Operating principle of the clutch system

To transmit torque to the driving wheels of the vehicle from the engine crankshaft, a box is provided, because smooth transmission of torque from the motor to the wheels is unprofitable.

The car will not be able to move without a clutch, and the operation of the power unit itself will be ineffective. For comfortable operation of the power plant, the torque removed from the crankshaft must be changed in advance in the gearbox (gearbox). After which it moves to the driven axle. Since changing gears forces the gearbox gears to spin, which hit each other with force, it can be difficult to change gears. If the box is always connected to the unit, in order to completely stop the vehicle, it will be necessary to stop the motor.

Clutch operation in a Gazelle car

To solve these problems, the car is equipped with a clutch, which is a special box assembly. It promotes temporary separation of the engine and gearbox, which leads to an interruption of torque. By pressing the clutch pedal, you can change gears or stop the car. The clutch allows the car to move off smoothly and accelerate.

The principle of its operation is similar for any brand of car. It eliminates the possibility of rapid wear of components and parts that connect the power plant and the gearbox.

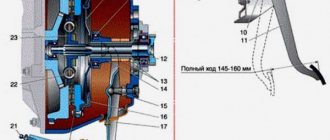

The clutch pressure plate, attached to the housing, presses the driven disc against the flywheel. The disk hub attached to the input shaft must be able to move freely along it. The hub body is equipped with damper springs, which act as vibration dampers and ensure smooth operation.

To make the required force when pressing, a spring with petals is provided, which are exposed to the release bearing. It is a connecting link between the drive and the clutch, onto which the fork with the lever is attached. Another lever or cable is attached to its end, leading to the clutch pedal.

Replaced early in the afternoon on a weekend

I'm

using the clutch fork

.

Replacing the clutch fork

Replacing the clutch fork on the Gazelle Business model is very easy to do; you do not need to remove the gearbox for this. This type of repair can also be done by yourself.

To replace the fork, unscrew the two bolts of the clutch slave cylinder (CLC), the cylinder on the hose is moved to the side. We remove the old plug and install a new one. You need to make sure that the fork hits the special ebb of the release bearing clutch, otherwise the clutch pedal will not be pressed normally.

Having installed the new fork, we press the control center through the rod with our hands, bring it to the mounting points, and fix the cylinder with bolts. Of course, the clutch hose can be unscrewed and it will be easier to install the control unit, but then you will have to bleed the clutch. We have described replacing the plug in the simplest and most optimal way. ” alt=””> ” alt=””>

Source: znanieavto.ru

Which Gazelle clutch to choose?

Clutches for Kamaz

Today you can find products from various manufacturers on sale. However, some clutch kits are soft and smooth, but may have a shorter service life, while others operate more harshly, but handle loads better and last longer.

First of all, comfort is affected by the number of damper springs (they affect the angular stiffness). The driver has the opportunity to select a clutch taking into account the stiffness that is characteristic of a particular clutch package, depending on the manufacturer.

Different manufacturers independently determine the number of springs. The material used to make the friction linings may also differ, there may be unique manufacturing features for the release bearing, etc.

If we talk about the clutch manufacturers themselves, SACHS, LUK and VALEO are considered to be the market leaders. The Sachs clutch is traditionally considered reliable and durable, but some complain about being too stiff.

The LUK company is famous for its high-quality baskets, which allows full transmission of torque and ensures sufficient softness of the mechanism. The VALEO clutch is soft, the comfort is high, but the service life is somewhat reduced.

If you separately take into account the operating features of the car, and also pay attention to the characteristics and design of a particular clutch kit, you can easily select the most suitable solution.

Let us also add that when designing a clutch assembly, the world's leading manufacturers separately take into account the power of the internal combustion engine, the operating features of the gearbox, the drive axle gearbox, etc. At the same time, cheaper analogues from unknown manufacturers may be of significantly worse quality or manufactured without taking into account certain characteristics and indicators.

For this reason, it is better to choose clutches from well-known brands, even taking into account the high cost. Otherwise, the mechanism may fail, for example, after 15-20 thousand km, and not after 80-90 thousand.

