Replacing the idle speed regulator VAZ 2107 (injector)

A faulty idle speed controller leads to various engine malfunctions. One of them is when the engine stalls when the speed is reduced, which is fraught with an emergency situation. How to determine the malfunction of the IAC and replace it in the article.

Drivers often call the IAC sensor an idle speed sensor, which is completely wrong. The sensor “takes” readings and displays them on the screen (or device), and the regulator directly controls the operation of the engine. However, he is a sinner and I often call him that out of habit.

Typically, injection sevens have an IAC with article number 2112-1148300-04 (the last digit is the IAC version).

The idle speed sensor is installed on the injection VAZ 2107 in the lower part of the throttle valve on the right. You won't be able to replace it with a new one without removing it, but you will have to disassemble it a little. But more on that below, but first let’s look at the signs of a malfunction. Although I note that it is still possible not to remove the damper if you have a special screwdriver.

Idle speed is not adjustable VAZ 2107

Idle speed regulator VAZ-2104, VAZ 2105, VAZ 2107

Idle speed regulator VAZ-2104, VAZ 2105, VAZ 2107

The sequence of work to check the idle air control on a VAZ-2104, VAZ 2105, VAZ 2107 car

1. Release the clamp of the wiring harness block and disconnect the block from the idle speed control.

The terminals are marked on the idle air control block.

2. Connect the negative probe of the engine voltage.

3. Having turned on the ignition on the VAZ car, use a voltmeter to measure the voltage at terminals A and D of the idle speed control block.

ATTENTION The voltage on the idle speed regulator block must be at least 12 V (the negative probe of the device must be connected to the engine ground). If the voltage does not reach the idle speed control block or it is less than 12 V, the battery is discharged, the power circuit is faulty, or the ECU is faulty.

4. After completing the voltage measurement, turn off the ignition on the VAZ-2104, VAZ 2105, VAZ 2107.

Removing the idle speed regulator from a VAZ-2104, VAZ 2105, VAZ 2107 car

1. Remove the throttle body.

2. Using a Phillips screwdriver, unscrew the two screws securing the idle air control to the throttle body.

3. Remove the idle speed control. An O-ring is installed in the connection between the VAZ idle speed control and the throttle body. Replace a ring that has lost elasticity or is cracked.

4. Using an ohmmeter, we measure the resistance between the terminals of the windings of the idle speed control VAZ-2104, VAZ 2105, VAZ 2107.

The electrical resistance between terminals A-B and C-D should be within 52-53 Ohms. The resistance between terminals A-C and B-D should be high (tend to infinity). The faulty idle air regulator on a VAZ car needs to be replaced.

ATTENTION Before installing a new idle air regulator on a VAZ-2104, VAZ 2105, VAZ 2107, you must make sure that the valve needle protrudes no more than 23 mm.

5. Using a caliper, measure the protrusion of the needle of the new valve.

6. If the needle protrusion is more than 23 mm, its position must be adjusted. To do this, we apply 12 V voltage from the battery to terminal D of the idle air control regulator (the connection of the wire to the terminal must be insulated). With the bare end of the wire connected to the negative terminal of the battery, briefly touch terminal C of the idle speed control.

Since the valve moves slowly, we touch it repeatedly, simulating the operation of a switching power supply. After installing the needle in its extreme position, check the protrusion of the needle, which should be 23 mm. Otherwise, replace the valve with a new one.

Installation of an idle air regulator on a VAZ-2104, VAZ 2105, VAZ 2107 car

1. Apply engine oil to the sealing ring.

2. Installation of the idle air regulator is performed in the reverse order.

The VAZ 2107 idle speed control is removed to replace it with a new one if the old one fails as a result of any mechanical damage. Before removing the regulator, it is recommended to test it with a performance tester; the test comes down to simply measuring the voltage at the terminals of the block, and after removing it, measuring the resistance at the same terminals. To check, you will need a multimeter with voltmeter and ohmmeter mode, as well as a standard set of tools.

The procedure for checking and subsequently replacing the idle air regulator is as follows:

- Connect the negative terminal of the voltmeter to engine ground and turn on the ignition on the car.

- Disconnect the block from the regulator; the terminals will be marked on its body.

- Connect the positive terminal of the Vols and then to the “D” terminal. The voltage at the terminals should be 12V. For any significant deviations from the norm of more than one volt or a complete absence of voltage, the cause may be either a weak battery charge, faulty power wiring or a malfunction. After measuring, turn off the ignition.

