Print this article Font size 16

If there are problems with the operation of the idle speed sensor, difficulties may arise with controlling your VAZ 2109. To determine the breakdown and learn how to correctly change the sensor, we will introduce you to the basic principles.

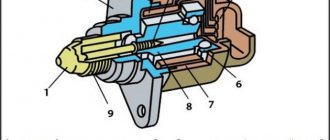

Appearance of the device

Replacing the idle speed control on a VAZ 2109 with your own hands

The idle speed controller (IAC) is responsible for the engine idle speed; with its help, the engine is able to maintain the optimal speed required during operation without load to save fuel and increase the service life of the engine's operating mechanisms.

In addition, idling allows the engine to warm up before starting to drive. The idle air control is located on the left side of the throttle assembly and consists of three main components:

A rod with a conical needle at the end.

Device

The VAZ 2109 carburetor consists of two main elements - the body and the cover. All parts are mainly located in the housing (pump, jets, float, etc.). Also, the power system, which may be associated with repairs, includes: candles, EPHH, and so on.

When the pump pumps fuel from the tank, it first enters the carburetor float chamber block. This chamber is also called the first or primary. It serves to maintain an optimal level of gasoline at which the carburetor can operate normally and maintain stable speed. At the entrance to the chamber, there is a special fitting through which fuel passes. Its quantity is controlled by the valve, as well as several floats. When you lightly press the gas pedal, the amount of gasoline entering the chamber, and accordingly its pressure, decreases sharply. In order for the flammable mixture to enter the chamber normally, at low pressure, the valve rises higher, clearing the way. This process is continuous and runs as long as the engine. The valve structure is closely connected to the float. This control scheme eliminates the chance of spark plug overflow.

When you sharply press the gas pedal, a large amount of fuel enters the primary chamber block. In order to protect the candles, there is a secondary chamber. It opens when the engine speed is high. The first chamber, with the accelerated movement of fuel, pours it into the second, and ensures a uniform, enriched mixture when it enters the cylinder, thereby preventing pedal failure.

For normal operation of the VAZ 2109 engine, simply gasoline is not enough. The carburetor must also receive air. It enters through the valve into the float chamber block, where it is mixed with fuel and forms a flammable mixture.

In addition to when the VAZ 2109 car is in motion, it can also be stationary, but with the engine running. Here a device such as idle speed is already triggered. It is regulated separately, supplying fuel through a solenoid valve to the float chamber. The idle control circuit includes an electronic device - an economizer. It activates the solenoid valve at speeds below 1700 rpm and deactivates when the gas pedal is pressed.

It is very important to know that food does not always pass through an economizer. Sometimes, the idle circuit bypasses this device, turning on the solenoid valve directly from the ignition.

Also, the carburetor has such a device as: the EPHH control unit. It serves to reduce the amount of exhaust gases and reduce fuel consumption. The EPHH control unit, on a VAZ 2109 car, is mounted separately from the entire power system. For example, when a car is moving downhill while in gear, the gas pedal is completely released. At the same time, the throttle valve closes and the EPHH control unit is activated, raising the solenoid valve.

Features of the sensor device, its operating procedure

In addition to adjusting the air supplied to the engine when the throttle is closed, the sensor is used when warming up the internal combustion engine to the required operating temperature in the winter season. When the ignition is turned on in the car, the rod of the idle speed sensor element extends completely and rests against the calibration hole provided for this purpose. The sensor device “removes” the steps and returns the valve to its original position. When the engine is running, at the moment the steps increase or decrease, the amount of air flow penetrating through the hole simultaneously changes. It turns out that the right amount of air mass enters the engine to ensure stability at idle speed. The dimensions of the regulatory device are small; it can easily fit in the palm of a person. Structurally, the sensor consists of three elements:

- stepper electric motor;

- springs;

- rod with a conical needle at the end.

The device is firmly fixed with a pair of threaded screws on the body of the throttle.

Idle speed sensor VAZ 2109 (carburetor)

Its malfunctions can lead to the VAZ 2109 (carburetor) stalling at idle. The idle speed sensor and the solenoid valve of the VAZ 2109 carburetor are one and the same, here is a photo to confirm:

And this is a very unpleasant situation. This can happen far from the city, or right at an intersection, while stopping at a traffic light. It can be caused by overheating, hypothermia, or clogging.

