Why the speedometer does not work on VAZ 2110, 2111, 2112

A car's speedometer is an important component of a safe and comfortable trip.

Every car owner knows what this device is intended for, but not everyone can immediately figure out the reason why the speedometer stopped working. And this is an unpleasant thing when the speed indicator shows incorrect numbers or has stopped functioning altogether. There is a high probability of speeding and getting a fine from a traffic police officer. Or not fit into the turn at all. To avoid these unpleasant situations, you should know the principle of operation of the device and the most likely causes leading to its failure.

Signs of device failure

The fact that there is trouble with the speedometer is evidenced, first of all, by the immobility of its needle while the car is moving. In this situation, the driver must immediately proceed (with all precautions) to a service station or garage.

You should suspect that the device is not working when the arrow:

- begins to fluctuate sharply;

- freezes periodically;

- shows the speed while the engine is warming up, and stops as soon as it starts moving.

In all cases, it is important to find the causes of the breakdown.

Signs and causes of DS problems

VAZ “tens” are equipped with pointer indicating devices, i.e. the speed is judged by the angle of its deflection. If, while driving, the speedometer needle jumps and jumps, lies at “zero” or shows values that do not correspond to the true ones, and the odometer does not record the distance traveled, then this indicates a breakdown of the DS.

This situation occurs due to contamination of the sensor contact block, since the primary device is located on the gearbox housing under the hood and is not protected from dirt. The pad may be exposed to oil vapors penetrating through damaged seals. This leads to loss of contact and, as a result, incorrect speedometer readings. Such a breakdown can occur both with sensors with a square connector and with a round one. The difference between them is that the former are used in Bosh systems, and the latter in January 4 and GM.

When the speed sensor fails, unstable engine idling is often observed, and fuel consumption also increases. In this case, the DS is replaced. When choosing a working sensor, it is advisable to choose a model that is identical to the old one. Preference is given to products whose pinouts are indicated in the form of “-”, “A” and “+” rather than a digital designation. This will help when repairing the device and measuring the output signal.

The DS drive rod must be metal, not plastic. Otherwise, the service life will be no more than six months. When purchasing a working device, check that it is complete, that there are no backlashes, and that there is a washer on the rod. Replacing the DS is carried out independently and does not cause any difficulties.

Purpose and principle of operation of the speedometer

The car speed meter kit consists of a speed sensor (DS), connecting wires, a mains fuse and an indicating device. On the “tens”, a dial speedometer is installed. It is located on the dashboard and is made in a single unit with other instruments and indicators. When the car is moving, the speedometer needle shows the true speed, and the odometer records the distance traveled. Readings are displayed either on the LCD display or on the drum counter.

On VAZ-2110 cars of the first production, a mechanical speedometer drive was used, made in the form of a cable in a metal braid with tetrahedrons on both sides. For fastening to the device and the drive device there were special union nuts. The torque from the secondary shaft of the gearbox was transmitted directly to the indicating device via a cable.

The VAZ-2110 electronic speedometer is installed on models with injection engines.

The operating principle of the device is based on the Hall effect. The signal from the DS is transmitted to the electronic control unit (ECU) and, converted, enters the input of the speedometer circuit. In addition, it is involved in the ignition system and fuel supply to the injectors. DS is an asynchronous generator excited by permanent magnets. The signal enters the ECU in the form of electrical impulses proportional to the speed of the vehicle. For example, while a car travels a distance of 1 km, about 6 thousand of them enter the control unit.

What else is the reason for the speedometer not working?

However, often the reason for the speedometer malfunction lies elsewhere:

- Oil and dust get into the speed sensor, which is located in the engine compartment under the hood of the car.

The malfunction is eliminated after removing dirt and oil by washing the sensor. If the DS fails and needs to be replaced, any car owner can perform this simple operation independently.

The replacement sequence is as follows:

- place the machine on a flat horizontal surface;

- open the hood and find the speed sensor on the gearbox;

- by pressing the latch bracket, the plug is disconnected from the DS:

- to remove the sensor, use a 22 mm wrench, turning it counterclockwise;

- The new part is installed by screwing it in by hand. The use of a wrench is not recommended, as you may miscalculate the rotation and break the thread;

- install the connector, as evidenced by the click of the fixed part.

Speedometer Troubleshooting Options

Before troubleshooting, you need to find out exactly the reason why the speedometer on the VAZ 2112 does not work. There is a reliable and simple method for this. The check begins with the speed sensor and, in search of a breakdown, moves towards the speedometer.

