TIE ROD JOINTS

The most important components of the side rods are the steering rod joints, but they are also called tips. They are designed to be effectively connected to so-called threaded lugs. The hinges themselves look like hemispherical fingers. They are also very unreliable, and therefore problems arise specifically in them. But in order to replace the steering rod joint, you need to have a complete assembly of the mechanism, because it is impossible to repair or restore it. In this regard, remember, when you change the hinges on one side, it is recommended to replace them on the next, so as not to encounter this problem again.

Features of use

The described parts are constantly exposed to severe loads. The vehicle's reaction bars experience loads in both the longitudinal and transverse directions. However, since these knots are part of the undercut, they also work to twist.

Jet thrust is made mainly from steel of more elastic grades. This is necessary to be able to work in very harsh conditions for quite a long time.

The lugs are not part of the design. They are welded separately onto the rod. Welding seams often have a short service life and over time, and even under loads, can collapse. If the seam breaks, they must be replaced. Such spare parts for cars are inexpensive, you can buy them almost anywhere.

Set

Tuning Volkswagen Polo sedan

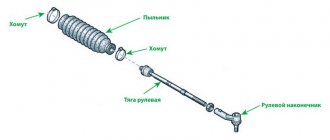

The steering rod kit includes the rod itself and the tip (hinge). There are also several other main components.

- The main one is the housing; the axle shaft is installed in it.

- There is a ball pin on which a thread is cut for tightening.

- The third component is considered to be a Teflon limiter; it prevents the ball pin from moving and fixes it in place.

In order to protect the tip from debris and early breakage, a cover is provided that closes the housing. The kit includes several more protective devices and a nut for securing.

The kit also includes a ball joint; it is installed on the steered wheels and maintains a tight grip and limits the mobility of the steering arms. The ball joint is more of a part of the suspension because it helps keep the car on the road when cornering, keeps the wheels level, and helps steer the car.

Front traction

When driving, different forces can act on the wheels. Some of them work in longitudinal directions. These effects can be especially felt during acceleration or braking. The wishbones cannot cope with these loads because they were not designed for such tasks. To keep the wheels in place longitudinally, jet traction is used. Often these parts are attached to the main arm, more often to the lower arm, and the other end is installed on the car body. This makes it possible to achieve greater longitudinal stability.

Functions

Body dimensions of carsBody. Exterior. Volkswagen Polo 3

The tip performs a rather important task in driving a car; it also connects the wheel, which must turn through. The hinge also adds elasticity to the suspension due to its mobility.

Each car has at least four and no more than six hinges, depending on the configuration and other characteristics. Often, tie rod ends are simple in design, which adds durability. Despite the simplicity of the design, the tips often fail and need to be replaced. The part is attached with one side to the steering rod, and the other to the ball joint, which is mounted on the steering knuckle.

Tie rods

| Rice. 239. Steering parts with a transverse tie rod: 1 - transverse tie rod joint; 2 — hex nut, 50 Nm; 3 — clamping ring with antennae upward; 4 — cover; 5 - clamp; 6 — right transverse steering rod; 7 — lock nut, 50 Nm; 8 — left transverse steering rod; 9 — hexagonal self-locking nut, 30 Nm; 10 — lever; 11 — hex nut, 30 Nm; 12 — left tie rod joint; 13 — hex bolt, 30 Nm; 14 — adjusting screw; 15 — steering mechanism; 16 — rubber seal; 17 — hex bolt, 30 Nm; 18 - intermediate shaft with universal joints |

Tie rods cannot be replaced when the steering is installed. The left steering linkage on the new car is non-adjustable. When replacing it, you can only install an adjustable steering rod. The mechanism must be clamped in a vice. In Fig. shows how the tie rods are attached to the rack and pinion.

To replace steering rods, you must perform the following operations:

- open the clamping ring of the boot on the outside, to do this, squeeze both ends of the ring, remove the cover from the rack housing and move it along the steering rod without damaging it;

- Loosen the large locknut at the end of the rack and disconnect the old transverse link. An open-end wrench is used for this purpose;

- Using a wrench, loosen the body of the ball head bolt.

