VAZ 2109 speedometer drive - we repair breakdowns with our own hands

The VAZ 2109 speedometer drive is an important part of the mechanism that provides the driver with useful and necessary information about the speed of the vehicle and the distance it has traveled. A drive failure, therefore, is an extremely undesirable defect that brings a lot of problems to the driver.

The VAZ 2109 speedometer drive is a common cause of its breakdown

The VAZ 2109 has a mechanical drive. Its driven and drive gears are mounted on the (secondary) shaft of the gearbox. From them, the torque is supplied through a flexible shaft to the car’s speedometer, which is located on the instrument panel.

Since the VAZ 2109 is produced with a high and low front panel, the specified flexible shaft can have different lengths (longer when the panel is high, shorter when low).

speedometer

It is the break of this shaft that most often becomes the reason that the speedometer stops working, and this already leads to difficulties with cornering (changing gears correctly can be quite difficult) and unpleasant meetings with traffic police officers (the likelihood of a fine for speeding is high). As a rule, the shaft breaks near the entrance to the checkpoint. You can check for a break like this:

- the shaft (flexible) is disconnected from the speedometer on the instrument panel;

- start the engine and drive 20–30 meters, while carefully monitoring the end of the shaft.

In cases where the tip is stationary (does not rotate), it must be pulled out by opening the hood and freeing the shaft from the fastening with the union nut. In cases where only its shell is pulled out, the shaft is completely torn off. The remaining tip can be removed from the drive only with pliers and nothing else. If the shaft comes out together with the shell, this means that the edges have been “eaten off” at its tip. It is not broken, but due to this defect it cannot transmit torque. However, in both the first case and the second, the flexible shaft will have to be replaced with a new one.

Replacing the VAZ 2109 speedometer drive due to gear wear

The drive also fails due to wear of the paired gears. In this case, its repair is carried out without removing the gearbox according to the following scheme:

- the car is placed on an inspection hole or overpass;

- using a socket wrench, unscrew the fixing bolt that secures the drive housing and gearbox;

- remove the case (it should be pryed off with a screwdriver);

- remove the gears and change them.

It is important to immediately count the number of teeth on the old gears. New parts must have the same number. Otherwise, the speedometer will provide incorrect information both in terms of mileage and speed. When inspecting the housing, you can see oil leaks on it, which indicates the need to replace the o-ring. It is pushed out after the driven gear is removed. It is recommended that after all replacements, wash the drive parts using clean kerosene, and then reassemble the unit in the reverse order.

A few words about repairing the VAZ 2109 speedometer

The speedometer, of course, can break down for other reasons; the drive is not always to blame for its failure. The following symptoms indicate a speedometer malfunction:

- Why the speedometer on the VAZ 2110 does not work - reasons and repairs

- incorrect information about the speed of the vehicle is given;

- the numbers on the meter become crooked, and over time they stop altogether;

- sensors burn out.

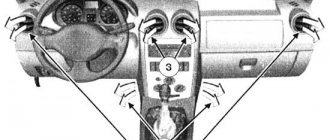

All these problems can be solved. You just need to properly dismantle the front panel. And this is done like this:

Nanofilm on license plates invisible to cameras Fines for crossing the stop line and speeding will no longer bother you!

- two screws supporting the bottom panel are unscrewed, which makes it possible to remove the “beard”;

- the clips are removed on the top panel, after which you need to turn off the emergency lights, side lights, and low beam;

- then the cigarette lighter is turned off;

- The screws securing the panel (there are two of them) are unscrewed, the pads are dismantled, and the panel is removed.

After this, you can unscrew the screws that secure the speedometer.

Didn't find the information you are looking for? on our forum.

If you find an error, please select a piece of text and press Ctrl+Enter.