Replacing the clutch and fork on a Gazelle car with your own hands

Replacing the clutch of a Gazelle car is required quite often, as it is a vulnerable point. The machine is mainly intended for business, the components and assemblies of which always operate under load. Therefore, the service life of the parts is limited; on average, the clutch requires replacement every 50–70 thousand kilometers. As a rule, it changes as a set (pressure disk, driven disk, release bearing).

Gazelle business clutch replacement

Replacing the clutch of Gazelle business model cars is not difficult to do. To do this, you just need the appropriate tool. Work must be performed on a car lift or in a pit.

Removing the driving and driven clutch disks of a car with an engine model ZMZ-405, ZMZ-406

Replacing the VAZ Classic clutch master cylinder

We remove the clutch housing (see article - Removing the clutch housing (ZMZ-406 engine)

We use a core to mark the relative position of the casing and flywheel.

1. While holding the flywheel from turning with a screwdriver or a spade, a wrench or a 12mm socket, unscrew 6 bolts

2. Remove the drive disk assembly (basket) and driven disk

After disassembling, the clutch parts should be washed in kerosene and inspected.

Cracks, burrs and deep grooves are not allowed on the surface of the drive discs.

If present, replace the flywheel and basket assembly.

We replace the driven disk with linings worn to the rivets, warped, cracked, oiled and burnt.

The protrusion of the ends of the diaphragm spring petals is controlled using a spacer.

When moving the ends of the petals 8.5 mm down, the pressure plate offset must be at least 1.3 mm, otherwise we replace the drive disk (basket) assembly.

Any cracks or breaks are not allowed on the crankcase.

During assembly, we coat the rubbing surfaces of the fork, coupling, pushers and shaft splines with CV joint-4 lubricant.

Install the disks in the following sequence

We insert the centering mandrel into the engine flywheel bearing.

We put the driven disk on it.

On one side the disc hub protrudes less than on the other. This side should be facing the flywheel.

We attach the basket to the flywheel and fasten it with 6 bolts (the holes match only in one position).

After tightening the bolts, remove the mandrel

Dismantling the clutch of a car with an engine model ZMZ-402

We carry out the work in an inspection ditch.

We remove the gearbox.

We remove the hydraulic clutch slave cylinder (see article - Replacing the master and slave cylinders of the clutch of a Gazelle car

1. Using a 10mm wrench, unscrew the fastening bolt

2. Remove the clutch release fork along with the protective cover.

3. Remove the clutch release bearing (release bearing).

4. Using a 12mm wrench, unscrew the two lower bolts

5. Using a 14mm wrench, loosen the two upper bolts securing the clutch housing amplifier.

Similarly, loosen the amplifier mount on the other side of the engine.

6. Using a 12mm wrench, unscrew the four bolts securing the lower part of the clutch housing

7. Squeeze out with a mounting spatula and remove the lower part.

A cardboard gasket is installed between the pan and the crankcase.

In order not to disturb the joint balancing of the flywheel and the clutch drive plate when assembling the unit, we mark their relative position with a chisel or punch

9. While holding the flywheel from turning with a mounting blade, use a 12mm wrench to unscrew the six bolts securing the “basket” to the flywheel.

Semicircular plates are installed between them.

To facilitate access to the bolts, periodically rotate the flywheel.

11. Remove the “basket” and the driven disc of the clutch

We install the clutch parts in reverse order, centering the clutch driven disc with a special mandrel.

If there is no mandrel, you can center the clutch driven disc using the gearbox input shaft.

To do this, when installing the clutch “basket”, we only tighten its fastening bolts, leaving the driven disk free to move.

Having installed the box and tightened the nuts securing it, rotate the flywheel, evenly tightening the bolts securing the “basket”.

Little secrets of replacing the clutch disc

When dismantling the gearbox and clutch, troubleshooting is necessary. Before installing the disk, it must be carefully inspected. If the wear is uneven (for example, the edges are too thin compared to the thick center), then the basket and flywheel will also have unevenness.

Clutch disc

During the work process, it is necessary to monitor not only how to install the clutch disc, but also take into account the location of the basket and flywheel. For example, if other parts were not touched when mounting the disk, the clamping area will be insufficient. In this case, after an indefinite period of time, you will have to remove the gearbox again.