If the voltage at the terminals is normal, but the regulator does not perform its direct functions, then it must be changed. Removing and replacing the regulator looks like this:

- It is necessary to remove the throttle body, see for more details.

- After that, use a Phillips screwdriver to unscrew the two screws securing the regulator to the damper body and remove it.

- A rubber sealing washer will be installed between the regulator and the housing. Replace it if cracks or other damage is found.

After it is removed from the car, it must also be tested with a tester in ohmmeter mode. For this:

- Switch the tester to ohmmeter mode and measure the resistance between terminals A-B and C-D, it should be about 52-53 Ohms. Next, measure the resistance between terminals A-C and B-D, the resistance should tend to infinity or be large enough. If there are any deviations from the norm, replace the regulator.

This completes the repair work. Install the new regulator in the reverse order of removal. Before installing the regulator, measure the length of the valve needle protrusion; it should not protrude more than 23mm. To measure, use a caliper or any suitable ruler. Before measuring, it is necessary to extend the needle to the maximum distance; to do this, apply voltage from the battery to the valve, connecting the positive pole to terminal “D” and the negative pole to “C”. The regulator solenoid valve works slowly, so touch the wires repeatedly until the needle reaches its maximum length. Measure with a ruler and if the needle protrudes more than 23mm, replace the valve.

If the idle speed sensor does not work on a VAZ 2107 with an injector engine, this manifests itself in unstable operation at idle and during startup. In the event of a malfunction of the DZH, an emergency situation may be created, since it is not visible that the driver is backing up. The article provides instructions for replacing the DZH and IAC, and also includes photos.

Signs of a VAZ IAC malfunction

Signs of a regulator malfunction vary, here are the main ones:

- the engine stalls when the gas pedal is released;

- poor engine starting;

- floating engine speed;

- increased speed.

It should be borne in mind that some symptoms of a broken IAC may coincide with a malfunction of other sensors: crankshaft position, throttle valve or mass air flow. Therefore, you can accurately determine its malfunction by taking some measurements yourself or using computer diagnostics.

How to check the XX regulator

Self-checking the serviceability of the IAC VAZ 2107 and other models consists of measuring the voltage at the connection block, checking the resistance between the sensor terminals and measuring the length of the rod.

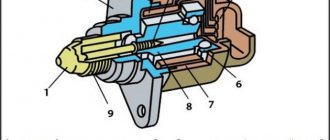

The figure below shows a drawing of the idle air control device. I am citing it to better understand the necessary checks.

VAZ idle speed control device

As you can see, there are 2 windings on the sensor. This is a stepper motor, one winding of which extends the rod, the second winding retracts it. A break in these windings, a short circuit between turns or even windings indicates a malfunction.

The regulator cannot be repaired and if a malfunction is detected, it must be replaced.

To check the regulator, you need a multimeter and a caliper (or ruler).

- First you need to disconnect the block and turn on the ignition and check for voltage at terminals A and D. It should be equal to the on-board network voltage. Its absence may indicate a malfunction of the ECU or the IAC power circuit. Sometimes a resistor breaks in the ECU and no power is supplied.

- Next, switch the multimeter to resistance measurement mode and look at the resistance between windings AB and CD. It should be about 52 ohms. In other positions there should be no resistance.

- Measure the length of the extended rod, it should be 23 mm. Deviation from it also indicates a malfunction.

How to replace idle air control

To replace the regulator, you can go in three ways:

- with complete disassembly of the throttle valve;

- partial;

- without removal.

I changed the regulator with complete disassembly, as I discovered clogged tubes, and a dropped plug rattled inside the receiver. When disassembling and cleaning I used carburetor cleaner. Although this is the same acetone and could have been saved.

Carburetor cleaner, if it is not needed under pressure, can be easily replaced with simple acetone

In the second option, the replacement is made without removing the tubes, but with removing the throttle. In this case, the air duct clamp is loosened, the throttle is unscrewed and, by moving it a little, removed from the studs. You need to turn it a little, this will give access to the sensor mounting bolt.

In the third option, you need a special screwdriver capable of unscrewing the sensor mounting screw. Typically, this is a flexible screwdriver for hard-to-reach places or an angled attachment for a screwdriver.