- bring the gear rack to the middle position, turning its gear until the gear rack comes out at both ends to the same length from the housing, as shown in Fig. .

| Rice. 248. Installation of steering rods: 1 - internal hinge; 2 - lock nut; 3 - toothed rack |

When installing new tie rods on the rack, several measurements should be taken:

- Move the rack in the housing until both ends of the rack protrude exactly 67.0 mm. Measurements are taken from the edge of the body to the end of the rail, and the resulting size is designated as a;

- screw the locknuts to the end of the rack and screw in the tie rods until the dimension b indicated in the figure is exactly 69.5 mm. In this case, the size is taken from the edge of the body to the plane of the internal ball joint;

— tighten the lock nut to a torque of 50 Nm and put on the cover. Insert the clamping ring into the groove and release the ends.

Even if two adjustable tie rods are installed, wheel toe can only be adjusted on the right tie rod.

When replacing the left tie rod with an adjustable one, adjust the new tie rod to the same length to which the old, non-adjustable tie rod was installed. To do this, measure the size between the vertical and downward-facing ball head bolt and the inner surface of the inner ball joint of the tie rod. Rotate the tie rod end accordingly and tighten locknut 2 (see fig.) to a torque of 50 Nm. Although a new tie rod is supplied pre-adjusted, the measurement must still be carried out.

When replacing the right (adjustable) tie rod, move the steering mechanism to approximately the middle position and adjust the size using the method described above to the specified value.

After replacing one of the steering rods, always check the wheel alignment and, if necessary, make adjustments (see subsection 10.5.1).

| previous page10.3.1. Removal and installation | next page 10.5. Front wheel adjustment |

How to choose and replace the steering rod

Steering rods are subject to significant loads during vehicle operation, so they quickly become unusable. Most often, problems arise in ball joints; rods are also subject to deformation and cracks with subsequent destruction of the part. A malfunction of the rods may be indicated by the appearance of play and wobble in the steering wheel, or, on the contrary, an excessively tight steering wheel, various knocks while driving, as well as a loss of directional stability of the car (it is pulled to the side). When these signs appear, the steering should be diagnosed, and if problems are found with the rods, they need to be replaced.

For replacement, you should choose those tie rods and ends that were installed on the car earlier - this is the only way to guarantee that the steering will function correctly. If the problem occurs in only one side link or tip, then it is better to replace these parts in pairs, otherwise there is a very high probability of the link breaking on the second wheel.

Replacement of rods must be carried out in accordance with the vehicle repair and maintenance instructions. Usually this operation comes down to lifting the car on a jack, dismantling the old rods (for which it is better to use a special puller) and installing new ones. After repair, it is recommended to adjust the wheel alignment. New linkages on some vehicles (especially trucks) need to be lubricated periodically, but usually these parts do not require maintenance during their lifetime.

With the correct selection and replacement of steering rods, vehicle control will be reliable and confident in all driving modes.

Source

Device

A tie rod usually consists of a metal rod and two ball joints at its ends. Each hinge is protected from dirt by a rubber boot. Some tie rods may be adjustable in length. This is necessary to adjust the wheel alignment. Sometimes there are designs that have only one ball joint. Their second hinge is rubber-metal, which does not need protection with a boot.

The most popular in the design of front-wheel drive passenger cars is the rack and pinion steering mechanism. Its tie rods are the same on both sides and most often consist of a rod and two ball joints. The inner hinge is attached coaxially to the rod and is located under the cover of the rack, and the outer one is perpendicular to its axis with its boot. The steering knuckle lever has a tapered hole for attaching a hinge. The surface of the finger mating to it is also made in the shape of a cone. Therefore, it is quite difficult to disassemble the lever-pin connection without a puller.

Troubleshooting

Some signs of steering failure can be identified visually. Their diagnosis begins with an external examination of the anthers and rod.

- The boots should not have ruptures or cracks, and no grease should leak from underneath. Leaky covers need to be replaced if the wear of the hinge does not exceed the permissible limits. Before installing a new boot, remove dirt from the joint and place a little Litol between the ball and the liner.

