The need to restore this element of the car is usually signaled by an increase in fuel consumption, engine noise and loss of power. In this case, you will need special skills and equipment to do everything “to the highest standard.”

The cylinder head is an integral part of the engine and endures enormous loads (up to half of all those attributable to the internal combustion engine).

Regularly conduct visual and “deep” diagnostics of the unit, promptly correcting detected problems. Experienced car owners recommend doing this every 250 thousand km. Find out the cost of repairing a cylinder head online in 3 minutes. Don’t waste your time - use the Uremont search and get offers from nearby services with specific prices!

Get prices

DIY cylinder head repair

The need to restore this element of the car is usually signaled by an increase in fuel consumption, engine noise and loss of power.

In this case, you will need special skills and equipment to do everything “to the highest standard.” The cylinder head is an integral part of the engine and endures enormous loads (up to half of all those attributable to the internal combustion engine).

Regularly conduct visual and “deep” diagnostics of the unit, promptly correcting detected problems. Experienced car owners recommend doing this every 250 thousand km.

Planned repairs

Such an important element of the entire engine, represented by the cylinder head, requires qualified diagnostics with the involvement of experienced craftsmen and appropriate equipment. To avoid unintentional damage, work should be undertaken by people who know their job well.

All visible defects can be identified visually during inspection of the removed unit. The following damages are clearly visible:

- seat wear;

- shells from corrosion;

- broken studs;

- cracks.

If the owner of a personal vehicle feels that he lacks any skills, abilities, or is simply apprehensive, then the best option is to contact the nearest car service center.

What is needed to repair the cylinder head?

Maximum efficient work is possible only if the performer and equipment have special skills. Preparation includes: washing, crimping, disassembly and troubleshooting. Next comes the restoration of camshafts, valve assembly parts, holes and threaded parts. Finish by processing the planes and final installation.

The preparatory stage before repairing the cylinder head begins with the removal of contaminants (oil residues, combustion products) to identify problem areas. Only after this can you really assess the order and scope of work.

Crimping is required to search for mechanical microdamages in the cooling jacket and check valve seats.

The list of tools for repairing the cylinder head block is given below:

- micrometer (for measurements);

- mandrels for pressing in caps and bushings;

- development for new parts;

- spring desiccant;

- countersinks for restoring valve seats;

- electric stove for heating the assembly (useful before pressing in the bushings).

Final defect detection is carried out after disassembling the valve mechanism.

Any repair work on cylinder head heads includes dismantling (with the exception of removing/installing oil seals). Do not neglect careful preparation so as not to face a shortage of spare parts and tools during the process of restoring the unit. You can purchase a ready-made repair kit or assemble it yourself, but in the technical center the entire technological process is carried out under strict control.

Cylinder head overhaul

The need for comprehensive measures can be determined by the following criteria:

- guide bushings failed;

- the camshaft is faulty;

- broken cast iron cylindrical blocks (needs welding);

- cracks appeared on the head;

- the connecting rod or valves are broken;

- complete wear of the gasket;

- the integrity of the sleeve is compromised (occurs due to an error in tightening the fasteners and screws).

Breakdowns occur due to regular driving with an overheated engine, insufficient lubrication of the power unit (low-quality oil, fuel or antifreeze entering the unit) and the end of the service life of spare parts.

Engine cylinder head repair

It is always better to read the vehicle manufacturer's instructions before starting restoration work. Also nowadays you can find suitable videos on the Internet.

The need to replace valves and the procedure for “drying them out” occurs quite often. In the second case, you will need a special device suitable for your car. An analogue can be a metal pipe with a diameter of 2 cm. A support is placed under the valve in the combustion chamber, and the head is placed on the floor. Next, the tube is placed in the upper valve part and struck (usually with a hammer). After several blows, the “crackers” crumble. The released springs are dismantled and the valves are removed. Installation is carried out in reverse order.

Replacing bushings

They are removed using a special mandrel. When purchasing new spare parts, choose parts slightly larger than the original ones (0.05 cm). For this you will need:

- lubricant (engine oil will do);

- mandrel;

- hammer;

- electric stove;

- lapping paste;

- lapping device.

The assembly is placed on a stand, the bushings are treated with lubricant. The unit is heated to 100 degrees Celsius and the parts are changed. Then the head is allowed to cool and the valves are checked for seating. If they stick or wobble, fix them.

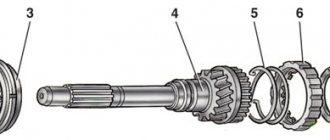

Camshafts

Their destruction occurs due to insufficient lubrication and overheating of the unit. As a result, the camshafts are deformed, and the cams and journals quickly become unusable. Scratches and nicks form on these elements and on their beds. Due to such damage, the internal combustion engine may fail. If you take the right steps in time, you can extend the life of spare parts without replacing them.