Preparing the machine

The preparation operations are not complicated and standard for any repair, but your personal safety, the time spent on maintenance and repair, as well as the quality of the work largely depend on their implementation. We prepare our VAZ2107 car for replacement as follows:

- We do car washing

- If possible, it is advisable to wash the outside of the car before work (you will get less dirty while working), including the bottom if necessary

- If the work (as in our case) is to be done in the engine department, then it should be washed there too

- The operation associated with washing the engine compartment is best performed in a non-automated car wash.

- Here, the engine compartment of your car will be washed by hand, having previously treated the outside of the body and the engine compartment with specific cleaning compounds.

- They will also remove dirt stuck in the wheel arches, as well as from the bottom of the body, using a directed jet of water under pressure, with drying completed.

Which IAC should I choose?

I can recommend IAC from two manufacturers: Kaluga and Startvolt. Samarsky staged it, but there was some luck with him, it lasted for a year, just like with “PEKAR”. So which regulator is better can be checked with sellers, since they have information on the number of returns.

When purchasing, pay attention to the presence of quality control stamps and dates. Check the rod for play and absence of rotation. The presence of Chinese counterfeits on the market is quite large.

Whether the valve should have a wide or narrow cap seems to me to make no difference. Since the main role is played by the narrow part before expansion.

How does the idle air control control work?

As you can see in the photo, the valve opens the bypass channel when the engine starts and closes it as it warms up. The narrow part of the valve is involved in the work.

Source

Idle speed regulator (sensor) VAZ 2107

In everyday life, the IAC is called a sensor, although it is not one. The fact is that sensors belong to measuring equipment, and regulators belong to executive equipment. In other words, it does not collect information, but executes commands.

Purpose

The IAC is a component of the fuel supply system of an engine with distributed injection, regulating the volume of air entering the intake manifold (receiver) when the throttle valve is closed. In fact, this is an ordinary valve that slightly opens the spare (bypass) air channel by a given amount.

IAC device

The idle speed control is an electric motor of a stepper design, consisting of a stator with two windings, a magnetic rotor and a rod with a spring-loaded valve (shut-off tip). When voltage is applied to the first winding, the rotor rotates to a certain angle. When it is fed to another winding, it repeats its movement. Due to the fact that the rod has a thread on its surface, when the rotor rotates, it moves back and forth. During one full revolution of the rotor, the rod takes several “steps”, moving the tip.

Operating principle

The operation of the device is controlled by an electronic unit (controller). When the ignition is turned off, the IAC rod is pushed forward as much as possible, which is why the passage hole of the bypass channel is completely blocked, and air does not enter the receiver at all.

PURPOSE AND DEVICE OF IDLE CONTROL.

The idle speed regulator is designed to regulate the amount of atmospheric air entering through the bypass channel (bypass) into the suction manifold when the engine is idling. The main channel is closed by the throttle valve.

The regulator is a DC electric motor. It has two windings on the stator and a rotor with permanent magnets. The rotor is connected to the rod by a lead screw. At the end of the rod there is a valve that closes the hole in the bypass. Power is supplied either to the first or to the second stator winding. At the same time, the rotor rotates in one direction and then in the other, extending or retracting the rod and the valve with it using a screw.

Signs of IAC malfunction

Signs that the idle air control valve is faulty may include:

- unstable idling (the engine troits, stalls when the accelerator pedal is released);

- decreasing or increasing the number of engine revolutions at idle (floating speed);

- reduction in the power characteristics of the power unit, especially with additional load (turning on the heater fans, radiator fans, heated rear window, high beam, etc.);

- complicated engine starting (the engine starts only when you press the gas pedal).

But here it should be borne in mind that similar symptoms may also be inherent in malfunctions of other sensors, for example, throttle position sensors, mass air flow or crankshaft position sensors. In addition, if the IAC malfunctions, the “CHECK ENGINE” indicator lamp on the dashboard does not light up, and it will not be possible to read the engine error code. There is only one way out - a thorough check of the device.

Checking the idle air control circuit

Before moving on to diagnosing the regulator itself, it is necessary to check its circuit, because the reason that it stopped working could be a simple break in the wires or a malfunction of the electronic control unit. To diagnose the circuit, you only need a multimeter with the ability to measure voltage. The procedure is as follows:

- Raise the hood and find the sensor wiring harness on the throttle assembly.

- Disconnect the wiring harness block.

The voltage between ground and each of the terminals must correspond to the voltage of the on-board network, i.e. approximately 12 V. If it is less than this indicator, or is absent at all, you need to diagnose the wiring and electronic control unit.