Important! When installing a new disk, it is necessary to mount the basket and release disk. If it is not possible to buy a new flywheel (it is expensive), it can be turned by a lathe. If the working surface of the flywheel protrudes, only the non-working side is processed. Stitching occurs evenly on both sides. This way, the basket damper will fit tightly.

Useful advice from professionals

If it is not possible to completely replace the clutch kit, you can grind the basket. If the surfaces are properly processed, the structure will serve well for several years.

The unevenness of the basket petals can be assessed visually. If they are not level, the damper will not press against the basket sufficiently and it will have to be removed. When the elements are normal, the basket must be blown out from the inside.

During installation, it is necessary to replace the seals:

- on the primary shaft of the gearbox;

- root.

The first oil seal is installed in a removable cover, but sometimes in order to replace it, you need to dismantle the gearbox halfway. Also, you will have to replace the release and support bearings. If this is not done, they will soon cease to function normally. Repairs will cost more than buying new parts.

After installing the clutch disc, it needs to be centered to simplify installation of the gearbox and prevent deformation of the damper.

Important! The basket bolts are tensioned in a diagonal direction. When changing direction, the damper will crack.

It is necessary to lubricate the teeth of the input shaft and the release fork tabs in the area where they contact the release plate. Thus, the clutch disc will be mounted reliably and for several years.

How to make a quality replacement

Clutch adjustment VAZ 2109

Carrying out minor repairs, replacing the clutch fork, including adjusting its pedal, will not require much time. If there are high-quality parts, for example, made by Sachs or Kraft, the replacement will only take about 2 hours.

The Gazelle clutch requires proper handling and timely replacement as a result of frequent repairs and adjustments. Replacing the entire assembly is not necessary in every case. The stages of replacement depend on the brand of Gazelle car, determined by the engine, for example, Cummins ZMZ 406 and 405, etc.

The clutch kit must include a fork, a disc, a hydraulic hose, a hydraulic clutch, a clutch basket, a release bearing, the price of which from the manufacturer is lower than the cost of parts offered by chain stores. After diagnostics, it may be necessary to replace only the clutch slave cylinder, which operates under fairly high loads. In some cases, it is necessary to solve the problem with changing the gearbox, discovered as a result of system diagnostics.

Sometimes it may be necessary to check the entire pipeline and also bleed the system. The cause of the violation may be damage to the reservoir included in the Gazelle clutch kit.

Causes of clutch failure

Replacing the clutch may be necessary as a result of intensive use of the Gazelle car and if the following errors occur:

The process of replacing the clutch on a Gazelle

- Low quality parts were used during assembly.

- The clutch pedal was kept depressed while driving, which is strictly prohibited by the manufacturers.

- There were jerks from a standstill at high speeds.

To increase the service life of the Gazelle clutch, installation of parts manufactured by the Sachs manufacturing company will be reliable. They are recommended by the manufacturer because they are reliable and have been tested for installation compatibility with the transmission and engine. Under the same conditions, the Sachs clutch, unlike parts from other manufacturers, will last longer. A common analogue of the Gazelle Business clutch, produced by Kraft, is not only of good quality, but also has a fairly low defect rate. The most common reasons why Gazelle owners contact service departments are malfunctions related to the clutch release drive.

Among the main problems are:

- leak of the Gazelle clutch master cylinder (MCC);

- removal of brake fluid from the hydraulic fluid reservoir;

- Clutch slave cylinder (CLC) leak;

- bypass of the cuff of the central nervous system;

- bent or fallen out working cylinder rod, etc.

Careful operation of the car does not imply any jerks, but only the presence of conditions that allow you to move off smoothly and change gears while the car is moving. Most often, clutch replacement is required for trucks. A Gazelle car intended for business requires increased attention to this unit, the elimination of breakdowns in which is often not possible. Since replacing the device does not require removing the motor, you can repair the clutch or install new parts yourself.

How to correctly install the clutch disc on a gazelle

Awareness of how to correctly and which side to place the clutch disc when repairing or replacing a unit will allow you to avoid repeated disassembly of the unit and prevent the occurrence of additional malfunctions of the car and its elements. Thanks to the clutch, the vehicle can start smoothly without overloading the power unit, facilitating the normal and long-term operation of its units and gearbox components.