- If the rod shows signs of deformation from impact, the steering rod must be replaced.

- When it was not possible to determine the malfunction by external inspection, you need to check the degree of wear of the tips.

To check the hinges without removing the traction, place the car in an inspection pit or on an overpass. Stand under the front of the car. Grab the rod with both hands close to the outer joint and rock it up and down. The body of the outer tip can have a free play along the axis of the pin of no more than 1.5 mm. This play is due to the mobility of the conical plastic liner along the axis of the pin. It should not be perpendicular to the center line of the finger. You need to have an assistant check the internal rack and pinion steering joint. He should frequently turn the steering wheel from side to side by 15–20 ◦. Meanwhile, by touch, determine the presence of gaps. If you can feel the play with your fingers, the hinge will not last long - change it.

15.14. Transverse and longitudinal thrust

1. Jack up the rear of the car and place it on secure supports.

2. Remove the wheels.

3. Removal is carried out in the sequence shown in the figure.

4. Before removing the nuts, make alignment marks on the cover plate and cross member.

5. Place a jack under the cross member and then remove the nuts.

Warning

Do not allow the crossbar to fall.

6. Check the condition of all parts and, if necessary, repair or replace them.

7. Installation is carried out in the reverse order shown in the figure, taking into account the following.

8. Install the cover plate so that it is oriented in the same direction as the cutout on the plate adjustment bolt and cover plate.

Tightening torque: 86-117 N m

9. Install the wheels.

Tightening torque: 88-118 N m

Warning

Having not fully tightened the transverse link and longitudinal link mounting bolts and nuts, lower the vehicle and finally tighten all bolts and nuts to the required torques in an unloaded condition.

10. Having installed the transverse and longitudinal rods, measure the wheel adjustment parameters and, if necessary, make adjustments.

Replacing jet rods

Replacement may be necessary if the rod is cracked or if knocking noises are heard when driving. It must be remembered that a replacement not made in time will lead to loss of movement stability. This is the risk of an accident.

To perform the replacement yourself, you need to prepare the necessary tools. To work, you will need a metal brush, keys, and WD 40 universal lubricant. VAZ jet rods can be bought at any store. They are inexpensive.

The first step is to clean all the joints very well with a brush. Then all this needs to be generously filled with universal WD 40 and left for a while until the lubricant takes effect. Next, unscrew the nut that holds the rod on the free side. It will go very tight. A pipe may be needed. When the nut is even with the end of the bolt, you need to tap the bolt with a hammer. The latter sticks and cannot be removed so easily. Next, remove the bolt and nut.

Now the same needs to be done on the other side. You will need to unscrew the lower part of the shock absorber. The nuts here will also be unscrewed with noticeable force; If everything is unscrewed, you can get the rod. There's no need to try to fix it. These car parts cannot be repaired. After the operation, you will have a working suspension, no knocks and a high level of safety when driving. That's all.

So, we found out what jet propulsion is and how to replace it on domestic cars.

Source

How the system works

Steering is a set of mechanisms that includes many elements, each of which is important in its own way. For example, the tie rod boot, which is part of the steering system, protects the rod from contamination and premature failure.

Indirectly, the steering system includes suspension elements such as stabilizers and struts. The fact is that the car tilts when turning and with intensive rotation of the steering wheel it can tip over, this is prevented by properly working ones.

The stabilizer is installed on both the front and rear axles of the car through a bearing or special bushings. The stabilizer is made of spring steel and has a complex shape due to the specific location of components and assemblies on each car, so you need to choose a stabilizer specifically for your car.

It is worth noting that there is a steering system not only for the front wheels, but also for the rear ones. Most often, such systems are installed on work equipment. The fact is that cargo and specialized vehicles are often loaded on the front, and the front wheels become the drive wheels, and the rear wheels become the turning wheels. This is done so as not to exert effort to turn the wheels. In such a system, everything is installed with increased strength, even the hinges, due to the fact that the load is greater and wear is correspondingly greater.

All rods are divided into three types:

- The first type is a transverse steering rod; it is located perpendicular to the bridge and parallel to the body.