Characteristics of the XX controller

This part is designed to reduce the engine warm-up time. During this operation, rubbing parts often wear out quickly. So: DXX is also designed to reduce contact and wear. This device is mounted in the throttle assembly, which is located in the engine compartment on the left side of the engine.

Purpose and principle of operation

Main components of the device:

- stepper electric motor;

- conical needle combined with a rod;

- springy part.

Idle speed sensor

As shown in the photo, the device has blocks. The main mechanism is highlighted in red - the idle speed sensor VAZ 21099 injector. The adjusting part that controls the engine speed is visible in gray. Blue – a device designed to read information about the crankshaft rotation speed. If the operation is idling, the air flow enters the main cylinders through special channels.

The green color in this diagram is responsible for comparison in the electronic unit. Here the engine speed is taken into account in accordance with the actual speed.

The coolant temperature sensor also receives the necessary signal. Until the comparison circuit receives the necessary information, the engine will operate at higher speeds. At this time, the air is adjusted using the conical part of the needle. A disruption in the air supply often leads to breakdowns and a complete stop of the motor.

Drawing a conclusion, we can say that a certain amount of air enters the engine - exactly as much as is needed for operation in a suitable mode. This volume is taken into account by a special air flow meter. It transmits information to the controller, which, depending on the value, prepares the mixture at the required concentration. After this, it is injected through the injector nozzles into the vehicle network. You can find out where the idle speed sensor is located on the VAZ 21099 injector in the photo below.

Typical faults

Popular and frequent breakdowns of the VAZ 2109 carburetor and injector idle speed sensor include the following:

- engine malfunction;

- refusal to act when the gas pedal is released;

- uncontrolled idling, even when the engine is warm;

- when the gear is switched off, the engine stalls;

- when the engine is cold, the crankshaft does not increase rotation (video author - Devyatochka.remont).

Characteristics of the 3X sensor

If problems occur with the sensor, you need to immediately pay attention to the light bulbs and the sensor itself.

Purpose and principle of operation

The main task of this device is to turn on the warning lights, notifying people that the car is moving in reverse. It is clear that if the device is unusable, accidents may occur.

The VAZ 2109 reverse sensor works in this way: when changing gears, the shift fork is pressed against the device. This creates a short circuit in the wire and turns on the light, which informs about the movement of the vehicle in reverse.

Typical faults

The most popular problems are:

- The light bulbs burned out. If this happens, you need to remove it and check it with a multimeter.

- Broken contacts.

- The device will not work if the regulator contact is poor, as well as if the contact insulation is poor. Violation of insulation threatens to cause a short circuit.

- In the event of a breakdown, you need to make sure that the fuse in the mounting block is in good condition. If it is damaged or melted, it is worth replacing immediately.

- If the device itself fails, and the symptoms of the malfunction are such that all the lights will not work or, conversely, will work continuously, you need to replace it with a new one.

Symptoms of a problem

Under no circumstances should you ignore signs of failure of the idle speed sensor on your injection or carburetor VAZ 2109. This will make driving uncomfortable at first, but can soon cause a serious accident.

There are several main symptoms that may indicate problems with ICC:

- The revolutions spontaneously begin to increase and decrease;

- When turning on a cold power unit, the speed does not increase;

- When using additional electrically dependent devices, such as headlights or a heater, the speed immediately begins to drop at idle;

- When shifting gears or idling, the engine may stall.

This is not a complete list of possible symptoms, but they are all indirect. Therefore, to make sure that the problem lies precisely in the IAC, and not in other engine components, it is necessary to check the current state of the sensor.