CHECKING THE ELECTRICAL IAC CIRCUIT.

What can you do yourself when checking the electrical circuit of the idle speed control of a VAZ 2107? Measuring the voltage at the connection block to the control unit and measuring the resistance of the regulator motor windings. To measure you need to have a tester. The diagnostic procedure is given below:

- Disconnect the block with the wiring harness from the regulator. It is located on the throttle assembly.

- Turn on the ignition.

- Set the tester to voltage measurement mode in the range from 0 to 20 volts.

- Connect the probe from the tester with a minus sign to the ground of the car.

- Connect the probe from the tester with the “plus” sign in turn to terminals “A” and “D” on the harness block. The voltage between ground and terminals should be 12 volts. If there is no voltage, the controller may not be corrected.

- Next, move the tester to the resistance measurement position. Measure the resistance of the first winding between terminals “A” and “B”. Measure the resistance of the second winding between terminals “C” and “D”. There should be 52 ohms on both windings. In other variations of measurements between the terminals, the device should indicate an open circuit. If the tester shows the opposite, then the electric motor is faulty.

IAC malfunction.

The electric motor is not the only component in the regulator that can break; there are a number of other breakdowns:

- oxidation of connector contacts, broken wires;

- contamination of the rod, preventing movement;

- the o-ring is torn;

- wear of the screw thread on the rod.

Of the above breakdowns, the most common is contamination of the rod. If during operation the throttle assembly has not been maintained for a long time, carbon deposits on the regulator rod are possible. To remove dirt, you need to remove the IAC and rinse with acetone.

The stem needs to be cleaned periodically. Otherwise, the load increases, which can damage the ECU. Then you will have to contact service station specialists.

Problems in the mass air flow sensor - mass air flow sensor.

The mass air flow sensor is located in the air duct between the throttle valve and the air purification filter. It shows the volume of air entering from the atmosphere into the suction manifold. Based on these data, the control unit calculates the amount of fuel required for the current operating mode of the internal combustion engine.

If the sensor is faulty, the “Check Engine” light on the panel lights up. In parallel with this, a number of signs of failure are possible:

- Fuel consumption has increased.

- Idle speed is increased.

- The dynamics of the car are disrupted due to a decrease in power.

- It is impossible to start the internal combustion engine, even when “hot”.

- The speed changes at any throttle position, even under engine load.

Such sensors are not repaired, but replaced. Therefore, you need to make sure that this is the reason. Often the cause may be contamination of the platinum thread inside the device; it can be cleaned. Or the cause of air leakage through a damaged air duct.

Air leaks through cracks in hoses and seals.

There are many places where excess air can enter the suction manifold, bypassing the mass air flow sensor. The fuel mixture becomes leaner, the speed decreases, and the power drops. The ECU tries to correct these errors. A failure occurs in the system, the speed and “thrust” do not correspond to the specified parameters. The "Check Engine" warning light on the dashboard does not light up. The conclusion from this is that the sensors are working, but the internal combustion engine is sucking in air somewhere.

There are several places for air leaks that you should pay attention to, these are:

- the manifold with its gaskets, all kinds of joints, gaskets under the equipment attached to the manifold;

- vacuum brake booster and its hoses:

- throttle body;

- vacuum pipes.

After eliminating these shortcomings, the power unit will operate normally.

Other reasons.

A car is a complex engineering structure. During operation, its units, components, systems, and blocks are subject to wear. And it is impossible to describe all combinations of breakdowns.

Here are some reasons for the internal combustion engine not working properly:

- The ignition system has many of its own “sores”.

- Nozzles requiring professional care.

- Low quality gasoline.

- Presence of water in the fuel tank.

- Fuel and air filters are clogged.

- Other.

In each case it is necessary to understand, identify cause and effect. If you can’t do it yourself, you should contact a service station specialist.

In this article, “Why do idle speeds fluctuate on a VAZ 2107 injection engine,” the emphasis is on the breakdown of the XX Regulator. If it is broken, it can hardly be repaired. It's better to change it. It’s not difficult to do it yourself, having a new IAC and a minimum of tools.

Diagnostics, repair and replacement of idle air control

To check and replace the regulator itself, you will need to dismantle the throttle assembly and disconnect the device from it. The following tools and resources will be needed:

- screwdriver with Phillips bit;

- slotted screwdriver;

- round nose pliers;

- socket wrench or socket 13;

- multimeter with the ability to measure resistance;

- calipers (you can use a ruler);

- clean dry cloth;

- coolant for topping up (maximum 500 ml).

