Scheme

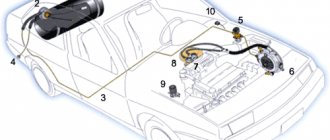

The second generation system has the following design:

1. Cylinder 2. Multivalve + Ventilation unit 3. High pressure hoses and pipelines (gas line) 4. Filling device 5. Gas valve with filter (electromagnetic) 6. Reducer (gas evaporator) 7. Gas dispenser 8. Mixer (mixer) 9. Gasoline valve (solenoid) or Injector operation emulator 10. Fuel type switch (gas-gasoline)

The diagram also shows a gasoline valve, but in most cases on injection engines, its installation is practically impossible. It is much easier and more correct to turn off gasoline using an injector emulator.

What is gas equipment

GBO is gas-cylinder equipment. It is a gas installation that powers the engine instead of conventional fuel. Gas can be of two types - propane or methane. In practice, they differ little (except for the state of aggregation), but in terms of price and storage they still have slight differences.

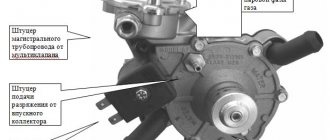

LPG for a passenger car

There are several types of HBO:

- First;

- Second;

- Third;

- Fourth;

- Fifth generation.

The higher the generation, the more advanced the system (more sensors and electronics are used, everything is calculated more accurately and the operating efficiency is higher). But the generation of HBO is selected depending on the type of engine and it is not always possible to use the 5th generation installation on an old engine.

Balloon

Made of 3-4mm thick steel to ensure safety even in case of accidents. Currently, cylinders are produced in various sizes depending on the engine size.

A cylindrical cylinder is the most common shape in first-generation LPG installations.

Cylindrical cylinders, options and cost Toroidal cylinder - designed for mounting in a spare wheel storage area. This shape allows you to conveniently place the cylinder in a car while maintaining useful space, for example in a station wagon. Toroidal cylinders, options and cost There is a variation in the cost of cylinders; toroidal options are best for installation.

Multivalve and Ventilation unit

A multi-valve is installed together with the cylinder. It prohibits filling the cylinder above 80%. Cylinders should not be 100% full.

Free space is necessary in the cylinder to ensure safety. Even if the cylinder is heated to +70 C, which is impossible even if the machine is used harshly, the liquid will fill the residual volume.

Multivalve TOMASETTO 315/30 class A Multivalves, options and cost The cost of a multivalve is within 2000 rubles. There are options for 1500 rubles.

The multivalve also performs other functions:

- Filling during refueling

- Gas level detection

- Gas supply

- Shutting off the gas supply

- Refill volume limitation. (up to 80%)

The multivalve is installed in the ventilation unit. It avoids possible gas accumulation as a result of any unforeseen circumstances.

Ventilation chamber TOMASETTO

The removable cover provides easy access to the multivalve.

Ventilation chambers, options and cost On average, a ventilation chamber will cost 300 rubles.

Hoses and pipelines

Made of copper and can withstand pressure of 45 bar, from 6 to 8 mm in diameter. The cylinder is connected to the multivalve and reducer through this particular pipeline.

Copper pipes, options and cost The pipe must be secured to the bottom of the car, far from the exhaust pipe and the car suspension.

There should be elastic pads at the attachment point to dampen vibration.

A pipeline with a diameter of 8 mm is supplied to the filling line. For all other ligaments - 6 mm.

The rubber hose is used to install the antifreeze connection from the point of insertion into the line to the gearbox and to install the connection between the gearbox and the injectors.

Rubber hoses, options and costs All prices are indicated for 1 meter.

Gas valve with filter

This valve automatically shuts off the gas supply from the cylinder to the engine.

The gas valve is closed when there is no voltage (12v) applied to it. When the electrical circuit is closed, the valve opens and opens the gas supply.

Lovato gas solenoid valve There are arrows on the surface of the valve that indicate the direction of gas flow - that is, from the cylinder to the engine.

Average valve cost -

Gas valves, options and cost The valve is fixed in a vertical position, usually on the wall of the engine compartment.

The valve is also equipped with a filter (to clean the incoming gas). Filters come in different sizes and shapes, depending on the type of valve used.

Filter options The cost of a filter also depends on its type and amounts to 100-150 rubles.

Which system should you choose?

There are several leading LPG manufacturers in the world, one of which is Lovato. The equipment has a fairly high build quality, as well as high performance indicators. A particular advantage is the electronic control unit, which calculates all readings with excellent accuracy and very rarely fails. You can also note the compactness of this installation, in comparison, for example, with BRC equipment. It is worth choosing LPG for a specific type of gas, that is, either for liquefied propane or for compressed compressed methane. By the way, when using propane, gasoline injectors can be used, since the density and consistency of the gas is close to gasoline. When working with compressed gas, it is necessary to use special gas injectors.