We recommend reading:

Как ускорить дворники на ваз 2114Замена подвесного подшипника на ваз 2107Как снять сиденье на ваз 2114Установка заднего бампера на ваз 2114. Пошаговая инструкцияКак заменить тросик открывания капота на ваз 2107Схема передней подвески на ваз 2108Направляющие клапанов для вазКак менять печку на ваз 2109 -2115, видео по замене

Similar articles

What kind of oil to pour into the VAZ 2115 engine? Choosing oil for the VAZ 2110 VAZ color chart, codes, names, descriptions VAZ error codes - table with a list of all errors—> VAZ Masters / Chisel / Repair and operation

Damage to the VAZ 2109 speedometer, standard VAZ speedometer

How to replace the speed sensor on a VAZ 2108-VAZ 21099?

Removal: 1) First unscrew the nut that secures the “-” terminal to the battery, and then remove the terminal from it. (How to unscrew the nut that secures the terminal, read the article: “Replacing the battery”, in paragraph “1”)

2) Next, using your hands, disconnect the sensor harness (Indicated by a red arrow) and the wire block (Indicated by a blue arrow), which are connected together.

3) And then, taking a wrench in your hands, use it to unscrew the sensor itself, beyond the edges that are present on it.

4) After unscrewing, remove it from the vehicle's gearbox.

Installation: 1) First install the new speed sensor on the gearbox, and after installation, use a wrench to tighten it until it stops.

2) When the sensor is installed in its place, then connect to the speed sensor harness (Red arrow), the wire block (Blue arrow), which you disconnected from the old sensor earlier.

3) And at the end of the operation, in the reverse order of removal, connect the “-” terminal to the battery, using the same article on “Replacing the Battery”.

You may also like

Purpose of the speedometer and possible causes of problems

Before you figure out why the speedometer needle jumps on a VAZ 2109, you should understand what is where and what it is intended for. Speedometers are designed to convert the rotational speed coming from the drive shaft to the speedometer sensor into an indication of the speed of the vehicle and, in addition, the number of revolutions that the speedometer sensor drive shaft makes are converted into readings of the trip meter (kilometers) traveled by the car. But when the speedometer needle jumps or even spins as it wants, or may even freeze in one position, it means that there are problems with the speedometer mechanisms and there may be several reasons for this. This:

- Why the speedometer doesn't work on 4: check the speed sensor

- A breakdown inside the speedometer itself (see VAZ 2109: how to properly repair the speedometer)

- Broken or damaged speedometer cable

- The speedometer gearbox (aka drive) is broken

Diagnosing the malfunction

It is important to first understand why the VAZ 2109 speedometer does not work:

- To find the reason, we climb under the car from an inspection hole, overpass or lift

- If you don’t have any, you can get by this way - just slightly lift the car, put a reliable safety net (thick wide wooden blocks - you can’t use bricks), then unscrew the nut securing the speedometer cable

- We call an assistant and with his help we check the serviceability of the speedometer and its cable

- While you are turning the speedometer cable from below with your hand (having disconnected it from the drive) in one direction and then the other, an assistant in the cabin monitors the arrow - if at the same time the speedometer arrow jumps, then the cable and speedometer are working, and you should check the drive

- However, there are cases, even though the arrow jumps, there may still be a problem in the cable, it has fluffed up inside the braid and sometimes touches it

If problems occur when installing a new panel

A “twitching” needle during ignition indicates that power is coming to the speedometer. Possible problems could be:

- incorrect connection of wires;

- there are breaks in the wiring - check the integrity of each wire separately;

- There are problems in the device itself - burnt out tracks or the speedometer drive.

By the way, the mere fact of replacing the sensor does not yet indicate its performance. VAZ sensors often turn out to be “dead” immediately after purchase. Ideally, ask your friends for a similar sensor that is known to work.

Speed sensor VAZ 2109

The speedometer operating system is quite simple. The speedometer sensor produces a signal. Further along the wiring it is duplicated and simultaneously goes to the ECU and the dashboard. Next, along the tracks on the dashboard board it gets to the speedometer mechanism - the arrow rotates to the desired angle.

