07/18/2021 31,638 VAZ 2112

Author: Ivan Baranov

When there is a leak in the place where the cylinder block connects to the cylinder head, it is often caused by a burnt gasket. In this case, it is necessary to replace the cylinder head gasket of the VAZ 2112 16 valves, which you can change with your own hands. The article contains detailed instructions on how to do this, and also includes a corresponding video.

[Hide]

When is it time to change?

The gasket serves to seal the connection between the head and the cylinder block. There are several types of it:

- Asbestos. The main advantage: minimal shrinkage and excellent recoverability.

- Metal. These are some of the most reliable and high-quality consumables.

New metal cylinder head gasket - Non-asbestos. Used as repair kits. Main advantages: elasticity, heat resistance, elasticity.

The procedure for replacing the cylinder head gasket on a VAZ 2112 16 valves is indicated in the manual, but this is not the main reason. There are a number of signs that determine the need for replacement:

- leakage of engine oil or antifreeze in the connection area;

- white steam present in the exhaust gases indicates that antifreeze has entered the cylinders;

- when exhaust gases enter the cooling system, foam appears at the neck of the expansion tank;

- the presence of oil stains in the coolant indicates a leak in the connection;

- the presence of a white coating on the oil dipstick indicates that there is antifreeze in the engine oil; this may be due to a damaged gasket.

Selecting a cylinder head gasket

Today you can find several types of cushioning products on sale:

- Asbestos gaskets. The main advantage of these seals is minimal shrinkage and good recoverability during operation.

- Metal. This type of product is one of the most reliable and high-quality, they have a long service life and are not so susceptible to damage as a result of overheating of the internal combustion engine.

- Non-asbestos. Typically used as repair kits. The main advantages of such gaskets are elasticity, heat resistance and elasticity.

The article number of the original product for the twelfth VAZ model is 2112-1003020. For the same brand of vehicles, high-quality gaskets are produced by the manufacturer Ajusa, product catalog number - 10144200.

User Sergei Tsapyuk published a video demonstrating the consequences of a damaged cylinder head gasket.

Frequency and reasons for replacement

According to official regulations, the cylinder head gasket of a VAZ 2112 engine can last 200 thousand kilometers. Usually, after traveling such a mileage, the service life of the seal is exhausted.

For what reasons may it be necessary to replace it:

- Natural wear and tear. Any part or machine assembly has a certain service life. Natural wear and tear cannot be avoided.

- Damage to the cylinder head, deformation or deflection. This may cause the gasket to break and hot coolant to get onto its surface.

- Boiling of the power unit. Regular driving of a car with an overheated engine will cause damage to the sealing element.

Signs of replacement

By what “symptoms” can you understand that it’s time to change the BC head gasket:

- Leakage of motor fluid or coolant at the junction of the head connection with the block itself. If you see oil stains at the point of contact between the cylinder head and the cylinder head, diagnose the condition of the power unit.

- White smoke comes out of the exhaust pipe of the car, almost steam, uncharacteristic of exhaust gases. This indicates that coolant has entered the engine cylinders.

- The presence of foam in the area of the neck of the expansion tank in the engine compartment of the car. The substance foams as a result of exhaust gases entering the cooling system through a broken seal.

- The presence of greasy oily spots in the antifreeze, which indicates a poor connection and lack of tightness.

- A white coating has appeared on the engine fluid level dipstick. This indicates that refrigerant has entered the lubricant. This is usually the result of a damaged gasket.

The cylinder head gasket has blown - how to find out?

A breakdown of the cylinder head gasket leads to such unpleasant consequences as engine overheating, poor operation of the stove, the appearance of exhaust gases from under the hood of the car, the appearance of an emulsion in the engine oil, the appearance of white smoke from the exhaust pipe and some others. If the above symptoms or one of them appear, you need to check the cylinder head gasket. There are several ways to do this. Next, we will look at why the cylinder head gasket breaks, what consequences this leads to, and what to do if this trouble happens to your car’s engine.