Regulating gas equipment on your own takes half an hour. And replacing a gas filter with a 2nd generation Lovato gas filter is also not a source of difficulties. It is extremely important in this matter to maintain attention and concentration, avoid haste and strictly follow the practical guidance.

Mixer

Supply the engine with the required amount of gas and air. This happens in various ways through the carburetor diffuser, or by creating a diffuser in the design of the mixer itself.

For each type of vehicle there is a specific mixer model.

Mixer 300-489 FIAT Punto2 Mixers can also be divided into several groups: 1. Mixers installed in the upper part of the carburetor; 2. Mixers - spacers that are installed in the middle part of the carburetor. 3. Fittings, so-called inserts, inserted into the carburetor using drilling. 4. A fork-shaped system consisting of tubes that are inserted into the carburetor without drilling. 5. Mixers for injection systems of various modifications. Faucets, options and costs

Gasoline valve

Blocks the supply of gasoline when the car is running on gas. The valve is closed when no electricity is supplied to it and opens when turned on.

Lovato gasoline solenoid valve It is installed in the engine compartment only on carburetor cars between the gasoline pump and the carburetor.

There are arrows on the valve body indicating the direction of gasoline flow. The valve must be mounted vertically, away from hazardous engine parts.

Gasoline valves, options and cost The cost of the valve is within 1000 rubles.

In most cases, on injection engines, installing a gasoline valve is practically impossible. It’s easier and more correct to turn off gasoline using an injector emulator.

Is it worth installing HBO on your car?

Installing HBO on your car is a completely individual matter, but still, such a decision is justified.

Gas is much cheaper than conventional fuel and this is already one of the reasons to switch to it. The second is, of course, environmental friendliness.

The gas burns almost completely, leaving behind no harmful emissions or toxic substances, and significantly less carbon deposits are formed. Gaseous fuel does not harm the engine at all and does not cause frequent breakdowns, and most problems associated with valves and pistons are rather a problem of saving on fuel and maintenance. The only disadvantage of HBO is that it requires constant and timely adjustment, especially at the beginning of a new season.

Injector operation emulator

When installing LPG, the gasoline supply is interrupted by turning off the injectors. The standard ECU initiates injector shutdown as a break in the injectors, turns on the fault lamp (Check Engine) and puts the engine into emergency mode (the latter rarely happens).

The injector operation emulator is used to prevent the ECU from seeing the injectors breakage.

Let's look at its diagram.

Injector operation emulator circuit When running on gasoline, the circuit is closed, and when running on gas, the circuit opens and runs through the load resistors, thereby not indicating to the ECU that the wires are broken.

The emulator is selected according to the number of engine injectors, usually 2, 4, 6 injector models.

The cost of such an emulator is within 1500 rubles.

Jet selection

There is a misconception that the jets are located at the end of the hose and are installed in the manifold; in fact, the jets are installed directly into the gas injectors.

Where can I find Lovato LPG jets?

Make sure you have the correct jets selected. Here is a table of diameters, depending on the power of one cylinder.

| Power per cylinder, hp | Diameter, mm |

| 13-20 | 1,6 |

| 20-26 | 1,8 |

| 26-29 | 2,0 |

| 29-34 | 2,2 |

| 34-39 | 2,4 |

| 39-45 | 2,6 |

If necessary, drill out the jets.

The use of gas systems in cars is a justified step in saving money. The cost of gas (a mixture of propane and butane is used) is almost half the cost of gasoline, and the final result is almost the same. Installing gas cylinder systems on budget and middle-class cars will not cause serious difficulties for an experienced car enthusiast who is fluent in a jigsaw and grinder.

Fuel switch

Gas/gasoline switch is a device designed to switch the operating mode of a vehicle from one type of fuel to another at the moment when a certain number of vehicle engine revolutions is reached.

Switch K-5 Tamona All switches are divided into three main groups.

1. For injection engines. This type of switch has three positions: petrol, gas and automatic mode. 2. For carburetor engines with the installation of an electronic gearbox. In these switches, the “GAS” position is equipped with an automatic shutdown of power from the shut-off valves. 3. For carburetor engines with the installation of a vacuum reducer. And on this gas-gasoline switch there are two toggle switches. One for switching the type of fuel, the second for pumping gas before starting the engine.

The cost of switches usually does not exceed 1000 rubles.

Switches, options and costs All switches come with a wiring diagram and mounting kit.

Advantages and disadvantages of 1st generation HBO

The undoubted superiority over all subsequent generations is the simplicity of the design and the cost of the kit, its installation and connection. All the advantages. And now the disadvantages. The first generation of HBO requires constant attention of the car owner. Design imperfections cause additional troubles. Adjustments and cleaning of filters are a common process.