What loads is the cylinder head exposed to while the engine is running?

During engine operation, the head is subjected to the following loads:

- Large temperature difference;

- Exhaust gas pressure;

- Serious mechanical stress.

During fuel combustion in different parts of the head, temperature differences can reach up to several hundred degrees. For example, in the area of the combustion chamber, the heating of the metal can be about 300 degrees. In the same place where the cooling system channels are located, the temperature will be around 90-95 degrees.

The same can be said about the pressure of gases formed during fuel combustion. Uneven loads acting on different parts of the cylinder head can lead to metal deformation. To prevent such an outcome, special requirements are placed on the cylinder head, in particular:

- High structural strength;

- Long service life;

- Strictly verified dimensions of the combustion chamber and channels;

- Good sealing of gas joints;

- Simplicity of design, allowing for necessary repairs;

- Minimum weight and dimensions.

In what cases does the cylinder head need repair?

In principle, anything can happen to the cylinder head, from the breakdown of small parts to the appearance of cracks in the structure of the head itself. But we will not consider all these nuances, but will focus on the most typical breakdowns of large components and elements.

The process of grinding the cylinder head assembly

There are several reasons why the cylinder head breaks and, accordingly, repairs.

- regular driving with an overheated engine;

- malfunction and breakdowns in the internal combustion engine lubrication system (meaning low-quality motor fluid, antifreeze or fuel getting into the oil);

- wear of components as a result of spent service life.

Sorry, there are no surveys available at this time.

In what cases is cylinder head repair necessary?

- Failure of the camshaft or other components associated with this assembly.

- Failure of guide bushings.

- Breakage of cast iron cylinder blocks and cracks in the head. In this case, the repair process at home is carried out only if you have welding equipment and know how to use it.

- Replacing the cylinders themselves. Scores, cracks may appear on them, or the cylinders may simply have “outlived” their useful life.

- Broken valves or connecting rod. Such cylinder head failures may subsequently cause the need for major engine repairs.

- The appearance of cracks in the sleeve. Typically, this problem occurs in cases where a motorist or a mechanic at a service station has incorrectly tightened the head mounting screws.

- Broken gasket. It is also one of the most common breakdowns. Usually wears out due to spent service life.

Actually, this is only a small part of the reasons why it is necessary to remove the cylinder head and repair it. We will describe in more detail below the most common fault repair methods.

Puzzle

you will never encounter the problem of repairing a cylinder head or cylinder But if trouble does happen, you should not repair the cylinder head using artisanal methods. Modern equipment and technologies can save heads that garage technicians write off as scrap.

The most common reasons why the “head” has to be repaired are its warping as a result of overheating, burnout of valves, “meeting” of valves and pistons, and breakage of spark plug threads. Sometimes the culprit is a manufacturing defect (such as internal sinks).

After removing the head, micrometering is carried out to identify defects and determine the amount of work required. At the same time, the lower plane of the cylinder head, wear of the camshaft bearings, seats, valve stems and guide bushings are checked.

The presence of cracks, including internal ones, can be detected by pressure testing. A visual inspection does not guarantee the detection of cracks. Firstly, they may be so small that they will not be visible to the naked eye. Secondly, they can hide in internal cavities. And thirdly, the crack may not be visible at normal temperatures, but “open” only when heated. Crimping on a special installation helps to find a defect in all the described cases.

Before carrying out the inspection, the mating plane of the cylinder head is sealed, and plugs are installed in the cavity. One of the plugs has a fitting through which air is supplied under pressure into the cavity being tested. The cylinder head is immersed in a container with water heated to operating temperature (70-80 degrees). Thus, existing cracks “open up”. The presence of defects is determined visually by air bubbles. The installation allows you to rotate the head around its axis for ease of research.

Specialized machines allow you to perform any cylinder head repair operation quickly and efficiently. The camshaft bed is restored on a jig boring machine.

For removing and installing valves, there is a separate machine with sets of pullers, grippers for crackers, etc. In this case, the cylinder head rests on an elastic plane, which prevents damage to the valve stem.

Cylinder head repair by handicraftsmen

The valve is removed using a hand tool, which requires a lot of force. In this case, the crackers scatter throughout the room, and if you squeeze, you can bend the valve.

To replace valve guides, the most advanced “garage” technology suggests heating the head using an electric stove, cooling the guide in the freezer, and lubricating it with engine oil before installation. The actual installation is done using a hammer and a mandrel.