The disc is usually replaced along with the entire clutch basket. There are two ways to carry out the work: with and without dismantling the gearbox. The latter method is less labor-intensive and more convenient. The work process is carried out on a lift or inspection pit.

Removing the clutch

How to place the clutch disc correctly and which side to use is a question that often arises among novice motorists who do not pay attention to some nuances when performing work, ignoring which can lead to useless repairs and serious problems with the car.

Clutch disc GAZelle Next, Business, Sable and modifications

CLUTCH DISC GAZELLE NEXT, BUSINESS, SOBOL AND MODIFICATIONS

The GAZelle clutch disc is an important part of the clutch kit for the GAZ light commercial vehicle. Thanks to the frictional properties of the lining, torque is transmitted from the engine to the manual gearbox. A high-quality Sachs driven disk makes it possible to start moving smoothly and easily change speed modes by changing gearbox gears. If the clutch breaks down or is worn excessively, problems arise that can be avoided by reading this article.

CAUSES OF BREAKAGES AND MALFUNCTIONS OF THE GAZELLE CLUTCH DISC

Any clutch can be “burned out” by frequent starts at maximum speed or by carrying loads many times greater than those permitted by the technical characteristics of the vehicle. Improper operation of a commercial vehicle will likely result in premature failure.

If you operate the car in accordance with the technical requirements, bought and correctly installed a high-quality spare part (either on your own or at a service station), then in most cases, disc failure is due to natural wear: friction linings, damper springs.

Which clutch disc is better to buy for GAZelle Business and NEXT?

Among the GAZelle Business and NEXT clutch elements, it is the driven disc that is subject to the greatest wear. Is the clutch moving or is there noticeable slipping? Then it's time for replacement and repair!

Manufacturers recommend changing the clutch assembly, but the crisis has not yet been canceled. If, when removing the kit, the basket petals and the release bearing are in good condition, then few people will raise their hand to buy an assembled clutch kit.

Demand creates supply, so not only GAZ dealers, but also ZF, offer this spare part separately.

Installing a clutch on a GAZelle

In any case, it is better to purchase an original GAZelle driven disk under the Sachs brand from the German company ZF. Before installation in a vehicle, it is recommended to check the lateral runout, which should not exceed 0.5 mm. If the parameter is exceeded, make an adjustment. Make sure you place it with the correct side facing the flywheel!

You really have to forget about the warranty. But in practice, by changing only the driven disk, you can drive more than 40,000 km in the city, and many times more on the highway. The savings are significant.

Types and sizes of GAZelle clutch discs and their differences

GAZelles are mainly equipped with clutch discs of 3 types and 2 sizes:

- 240TP - 1878005402 (1878005153, 1878000041) Diameter: 240mm Hub profile: 23×29-10N

Used in Sachs kits 3000950069, 3000951401. - 240VTB - 1878005456 (1878006095)240 mm23×29-10N

Set Sax 3000950503 - 280VTB - 1878008502 (1878006639, A21R22.1601130)280mm23×29-10N

Included 3400700645

Despite their apparent similarity, 1878005402 and 1878005456 are not interchangeable and are designed for different torques. The first is for gasoline engines, the second is for Cummins diesel engines.

The old model range of GAZelles with the ZMZ 402 and Volga engines was equipped with type 225TB, diameter 225mm with Sachs article number 1878005404.

Applicability of Sachs clutch discs to GAZelle

Models by engine type:

- 1878008502 - for diesel Cummins 150 hp (330 nm).

- 1878005456 - Cummins ISF 2.8 120 hp.

- 1878005402 - for Gazelle with a gasoline engine (ZMZ 406, UMZ 4216, Evotech).

Let's also say that disk 1878 005 456 is used on the UAZ Patriot.

Sachs clutch disc markings

The markings of the original Sax discs are shown in the corresponding photos.

What is the difference between the clutch disc for Next and Business models?

Nothing, because applicability depends not on the GAZelle model, but on the engine. But be careful when purchasing kits. On ZMZ-406 and UMZ-4216 they will differ in release bearings.