Short service life of the vacuum reducer membrane due to large temperature changes. Gas consumption in physical terms is up to 30% higher than gasoline consumption (if gasoline is 10 liters per 100 km, then gas is 13). The unreliability of the system leads to gas leaks, which settle in inspection pits and cellars. This leads to fires. It is no coincidence that in large vehicle fleets all parking lots run on gas, only in the open type.

The advantages of running gas engines relative to gasoline and even diesel engines are quite obvious. From environmental regulations to operating costs. This is especially noticeable during long daily runs. Owners of minibuses and passenger taxis have long realized this.

Installation

2nd generation LPG is usually installed on carburetor cars. Very often the price of equipment is a decisive parameter. If the car is not in the premium segment, then there is no point in installing expensive equipment on it.

The cost of all gas equipment with its installation starts from 15,000 rubles.

You can also purchase all the equipment as a mini kit for self-installation. The average price is 6,000 rubles.

Mini kits for HBO, options and cost Typically, such a kit consists of:

| HBO-2 has a number of difficulties when installed on an injection car. |

An experienced technician can always answer your question: is the 2nd generation LPG suitable for your fuel-injected car or not?

The installation of 2nd generation LPG on modern fuel-injected cars was carried out mainly when 4th generation systems had not yet been invented.

The second generation gas equipment fully meets the environmental requirements of Euro-1.

Systems approach Euro-2 standards only in individual cases. This was the main reason why 3rd and 4th generation systems appeared on the market.

1 Cylinder Included in a set with fastening tapes or bolts, depending on which cylinder you chose

2 Multivalve for cylinder 3

Gearbox

4 Filling valve (it is often sold complete with a multi-valve) (comes with a multi-valve)

5 Fuel shut-off valve (gasoline if the car is carburetor) If the car is not a carburetor, but an injection one, you will need to buy an injector emulator in place of the gasoline shut-off valve (emulators are different, for example, if there are 4 cylinders, then the emulator should be for a 4-cylinder car, and so on .) Most often, 2nd generation gas cars are four-cylinder.

6 GAS-PETROL switch button There are 2 options for the buttons for carburetor and injection cars. When purchasing a button, you need to clarify to the seller that your car is either carburetor or injection. This is necessary in order to correctly assemble the electrical circuit in the future.

7 A mixer for your carburetor or, if the machine is an injection machine, a mixer for your type of injector. It is needed so that we correctly supply the gas mixture to your intake manifold.

Looking for an alternative to gasoline

Gas is much cheaper than gasoline and it is enough to install special gas equipment on your car and refueling costs will decrease.

Attempts to use gas as a fuel for cars have been made almost since the advent of the automobile.

But much later, a set of equipment appeared, with which it was possible to convert any car to run on gas.

Passenger cars use equipment that runs on liquefied gas (propane-butane). It is not advisable to use compressed gas on such vehicles due to the large weight of the cylinders.

Several generations of this equipment are produced, in accordance with the design features of the car and Euro toxicity standards:

- HBO 1st generation. Toxicity is below Euro, used on carburetor cars and on cars with a monoinjector;

- HBO 2nd generation. Toxicity up to Euro-2, also installed on carburetor and injection cars;

- HBO 3rd generation. Toxicity up to Euro-3, used on injection cars;

- HBO 4 generations. Toxicity – Euro-4, used on injection cars;

- HBO 5th generation. Provides precise control of liquid gas injection. The operating principle is 100% similar to the operation of the gasoline system;

- HBO 6th generation. It differs from the 5th in the presence of a fuel substitution unit - FSU, to which gas and gasoline are simultaneously suitable. The operating principle of all systems will be discussed in the following articles.

Operating principle and differences between buttons

The 1-2 generation button on the carburetor has two working positions and one neutral.

Changing the fuel type should only occur through the neutral position. If you turn on the gas right away, two types of fuel will enter the combustion chambers and the engine will most likely stall.

Some copies have an indication of the fuel level in the cylinder, as well as an additional button for the pre-start supply of a portion of gas, which is needed to enrich the mixture when starting a warm engine on gas (for example, Lovato, Logo buttons for a vacuum reducer).

A key such as, for example, Stag 2-G already has a pre-start function built into it, with the ability to adjust by time.

In the injection version, instead of the middle position, there is an automatic mode (on some types, such as Stag 2-W, it can be extreme). In this position, the engine starts on gasoline, and when a certain engine speed is reached, the gas supply is automatically turned on.

The transition speed is regulated using a potentiometer on the side surface of the housing. This key can also come with a level indication.

The universal option involves installing a toggle switch on both the injector and the carburetor. The transition between modes is carried out using a jumper/jumper on the case (example SVG switch).