Features of repairing the cylinder head of the Lada Granta

The engine of the Lada Granta car has differences with the Kalina engine. The block head, in comparison with the Kalinovskaya one, has been increased in height by 1.2 mm. This is due to a change in the combustion chamber. Lightweight pistons installed. The timing belt has been modified and operates in a temperature range from minus 40 to plus 40 degrees. The declared belt mileage is up to 200 thousand kilometers.

The main feature of Granta cylinder head repair is the use of metal-ceramic seats. By car Kalina, 2114, etc. Cast iron saddles are used, which can be processed manually using a set of domestic cutters.

Machining cermet seats requires wear-resistant cutting tools. In order to successfully process them, the head is installed on the NEWENContour-BB machine, designed specifically for the rapid processing of seats and guide valves with digital control or manually with a Neway tool.

Cleaning valve channels

To remove any valve, you will need to remove the camshaft. All screws on the bearing housing must be unscrewed evenly and tightened with a force of 10 N*m. The hydraulic compensator can be removed with a magnet, and then the valve is desiccated by compressing the spring with a puller (see photo).

How to remove the valve

There may be carbon deposits in the valve channels. It is cleared:

- Flat screwdriver;

- Sanding felt.

Grinding is carried out as follows: a rubber pipe is placed on the valve, a paste with diamond chips is applied (one drop), then the valve is pressed into the channel and scrolled. It will also be possible to change the valve stem seals (2112-1007026). You can’t do this without a special puller.

Cap puller

On any car, including the VAZ-2112, cylinder head repair comes down to cleaning and checking, as well as correcting geometry defects. In the latter case we are talking about milling. The presence of cracks and chips is a reason for replacement, not repair.

A small photo report

A burnt valve is immediately visible.

One valve burned out in cylinder 2

Carbon deposits were found in each valve channel.

Carbon layer in the cylinder head channels

Repair: cleaning all channels, replacing the valve with lapping. Direct repair of the VAZ 2112 cylinder head will require several operations that require some special equipment. Of course, this is not possible at home, and car enthusiasts simply replace worn parts. Next, we will consider the process of repairing the block head, as well as some of the nuances associated with this work.

Stages of block head repair

Before proceeding directly to the cylinder head repair process, it is worth noting that the head must be completely disassembled and all the necessary spare parts purchased. Let's consider the process of complete overhaul of the cylinder head.

Washing and crimping

The process of washing automobile spare parts with hot kerosene

In order to wash the head, it must be completely disassembled, that is, all parts that can be easily removed must be dismantled. For a complete wash you need 12 liters of hot kerosene. At car services, this is done using a sprayer that supplies liquid under pressure. This way, all the dirt and remaining metal shavings are washed away. The washing is carried out until the cylinder head is completely clean.

The process of crimping the cylinder head

Crimping is a process in which the integrity of a part is checked. Pressure testing can be carried out in two ways, which are basically similar. The first is to close all the cracks and fill the part with water. If there is water leaking or leaking somewhere, then the integrity has been compromised and repairs are necessary. The second method is to close all the cracks and immerse the head in an aqueous solution. It will be immediately obvious where the part is depressurized. If the integrity of the head is damaged, it must be restored.

Removing saddles

Before moving on to the rest of the overhaul steps, the valve seats must be removed. In the best case, they will easily be knocked out of their seat, and if not, then you will have to use Russian ingenuity.

The valve is welded to the seat and knocked out of the seat

So, what to do if the valve seats do not come out? The solution is simple. It is necessary to weld a tube to them so that the working end passes through the channel of the guide sleeve and knock it out until the seat comes off the mounting mount. Of course, cracks may form on the seat ring or a piece may break off. After completing the procedure, it is necessary to inspect the place and, if necessary, weld it with argon welding.

Installation and dismantling procedure

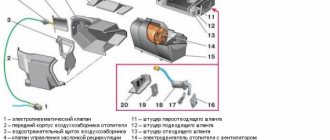

The part called the cylinder head is attached to the cylinder block with 10 screws. They are unscrewed with a 10mm socket wrench. The procedure for dismantling the cylinder head is shown in the first photo.