- The second type is a longitudinal steering rod; on the contrary, it is located parallel to the bridge and perpendicular to the body. The longitudinal steering rod can be lower or upper. The length of the lower rod is always greater than the upper one.

This is the whole difference in longitudinal and transverse thrusts. All of them are located in the front of the car and in rare cases in the rear.

From the history of the rocket rod

As technology advanced in the automotive industry, engineers constantly worked to increase the speed of cars. Even before the outbreak of World War II, the developers came to the conclusion that the then low-tech and simple rear suspension, where a spring was used as an elastic part, was also a stabilizer.

So, when driving at high speeds, there were reasons that significantly influenced the controllability. This is body swaying, various rolls. If you move along the road at low speeds, this will not cause any discomfort or negativity; these forces will not be felt. However, if you increase the speed, such movement can cost the driver of the car his life.

To put it another way, automakers began to think and conduct tests in order to somehow remove the impact on the car of forces that could overturn it. For this, developers and engineers came up with a special system of levers, which laid the foundation for the creation of independent suspensions. The developments did not stop there. To ensure stability of the car body, jet thrust was created.

Synchronized wheel turning

In order for the wheels to turn synchronously and help each other, a trapezoid was developed. The fact is that the trapezoid was developed long before the first steering wheel appeared. The trapezoid was used on the first steam cars. With the advent of independent suspension, the trapezoid greatly changed its design and became more modernized.

Oddly enough, the trapezoid in the car is also subject to wear and tear. The main signs of a worn-out trapezoid are extraneous sounds and other accompanying signs (for example, when the wheels turn to the right, the left wheel turns, but not as before).

Consequences of a faulty steering rack

If the first symptoms of a malfunction appear, it is better not to take risks and stop using the car. The purpose of the steering rack is to simplify the control of the car, and this function is directly related to safety. The consequences of a malfunction of this mechanism can be very serious, including complete loss of controllability. Therefore, it is better to repair the steering rack at the stage when it just begins to creak and show other initial signs of failure.

Popular brands:

Kia Sportage

Replacement

Most often, the boot is damaged due to the fact that it is made of rubber, and the boot can be damaged even when installing a new steering rod. When replacing the boot on the right side, you need to replace it on the left side as well.

You should not put off replacing the boot because the boot protects the entire linkage from dirt and other debris getting into the important steering unit

When replacing the boot, you should pay attention to the place that the boot covered; perhaps it already requires replacement

If, after all, a malfunction of the boot was noticed late, then in any case the entire linkage will have to be changed.

But hinges rarely become unusable if they are properly cared for. The new hinge has no play at all due to the fact that the new additional parts for the hinges are made of high-quality materials.

You should not delay the process of replacing old and faulty ball joints, otherwise this may lead to a serious accident. If it was decided to change the right front steering tip, then you should inspect it from the other side, because they usually become unusable at the same time.

Purpose of steering rod

Even if we take into account the fact that for different car models there are a large number of design features of this component part, the essence of the drive does not change. The connection between the lever of the corresponding mechanism and the longitudinal element is carried out using hinges. When the bipod rotates, the middle link moves to the right or left. The wheels turn in the desired direction using side rods.

Video about tie rod

There is also a steering drive that is simpler in its organization - a rack-and-pinion mechanism. Its main difference is that it uses only two steering rods, which force the car's wheels to turn in the desired direction and interact with the steering arms through a slight effort on the part of the driver.

What is the torque rod for in gear motors and what functions does it perform?

The device is a special metal part and is placed in the gear motor to provide compensation for the torque that comes from the adjacent structure. The damping sleeve can be attached additionally to the mechanism to ensure high functionality.

Another additional component can be a drive shaft (one-sided or two-sided), which uses various elements of the system.

Reaction rod for worm gearboxes

The device is used in a wide variety of technical fields. The main element of the system is a special worm, which is a screw equipped with a thread. A gear with a specific tooth shape is attached to it. As the main mechanism moves, the thread elements move along the axis, pushing the wheel teeth in a certain direction. The size of the gearbox is determined by the distance between the wheel axle and the worm axis.