The 4th generation HBO button has an LED indication and 2 operating modes on/off. In the on position, the gas turns on automatically after the reducer-evaporator warms up to 35-45˚C. The temperature is programmed in the controller when setting up the equipment.

Button signals using Stag as an example:

- LED is on/off – the engine is running on gas/gasoline;

- blinks at intervals of 1 second. – the engine is not warmed up;

- flashes every 2 seconds – the system is ready to switch to gas;

- blinks every 4 seconds – the tank has run out of fuel;

- the buzzer beeps three times - the system switches from gas to gasoline due to lack of fuel;

- three short signals 1 long – ECU (control unit) error;

- two short beeps 1 long beep (with the ignition off) – maintenance of gas equipment is required.

In addition, the fourth version of the gas system has an emergency start on gas. The mode is activated as follows: hold the button with the ignition off until the LED lights up continuously. Then, without releasing the key, we start the engine. Deactivation occurs after stopping the internal combustion engine.

Types of buttons (video):

Selection table (with approximate prices):

| Name/labeling | injector/carburetor/generation | Level indication, +/- | Price in rubles |

| REG OMVL Dream XXI King | engineer/4 | + | 1020 |

| Logo 145 | engineer/4 | — | 280 |

| Logo 101 | carb./1.2 | — | 470 |

| Atiker (K01.003.000.020) | carb./1.2 | + | 600 |

| Stag 2-G | carb./1.2 | — | 550 |

| AEB 722 | carb./1.2 | + | 1050 |

| Tamona K-5 | carb./1.2 | — | 520 |

| Lovato | carb./1.2 | — | 590 |

| Torelli | carb./1.2 | + | 630 |

| Stag 2-W | engineer/2 | — | 600 |

| Tamona in-3 | engineer/2 | — | 540 |

| Stag LED-401 | engineer/4 | + | 750 |

| Stag LED-300 | engineer/4 | + | 580 |

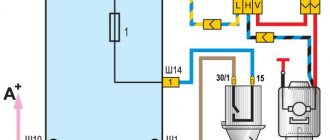

Connection diagram of the 2nd generation HBO button to the injector

Installing and connecting the 2nd generation HBO button with your own hands on a car with an injector sometimes causes difficulty.

In fact, everything is much simpler than it seems. The factory instructions for installing the switch indicate the following pinout:

- the white wire should go to the level sensor on the multivalve (if such an indicator is installed);

- yellow goes to the positive of the gasoline valve (if there is emulation of gasoline injectors, this wire is not connected);

- blue connects to the positive terminals of the gas valves of the reducer and the additional remote valve with filter. The injector emulator also cuts into this circuit;

- red goes to the positive terminal of the ignition coil (necessarily with a fuse);

- black - mass;

- brown to the negative terminal of the coil.

It’s hard to disagree with the first three points. But for the rest we will make recommendations:

- The red wire is best connected to the positive side of the ignition switch. Because the coils may have voltage surges. In order not to disassemble the panel, the contact can be found on the fuse block.

- The black wire should only be attached to the car body, like all negative equipment cables.

- Brown, must be wound onto the central high voltage wire of the coil.

It is advisable to do 10-15 turns, without using electrical tape. The electrical tape dries out over time and falls off; it is better to make a knot similar to tying a fish hook.

If the ignition system consists of separate coils, it is necessary to wind the wire onto the first two armor wires (for a more accurate signal), without breaking the brown one, i.e. first to the first then to the second.

After connecting the button, it must be adjusted. Periodically increasing the engine speed with the accelerator, it is necessary to smoothly turn the potentiometer screw clockwise and back. It is necessary to ensure that the gas supply is turned on in the “automatic” mode when the tachometer reading is 2000-2500 rpm.

List of required tools and equipment

Installing a 4th generation gas system with your own hands is not a difficult task. Before you carry out installation yourself, you need to acquire a certain set of tools.

No specialized tools are required to carry out work related to the gas system.

have :

- standard set of socket bits and sockets;

- pliers;

- WD-40;

- electric drill;

- a set of metal drills;

- thread tap (for injector threads);

- sealant and thread locker;

- a set of screwdrivers (including torx screwdrivers);

- torque wrench (optional);

- spare bolts, nuts and washers (preferably).

Connection diagram of the 2nd generation HBO button to the carburetor

For a carburetor engine, the connection looks similar:

- Red - through the fuse to the ignition coil/switch.

- Light blue (blue) – gas valve positive.

- Yellow – positive of the gasoline valve.

- Black – minus (car body).

- The brown one goes to the ignition coil armored wire. It is needed to transmit an impulse to the key, which determines whether the motor is running or not.

If you still have questions about connecting or selecting buttons on the HBO, ask them in the comments. We will be happy to answer them.