The friction lining has worn off. Is it possible to buy it and restore the disk?

It is theoretically possible to buy and rivet a ferodo overlay yourself, but we strongly do not recommend doing this. Even on expensive driven clutch discs, KAMAZ has long abandoned this. The disc can be restored, this applies not only to Ferodo linings, under special factory conditions.

A self-rebuilt clutch disc can cause damage to the basket and clutch. And a new set will cost more than one slave.

IS THERE A REINFORCED GAZELLE CLUTCH DISC AND WHERE TO BUY IT?

In relation to the GAZelle, if we talk about high-quality clutch parts, in our opinion, the concept “reinforced” does not apply. If this disk is “strong”, then the other one is “weak”? Why release a bad “weak” one?

As a rule, improvement is required for low-quality products. The first ones received negative reviews from drivers and the “reinforced” line is expanding. We put this word in quotation marks on purpose, because... The original Sachs clutch disc is designed specifically for the specific characteristics of the GAZelle engine and gearbox. This disc fully complies with the design features and lasts longer. But it doesn’t say about the original – “weak” or “strengthened”. It's standard!

Original Sachs wheels for GAZelle are expensive, but if they are cheap, they are definitely a fake!

This statement can often be encountered. “Expensive” and “cheap” are relative terms. Compared to a disk with a diameter of 430 mm for MAZ and KAMAZ trucks, the Gazelle 240 mm will be 3 times cheaper, and relative to 362 mm for PAZ buses - 2-2.5.

The guaranteed quality of the supplier in the series allows you to be sure that Sax disks will last a long time with a long service interval.

How long will a disk from an unknown manufacturer of questionable quality last? Based on this, the economic efficiency of the purchase is calculated. The price list of GAS Quatro LLC includes individual elements and the GAZelle clutch assembly.

For example, the price of clutch disc Sachs 1878008502 (A21R22.1601130) for GAZelle Next 330 nm is 7,321 rubles.

Compare these prices with analogues, taking into account the mileage and the cost of replacement at a service station, while the original kit would continue to work properly. Even if you change the clutch yourself, it’s still the same time as a simple commercial machine.

Is it possible to buy a non-original but good clutch disc for a GAZelle?

The selection of any non-original vehicle spare part should be approached with caution. Study reviews on the Internet, who represents this brand, recommendations of automotive manufacturers, compare the cost with the original.

In our opinion, high-quality clutch discs are produced by the Italian plant E.Sassone:

- GAZelle Next and Business with Cummins engine – 9280ST;

- GAZelle with petrol engines Evotech, UMZ, ZMZ – 6222ST.

Why is it better to buy a GAZelle clutch disc from you?

GAS Quatro LLC is a dealer of Zahnrad Fabrik Friedrichshafen AG (ZF) selling Sachs clutches. You will receive the following benefits when purchasing a clutch disc for LCV GAZ from us:

- Low prices for original GAZelle clutches;

- Warranty from the manufacturer;

- Constant availability of baskets, discs and couplings in our warehouses;

- Prompt delivery.

GAS Quatro is your reliable supplier of high-quality GAZelle clutches! To order, use the website form (in the upper right corner) or write by email.

Useful materials:

Source: https://kvatro.biz/articles/primenyaemost/disk-scepleniya-gazel-nekst-biznes-sobol-i-modifikacij

Clutch of a GAZ-53 car

The clutch of the GAZ-53 car (Fig. 1) is single-disk, dry, with a damper device on the driven disk. Installed in a cast duralumin crankcase 4.

The GAZ-53 clutch disc housing is attached to the crankshaft flywheel with six centering (special) bolts. disk is placed inside the casing

(basket).

Rotation of the GAZ-53 clutch basket is transmitted from the flywheel through three protrusions located in the disk and entering the casing windows. The torque from the motor to the gearbox is transmitted through the driven disk 3, clamped between the ends of the flywheel 1 and the pressure disk by the force of 12 springs 12.