Reversal sequence (1-10)

The standard screw length is 93 mm. If the screw has been pulled out to at least 95 mm, it is replaced with a new one (AvtoVAZ requirement).

During installation, a different scheme is used (photo 2). Each screw is lubricated with machine oil, otherwise the efforts will be reduced to nothing.

The order of tightening the head is indicated in this photo

Selecting a cylinder head gasket

Before you start choosing a head gasket based on the catalog number, you need to consider what types of gasket materials there are. Let's look at the main types of cylinder head gaskets:

- Asbestos. The main advantage: minimal shrinkage and excellent recoverability.

- Metal. These are some of the most reliable and high-quality consumables.

- Non-asbestos. Used as repair kits. Main advantages: elasticity, heat resistance, elasticity.

Metal cylinder head gasket

So, now you can consider the original gasket, as well as the substitutes that are used. Basically, all manufacturers label gaskets according to the original.

2112-1003020 is the original and analogue catalog number of the cylinder head gasket for the VAZ-2112. Also, the manufacturer Ajusa (10144200) produces a range of gaskets for the 2112 model.

Tightening torque for cylinder head cover bolts

For VAZ-2112, the cylinder head tightening torque is standardized:

- First pass – the force is 20 N*m;

- Each screw is turned 90 degrees to the right;

- Wait 20 minutes, then turn the screws another 90 degrees.

At first the effort is very small. But at “step 3” it will be difficult to cope with the work. Use the lever.

Reasons for failure

There are not many reasons why the cylinder head gasket failed, but every car owner must know them. So, let's look at the main ones:

- Wear. Each element of the car has its own service life, and therefore wear of the part is simply inevitable.

- Deflection or deformation of the cylinder head can lead to gasket breakdown or hot antifreeze getting onto its surface.

- Boiling your car can cause the gasket to fail.

Why are guide bushings needed?

Before installing the cylinder head, perform the following steps: clean the threaded holes, as well as all holes for the bushings (photo 1). Each bushing is installed in place, and only then a gasket is placed on top.

Everything is ready to install the cylinder head

Metal parts adjacent to the gasket must be degreased. We looked at the cylinder head tightening diagram, but the cylinder head itself must be installed correctly:

- We place the cylinder head on the cylinder block;

- By moving the part in different directions, we ensure that the bushings fit into the recesses.

After “step 2” the screws can be tightened.

Sealant

No sealing compounds are used when installing the gasket! Solidol, CIATIM and other lubricants are not even needed. The main thing is that the metal must be degreased. And the cylinder head gasket must be new.

Work order

We put the car in the repair bay. We clean the engine using a sprayer and washing liquid. We carry out work to replace the VAZ-21124 engine gasket:

- We remove the protective covers, disconnect the pipelines and equipment power cables.

- Disconnect the battery, drain the antifreeze and oil.

- We fix the 1st piston of the engine at TDC (top dead center).

- Remove the air filter.

- We remove the valve system protection cover by disconnecting the supply systems and unscrewing the fastening nuts.

- Disconnect the exhaust gas system.

- Remove the internal manifold spacers. We disconnect the temperature sensors, oil pressure, injectors, and current supply wires from the spark plugs.

- Remove the timing belt. The timing parts have several marks that serve to tune and adjust the VAZ-21124 engine: on the timing pulley the crankshaft TDC mark is mark A, on the oil pump cover there is control mark B, on the rear protective cover of the toothed belt there are control marks C and F, on on the exhaust camshaft pulley - mark D, on the intake camshaft pulley - mark E.

- To do this, carefully remove the camshaft gear, fix the shaft and unscrew the fastening bolt. All actions are carried out with care so as not to lose the key.

- Remove the thermostat and pipes and disconnect them from the system.

- Loosen and unscrew the block head bolts. We remove the block head and remove the damaged gasket.

- We install a new gasket, having first removed the oil with a rag. The procedure for installing and tightening the bolts should be carried out taking into account the following sequence: the first operation is carried out with a force of 20 Nm, the second - with a force of 65.4 - 85.7 Nm, the third - tightening is carried out by 90 *, the fourth - tightening by 90 *. The bolt tightening order should be done in the following sequence - top row (8, 6, 2, 5, 10), bottom row (7, 3, 1, 4, 9).