The malfunction may be in any of these elements

Always pay special attention to the chips (contacts oxidize, measure with a tester, spray with a wedge, bend if necessary)

Just like any other old car, there are problems with the wires - they burn out, break under the insulation (check with a continuity tester). You can use a multimeter or a universal probe that “can” find plus, minus and absence of a signal. A 12V screwdriver, which detects only power, is an inferior assistant.

Procedure

Now let's figure out how to remove the drive when the speedometer on a VAZ 2109 does not work:

- To do this, release the cross member that secures the gearbox to the body, give back the nut that secures the drive

- Pry off the drive housing with a flat screwdriver (as in the photo below)

- By pressing the gearbox to the side (for example, with a piece of pipe) from the drive, we pull the drive out of it

- Then we check its serviceability

- To do this, twist the gear and see whether the groove for the speedometer cable begins to turn or not

- If the groove does not turn, then replace the speedometer drive

- When going to the store for a new drive, it’s better to take the old one with you as a sample just in case (you can confuse the number of teeth on its gear)

- And if you install a “foreign” (not the one you need) drive, then in no more than 100 meters it will break the box cover, because a mismatched gear pitch will simply turn the entire drive outward and result in serious damage to the gearbox

- To be able to use this gearbox in the future, it will be necessary to replace its rear cover and completely change the oil

- If the old one suddenly pours out, there will still be fragments and crumbs of the housing left in it, which can subsequently fall on a gear tooth or clog the oil channel

Now that you know how to determine what the reason is if the speedometer needle suddenly starts jumping and fix it with your own hands.

Drive repair

We only considered replacing the drive, if the speedometer does not work in the VAZ 21093, sometimes this is easier and cheaper to do:

- The speedometer drive is removed, as a rule, to replace its housing, or the sealing ring from under which lubricant flows, or the drive gear itself

- It can be removed without dismantling the gearbox assembly; for this purpose it is better to drive the car onto an overpass, inspection hole or lift

The repair procedure will look like this:

- Using a socket wrench, unscrew the bolt that secures the drive housing, pry it off with a screwdriver, then remove it

Unscrew the drive nut, remove it, then pry off the housing with a flat screwdriver and remove the drive

- Now we can remove the driven gear

- This gear is made of plastic, so it is important to carefully inspect it and if signs of wear are found, replace it immediately

We inspect the condition of the rubber seal (shown by the arrow), then remove and inspect the plastic gear

- In addition, it is important to pay attention to the condition of the mounting socket, where the tip of the flexible rod (cable) of the speedometer enters

- The socket should not have licked corners or be broken, otherwise such defects are the reason for replacing the gear

- It is also worth paying attention to the condition of the box body in the place where our drive is installed

- If traces of lubricant leaks are visible, then it will be necessary to replace the rubber ring of the drive seal, which is located on its body

- To remove it, you will need to remove the driven gear, then push the o-ring out of the groove

- All parts are then washed in clean kerosene

Of course, no one has canceled the service station services, if you are too lazy to tinker, although tinkering is probably not an applicable expression here (it only takes 10-20 minutes), and the price of their services suits you, then decide for yourself.

Replacing the cable

Almost everywhere, car owners are faced with the problem of speedometer failure, which is often caused by a faulty cable. To replace the cable, it is not at all necessary to go to a car service center, because you can easily cope with this task yourself, our instructions will help with this. So:

- Why does the speedometer on the VAZ 2112 not work? Some repair tips

- Go down the car (on a pit or overpass), then you need to unscrew the cable from the drive of your speedometer, located on the side of the engine compartment, move the rubber cap up, and unscrew the nut on the cable

- After this, disconnect the cable

- To disconnect the cable from the speedometer, you must first remove the instrument panel from the dashboard

- At the same time, if your car has a low dashboard, then unscrew two bolts and carefully remove the visor, squeezing the spring-loaded clamps with your fingers

- Then you can remove the instrument cluster

- If the car has a high dashboard, then first you will need to remove the trim, then unscrew the instrument panel

- Then you should unscrew the cable nut from the speedometer from the back side and pull out the old cable through the engine compartment, remembering how it went through

- Because the next step will be laying (pulling) a new cable

- It will be much easier to insert the plug into the compartment bulkhead if you first lubricate it with oil, for example Lithol

Important: Since there are high and low instrument panels, there are two types of cables, shorter and longer, for different panels, respectively. When purchasing a new cable, you should either have a sample or know its length, otherwise it will either not fit (too short will not reach) or will dangle and snag.