Longitudinal steering rod - Great Encyclopedia of Oil and Gas, article, page 1

Longitudinal steering rod

The longitudinal steering rod from the bipod to the front wheel should be positioned so that during any movement of the wheels it is subject to the least axial movement. The deviation of the longitudinal thrust from the theoretical position, caused by the movement of the front wheels, worsens the quality of control.

Longitudinal steering rod / tubular.

The longitudinal steering rod (Fig. 136, c) is made of a pipe with thickenings at the ends for assembling hinges. One hinge connects the rod to the steering bipod, and the other to the swing arm of the left steering axle.

The longitudinal steering rod 13 (see Fig. 109) connects the upper lever 11 of the left steering axle with the steering bipod. Tip 1 is screwed onto the rear end of the rod (Fig. 115), with which you can change the length of the rod and thereby adjust the maximum angles of rotation of the steered wheels. Thanks to spring 5, a gap is automatically selected in the connection, and the shock load on the steering mechanism parts is softened.

The longitudinal steering rod connecting the bipod to the steering knuckle lever of the front axle is located along the frame spar on the left side, and the steering linkage is located behind the front axle beam.

The longitudinal steering rod 2 is connected by a ball pin / to the steering bipod.

Tie rods of the described design are quite reliable for heavy-duty trucks.

A longitudinal steering rod with a spring is used, which can soften shocks (Fig. The spring works in compression both when the wheels compress the rod and when they stretch it.

The longitudinal tie rod inserts must move freely in the rod cavities.

The longitudinal steering rod joints are adjusted by turning the plug screwed into the end of the rod. To adjust the hinges, you need to unscrew the plug of one of the hinges, screw it in with a special screwdriver until it stops, and then unscrew it Yz-V of a turn so that you can install the cotter pin.

The condition of the steering rod joints is controlled by turning the steering wheel in both directions.

Pages: 1 2 3 4

Steering rods, what are they? Is it worth delaying renovations?

Many drivers ignore steering problems. As long as the car is driving, it’s fine, but if it breaks down, then they go to a service center to repair it. But due to control problems, the chance of getting into an accident in a difficult road situation increases, and due to a violation of the toe angle, the tires will very soon “die for a long time.”

Functions of steering rods.

The tie rods transmit forces to the steering arms of the hubs from the steering mechanism, which turns the wheels. They are also part of the steering linkage, simultaneously ensuring that the wheels turn at different angles - after all, during a turn, the wheels roll along different radii.

Hinges are mounted at the ends of the steering rods. Thanks to them, during the mutual movements of rods, body, wheels and suspension operation, the possibility of transmitting forces from the steering mechanism remains unchanged, and the selected angle of rotation of the wheels remains unchanged. The rods (one or two) have threads for changing the length of the rod, which is necessary to adjust the angle of the wheels (the so-called toe angle). In cars with a common rack and pinion mechanism, there are two rods and four lugs.

Excessive wear of the hinges is a malfunction inherent not only to the steering rods, but also to the steering system as a whole. This is usually an excessively worn liner (or in some designs, a rubber bushing). In hinges with liners, after a significant mileage, wear may appear on the spherical surface of the “pin”. Its cone, surface or thread may be damaged due to corrosion or unqualified installation or dismantling. Actually, the rods themselves bend infrequently - as a result of a wheel hitting the edge of a pit or a direct impact with a stone.

The cotter pin (something like wire) that secures the castle nut should not be reused. If you save money in this way, install it incorrectly or poorly, it may fall out. Because of this, the nut can loosen, unscrew, and the “finger” loses tight contact with its part, which leads to a violation of the geometry of the steering linkage and loss of control of the car. If the repair of hinges with a collapsible design is carried out unskillfully, they may unexpectedly fail or simply fall apart due to a retaining ring that is installed incorrectly.

Signs of faulty steering rods.