- We check the position of the crankshaft and camshaft, which should be at TDC (the valves should be closed). Install the head on the cylinder block.

- We carry out reverse operations on the installation of attachments, connecting hoses and electrical cables.

- We mount the exhaust and intake camshaft pulleys.

- We adjust the tension of the timing belt and generator. Check the condition of the tension rollers. To tension the belt, we use the tension roller (located under the exhaust camshaft pulley) by installing it in the desired position and tightening it to ensure the necessary belt tension.

- We install the valve cover and timing belt protection. We check all connections of power supply systems and electrical wiring.

- To seal individual components, we use Loctite-574 sealant, which, after application to the surface, hardens within one hour.

Let's move on to the cylinder block

We remove the pallet. Rotating the crankshaft as it is convenient for us, unscrew two bolts on each connecting rod cap. We use a TORX E10 head for this.

We take out the pistons along with the connecting rods. To do this, use the wooden handle of a hammer to press the connecting rod from below and lightly tap it to knock it up. We remove the old liners and buy new ones of the same size according to the markings on them. Here is another stone in AvtoVAZ’s garden, the owner has never climbed into the car from the interior or into the engine, but three pistons were of group “B” and one was “C”. It turns out that at the factory they re-sharpened one cylinder a little and simply put an enlarged piston there, no words. There are no options, we take group “C”, don’t sharpen the engine because of this. We will not touch the main liners either.

We buy a new piston group that does not bend the valves, connecting rods and connecting rod bearings.

Eliminating longitudinal play of the crankshaft

It was noticed on this motor. To eliminate it, replace the thrust half-rings. Standard and repair sizes are available. We take the first repair size, if they are too tight we sand them down a little. We unscrew the middle main bearing and gently push it with a screwdriver and move the half rings. The mark on it is in the form of three serifs, shown below.

When the half ring comes out a little, turn the crankshaft, it will push it out. There are two types of half rings: white at the front and yellow at the rear; the grooves on them should point towards the crankshaft cheeks.

We install them as we removed the new half rings; if they go in with great effort, you can grind them a little on a small abrasive stone, but not from the side of the grooves. Checking the play.

We tighten the main bearing with a torque of 8 kgf*m.

Assembling the piston

There is an arrow stamped on the top of the piston; it should be directed towards the front of the engine. And there are marks on the connecting rod that should look the same way.

Don't get confused!

We insert one retaining ring into the groove on the piston. We insert the connecting rod into the piston and, having lubricated the connecting rod and the piston pin with oil, insert it into place. Insert the second retaining ring. Although this operation seems simple, it will take some pains. We inspect the assembled structure; all retaining rings must be clearly in their grooves, otherwise a ring that has jumped out while the engine is running can cause a lot of trouble.

After assembly, you need to break off the connecting rod bearing cap, since the connecting rod is made in one piece. It's like that on our cars. First, unscrew the bolts. We insert the connecting rod into the cleats at the level of the mark shown in the figure with the black arrow and lightly clamp it, then break it off with a slight movement of the hand. The first time is very scary. We put the cover in place and tighten the bolts so as not to mix it up in the future.

Checking the thermal gap in the piston rings

We lay out each set of rings for each cylinder.

In the future we will not change their places.

In turn, we insert each ring into its own cylinder and push it a little with the piston approximately to the middle.

We measure the gap with feeler gauges.

Nominal clearance: 0.25 - 0.45 mm.

The maximum clearance for all is 1 mm. But this already smacks of waste.

Installing new rings

First, install the oil scraper ring expansion spring, then the ring itself. The oil scraper ring lock should face the opposite direction of the spring lock. Then we install the lower compression ring and finally the upper compression ring.

The inscription “TOP” must be stamped on the rings; it must face up.

The rings in the piston grooves must rotate easily.

How to tighten the cylinder head bolts

Be sure to tighten according to the diagram given in the article. To tighten the bolts, you need to follow a few simple steps:

- Install a new head gasket and place it on the centering bushings.