Dismantling the throttle assembly and removing the IAC

To remove the throttle assembly, you must:

- Raise the hood and disconnect the negative cable from the battery.

- Using a slotted screwdriver, hook the end of the throttle cable and remove it from the gas pedal pin.

- On the throttle block, use round pliers to disconnect the clamp on the throttle valve drive sector.

Video: removing and cleaning the throttle assembly on a VAZ 2107

Instructions for diagnosing and replacing the idle speed controller

To perform diagnostics and replace the regulator, it is enough:

- Turn off the ignition

- Stop the VAZ 2107 car with the hand (parking) brake to avoid spontaneous movement

- If the parking brake is faulty, you should use wheel chocks to secure the vehicle.

- The idle speed sensor is located on the throttle valve

- We unclip the clamp of the wire block and disconnect the block itself from the idle air control sensor

- It has terminal markings (ABCD, see photo below)

- Connect the minus volt probe of the motor

- We turn on the ignition on the car, using a voltmeter, measure the voltage at outputs A and D of the block of our idle air control

The terminals are on the ABCD block, using a voltmeter we measure the voltage at terminals A and D, the negative contact of the voltmeter is connected to engine ground

Attention: The voltage at the terminals of the idle speed sensor block should not be less than 12 Volts (“the negative” probe of the voltmeter must be connected to the “ground” of the motor). If suddenly there is no voltage or it is less than 12 Volts, it means either the battery is discharged, there may be a malfunction in the power circuit, or the ECU is faulty.

- Upon completion of the voltage measurement, turn off the ignition on the car

Idle speed sensor VAZ 2107 replacement

Remove the sensor along with the throttle body. The throttle body itself of a car's fuel-injected engine is removed to replace the gasket, idle speed sensor, or throttle body.

Attention: To avoid burns, begin work only after the car engine has cooled down.

So:

- Disconnect the wires from the battery terminals

- Unhook the throttle valve drive cable from the sector

- Disconnect the wiring harness from the throttle position sensor

- Press the latch and disconnect the block with wires from the idle speed sensor

Attention: During the following operation, some coolant will leak out of the fittings and hoses.

- Loosen the clamp and pull off the coolant drain pipe from fitting A on the throttle body

- Similarly, remove the coolant supply pipe from fitting B

Remove the pipes from the drive fittings

- Loosen the clamp and pull off the engine crankcase ventilation pipe from the housing fitting

- Using a Phillips screwdriver, loosen the worm clamp of the pipe supplying air to the throttle body, then remove it from the pipe

- Using the same screwdriver, loosen the clamp of the hose supplying fuel vapor to the throttle body, then pull off the hose

- Using a 13 mm wrench, unscrew the nuts (there are only two) securing the throttle body

The arrows indicate the nuts securing the housing

- Remove the throttle body from the receiver studs and take out the sealing gasket

- Using a Phillips screwdriver, unscrew the two screws securing the idle air control directly to the throttle body

- We take out the idle speed sensor

Use a Phillips screwdriver to unscrew the screws and remove the regulator.

- There is an O-ring between the idle air control valve and the throttle body.

- If it has lost its elasticity or is cracked, replace it

- Using an ohmmeter, measure the resistance between the outputs of the regulator windings

Using an ohmmeter we measure the resistance between the outputs of the regulator windings

- The resistance between the terminals of windings A-B and C-D is

- within 52-53 Ohm

- And the resistance between the terminals of windings A-C and B-D is reflected as huge (tends to infinity).

- Otherwise, the idle air control is faulty and must be replaced urgently

Attention: Before installing a new regulator on a car, you need to make sure that its valve needle protrudes outward no more than 23 millimeters

- Using a caliper, measure the distance by which the needle of the new valve protrudes

- If the needle protrusion exceeds 23 millimeters, it is necessary to correct its position

- To do this, apply a voltage of 12 Volts from the battery to output D of the idle speed sensor (in this case, the connection of the wire to the output must be insulated)

- Using the bare end of the wire, which is connected to the negative output of the battery, briefly touch terminal C of the idle speed sensor

- The valve moves quite slowly, so we touch it repeatedly, thereby simulating the functions of a switching power supply

- When the needle is in its extreme position, check the protrusion of the needle again; if it is not equal to 23 millimeters, replace the valve with a new one

- Now that the valve is adjusted, lubricate the O-ring with engine oil

- The regulator is installed in the reverse order of removal.