You should make sure that all wires and devices are in good working order. To determine the presence of a signal, you can use a lamp to which wires are soldered. It can be easily connected to the vehicle's on-board network.

- The first wire is connected to the negative terminal of the battery.

- The second simulates impulses, trying to touch contact “A” with a certain frequency.

- If the speedometer reacts - the arrow turns at a small angle - then this part of the electrical circuit is working.

- By touching the contacts all the way from the block to the device, you can determine where the break is located.

If the arrow does not react, then the cause of the malfunction is in the speedometer and it must be replaced.

Replacing the speedometer

For the VAZ 2110, spare parts suitable for repairing the speedometer are not produced. If something goes wrong and it’s the one that breaks, the device can be repaired by replacing the “Schetmash” instrument panel. Or by purchasing products from another manufacturer, for example, a VDO instrument cluster. But, according to statistical data, the indicating elements are quite reliable and break very rarely. Sensors fail much more often, and the most common failures are oxidized contacts and faulty wires.

Reasons why the VAZ 2110, 2111, 2112 speedometer stopped working

The operation of any speedometer is based on the Hall effect. The controller receives data from the speed sensor, which produces a signal proportional to the tire rotation speed. On cars of the “tenth” VAZ family, one of the most common reasons for speedometer failure is contact oxidation. Cleaning them will take about 10-15 minutes; this is the simplest and most effective solution to the problem.

This video describes the reasons why the speedometer on a car does not work:

But, if this did not help and the speed meter still refuses to work in the VAZ 2110, VAZ 2111, VAZ 2112, then the owners of these cars will have to prepare for more painstaking work. The following possible malfunctions include:

- Deformation of wires in domestic cars is also a common problem. It is necessary to visually check all wires for defects. If nothing was found, to be completely sure, “ring” the wire; the internal conductors may be damaged;

- The fuse should be checked. It may simply simply burn out;

- The problem may be hidden in the speed sensor itself. In VAZ 2110, 2111, 2112 cars, in this case, it is necessary to urgently replace the faulty mechanism. But, first, it’s still worth checking the mechanism for functionality: remove the device from the box and connect a drill to the device. If it is working properly, then torque will be transmitted to the device;

- It is advisable to check the instrument panel for faults. If the instrument panel was removed, then incorrect reinstallation could result in the arrow touching the trim.

These are the most likely reasons that answer the question: why does the speedometer not work? This principle should be observed for both owners of an “injector” engine and owners of a “carburetor”. If, after going through all the procedures, the problem was not detected and solved, then in this case it is necessary to carry out a comprehensive diagnosis of the vehicle.

Some recommendations

- The search for the cause of the speedometer's inoperability should begin with an external inspection of the DS and the wires going to it. Wires often break in close proximity to the plug.

- If the speed sensor is covered with a layer of dirt or oily, you need to remove it, wipe it, reinstall it and check the speedometer readings again. Perhaps after this the instrument needle will again begin to show speed normally.

- If you cannot figure out the problem yourself, you should contact an electrician at a car service center.

Causes of malfunction on a VAZ 2110 with a carburetor

In the “ten” with a carburetor, torque is transmitted from the gear in the gearbox (gearbox) through a flexible shaft to the speedometer mechanism. In most cases, it is the shaft that may be causing the problem.

Flexible drive in the shell is the main cause of speedometer malfunction

If the speedometer stops working, first check the mounting points of the flexible drive . Tighten the nuts. If even after tightening the speedometer does not work, then the shaft has probably broken or there has been a breakdown in the mechanism on the instrument panel. In this case, the flexible shaft must be replaced. You can do this type of repair yourself. When installing a new drive, avoid extreme bending. Incorrect installation of the shaft will lead to unpleasant knocking.

If everything is in order with the flexible shaft and the instrument panel mechanism, then the problem is in the gear. It is located inside the checkpoint. We recommend that such repairs be carried out at a service station.

We are replacing the speed sensor

If the reason turns out to be the sensor, then you can replace it yourself. This can be done with a little experience with the operation of electrical appliances. Procedure:

- Be sure to wear rubber gloves, since de-energizing the on-board system of the machine can cause unpleasant sensations.

- Then you need to detect the sensor. As a rule, on a “tenth” generation car, the mechanism is located between the drive and the tip of the flexible shaft.

- Having found the device, it is necessary to disconnect the block with the wire by removing all spring clips.

- Next, use a 22 key to unscrew the mechanism from the drive.