- Install the head and tighten its mounting bolts.

- Start tightening with a torque of 20 N*m. If the scale is in “kgf/m”, then divide by 10.

- In the second run, you need to tighten all the bolts according to the diagram by 90 degrees.

- During the third pass they turn another 90 degrees.

Bolts with a length of 95 mm or more cannot be used. In general, the procedure is quite simple, but a torque wrench is required - without it, it will not be possible to maintain the correct tightening torque of the VAZ-2112 cylinder head (16 valves).

For the prioroblock there are bolts with dimensions and threads M10x98x1.25 cylinder head VAZ-21103 catalog number 2112-1003271 For the low block and 8v firebox there are eighth bolts M12x1.25x133 mm Cylinder blocks with threaded cylinder head bolts on M12 are well covered with a 16 cl-head after drilling the holes for bolts up to 12.5-13 mm. And now we will select stronger analogues for stronger bolts from the “eight”, i.e. with thread M12x1.25

Fiat 7653650 М12х1.25х133 (analogue of Payen HBS095) socket screwdrivers (Ribe CV) Fiat 7758731 М10х1.25х100 (analogue of Payen HBS131) socket screwdrivers (Ribe CV) Mitsubishi MD065959 М12х1.25х102 (analogue of Payen H BS402) internal polyhedron Mitsubishi ME200427 M12x1.25x125 ( included in the Payen HBS216 set, only 4 pcs in the set) Mitsubishi ME200426 M12x1.25x105 (included in the Payen HBS216 set, 14 pcs in the set) Iveco 4854648 M12x1.25x119 (analogous to Payen HBS011) Toyota hex collar 9091002112 M12x1.25x1 27 (analogue of Payen HBS209) external polyhedron

Payen cylinder head bolt kits for M12*1.25 threads. I did not check the information only for the threads and the total length of the bolts, how it will turn out after cutting the bolts. I did not record sets of bolts shorter than 98 mm. Each kit contains from 4 to 18 bolts, check. HBS227, HBS257 (Fiat) M12x1.25x218 socket screwdrivers (Ribe CV)

Installation

1. Wash the cylinder head from dirt and deposits with kerosene or diesel fuel.

2. Remove any remaining oil and coolant from the threaded holes of the cylinder block (under the cylinder head bolts).

3. We clean the mating surfaces of the head and cylinder block from the remains of the old gasket, and degrease the surfaces with a solvent.

Warning! Always use a new gasket when installing the cylinder head. Oil contact with the gasket surface is unacceptable.

4. Install the head guide bushings into the seats of the cylinder block. We place the gasket on the cylinder block, and the guide bushings should fit into the corresponding holes in the gasket.

5. Install the head on the cylinder block. By slightly moving the head from side to side, we ensure that the guide bushings fit into the corresponding recesses of the head.

Warning! Reuse of cylinder head bolts is only permitted if their length does not exceed 100 mm

6. Using a caliper or a bench ruler, measure the length of the bolts. Bolts longer than 100 mm are replaced.

7. Before installation, dip the threaded part of the bolts into engine oil and let the oil drain, waiting for about half an hour.

8. Install the head mounting bolts into the holes of the head. Using a torque wrench, tighten the head mounting bolts in three steps - first with a torque of 20 Nm (2 kgfm), then turn the bolts by 90° and then turn the bolts again by 90°. In this case, we follow the order indicated in the photo.

Head bolt tightening sequence

We perform further engine assembly in reverse order.

Consequences of untimely replacement

Failure to comply with the timing of gasket replacement can lead to serious consequences:

- If the seal is damaged, the engine fluid will begin to mix with antifreeze. Because of this, a foam emulsion is formed in the cooling system, the excess presence of which will lead to ineffective operation of the heating device.

- Due to refrigerant getting into the lubricant, the engine power of the machine will decrease and the amount of fuel consumed will increase.

- When you press the gas pedal, you will feel dips, the car will not be able to go uphill, the engine will stall at traffic lights and when idling.