A sign of a malfunction of the steering rod joints is a large free play of the steering wheel and knocking, extraneous sounds that appear when turning the steering wheel to the right - to the left. Significant tip

or a hinge that “

has sorted itself out

” manifests itself in the car’s unauthorized deviation of the selected line of movement or turning radius, inaccurate control. As a rule, this does not lead to a complete loss of control, since the ball part of the “finger” does not fall out of the body. But if the fastening nut of the “finger” is unscrewed, the wheels can turn in different directions, and your car will no longer obey the steering wheel. In order to avoid a sudden loss of control over the car, you should not ignore independently checking the fasteners of the steering linkage and the condition of the steering rods, and from time to time call for a service.

Don't skimp on steering, ride carefully.

Source

System components

In addition to the rods, the system has levers. The main task of both rods and levers is to connect the wheels to the car body. Levers, unlike rods, do not have an elongated shape, at the end of which there are hinges or silent blocks. Steering rods and levers always have differences in length and other dimensions.

The steering wheel is the most famous part of the car, which is also considered part of the steering system. On modern cars, the length of the column shaft varies. Without this shaft, driving a car is simply impossible due to the fact that the wheels will always be in one position. When turning the steering wheel, all the energy goes to the steering rack, and from it to the wheels. Many drivers replace the factory steering wheel with another, more comfortable and beautiful one. In order to replace the steering wheel, you need to unscrew the nut, the main thing is not to damage the thread, which can be done by unscrewing it incorrectly.

An important element of the system is the column; it also connects the mechanism. The column itself looks like a shaft and includes many different joints. When developing the column, the manufacturers made sure that upon impact the column folds, which reduces possible injuries that can be sustained as a result of the impact.

Bearings are also considered an important part of the steering system; they help reduce play in the system and improve controllability. The first sign of bearing failure or loss is play and poor controllability of the steering system.

In order to replace bearings you will need to purchase them. To purchase the right set of bearings, you need to know the bearing size you need. Having purchased bearings, they can be replaced; this can be done either independently or at a car service center. A diagram for disassembling the required node can be found on the Internet.

Longitudinal thrust

When the amplifier is placed in the longitudinal link (see Fig. XVI. The longitudinal link is loaded with a joint load - from the amplifier and from the steering wheel; the steering linkage is part of the total load, since the other part.

The connection of the right brace with the longitudinal rod and lever is similar to the connection of the left brace. The length of the brace when plowing is usually set to a certain size. Depending on the depth of plowing, the plow is installed horizontally in the transverse plane, changing the length of the brace.

| Schemes for mounting agricultural machines and implements. |

MTZ-80 before installing the cross member, remove extensions with ball joints from the lower longitudinal rods. The towed eyelet 4 is attached to the crossbar with two fingers 6 if the towed machine uses a PTO drive, in other cases - with one finger. The machine's towing loop is inserted into the tractor's towbar, secured with a pin 5 and pinned from below to avoid possible spontaneous disconnection.

When changing the oil, you should disconnect the vehicle's longitudinal link (ZIL-130) and open the lid of the power steering pump reservoir.

Before changing the oil, disconnect the vehicle's longitudinal link and remove the power steering pump reservoir cap.

The main elements of the drive are a bipod, a longitudinal rod, a pivot arm and a trapezoid formed by the side arms and a transverse rod. The length of the transverse rod can be changed (there is a threaded connection), which allows you to adjust the toe-in of the wheels.

To ensure uniform plowing depth, longitudinal rods are connected to braces through round holes.

To eliminate longitudinal movements of the engine, a longitudinal thrust is used; the front end of the rod is connected to the gearbox bracket, and the rear end is connected to the frame bracket.

To eliminate longitudinal movements of the engine, a longitudinal rod located on the left side of the block is used. The rear end of the rod is pivotally connected to a bracket fixed to the block, and the front end is attached to the frame cross member using nuts.

Along with the power cylinder, the longitudinal rod of the steering linkage, which is connected to the hydraulic booster, also moves. The steered wheels turn to the left, and oil from the rod (right) cavity flows to the drain.

| Diagram of operation of the power steering. |

Along with the power cylinder, the longitudinal rod of the steering linkage also moves, which is connected to the hydraulic booster. The steered wheels turn to the left, and oil from the rod (right) cavity flows to the drain.