- Having removed the instrument cluster, it will not be difficult for you to remove the speedometer and replace it

- Then we return the instruments to their place, having first screwed the cable nut to the speedometer, and insert the panel into its original place

Everything with the speedometer is clear; in addition, we offer you a training video.

Add a commentAdd a commentWe advise you to readVAZ 2109: maximum speed and other characteristicsVAZ 2109 with a rotary engine and its historyReplacing VAZ 2109 seat belts on your ownHow to check the VAZ 2107 generator - testing methods

The most common reason for a speedometer not working is a break in the flexible shaft , usually near the entrance to the gearbox. In order to check this assumption, you need to get to the instrument panel and disconnect the flexible shaft from the speedometer. Next, start the engine and drive about twenty meters, watching the tip of the flexible shaft. If it does not spin, then you will have to open the hood, unscrew the union nut securing the flexible shaft and pull it out. If the flexible shaft breaks, then only its shell will be pulled out, and its tip will remain in the drive. You can get it out using pliers.

If the flexible shaft is taken out along with the shell, it means that it is intact, but the edges at its very tip have been eaten away, so it cannot transmit torque from the drive gears. In both cases the flex shaft needs to be replaced, but remember that a tall panel requires a longer flex shaft.

In addition to the flexible shaft, the cause of failure may be wear of the drive gears . You will have to change them in pairs, and before you go to the car store for new speedometer drive gears, count the number of teeth on the gears that were there before. For new and old gears, the number of teeth must match, otherwise the speedometer readings will be incorrect, both in terms of speed and mileage.

Related posts:—>

A car's speedometer is used to convey information about its speed. If it is faulty, then you will not be able to control your movement on different sections of the route, putting yourself in danger. In this case, immediately carry out diagnostics of the vehicle and restore the operation of the device.

Diagnostics

Troubleshooting begins by disconnecting the wiring block from the speed sensor harness and checking them using a test light.

To make a control light bulb, you need any car lamp that can operate at a voltage of 12 V, and two wires about 1 meter long each. One of the wires is attached to the positive terminal, the second - to the negative terminal of the lamp. The resulting device also includes a Krona battery.

To carry out the test, one wire of the warning lamp is attached to the ground of the body or battery, and the second is made with short, frequent touches to the middle contact of the DC connector. If there are no faults in the connector-speedometer section, the speedometer needle will slightly tremble or rise. If the needle shakes, the answer to the question why the speedometer does not work can be considered found - the speed sensor requires replacement.

In cases where the needle’s response to tapping on the central contact of the block cannot be detected, it is necessary to “test” the speedometer power circuit. The procedure is carried out using a multimeter (multitester), or by using the same light bulb - a control. » alt=»»>

The wiring harness is first disconnected not only from the speed sensor block, but also from the speedometer itself. One terminal of the tester or warning lamp is connected to the end of the wire located under the hood, the other to the interior end of the speed meter current supply circuit.

If the tester in the “continuity” mode indicates a violation of the integrity of the circuit, further troubleshooting is carried out in this direction. It is necessary to check the fuses, the connection points of the wires, and their integrity inside the insulating braid.

How does the speedometer work?

The VAZ-2109 has a speedometer with a mechanical drive, consisting of a cable and two gears. Torque is transmitted from the transmission shaft to the gears and then to a cable connected to a dial on the dashboard.

If this mechanism stops working, then the following breakdown options are possible:

- unreliable speed readings on the dashboard;

- drive failure - the arrow does not move;

- cable rupture or damage.

The most common reason for speedometer failure is chafing of the cable leading from the gears to the needle. To replace this part, you must purchase it correctly. You need to focus on the height of the dashboard. If it is high, the cable should be longer.