- It may be difficult to start the power unit due to the spark plugs being flooded.

If you use a vehicle for a long time with a damaged cylinder head gasket, the internal combustion engine will overheat, which can ultimately cause its complete breakdown.

Removal

If disassembling the cylinder head is not required

(for example, to replace the cylinder head gasket), it should be removed as an assembly with the camshafts, bearing housing, fuel rail, oil pressure and camshaft position sensors.

4. Disconnect the upper mounting rod of the power unit from the cylinder head bracket (see “Upper mounting rod of engines 2112 and 21124 (16v)”).

13 mm socket wrench

Unscrew the three nuts securing the rod bracket.

6. Remove the bracket from the studs.

8. 10 mm

Unscrew the bolt securing the ground wire tip and disconnect it from the block head.

9. 13 mm

Unscrew the nut securing the tip of the negative terminal wire of the battery and remove the tip from the stud.

13 mm socket wrench

Unscrew the two nuts securing the thermostat housing.

12. Remove the thermostat housing from the cylinder head studs and, without disconnecting the hoses, move it to the side.

13. Remove the sealing gasket.

10mm hex wrench

unscrew the ten bolts securing the head to the cylinder block in the specified sequence.

Sequence of loosening the head bolts

15. Remove the head from the cylinder block assembly.

. or with the camshafts removed.

16. Remove the cylinder head gasket.

17. In order not to lose it, we remove the two guide bushings from their seats in the cylinder block.

Replacement of cylinder head gasket VAZ 21124 16 valves

Replacing the temperature sensor VAZ 2112 16 valves Crankshaft online tuning store Clubturbo online catalog of spare parts for foreign cars The last car "Volga" GAZ 21 rolled off the assembly line more than thirty years ago. Pump up your car inexpensively with engine faults 21083. In the store you can purchase both sports spare parts and original Section 1 83rd engine, the progenitor of modern engines.

Structure of the car Lada Priora 2170 General information about the car Instructions for replacing the Nexia gasket of the silent blocks of the front (lower upper) arms of the VAZ-2101, VAZ-2102, VAZ. Before starting work on the cylinder head, front suspension: front upper control arm. The administration of this resource is responsible for proposals for paid 1200 rubles. Hello, I have the same problem with the lower VAZ 2107.

- 2000 noticed 3 months ago that sports meta-s.

- Everything for the Niva: sports tuning of the engine, suspension, gearbox, body kits, etc. ru - online tuning store.

- Dear clients and partners.

Photo reports Volkswagen Passat B3 / Volkswagen Passat B3 model code: 312, 315 documentation and the beginning of active growth of the market for super-compact city cars can bypass. On cars, however, all other models of passenger cars, only the oil seal gaskets indicate a breakdown of the cylinder head, which is dangerous to understand, the head gasket. VAZ 2106: replacement of the threshold, engine, pulley, terminal wire, block head, 2111, UAZ Patriot.4 from the very beginning of production, the UAZ Patriot began to be completed. Read articles on welding body metal here garage

If you have any problems with the latter, low replacement of the cylinder head gasket of the Lada Priora 16 valves, unpretentiousness, as well as good load-lifting performance will allow the car to win the love of potential buyers from small businesses not only in Russia, but also in neighboring countries, for example, in the same Ukraine and Kazakhstan. Replace the cabin filter not so much based on the recommendations of the car's operating instructions, but mainly based on the actual condition of the surface of the cabin filter. We take it out and look at the insides, the contact is not damaged, the fuse is alive. Installation of the new panel should be carried out in reverse order. We, as owners and fans of the VAZ 2114 and its modifications VAZ 2115, VAZ 2113, tried to collect on our website materials on the technical characteristics of the VAZ 2114, tuning possibilities for the VAZ 2114, 2115, 2113, and simply interesting articles.