The towbar is installed in the rear hinges of the lower longitudinal rods when working with trailed machines.

| Tractor trailers.. |

Replacement steps

To replace the steering rods, we will perform the following steps step by step:

- Immediately before replacing the steering rods, it is necessary to move the car to the inspection hole in order to have access to the mechanism.

- Raise and lock the handbrake.

- Lock the steering wheel. Disconnect battery.

- Using a jack, raise the car to make room for the “goat”.

- Remove the wheels.

- Unscrew the nuts of the tips, having previously unscrewed them.

- Install the puller. Using a hammer, strike the ear of the swing arm and tighten the nut as close as possible. If the position of the lever remains unchanged, this procedure must be repeated.

- Unscrew the tie rod from the coupling. Since the battery was previously disconnected, the possibility of contact with the positive wire is excluded. If you have a problem separating a part from a rusty thread, use the universal technical fluid WD-40.

- Remove the boot and unscrew the rod from the steering rack.

- Lubricate the hinge with the grease supplied in the kit.

- Install a new tie rod without complex physical efforts or the use of a hammer.

- Connect the battery, secure the brakes, and check their functionality.

- Depending on the size of the old and new part, make the necessary notes in order to technically tighten the rod correctly and easily reach a technician at the service center. Using these marks, at the final stage he will make a wheel alignment. In order to avoid problems with this operation, it is necessary to count the number of turns it took to unscrew the tip.

After replacing the steering rods, you need to perform a wheel alignment

At the end of the work, you need to perform a wheel alignment. This procedure will save you from unnecessary purchases of tires in the future.

Checking and adjusting the work performed:

- During testing, play in the rods is unacceptable;

- the play adjustment should be about 15 degrees and it must be done on the steering wheel;

- smooth and continuous steering movement, equal number of turns left and right;

- it is necessary to make sure that the steering wheel returns to its place on its own after turning;

- It is advisable to carry out a new adjustment after 600-800 km. However, if a problem occurs, adjustments must be made immediately.

As you can see, in general, the process of replacing a mechanism is not that difficult if you identify the problem at an early stage and carry out the work strictly point by point. Some difficulties, however, may arise when searching for parts that are suitable for you, since the manufacturer may have already discontinued some of them. Of course, the best option would be to have it replaced at a service center by specially trained workers. Have you had any experience replacing the steering rod, and what problems did you encounter?

Repair and replacement of jet rods

The thrust rods are made of durable metal and are rarely damaged. However, there are cases when part deformation still occurs. If the bend is small, then it is possible to independently correct the correct shape of the jet thrust using impact tools. But if the damage is too serious, then replacement is necessary.

Repair of jet rods includes replacement of consumable parts. These include bushings that soften the fastening of the part to the body and suspension parts. Those bushings whose expiration date has already expired must be replaced. This can be determined by the cracks that have formed on the rubber parts of the product.

To change the bushings, you need to unscrew the nut securing the rod and pull out the long bolt. The rod is pulled out and the bushing is squeezed out of the special ring. Install a new one in its place and reassemble the units in the reverse order.

Perhaps this is all you need to know about the reaction rods used in car suspensions.

Principle of operation

Although there are several types of tie rods, the basic purpose of the tie rods remains the same. The main task is the process of turning the wheel. The wheels should not just turn, but turn so that they are both at a certain angle. For example, if the inner wheel is turned at a large angle, then the second wheel must be turned at a smaller angle.

To accomplish this task, a steering linkage rod was developed. In fact, there is not one thrust, but several. This system includes left and right linkage, as well as middle linkage and wheel arms. The scheme of work can be found on the Internet.

VAZ-2107, jet thrust: purpose, repair, replacement

VAZ-2107 is the latest model from the classics. This car was created on the basis of the Soviet “five”. The latter, in turn, originates from 2106, and that one - from the “troika” and “kopek”. What's all this for? Despite various modifications, many elements of these machines were similar (if not identical). All VAZ classic models have the same suspension scheme. At the front is an independent axle with coil springs, at the rear is a dependent axle with a Panhard rod. It is also called reactive. It is this element that we will talk about today.

