Average price of a factory product and its disadvantages

The factory version of the device has some disadvantages that significantly reduce the usefulness of such an acquisition.

It is always more convenient to set the ignition on carburetors with a strobe light

Firstly, the cost of factory stroboscopes is quite considerable. So the digital model Multitronics C2 will cost the buyer about 900-1000 rubles. The more functional AstroL5 strobe will cost 1,300 rubles. Focus F1 - a model suitable for servicing both gasoline and diesel engines - will require 1,700 rubles, its more “advanced” brother Focus F10 - 5,600 rubles.

Secondly, manufacturers often use an expensive gas-discharge lamp in the design of their products. It has a limited resource and may require replacement after a short time, which will not only hurt your pocket, but will be tantamount to buying a new strobe light.

How much will a homemade strobe light cost to adjust the ignition?

Based on the above disadvantages of a store-bought strobe, it seems appropriate to conclude that it is advisable to manufacture such equipment at home. Moreover, it is much more convenient and cheaper to equip it with affordable LEDs, which cost mere pennies. For such purposes, a cheap laser pointer, flashlight, etc. is quite suitable as a donor.

In the same way, there will be no problems with other components, as well as tools. The total budget for the venture should not be more than 100-150 rubles.

Video tutorial on setting up ignition with a strobe light

Pro Tip: How to Set Up Manufactured Strobes

Self-assembled strobes will essentially be no different from branded strobes purchased in car stores. Professionals recommend taking into account some nuances when diagnosing a car and the ignition system in particular.

- The engine of the vehicle being tested must be started and idling without gas leaks, etc.

- To a self-made strobe, you need to connect an external power supply, which can be a car battery, or another battery.

- A copper sensor must be wrapped around the core of the engine cylinder.

- The light should be directed at the mark located on the distributor body.

- The next step is to find a point on the flywheel pulley.

- The distributor body should be rotated until the two points come together, after which they should be fixed in a certain position.

How to make a strobe light with your own hands

There can be many options for designing a “home” strobe. However, in general, all such projects are structurally similar. Let's look at the principle of assembling this gadget using the following example.

Required parts:

- transistor KT315 (you can find it in any radio equipment of a bygone era, it can have different letter indices);

- thyristor KU112A (easy to find in the switching power supply of ancient TVs);

- small-sized resistors with a power of 0.125 W;

- a cheap (Chinese) flashlight with diodes (the number of diodes may vary, but better - from 6 to 10 pieces);

- capacitor C1 for voltage from 16 Volts;

- diode V2 - any low-frequency, for example KD105 or D9;

- small-sized relay (index BS-115-12A-DC12V or RWH-SH-112D, 12 Ampere, coil - 12 Volt); however, you can also use domestic relays, for example, type RES-10, with a coil voltage of 12 Volts;

- power wires of the required length (about 0.5-0.6 m) and alligator clips for connecting the strobe to the battery;

- shielded wire up to 0.5 m, a piece of copper wire about 10 cm.

Instructions for the manufacture of a device for installing the ignition

Easy way

There are many different schemes on the Internet, almost all of them are easy to assemble and do not require large costs for materials. Let's look at one of the most popular schemes for creating a strobe light at home. From the details we will need:

- transistor KT315;

- thyristor KU112A, resistors 0.125 W;

- any flashlight with diodes (there should be 6 or more diodes);

- capacitors C1;

- low frequency diode V2;

- relay with index RWH-SH-112D;

- power cord 1 meter long;

- special clamps;

- copper wire about 10 cm.

All parts can be purchased at the radio market or in a specialized store. You can use an old flashlight or camera flash as a housing for the device.

Assembly diagram of a car strobe light in a housing from an old flashlight

Such a device can be used not only for installing the ignition. They can check the spark plug and adjust the operation of the regulator.

Homemade gadget using a timer

A strobe based on timer devices has a more complex circuit. Its main advantage is stable light pulses that do not depend on battery voltage. The device can also operate in tachometer mode; to do this, you just need to change the position of the regulator.

Timer strobes can also be used as a tachometer

Tip: It is better to use diodes from the KD521 series in the circuit. If you can’t find a domestically produced timer, you can take the foreign analogue NE555.

Scheme for manufacturing a device using LEDs

This device is based on the 155AG1 microcircuit; it is triggered by pulses with negative polarity. The circuit uses resistances R1, R2, R3, which limit the amplitude of the input signal. The required pulse duration is set by capacitor C4 and resistor R6. With standard settings this is 2 ms. The car's battery will be used as a power source.