Troubleshooting

- First you need to unscrew the flexible shaft from the car's gearbox. This is done with ordinary pliers. Unscrew the nut on the cable, and also unscrew the shaft from the VAZ 21099 gearbox. Next, twist the shaft, it is better to do this with a drill, holding the cable in the chuck while turning on the drill, since this method is much more convenient. If the arrow deviates, the speedometer is working properly.

- If the speedometer works, carefully inspect the drive shaft. They may lose their factory cross-section, causing the shaft to slip and the VAZ 21099 speedometer needle to twitch. If the shaft tip is in good condition, replace the shaft itself.

- If your car has an electronic speedometer, then inspect the wiring. Quite often it frays. And the wires located near the exhaust manifold are exposed to temperature, as a result of which the insulation melts and a short circuit occurs.

- Worn speedometer cable. Over time, it can acquire burrs, crack and even break.

These options are also possible: worn speedometer gears, change in the shape of the speed arrow.

The speed sensor could also be faulty. There are three main ways to check the device:

First way to check

- remove the sensor;

- Using a multimeter, find the contact that creates the pulses;

- attach a tube to the axis of the speed sensor and rotate it;

- during rotation, check the change in voltage supplied to the speed sensor;

- the speed of rotation of the tube must be proportional to the frequency of pulses and the voltage supplied to the speed sensor.

Second way to check

- using a jack, lift one wheel in the car arch;

- connect the multimeter to the speed sensor, as stated in the first method;

- spin the hanging wheel of the car;

- If during rotation of the wheel the pulses become more frequent and the voltage increases, then the sensor is working.

Third way to check

- take a control lamp or a regular light bulb rated for 12 volts (you can take a lamp from a VAZ 21099 located in the turn signal);

- remove the impulse wire and connect it to the light bulb;

- hang one front wheel in the arch using a jack, as in the second method;

- rotate the car wheel;

- if a minus appears on the control lamp or if a regular 12-volt lamp starts blinking, then the sensor is in working condition.

How to check the device

To check the condition of the speedometer, you will need to drive the car onto an overpass or into a garage with a pit. You must have access to the bottom of the VAZ-2109 so that you can unscrew the cable fastening. Also invite an assistant who will turn the cable in different directions or monitor the instruments. The car enthusiast himself cannot simultaneously read the readings and be under the bottom of the car.

The results could be like this:

- the arrow moves - the cable is intact, the problem should be looked for in the device drive;

- the pointer twitches - the flexible shaft is worn out and needs to be replaced.

Symptoms of malfunction

The main part of the speedometer is the speed sensor. Thanks to this unit, information is transmitted to the speedometer about how fast the car is moving on the road.

Symptoms of a malfunctioning speed sensor are:

- Incorrect display of vehicle speed on the instrument panel. Or the speedometer does not show the car’s speed (the needle always remains at zero).

- Engine instability at idle.

- Increased vehicle fuel consumption.

- The engine is not running at full power.

How to repair the speedometer drive

Now we will talk in more detail about dismantling and repairing the drive. It often needs to be repaired if the O-ring begins to leak oil. To repair this unit, follow the instructions:

- Using a socket wrench, unscrew the bolt holding the speedometer drive housing.

- Then pry it up with a screwdriver and remove the drive.

- Inspect the driven gear; it is made of plastic and may show signs of wear. In this case, it is best to replace the part.

- Check the rubber seal. If signs of wear are visible on it, replace it.

- Then evaluate the quality of the seat for the cable end. It should also not be worn or damaged.

- Look at the drive mounting location on the gearbox; if there are oil leaks there, the O-rings must be replaced. They are located on the body.

- If you decide to replace these rings, you will need to first remove the driven gear and then push out the seal.

- Soak these parts in kerosene. If they are not worn out, replace them. Also wipe the remaining parts with kerosene and put them in place.