Replacing the support

There are cases when a ball joint becomes unusable, and after that it has to be replaced. You can do this either yourself or at a car service center. The main thing to remember is that when replacing the right ball joint, you should also replace the left one. Today there are two types of ball mounts.

- The first fastening is considered to be bolting, this type is considered simpler. When the ball joint is connected to the lever in this way, it can be unscrewed and a new one installed.

- But there is a second type of fastening - this is when the ball joint is pressed into the lever, in this case you have to change the ball joint along with the lever. Most often, it is Japanese manufacturers who install pressed ball joints into levers on their cars, but Asian spare parts manufacturers have already found a solution to this problem.

Joint - tie rod

The tie rod joints are forged ends, in the heads of which pins are hinged, connecting the rod to the steering knuckle arms. The tip finger rests with its lower conical head on the conical surface of the cracker, which has a spherical outer surface, which, in turn, rests on the spherical surface of the tip itself.

The tie rod joint does not require adjustment, since the gaps formed when its parts wear are automatically selected by a spring.

The tie rod joints are lubricated through grease fittings screwed into the ends.

The tie rod joint is sealed by a special rubber end seal 23, sandwiched between the end of the tip head and the end of the lever head.

A feature of the tie rod joint is that when the pin rotates, the cradle 24 (support liner) is motionless, and when the pin is rocked, the crayon moves along with it.

Checking the wear of the tie rod joint parts must be done periodically and carefully, since in operation there have been cases of the tie rod falling off while the vehicle is moving.

If a gap forms in the tie rod joints, it is necessary to disassemble the joint and replace the worn parts.

GAS: / - spring; 2 — adjusting plug; b - the same for heavy MAZ and KrAZ vehicles: / - wedge pressing device; 2 - crackers; c — tie rod joint.

You should regularly check the correct alignment of the front wheels. Before doing this, you need to make sure that there are no gaps in the wheel hub bearings, kingpins and tie rod joints.

You should regularly check the correct alignment of the front wheels. Before checking, you need to make sure that the front wheel bearings are adjusted correctly, that there are no gaps in the tie rod joints, as well as in the steering knuckle bushings.

| A play meter for checking the free play of the steering wheel. / - instrument arrow. 2 - sector with scale. — 3 — grips. |

The reasons for increased free play of the steering wheel can be determined by checking the steering control element by element. Steering elements should be checked after adjusting the steering wheel bearings and eliminating increased clearances in the pivot pins (bearings) of the steering axles. Before checking the steering, it is necessary to tighten the fastenings of the steering wheel, steering column, steering gear housing, steering bipod and steering axle arms, and check the tie rod joints. If the free play of the steering wheel does not decrease, then it is recommended to adjust the steering in the following sequence: adjust the hinge joints of the longitudinal steering rod; check and adjust the tightness of the tapered bearings of the steering shaft; check and adjust the engagement of the working pair of the steering gear.

A steered wheel is mounted on the tenon of each steering axle on tapered roller bearings. The wheel is mounted on a hub, which allows the installation of wheels with pneumatic or solid tires. In the boss of the lower ear of the axle there is a conical hole in which the rotary lever is secured to the key. At the second end of the swing arm there is a pin with a ball head, which fits into the socket of the tie rod joint. With the help of transverse steering rods, the rotary arms of the right and left axles are pivotally connected to the arms of the pendulum lever. The third arm of the pendulum lever is pivotally connected to the longitudinal steering rod. The use of a drive with a steering linkage to the rear steered wheels makes it possible to obtain different internal and external angles of rotation of the rear wheels, necessary to ensure rolling without wheel slipping when turning the loader.

Let's sum it up

The article talks about what a steering end is and what to do if it becomes unusable. The article just does not describe the dimensions of the tie rod and the dimensions of the steering tip.

The article describes that the steering mechanism is located in the interior of the car. Tips can be checked for functionality even from the outside, just by looking at them, and if they have become unusable, then the material from the article on replacing them will be a good help.

The article describes how to replace the boot, and what can be achieved in the end if you do not replace the boot in time. Signs of a faulty trapezoid and how to change the trapezoid are also in the article.