LED strobes are highly reliable and can be used even in bright daylight

Video: how to make a strobe light with your own hands

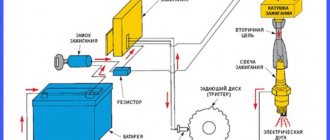

How to connect everything, strobe diagram

Strobe connection diagram

All the main parts of the device can be conveniently placed directly in the body of a pocket flashlight or a regular camera flash. At the same time, power wires pass through the rear hole of the flashlight (photoflash); at the ends they have soldered crocodile terminals of different colors or with markings (so as not to confuse “plus” and “minus”). A hole is drilled in the side wall of the housing (if it is missing) to route a shielded wire through it to pin X1. The braiding of this cable at the end must be insulated; a piece of copper wire about 0.1 m long must be soldered to the main core - this is a strobe sensor.

The operation of a strobe to set the ignition from a flashlight or flashlight

According to the diagram, after connecting the power wires to the battery, capacitor C1 begins to quickly charge through resistor R3. Upon reaching a certain degree of charge, the voltage through resistor R4 and the LEDs begins to flow to the base of the opening transistor. At this moment, relay P1 should operate. By closing, the relay contact prepares a circuit that consists of a thyristor, relay contact P1, LEDs and capacitor C1. Through dividers R1 and R2, the control electrode of the thyristor receives a pulse from contact X1.

The thyristor opens, resulting in a rapid discharge of the capacitor through the LEDs. A bright flash of a flashlight is observed.

By means of resistor R4 and a thyristor, the base of the transistor is connected to the common wire, which causes the transistor to close and the relay to turn off. At the same time, the glow period of the LEDs increases by several milliseconds due to the fact that the contact does not open immediately - due to the slight inertia and residual magnetization of the relay armature. After the contact opens, the thyristor is de-energized. The electrical circuit returns to its original state until a new impulse passes. By changing the capacitance of the capacitor used, you can change the glow time of the LEDs: more capacitance means they glow longer and brighter, but the trail from the mark on the flywheel is more noticeable.

How to set the ignition with a strobe light

A car strobe light is a simple and affordable device that can be easily purchased in a store and which makes life much easier for the car owner.

Indeed, with this mechanism, even a novice driver will be able to check and adjust the initial setting of the ignition timing in no more than ten minutes, as well as check both types of regulators (centrifugal and vacuum) for any damage. The principle of operation of this device is the stroboscopic effect, the essence of which can be explained approximately in this way: if an object moving in the dark is illuminated with a bright and at the same time short flash, then it will begin to visually appear frozen in exactly the position in which the flash caught it. For example, if you illuminate a rotating wheel with flashes at a frequency equal to the frequency of its rotation, you can also visually stop it. This is easy to notice due to the position of some mark.

In order to set the ignition timing, you should start the engine at idle speed, and in the meantime, use a strobe light to illuminate the previously mentioned marks. One of them, which is called “movable,” is located on the crankshaft (alternatively, on the generator drive pulley or on the flywheel), and the other takes place on the motor housing.

Flashes occur almost simultaneously with the moment when sparking occurs in the spark plug of one of the cylinders. For this to happen, the capacitive sensor of the described device is attached to the high-voltage wire of the spark plug. During flashes, both marks should be visible. Moreover, the following conditions apply here: if the marks are precisely located opposite each other, then the ignition timing will be optimal, but if the movable mark has moved, then the position of the distributor-breaker must be adjusted until the marks coincide.

The main element of a strobe is a pulsed stroboscopic lamp of an inertia-free type. In this mechanism, flashes occur at the moment when a spark appears in the spark plug of the first cylinder. As a result: the timing marks, along with other engine elements that rotate synchronously with the crankshaft, appear motionless when illuminated by the previously mentioned lamp. This allows you to control the correct setting of the initial ignition timing.

From all of the above, it seems possible to characterize the operation of a strobe in this way (at the same time, its structure will be explained): after connecting the leads to the battery, the voltage converter, which is a symmetrical type multivibrator, will begin to work. The initial voltage is supplied from dividers based on transistors, which begin to open, and one of them necessarily does this much faster than the other. This causes the other transistor to close, which is explained by applying a blocking voltage from the windings to its base. After this, the transistors open one after another, which causes the connection of first one or the other half of the winding from the transformer to the battery. At the same moment, a voltage appears in the secondary windings, having a rectangular shape and a frequency of about 800 Hz, the value of which is proportional to the number of turns in the winding.

At the moment when sparking occurs directly, in the first cylinder a high-voltage pulse is supplied to the igniting electrodes located on the stroboscopic lamp, through capacitors and a special arrester plug from the distributor socket. With all this, the energy accumulated by the capacitor is transformed into light energy from the flash of the lamp. After the capacitors are discharged, the lamp also goes out, but the capacitors receive a charge thanks to resistors to a voltage of approximately 450 V. Thus, preparation for another flash ends.