The total time for repair and dismantling of this VAZ-2109 unit will take about 30 minutes.

labavto.com

If the speedometer needle starts jumping on a VAZ 2109, this indicates that a problem has arisen. As a result, the device will produce incorrect data, due to which the driver may exceed the speed limit without knowing it, and this can lead to not only a fine, but also other troubles. Therefore, the problem must be solved immediately after it is discovered.

Device structure, its purpose and principle of operation

Before troubleshooting, you need to understand the structure and operating principle of the device. The speedometer drive is a set of mechanisms whose task is to display vehicle speed data on the dashboard.

The VAZ 2109 drive is of a mechanical type, consisting of a drive gear and a driven gear, a cable. Gears are attached to the other gearbox shaft. While driving, the shaft rotates, imparts torque to the gears, they transmit it to a cable, which is connected to an arrow in the speedometer on the dashboard, indicating the current information on the dial. The length of the cable depends on the installed dashboard. On the VAZ model in question, it can be high or low. When purchasing a new product, you should pay attention to this.

If the arrow stands still, jerks or rotates as necessary, then something is faulty in the mechanism. The following breakdowns are possible:

- related to speed readings on the panel;

- damage or rupture of the cable;

- drive failure.

What should you do to detect problems?

In order to diagnose a malfunction in the speedometer, you need to place the car on an elevated platform (overpass, inspection hole, lift). You can raise the car by placing it on reliable supports, for example, made of wooden blocks. It is important that the bottom of the car is accessible. Next, unscrew the nut securing the device cable.

An assistant will be required to carry out the diagnosis. From below, one person twists the disconnected speedometer cable, turning it to the right and then to the left. The other one is in the cockpit watching the instruments. If the arrow moves noticeably, then the cable is intact, the problem is in the drive. Although the reason for the twitching arrow may be the flexible shaft, if it is frayed and the braid touches it.

To check the drive, it must be removed. To do this, the cross member used to secure the gearbox is released. Then, using a flat-head screwdriver, pry off the drive frame. Taking the box to the side, remove the drive and perform diagnostics.

First, rotate the gear to check the rotation of the speedometer cable socket. If there is no rotation, then the drive must be replaced.

To avoid mistakes when purchasing a new device, it is advisable to take a broken drive as an example, since the number of teeth on the gear may not match. If you install a gear with the wrong number of teeth, it is possible that the drive will pull out once it starts moving, causing serious damage to the transmission. For future use, you will have to change the cover on the back and update the lubricant.

Speedometer drive repair

To replace an O-ring that has begun to leak oil, or to replace the housing, it will have to be dismantled. There is no need to remove the gearbox for this. The car is placed on a lift or other device. The process includes the following steps:

- Use a socket wrench to unscrew the bolt holding the drive housing.

- Next, use a flat screwdriver to pry up the housing and remove the drive.

- At the next step, the driven gear is dismantled and inspected, since it is plastic, defects are possible. If there are signs of wear, deformed or “licked” teeth, it must be replaced.

- The sealing rubber is inspected. We change it if it is worn out.

- You should also inspect the condition of the seat where the cable tip is located. It should not contain worn out components or chips, otherwise the gear must be replaced.

- During the inspection, you need to carefully inspect the area in the gearbox housing where the drive is installed. If oil leaks are detected, it is necessary to replace the drive seal rings located on the housing.

- First, when replacing the ring, the driven gear is removed, and then the seal is pushed out.

- Then, all parts must be washed in kerosene and installed in place.

Removal and repair takes no more than half an hour.

Cable replacement process

A common cause of problems with the speedometer is a faulty cable (flexible shaft). The replacement process is simple: you need to carry out the following operations:

- Going down under the car, located on a hill, we find a cable on the engine side. We move the protective cover up and remove the nut, dismantle the cable from the speedometer.

- We inspect the connection point with the drive. The inlet hole and the end of the cable are square. In case of licked edges, the cable remains at rest during rotation. Buying a new shaft will solve the problem.

- To ensure that rotation is accurately transmitted to the speedometer, we install a thin gasket at the entrance of the flexible shaft. It can be cut from a plastic bottle.