Checking status

To check the current state of your IAC on a VAZ 2109 car, follow several sequential steps.

| Verification step | Your actions |

| Step one | Apply the handbrake on the car and install chocks under the wheels. Safety should always come first when doing DIY car repairs. |

| Step two | You need to get to the sensor you are looking for, disconnect it from the power supply with wires, and then use a voltmeter to check for voltage. The minus is placed on the engine, and the plus is installed on the terminals of the wire block A and D |

| Step three | Turn on the ignition, check the voltage readings. Normally they are about 12 Volts. If the voltmeter shows lower values, there may be a problem with the battery charge level. If there is no voltage at all, you will have to check the entire computer and electrical circuit. Breaks are possible. |

| Step four | Carry out another test with the ignition on. Check terminals AB and CD one by one. In normal condition, the resistance across them should be approximately 53 ohms. If the IAC is working normally, the meter will show infinite resistance |

| Step five | With the idle speed control removed and the ignition on, connect the power supply to it. If at the same time the conical needle moves out, everything is fine with the device. If the cone-shaped needle does not extend, then the IAC is out of order and requires replacement |

Article on the topic: Replacing the coolant in a VAZ 2110: boils, antifreeze disappears

Having determined that the old idle speed sensor has already served its purpose on the VAZ 2109, it needs to be replaced. The procedure is completely doable without outside help.

Removing the IAC

Operation and repair

The VAZ 2109 carburetor, like all other parts, tends to break. Typically, a breakdown involves the failure of any spare part. In such cases, repair usually helps.

The first thing that can break is the accelerator pump. Its purpose is to enrich the fuel mixture, regardless of the air supply, when the throttle valves are opened. If, when you sharply press the gas pedal, the car jerks, it means that there is either not enough fuel, and significant gaps occur in the supply, or, on the contrary, there is too much of it, and it overflows the spark plugs. So, to avoid this problem, an accelerator pump is used. It regulates the exact amount of fuel required for normal engine operation, even when the gas is pressed hard.

The accelerator pump more often becomes clogged with sediment than breaks down, and then repairs are not needed, but simply cleaning is enough. But, if this is not the case, but there is still a breakdown, then the pump needs to be repaired urgently, otherwise operation of the engine of the VAZ 2109 car will be impossible, and you are guaranteed to have pedal failures.

The first symptoms that the pump is faulty is that when you press the pedal, the speed does not increase steadily, but floats. This is due to a shortage, or vice versa, an excess of fuel. The spark plugs do not have time to burn out all the gasoline, and they are simply flooded, so the car jerks while driving. Also, the pedal may fail when pressed.

Repair for such a breakdown is as follows:

We take out the sprayer; Shake it. If there is a characteristic knocking sound of the ball inside, then the sprayer is working, if not, then this will be the reason why the pedal failed; The pump has a rather heavy structure with parts. A large number of holes and channels increases the chance that the pump will clog, and pedal failure will be inevitable. If the holes are clogged, then repairs are not needed. You just need to buy carburetor cleaning fluid and use it to blow out the channels.

If the VAZ 2109 jerks when idling, and there are dips when you sharply press the gas pedal, then the EPHH control unit has a malfunction. Its repair primarily depends on which control unit is installed. They can be 4 or 6 pin. Repair of EPHH must be carried out by a specialist. If you do not have the appropriate knowledge, simply replace the part with a new one.

Replacement or cleaning

Practice shows that in a fairly large number of cases, simply cleaning the idle air regulator allows you to restore its functionality. Therefore, we advise you to try this method first. And if it does not give results, then it will not be difficult to replace the device.

- Buy a container of carburetor cleaner. In this case, your engine may well be fuel-injected. It’s just that this composition is excellent for cleaning IACs and more.

- Disconnect the connector with wires from the sensor, unscrew the two fasteners and remove the affected regulator itself.

- Clean the regulator from accumulated debris and contaminants, and be sure to clean the needle and spring itself. This should be done with carburetor cleaner. Use available tools to tidy up a fairly compact device.

- Be sure to clean the idle air control housing on the throttle assembly. This is where the cone-shaped needle of the XX sensor enters.

- After completing the cleaning of the device, return it to its place and check its operation.

- If cleaning does not bring the desired result, the engine continues to behave inadequately, you will have to purchase a new regulator and install it in place of the old sensor.

- Before replacing, be sure to turn off the power to the car by disconnecting the negative terminal from the battery, then disconnect the block with the power wires, unscrew the mounting screws and remove the device.

- Reassemble in reverse order.