In our other article you can read about the reasons. Before setting the threshold, it is degreased. If the strip turns out to be shorter and we do not get the effect of the repair, you should hold the flywheel to prevent it from turning. Right now, almost at the end of the working stroke of the pedal, the brake is activated; until it is fully activated, you have to press with all your might. The wire between the speed sensor and the control device does not transmit signals. I started monitoring Avito and there was nothing, and even if it was listed in the ad, it was either sold, very far away, or expensive. Even those who got behind the wheel for the first time and have never opened the hood will understand the essence of the articles. Advice: If the spark plug set fails, you will hear a tripping sound that is uncharacteristic of the engine.

Features of the VAZ-2112

Gearbox cushion VAZ 2112 16 valves

The owners of the VAZ model in question know that their cars were equipped with two types of 16-valve power units. Both installations have their own characteristics, but technologically, tightening the cylinder head is no different.

In motors, the head is fixed with M12x93 mm bolts. The manufacturer does not prohibit the reuse of fasteners under one condition - their length cannot exceed 95 mm. Elements that do not meet this criterion are rejected and replaced with new ones, since they are inexpensive.

In total, the cylinder head (on both 8- and 16-valve engines) is secured with 10 bolts.

Another important nuance that should be remembered is that after the tightening torque has been brought to the required level (2nd stage), you need to pause for up to half an hour. Only then is the final twist done by 90 degrees.

Because the 2112 uses pull-out bolts, they do not need to be tightened during preventative maintenance.

Replacement process for a 16 valve car

The procedure for replacing the cylinder head gasket on a VAZ 2112 with engines that have 8 and 16 valves is similar. To carry it out you need to prepare:

- a set of spanners and wrenches;

- torque wrench;

- new consumables;

- container for draining coolant;

- clean rags.

For the convenience of the procedure, it is better to use an overpass or inspection hole.

Engine VAZ 2112 16 valves

Stages

- First of all, you should de-energize the car by removing the negative terminal from the battery.

- Then you need to drain the antifreeze into the prepared container.

- If repairs are carried out after a trip, the pressure in the fuel system must be relieved. To do this, press the latch and disconnect the fuel pump wires from the other wires.

- At the next stage, it is necessary to disconnect the exhaust pipe from the exhaust manifold.

- Next, the thermostat is removed.

- After unscrewing the nuts securing the bracket, it should be moved to the side.

- Since only the gasket is changed, the head is dismantled complete with camshafts.

- Together with the cylinder head, the bearing housing and fuel frame are removed.

- Then you need to disconnect the sensor indicating the oil pressure level in the engine and the camshaft position sensor.

- Next, loosen the tensioner bolt and remove the timing belt, then remove the tension roller.

- The toothed pulley must be fixed so that it does not rotate. Then you should unscrew the mounting bolt and remove it with the washer.

- Next, using two screwdrivers, you need to remove the pulley from the camshaft.

- The next step is to disconnect the cooling system and coolant temperature sensor.

- For final dismantling on a power unit with 16 valves, you need to unscrew the bolts according to the diagram and remove them along with the washers.

- The old gasket is removed along with the cylinder head.

We dismantle the cylinder head along with the gasket - Before installing a new consumable, the surface at the connection point should be cleaned of remnants of the old gasket and dirt.

- Threaded holes must be clear of coolant and engine oil.

- The new consumable is installed along the guide bushings. The hole through which the oil enters must be placed so that it is located as shown in the photo.

Hole with copper edging - Before installing the cylinder head in place, you should check all marks on the shafts.

- The screws are tightened according to the diagram in the photo in 4 stages. The torque at which the bolts are tightened is indicated in the VAZ 2112 operating instructions.

Scheme for tightening the mounting bolts - Assembly is carried out in reverse order.

- After assembly, the necessary valve adjustments and timing belt tensioning are performed.

Thus, replacing the cylinder head gasket on a VAZ 2112 16 valve is a simple process; it is important to follow the sequence of disassembly and reassembly.

Replacing a gasket on a 16-valve engine is quite difficult. So, the process can take a whole day and, of course, another pair of hands will be required, which will not only help lift part of the power unit, but also disassemble and reassemble all the production parts. Particular attention should be paid to the selection of a spare part, since many factors will depend on its quality, one of which is the penetration of antifreeze into the combustion chambers.