But some “masters” act even simpler. Why bother with heating and cooling? If the head is aluminum and the hammer is heavy, then the guide will fit in anyway! True, a broken hole will allow oil to pass through, and the guide may become crooked in relation to the saddle... But how do most modern customers, for whom the engine compartment is a dark forest, know such wisdom?

In a professional service, the cylinder head is evenly heated (for example, in a heating cabinet), after which the old bushings are pressed out, and new ones, cooled in liquid nitrogen, take their place almost without effort or distortion. After pressing, the inner surface of the bushings is turned to the required size. For this purpose, sweeps are used. However, higher quality is again ensured by a special machine.

If the seats in the head are sagging or the camshaft supports are worn out, the “handicraftsmen” order it to be replaced. Why bother, the client pays! A specialized service has equipment that allows you to restore seats and bore their mounting holes, repair holes for hydraulic pushers, and drill out studs.

How are saddles repaired the old fashioned way? First, they are processed manually with various cutters (cutters), and then the valves are again ground in manually. The easiest way is to take lapping paste, put a rubber hose on the valve stem and use your hands, hands, just like how ancient people made fire.

True, there is also a special device, but again it is manual. The work is very labor-intensive, and, most importantly, does not guarantee a high-quality result, because everything is done “by eye.” The tight fit of the valves to the seats is checked by pouring kerosene into the intake and exhaust manifolds. If leaks appear, start all over again: dry out the valves, grind them in...

Cylinder head repair by specialists

The cutting head of the machine simultaneously processes all three seat chamfers with high precision, after which no valve lapping is required. The tightness is checked using a vacuum installation; there is no need to install springs and crackers. In it, the valve is “sucked” to the seat by vacuum. If the processing is done well, the valve is held in the seat by atmospheric pressure. And after that you can already carry out the final assembly.

A separate issue is eliminating cracks in aluminum cylinder heads. The heads of diesel engines are most often affected, as they experience greater loads during operation compared to gasoline engines.

Moreover, cast iron heads, due to their lower ductility, are damaged much more often than aluminum ones. Cracks appear, as a rule, in places of the greatest temperature difference, such as: between valve seats, near the prechamber.

In gasoline engines, the head suffers mainly due to overheating. Over time, the cracks that appear increase in size, reducing the strength of the cylinder head. As a result, the fit of the parts pressed into it—seats and valve guides—is weakened.

Even worse consequences occur when a crack breaks the tightness of the lubrication or cooling channels passing through it. Compression drops and the engine runs unsteadily. The coolant, entering the cylinder, washes away the lubricant from its walls, and flowing into the crankcase, mixes with the oil, worsening its properties. This increases engine wear significantly.

Car manufacturers do not provide repairs in such cases. Our service stations offer services for welding cracks using our own methods using argon-arc welding.

Before welding, the head is heated evenly. Then the welder eliminates the wall defect and deposits the material “with a reserve”. Next, the geometry of the head is restored by mechanical processing.

There is an opinion, including among specialists, that welding cracks is only applicable when preparing a car for sale. If you do repairs to the cylinder head “for yourself,” it is better to replace the head. In any case, inquire about the duration of the warranty and the equipment the workshop has.

Kolodiychuk Andrey

, especially for

What is needed to repair a cylinder head?

It is precisely the malfunctions and repairs of the cylinder head that we are interested in. Is it possible to repair the cylinder head with your own hands in a garage or at home? And the craftsmen answer unequivocally - yes, repairing the cylinder head with your own hands is possible.

Let's start by clarifying that repairing a cylinder head is a complex operation and will require from you: a little understanding of the structure of the block, the presence of special metalworking tools and the ability to use them.

Basic tools required for cylinder head repair

- Mandrel for pressing oil seals.

- Micrometer for measuring valves and guides.

- Reamer for unrolling new bushings.

- Mandrel for pressing out bushings.

- Mandrel for pressing bushings.

- Devices for loosening valve springs.

- Set of countersinks for restoration of valve seats.

- Electric hotplate for heating the cylinder head during troubleshooting and before pressing in bushings.

Don't forget about the necessary spare parts and tags

As a rule, almost any repair of the cylinder head requires its dismantling. Exceptions include, for example, replacing valve stem seals. Therefore, before you start dismantling the cylinder head, consider purchasing the necessary set of spare parts.

Today's market provides Head Sets (or, simply put, top sets), which include the cylinder head gasket and all the seals and gaskets located above the main gasket.

Well, the tool and the minimum kit are ready, let's begin troubleshooting the cylinder head.