Fig.1. GAZ-53 clutch and its drive

1 - flywheel; 4 - crankcase; 3 — driven disk; 4 — pressure disk; 5 — pressure plate lever; 6 — oiler; 7 — adjusting nut; 8 — clutch release; 9— box drive shaft; 10—fork; 11 - casing; 12—pressure spring; 13 — adjusting nut; 14—thrust; 15— tension spring; 16 — clutch pedal

The GAZ-53 clutch release levers 5 are located in the slots of the pressure plate protrusions and, through axles and needle bearings, are connected to the pressure plate and support forks, which are hinged to the casing by means of conical springs and spherical adjusting nuts 7. After adjustment, the nuts are cored and the levers are used during use. are not regulated.

The GAZ-53 basket pressure disk is balanced as an assembly with the crankshaft and engine flywheel, therefore, when changing the driven disk at the same time, the “O” marks on the flywheel and the pressure disk housing are aligned.

The GAZ-53 clutch control drive is mechanical. It consists of a clutch pedal 16, a roller with a lever, a rod 14, an adjusting nut 13. To lubricate the clutch pedal bushing, a grease nipple is installed at the end of the roller.

How to change the clutch: frequency and replacement order

With careful use and careful driving, you do not have to change the clutch often.

What can become an alarm bell and a signal for diagnosis - this is discussed in our article. Here you will learn how to replace a clutch and will be able to supervise the service center technicians.

When driving with a worn clutch, fuel consumption increases and the power of the internal combustion engine is significantly “lost.”

How long does the clutch last?

It is impossible to name a specific mileage after which it is time to change the clutch. Too many factors influence its service life:

- driving style - a sharp start and frequent slipping, and even more so, participation in races significantly reduces the period of operation;

- quality of the unit - original parts are always more durable than inexpensive analogues;

- foreign liquids or small solid objects can damage even a new unit;

- errors during installation and adjustment inevitably lead to reduced performance.

Wear of linings due to incorrect clutch settings

How do you know when it's time to replace the clutch?

Reasons and consequences that you will avoid if you go to the service station on time:

- Do you hear a loud noise when you depress the clutch pedal? there is a possibility that the release bearing is worn out;

- the smell of burning in the cabin indicates that the clutch discs are slipping relative to each other, so that the friction linings on them burn;

Damage to friction linings

- Strong jerks when shifting gears often indicate that the damper springs installed on the driven disk have failed.

Experts and car manufacturers recommend carrying out clutch diagnostics every 80 - 100 thousand km.

Symptoms of a problem

If the recommended mileage has not yet been completed, but you have already noticed the following “symptoms,” perhaps it’s time to hurry up with a replacement:

- changes in habitual driving dynamics, especially when climbing;

- increasing the free play of the clutch pedal;

- jerks when changing gears and starting off;

- heavy car acceleration and poor traction when the load increases;

- shifting gears with great effort;

- burning smell when engine speed increases;

- increased vibrations and extraneous sounds (such as crunching and grinding).

How to identify problems at the first stage?

The first thing any driver (even with little experience) will notice is the discs slipping in high gears, that is, as the speed increases, the speed does not change.

And here you have a choice: change the clutch as soon as possible, or one “fine” day you simply won’t move.

What tools are needed to replace the clutch?

Decided to do the repairs yourself? You will need a winch or jack to lift the front of the car, and to work underneath it - an inspection pit, overpass, hydraulic stand or two-post lift.

To protect important system components you need:

- bushings - they will prevent damage to the axle shaft seals;

- the covers will protect the ball joint boots;

- the yoke will provide support for the engine.

Tools you will need:

- a set of open-end and socket wrenches;

- mandrel for centering the clutch disc.

Replacement procedure

- Dismantling the gearbox.

This procedure is slightly different for front- and rear-wheel drive cars. In the first case, you need to remove the drive shafts and replace them with plugs, unscrew the bolts, disconnect the cables and drawstrings, and remove the gearbox input shaft from the bearing in the internal combustion engine. In the second, the coupling that connects the gearbox to the driveshaft is dismantled. - Replacement of clutch elements.

After the basket bolts are unscrewed, all clutch elements are removed from the flywheel. It is important that there is no oil on its surface. Otherwise, you will have to change the oil seal, and if there are scratches or cracks on the old disks, you will also have to change the basket. The new disc is inserted into the basket, and it is put on the flywheel. The fastening bolts are screwed crosswise.