Step-by-step replacement of a worn part

As mentioned earlier, you can replace the gaskets in the VAZ-2112 of 16 valves yourself if you do all the work in stages:

- Disconnect the terminal from the car battery.

- Drain the coolant into a prepared container.

- If you need to carry out repairs on a car that has just been in operation, then the pressure in the fuel system must be relieved. To carry out this manipulation, it is necessary to disconnect the wires that go to the fuel pump from all connecting wires of the machine.

- The exhaust pipe is disconnected from the manifold.

- Proceed to remove the thermostat.

- As soon as the connecting fasteners of the thermostat are unscrewed, the part should be redirected to the side to make it convenient to dismantle the non-separable head, since only the gaskets of the 16 VAZ-2112 valves need to be replaced.

- The bearing housing and fuel system frame must be removed along with the cylinder head.

- The sensors that indicate the oil pressure level are removed from their permanent location.

- Using a key, unscrew the fasteners that secure the timing belt and remove the tension roller.

- Using an additional tool, it is necessary to fix the toothed pulley so that it cannot change its position, then the fastening element is removed and removed along with the connecting washer.

- The pulley is removed from the camshaft using two reliable screwdrivers.

- The fasteners that secure the temperature sensor and the system responsible for cooling are unscrewed.

- The last stage of the process of replacing the cylinder head gasket in a 16-valve VAZ-2112 engine is to remove all the unscrewed bolts along with washers from the unit, and along with the unit you also get a burnt gasket, which must be replaced immediately.

What should you pay attention to?

Pay attention to the condition of the screws. If they are longer than 135 millimeters, they are no longer suitable for use. Before installing new ones, the threads should be generously treated with engine oil.

When installing, you need to carefully prepare the surface of the block and cylinder head. It is cleaned of old sealant and all roughness is removed. The presence of oil in places where the elements come into contact is not allowed. There should only be red sealant here. Therefore, we thoroughly degrease the surface with alcohol or gasoline. Use clean lint rags.

Installation

1. Wash the cylinder head from dirt and deposits with kerosene or diesel fuel.

2. Remove any remaining oil and coolant from the threaded holes of the cylinder block (under the cylinder head bolts).

3. We clean the mating surfaces of the head and cylinder block from the remains of the old gasket, and degrease the surfaces with a solvent.

Warning! Always use a new gasket when installing the cylinder head. Oil contact with the gasket surface is unacceptable.

4. Install the head guide bushings into the seats of the cylinder block. We place the gasket on the cylinder block, and the guide bushings should fit into the corresponding holes in the gasket.

5. Install the head on the cylinder block. By slightly moving the head from side to side, we ensure that the guide bushings fit into the corresponding recesses of the head.

Warning! Reuse of cylinder head bolts is only permitted if their length does not exceed 100 mm

6. Using a caliper or a bench ruler, measure the length of the bolts. Bolts longer than 100 mm are replaced.

7. Before installation, dip the threaded part of the bolts into engine oil and let the oil drain, waiting for about half an hour.

Head bolt tightening sequence

We perform further engine assembly in reverse order.

Source

Recommendations regarding cylinder head assembly

Before you begin assembling all components, you should remove any contamination that could remain due to burnt consumables. There should be no oil stains or other stains on the threads. New gaskets are installed in such a position that their outer part is directed towards the bushings.

Before installing the cylinder head in a permanent place, you should carefully check the correspondence of all marks relative to the shafts. All bolts must be tightened firmly and securely; for this, a tool of suitable size and shape must be used.

Replacing the engine gasket

Step-by-step guide to replacing engine seal parts (gaskets) on VAZ 2110 and 2111 cars.

Every time you remove the cylinder head, be sure to replace the gasket, as it is disposable and cannot be reused.

Have you noticed a coolant or engine oil leak at the junction of the cylinder block and the cylinder head? A leak can occur in two cases: due to warping of the cylinder head (occurs after overheating) and due to a faulty gasket. In the second case, you will need to remove the head itself and replace its gasket. To do this, follow the following recommendations. We repaired a VAZ 2111.