At this point, replacing the idle speed sensor can be considered complete, everything is simple and affordable, there is no point in paying through the nose for the services of a service station when replacing the regulator yourself, the cost of replacement is the cost of the sensor itself. In addition to the material, watch the video.

Add a commentAdd a comment We recommend readingReplacing the lambda probe of a VAZ 2112 is the cheapest way to do it yourselfVAZ 2112: crankshaft sensor - faults and replacementReplacing a radiator sensor is simple and quick!VAZ 2109: sensors on the engine, their location and replacement

Quite often, a violation of the idle operation of the internal combustion engine in the seventh model of Zhiguli is associated with the failure of the idle speed controller. The breakdown occurs if the car is equipped with a VAZ 2107 idle speed sensor for the injector, and in the carburetor circuit for supplying the fuel mixture, the valve responsible for the supply periodically fails.

How to check the idle air control

To check the IAC, perform the following steps:

- Turn the multimeter into ohmmeter mode with a measurement limit of 0–200 Ohm.

- Connect the probes of the device to terminals A and B of the regulator. Measure the resistance. Repeat the measurements for terminals C and D. For a working regulator, the resistance between the indicated terminals should be 50–53 Ohms.

If the resistance value between the listed terminals does not correspond to the specified values, or the stem overhang is more than 23 mm, the idle air control regulator must be replaced. There is no point in trying to repair the device. In the event of a break or short circuit in the stator windings, and it is these faults that cause changes in the resistance at the terminals, the regulator cannot be restored.

Cleaning the idle air control

If the resistance is normal and the length of the rod is fine, but it does not move after connecting the voltage, you can try to clean the device. The problem may be that the worm mechanism that moves the rod is jammed. For cleaning, you can use a rust-fighting liquid such as WD-40 or its equivalent.

The liquid is applied to the rod itself where it enters the regulator body. But don’t overdo it: you don’t need to pour the product inside the device. After half an hour, grab the rod and gently twist it from side to side. After this, check its functionality by connecting the wires from the battery to terminals D and C, as described above. If the regulator rod begins to move, the device can be used again.

Replacing the idle speed sensor

The idle speed sensor of the VAZ 2107 can only be removed together with the throttle body. To avoid burns when performing work, you must ensure that the engine is cool. To dismantle the sensor, perform the following operations:

- Disconnect the battery ground.

- Unhook the throttle control cable.

- Disconnect the wiring harness from the throttle position controller.

- Disconnect the wire block from the idle speed regulator (sensor).

- Loosen the clamps on the coolant pipes that supply it to the throttle body.

- Remove the pipes (there may be some coolant leakage).

- Loosen the clamp and remove the crankcase ventilation pipe.

- Loosen the clamp and remove the air supply pipe to the fuel injection system.

- Loosen the clamp of the hose supplying fuel vapor to the throttle valve and pull off the hose.

- Unscrew the two nuts securing the throttle body.

- Remove the throttle body from the studs.

- Get the gasket.

- Remove the screws securing the idle speed sensor to the throttle body.

- Remove the idle speed sensor (regulator).

After removing the sensor, you need to check the O-ring located at the mounting location of the idle speed sensor. If it is cracked or inelastic, it must be replaced.

Checking the idle speed sensor consists of monitoring the resistance between the terminals of its windings. Between AB and CD it should be approximately 53 Ohms, between AC and BD it tends to infinity. If the resistance is different, the idle speed sensor must be replaced with a new one.

Before installing a new sensor, you need to check the amount of protrusion of its needle. It should protrude no more than 23 mm. You can check this like this:

Apply plus to terminal D of the VAZ 2107 idle speed sensor.

Touch the ground wire to terminal C of the idle speed sensor. The needle will move out a little. Using repeated touches, simulating impulses from the power source, push the needle so that it takes the extreme position.

Use a caliper to check the size of the protrusion. If the needle protrusion is more than 23 mm, the sensor must be replaced with a new one.

Before installing the idle speed control, it is necessary to lubricate the rubber O-ring with machine oil.

Installation of the idle speed sensor occurs in the reverse order of removal. During installation, it is necessary to check the serviceability of the band clamps and, if necessary, replace them. It is also necessary to take into account that it is necessary to install the throttle body only on a new gasket.