- To replace the flexible shaft, you need to remove the instrument set from the panel. In the case of a high-mounted tidy, first remove the trim, and then the fastenings of the instrument unit. If the panel is low, then unscrew the two bolts and, squeezing the fasteners with your fingers, remove the visor.

- Now we dismantle the instrument unit.

- Then unscrew the nut of the flexible shaft and remove it through the motor compartment. You should remember how it goes in order to install the new one correctly.

- Next we stretch a new flexible shaft. We insert a plug into the compartment partition, lubricating it with Litol so that it fits in easier.

- After removing the instrument cluster, you can replace the speedometer if necessary.

- When all replacements have been completed, the devices are installed in place.

After replacing the cable, we check the operation of the speedometer.

Additional repair details

Another reason for a non-functioning drive is wear on the driven and drive gears. To replace them, you do not need to remove the gearbox. You should go under the car and unscrew the bolt securing the drive to the gearbox. Next, the housing and gears are removed. When purchasing new gears, you need to pay attention to the number of teeth. Their number should correspond to the old ones. The parts are assembled in reverse order.

If the numbers on the panel are askew, and over time the sensors stop turning or burn out, these problems can be solved by removing the instrument panel and troubleshooting.

Replacing the flexible shaft

If during the inspection process you find out that the problem is in the flexible shaft (cable), then you need to work according to different instructions:

- On the engine side, find the cable leading to the speedometer needle. Move the protective cover, remove the nut and unscrew the shaft from its drive.

- Inspect the places where the cable is attached to the drive. If the fastener is not square, the problem is that when the gear rotates, the flexible shaft will remain in place. In this case, replacement will solve the problem.

- To accurately transmit rotation, install a gasket cut from a plastic bottle at the entry point of the flexible shaft.

- Next you need to disassemble the dashboard. The work is carried out differently, depending on the type of structure. If the instrument panel is high, remove the trim and then remove the instrument cluster mount. If it is of a low type, unscrew the two bolts at the edges, and then, squeezing the clamps, remove the visor. Remove the instrument panel.

- Unscrew the cable securing nut and remove it through the engine compartment. Note the path of this shaft so that you can install the new one correctly.

- Mount the new part. Lubricate the plug with Litol and insert it into the partition of the engine compartment.

- Replace the speedometer if necessary. After this, you can reassemble.

If the panel worked before

The check is essentially the same, but you can exclude an error in connecting the wires from the list of possible faults when switching to a new chip.

If you have a VDO device, on our website you can see how to do its self-diagnosis. If not, purchase a “lace” or have it diagnosed at a car service center. Sources of errors can also show which way to dig.

There is a feeling that in your case the problem lies in the speedometer mechanism itself or the tracks on the panel. Disassemble the panel yourself - call the roads, check the mechanism (continuity, check the integrity of the gears in the speedometer drive or other problems - the unit is quite complex, there are many sources of malfunctions) - or take it to a good electrician.

Also on amateur radio forums you can find diagrams of simulators of the speedometer sensor. Assembling this circuit will be useful for checking the operation of the speedometer. Without it, the dashboard will have to be constantly placed on the car and removed back.

Purpose of the speedometer and fault recognition

Before you deal with car problems, you need to learn more about the speedometer.

Understand where it is located and what functions it is intended for. A speedometer is needed to convert the rotation speed coming from the drive shafts to the speedometer sensors and indicate the speed of movement of the car, as well as indicate the path that the car has traveled. When the speedometer needle jumps, stops or constantly turns (any “independent” actions), you need to pay attention to the problem, for which there can be many reasons.

For example:

- Problems in the speedometer mechanism itself;

- Breakage (damage) of the cable of a part;

- The speedometer drive is broken.

Next, you need to understand why the speedometer on the VAZ 2109 still does not work. To find the reason, you need to carry out an inspection under the car (in the inspection hole or using a lift). Then unscrew the nut that secures the speedometer cable. You need to call someone to help, so that when you twist the cable in different directions, the assistant follows the arrow.