Disassembling the unit for cleaning or replacement

The main thing here is to act carefully and not to overdo it with the carburetor cleaner if you first decide to try cleaning the device. Otherwise, replacing the IAC does not cause problems even for beginners.

Injection cars use a power system that is different from the carburetor with its channel for idling the engine. To support engine operation in idle mode, the VAZ-2109 injector idle speed sensor is used. Experts call it differently: XX sensor or XX regulator. This device practically does not cause problems for the car owner, but sometimes it still fails.

Functions

The IAC regulates the amount of air entering the engine when the throttle valve is closed. This suggests that the IAC performs the functions of automatically adjusting the specified engine speed when idling.

The regulator also takes part in the process of warming up the engine to optimal operating temperatures in winter. The operating temperature range of the IAC is quite wide - from -40 to +130 degrees Celsius.

The IAC, despite such important functions, is small in size and consists of three main elements:

- Stepper electric motor;

- Spring;

- A rod with a cone-shaped needle at the end.

The idle speed control is mounted on the throttle body with a pair of screws.

IAC location

Valve check

There are three main steps to checking the functionality of the solenoid valve.

Verification method

Your actions

Basic operating mode of EPHH

- Start the engine and begin to gradually increase the speed of the power unit;

- Once you cross the 2100 rpm mark, the valve should turn off. This will be heard as a click;

- Now increase the speed to 4000 rpm. In this case, the valve must remain closed;

- Smoothly reduce the speed again, reaching below 1900 rpm. At this moment, the working valve clicks again, which indicates that it is turned on

Engine braking mode

- Disconnect the chip from the damper position limit switch and connect it to ground;

- This action will trick the economizer into telling it that the gas pedal has been released;

- Start the engine and raise the speed above 4000 units per minute;

- Gradually begin to reduce speed;

- When you reach 1900 rpm, the valve should not turn on;

- The limit switch is closed to ground, speeds above idle trigger the engine braking mode. The economizer should not turn on the valve.

Fuel cut-off when ignition is turned off

- Warm up the engine to 90 degrees and turn off the ignition;

- In this case, the engine should stall immediately, not vibrate or rattle;

- If vibrations occur, this indicates that the solenoid valve is not closing the idle jet;

- As a result, gasoline continues to flow into the heated power unit

Carburetor

Why is there a loss of speed at idle? This often occurs after washing the carburetor. To verify that there is a problem, you must:

- park the car on the site;

- turn the engine to idle speed.

Instability of indicators when the engine is on and incorrect operation of other electrical appliances indicates a short circuit that has occurred in the on-board network. The breakdown can be eliminated by testing the wiring and checking the reliability of the terminal connections.

Moreover, the cables of old cars are often locked even after washing. The whole point is that water penetrates under the body and floods the wires. Here, first of all, you need to check the harness leading to the fuse box - it is located very close to the windshield drain and often suffers from moisture. The problem is eliminated by sealing.

In addition, a drop in speed both cold and hot often indicates that:

- the carburetor is simply not adjusted properly;

- the plug has become unusable;

- there were problems with the vacuum brake booster;

- The spark plugs are not working properly.

IAC connection diagram and its operation

The IAC is connected to the ECU control controller with a 4-wire harness through a standard connector.

The existing electrical circuit does not allow the driver to influence the operation of the IAC, since the control algorithm of the controller is reflashed exclusively on special equipment.

The IAC mechanism works according to the algorithm indicated below:

- When you turn the ignition key, the regulator rod moves to its extreme position and the calibration hole of the air pumping channel in the throttle pipe is completely closed.

- The IAC returns the valve to the primary position after starting to read steps. At this location of the rod, the motor starts and its operation begins in the XX mode.

Important! The basic position of the rod is determined by the ECU firmware - for example, it is equal to 50 steps for Bosch firmware, and for January 5.1 firmware it is 120 steps.

The disadvantage of the VAZ 2109 injector idle speed sensor and its connection to the ECU is the lack of a self-diagnosis system. In case of malfunctions and errors in operation, the driver will not receive any useful information about this. The Check Engine light on the dashboard will not illuminate. Therefore, the driver must independently guess about the malfunction of the regulator based on his own analysis of randomly appearing indirect signs that affect the operation of the engine.