- At this point the work is almost finished, but only a little remains. Next, the new device is installed. This is done simply, but the main thing is to get the sensor rod into the center of the drive. Then you need to tighten all the components in the reverse order, secure them and begin checking the new mechanism.

Share with friends on social networks:

Telegram

Step-by-step instructions for replacing a VAZ 2112 speed sensor with a mechanical drive

In order to replace a mechanically driven speed sensor on a VAZ 2112, follow the following instructions:

- First you need to de-energize the vehicle's on-board network; to do this, disconnect the negative cable from the battery.

- Next, disconnect the wiring connector from the controller itself. At this stage, it is important to remember what pinout these elements have.

- The controller itself can be unscrewed by hand. If you can’t do this on your own, try using a 21 or 22 wrench. In this case, the regulator may have certain differences in design.

- Also immediately check how well the drive functions. After the regulator is removed, it is necessary to unscrew the nut that secures the drive to the gearbox. The dismantling procedure must be done very carefully, because if you accidentally drop the rod into the transmission, the box will need to be removed and disassembled. As for the new drive, it is equipped with a rubber seal. Before installation, it must be lubricated with transmission fluid.

All new components must be installed in reverse order. Again, in this case the wiring pinout plays a big role. Inside the block itself you can see how the pinout is indicated. Using a tester with the ignition activated, it is necessary to determine which connector the drive should be connected to.

If the multimeter shows “-” and the drive was connected to the positive connector, this indicates that the polarity needs to be changed. Next, the drive is diagnosed, and you should also check the operation of the speedometer while driving or with the front of the vehicle raised (so that the wheels are suspended).

Mechanics

The following diagram shows exactly how the speed sensor is designed.

Speed sensor for VAZ-2112

Articles:

- 2110-3843010-13 – sensor;

- 2110-3843010-18 – sensor;

- 2108-3802820-10 – speedometer drive;

- 2101-3802718 - pad;

- 2108-3802822 – drive housing;

- 2108-3802830 - sealing ring;

- 2108-3802834-20 – driven gear;

- 2108-3802833-20 – drive gear;

- 2101-3802717 - washer;

- 15896211 – M6 nut;

- 12601271 – wavy washer;

- 11500121 – pin M6x14.

Elements 1 and 2 are interchangeable.

Dismantling

To remove the sensor from the car, you need to disconnect its connector. The sensor housing is fixed near the CV joint - the desired point is shown by an arrow.

First step in dismantling

When the connector is disconnected, take a flat key “22” and unscrew the plastic nut. Then you can change the sensor or repair it.

What you need here is a flat key

To replace the sensor drive, use a “10” key to unscrew the M6 nut and remove it together with the washer. The drive housing is rocked from side to side - you need a 14mm spanner.

Installation requirements: on the one hand, it is necessary to obtain a tight seal, on the other hand, the plastic must not be broken.

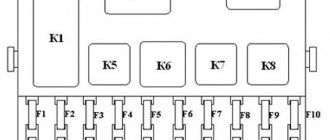

Dashboard connectors and speedometer contacts

The dashboard, as well as the speedometer on the VAZ-2112, may not work when they are disconnected from ground or power. Be aware that the speedometer receives power separately from the instrument panel. This also applies to the “mass”. Wiring:

- X2-2 : +12V to the speedometer;

- X2-3 : speedometer “mass”;

- X1-9, X1-10 : power supply for tidy;

- X1-1 : “mass” of the tidy.

Connector X2 is painted red, X1 – white. Terminals 8 and 9 in connector X2 are the speedometer output and input. The output is connected to the on-board computer.

Both terminals (X1-9 and X2-2) are connected to one wire - orange. This line is protected by a fuse installed in the main mounting block (F19).

Electrical diagram

The sensor itself is powered by a voltage of 12 Volts (pink-black cord), and another pin is connected to ground. The gray wire is the sensor output. It is connected to the voltage source through a resistor (see figure).

Typical connection diagram for DS on a VAZ-2112

The complete electrical circuit of the VAZ-2112 car is discussed here.

The diagram shows that the output is connected to the ECU terminal. Terminal number:

- 9 – block January 5.1, also BOSCH M1.5.4N (engine 21120, 1.5 l);

- 59 – BOSCH M7.9.7 module (ICE 21124, 1.6 l).

Another gray cord goes to the “red” block on the dashboard, where it connects to terminal 9.

Tidying up VAZ-2112

As you can see, everything is elementary.