle interface.

Ignition installation for KamAZ Euro-2

This car model has a diesel 8-cylinder V-shaped engine. This model has increased sensitivity to changes in the ignition timing angle.

You can set the ignition on KamAZ Euro-2, you can use the recommendations for KamAZ Euro-1, but at the final (last) stage you need to perform the following operations:

- lift the flywheel lock

- change position ninety degrees

- lower into the shock absorber bushing

- install the mudguard and secure it

- return the cabin to its original position

- lift the clamps to the upper position.

There is a statement by experts that the optimal ignition timing is achieved when the mark is aligned with the edge of the index arrow.

Settings

Injection timing and ignition are different names for the same process. Injection is the start of the supply of fuel mass when the piston moves to the maximum point. The KAMAZ EURO 2 starter must be in good working order. The intake valves must be closed, as well as the check valves. Due to this, maximum pressure appears in the functioning chamber. At the same time, fuel is supplied.

Of course, diesel cars are tuned during factory maintenance. However, such debugging is not enough. Due to operating conditions and varying quality of automotive fluids, the adjustment must be repeated periodically.

Each power plant has special marks (or degrees), which are marked for the convenience of self-calibration. If the device is debugged and the settings are set according to the marks, the motor will function in its optimal mode. The KAMAZ EURO 2 engine, fuel, lubricants and spare parts used in the process must comply with all GOST requirements.

After the procedure, during which the car owner has set all elements of the system to the factory marks, he must firmly tighten the special clamps on the engine and turn it on. The vehicle should not have any problems starting and should start the first time. If this does not happen, or white smoke begins to come out of the exhaust part, then this indicates an error - the injection pump has been positioned 180 degrees. The error is corrected in the reverse way: the parts are unscrewed, the elements are rotated, and the engine is restarted.

If there are no factory marks, the elements must be installed in the middle position of the adjustment marks. To ensure correct installation, special attention must be paid to the injection time.

Any automotive power plant has marks (degrees) designed specifically for setting the ignition. If the system is adjusted strictly according to the marks, the engine will operate in optimal mode, provided that the injection pump, engine and fuel meet the reference characteristics according to GOST. By and large, the indicators are a kind of guideline that allows you to understand how to set the ignition on a KamAZ.

On the car in question, the high-pressure fuel pump is placed on a key on the side of the box, and the injection pump coupling can be fixed in two positions with a difference of 180 degrees. As a rule, if the drive pressure screw is located in the upper part, then the injection pump and clutch marks should be placed opposite.

Ignition installation KamAZ Euro-3 fuel injection pump Bosch

The main difference between KamAZ Euro-3 and KamAZ Euro-2 is the presence of an ignition switch. The ignition switch activates the on-board network to the battery and generator and turns off after the engine starts. Has three positions:

- initial (no current in the system, mechanisms do not work)

- position 1 (engine is switched off, but individual components are working)

- final (starting the engine).

The first position indicates the inoperative state of the vehicle's devices is disabled; when switching to position 1, it becomes possible to turn on some mechanisms (audio system, optics) that are included in the ignition system when the drive engine is turned off. The final position is responsible for starting the engine.

The ignition switch can perform an anti-theft function; when the engine is off, it locks the steering wheel.

IMPORTANT:

- Turning the drive clockwise enhances early injection;

- Turning the drive counterclockwise normalizes late injection.

Video “How to make KAMAZ more economical?”

Recommendations and step-by-step instructions for repairing a KAMAZ in order to achieve its efficiency are shown in the video below (the author of the video is Petr Alekseevich Yurkov).

The ignition system in all vehicles is designed to ignite the fuel mass in the cylinders of internal combustion mechanisms. This part of the car must be well-debugged and must function properly in order to avoid unpleasant situations while driving. Ignition is an extremely important moment for the operation of the machine.

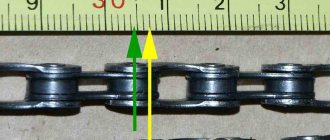

Is the injection angle adjusted correctly?

It is necessary to check the correct ignition settings by turning the engine on and off. If there are signs of incorrect engine operation, you must repeat the described steps until the desired result is obtained. Correct installation is indicated by the absence of extraneous noise and the speed at which the motor starts. You can verify correct operation by using the idle speed. The rotation speed should be 600 rpm. Do not forget about safety precautions while working. Make sure the fuel supply system is turned off and you have secured the vehicle.

What could be better for you and your car?! And the increase in your truck's fuel consumption will be felt quickly, the moment you make a quick visit to the gas station and pay the check. Keep an eye on the health of your iron “friend”!

Features of injection timing adjustment

After all the parts are aligned to the marks, you need to tighten the fixing elements and start the engine. The car should start without problems the first time. If the truck does not start or white smoke comes out of the exhaust system, then the alignment is not done correctly by 180 degrees. You will need to unscrew the required parts and rotate them 180° and restart the engine.

If there are no marks or there are unnecessary marks, it is advisable to place the elements approximately in the middle of the adjustment marks. To understand how to correctly set the ignition on a KamAZ, it is necessary to take into account the signs of late and early injection.

Features of adjusting the injection timingAdjusting the ignition on Euro standard unitsWays to check the correctness of the ignition adjustment

The question of how to correctly set the ignition on a KamAZ truck worries many drivers. Since a significant part of the Kama Automobile Plant's tractors are driven by diesel units, there is a problem with adjusting the injection timing. Starting the engine and its further efficient operation depend on the accuracy of the adjustment and the correct placement of the piston in a position that ensures optimal fuel injection into the cylinders. And the correct functioning of other components, such as the KamAZ 43118 transfer case, etc., also depends on the correct operation of the engine.

Late ignition: signs

At a late injection moment, the piston moves down from top dead center, and fuel is just starting to flow, the ignition follows. Signs of a problem:

- The appearance of white smoke from the exhaust system. The later the ignition, the greater the amount of smoke observed.

- The motor does not rev up correctly.

- The operation of the power unit is observed to be too soft.

- When the gas pedal is smoothly activated, the engine begins to shake at medium speeds, and when the torque increases, this effect abruptly disappears.

- Fuel consumption increases, the engine heats up, and the truck pulls poorly.