In the case when the speedometer arrow jumps, it means that the mechanism is working properly and the drive needs to be checked. But you should be more careful, as it happens that the needle jumps, but the problem is still in the cable (it fluffs up and touches the braid), which is why car owners get confused and do not understand what the problem is.

Next you need to figure out how to remove the drive if the speedometer on the VAZ 2109 fails. First, let's release the cross member that secures the gearbox and pry off the drive housing using a flat-head screwdriver. Then we’ll press the gearbox away from the drive and pull it out. Next, you need to check the serviceability of the drive mechanism. To do this, you need to turn the gear and check whether the groove under the speedometer cable turns. In the case when the groove does not turn, the drive needs to be replaced.

Now you are familiar with the instructions for identifying and eliminating problems and breakdowns if the speedometer needle begins to “jump”.

Functions

It is incorrect to assume that the DS serves solely to transmit information regarding the current speed of the vehicle. In fact, this device has several tasks.

- Transferring information to the dashboard, namely the speedometer, about the speed of the car.

- Supports optimal functioning of the idle air control.

- Transferring data to the electronic control unit in order to maintain optimal speed depending on the travel mode.

The DS is connected to the speedometer and controller using a mounting block located in the engine compartment. And inside the car, directly on the heater fan relay, there is a sensor fuse.

https://youtube.com/watch?v=7drLW_Qlgj4

Errors and symptoms

If the device starts to work incorrectly or breaks down, you should pay attention to the on-board computer screen. Diagnostics of errors will determine that the DS has stopped functioning properly and measures should be taken to eliminate the breakdown

| Error code | What does it mean |

| P0500 | This error indicates that the computer does not receive a signal from the speed sensor. |

| P0503 | This error code informs about the receipt of an unstable signal from the DS, which is intermittent. |

If these error codes appear on the dashboard, you should definitely inspect the electrical circuit for oxidation or damage to the integrity of the contacts. Often it is because of this that the DS stops transmitting information.

But there are other signs by which you can determine that the DS is out of order:

- On the dashboard, the speedometer shows incorrect speed data or the needle does not move at all;

- With a slight acceleration, the speed floats, the engine switches off on its own;

- Fuel consumption increases;

- Engine power is noticeably reduced.

These signs may be signals of problems with other systems. But if you find one of the characteristic signs of a DS failure, plus one of two error codes appears on the on-board computer, then the problem lies precisely in the speed sensor.

Functionality check

Do not rush to replace the device until you are sure that the faulty sensor is the culprit of the problem.

The check is performed in several ways. Decide for yourself which one you prefer.

Checking the operation of the DS

Before doing this, be sure to check the condition of the wiring and contacts. If they are oxidized or rusted, or there are breaks in the circuit, then the DS itself may well be operational. You just need to return the wiring and contacts to a functional state. If the check shows that everything is intact and there are no problems with the contacts, then diagnose the speed sensor.

- If you don’t want to remove the DS, then place the car on a level surface, secure it with blocks and lift the left front wheel with a jack. Connect the voltmeter to the contacts of the sensor and begin to rotate the wheel with your hands. At the same time, look at the voltmeter data. If the voltage increases with frequency in proportion to the increase in wheel speed, the DS operates normally.

- Another method also does not require removing the measuring device. But for this you will need a test lamp. Use a jack to lift the left front wheel and connect the test lamp to the DC contacts. After this, manually rotate the wheel. If the lamp lights up, the sensor is working well.

- The third method involves dismantling the sensor and then checking the input and output voltage. The device for measuring the indicators will be a voltmeter.

- The fourth method is actively used by those who prefer to repair their car with their own hands. Here you have to check the sensor drive. To do this, lift the wheel using a jack and remove the sensor. Feel for the DS drive, and then begin to rotate the wheel. You can feel with your fingers that the drive rotates. If there are no jams, everything rotates evenly, then the drive is in good condition.

If a malfunction of the DS is detected, the only correct solution is to remove it and replace it with a new sensor.

Having determined that your DS has already served its purpose, you can begin the replacement procedure.