Resistors also serve to prevent the windings from shorting out when the lamp flashes. And the diode is designed to protect the transistor of the converter if the strobe is connected in the wrong polarity.

The spark gap, which is switched on by the spark plugs and the distributor, ensures that the required high-voltage pulse voltage is obtained in order for the lamp to be ignited. In this case, the distance, pressure in the combustion chamber, between the electrodes of the spark plug and other factors do not play a role. It is thanks to the spark gap that uninterrupted operation of the strobe becomes possible even if the electrodes in the spark plug are short-circuited.

As you can see, the operating principle of the analyzed mechanism is quite complex, but this does not mean that it is impossible to understand it. Therefore, it is also important to understand how to set the ignition with a strobe light and try to carry out this process yourself.

How to use this strobe light

Using a garage-made strobe, you can easily and with great accuracy:

- set the ignition on a carburetor engine;

- check the spark plug or ignition coil;

- check the operation of the centrifugal and vacuum ignition timing regulator.

Homemade strobe is cheaper and more reliable

In order for the ignition timing to be set correctly, it is necessary to assume that the mixture is usually ignited a couple of degrees before the piston reaches the top stroke point. This angle is called the “ignition timing angle”. As the crankshaft speed increases, the SOP should also increase along a given curve. As a result, the advance angle is set at idle and then controlled in all engine operating ranges up to 5000 rpm.

When connecting a strobe, you need to wind its sensor (copper wire) directly onto the sheath of the high-voltage wire of the first cylinder of the internal combustion engine. Three or four turns will be enough. In this case, it is necessary to fix the wire in this way as close to the spark plug as possible - in order to minimize the influence of neighboring wires on the operation of the strobe. To power the device, its wires with “crocodiles” cling to the terminals of the battery. For better visibility, you will also have to additionally mark the flywheel mark with a white dot - paint or, for example, a clerical touch.

Setting up the strobe

After this device is manufactured, it needs to be configured. It happens this way:

- the engine is warming up, it needs to be started, warmed up, and then switched to idle mode;

- The strobe is connected by terminals to the battery;

- a copper wire (sensor) is wound around the core of the cylinder;

- the light that will be created is directed to a special point marked on the body;

- find a fixed plane (point) on the motor flywheel;

- Rotate the body of the ignition element so that the two points coincide, and then fix it in this place.

After these manipulations, the device is ready to perform its functions. The main thing is not to violate this installation order.

Characteristics of the strobe

So, you have decided to make ignition settings on your car, but you have no idea how to set and adjust the OZ. To ensure that the set angle does not cause discomfort to the driver while driving, you can use a strobe light for ignition.

Schematic diagram

Below is a diagram of a strobe. If you don’t know how to make a strobe light using LEDs yourself, you can use this diagram. In the end, you will get the simplest strobe, but the device you make will allow you to fully adjust all the necessary parameters.

In the device diagram, it is necessary to highlight several main parts:

- The power circuit, which consists of components - SA1, which is a switch, diode VD1, and capacitor C2. A DIY circuit must include a diode designed to protect other components from erroneous polarity reversal. The capacitor performs the function of blocking impulse noise, helping to prevent failures in the operation of the trigger. As for the switch, it can be replaced with a toggle switch, the main thing is that the component can turn the power on and off.

- A homemade strobe for ultrasonic installation must include an input circuit consisting of a controller, resistors R1, R2, and capacitor C1. The controller option in this case is provided by an alligator clip, which is fixed on the high-voltage cable of the first cylinder. As for components C1, R1 and R2, they form a simple differentiating chain.

- Another important component of the strobe used is the trigger board, which is assembled using two monovibrators designed to generate a signal of a given frequency at the output. Capacitors and resistors in this case are frequency-setting components.

- Another component is the output stage, which is assembled using resistors R5-R9 and transistors VT1-VT3. The transistors themselves are designed to amplify the output current of the trigger. Resistor R5 allows you to set the base current of the first transistor. And thanks to resistor R9, the likelihood of malfunctions in VT3 is eliminated.

Principle of operation

So, what is the working principle? A strobe light for installing the ignition yourself is in any case powered by a battery. When the switch closes, the trigger comes into operation. At this time, a high potential is formed at the inverse pins 2 and 12, in accordance with the circuit, and a low potential is formed at the direct pins 1 and 13. The capacitors C3 and C4 themselves are powered by resistors.

Strobe light for adjusting the ignition angle

The signal from the controller, passing through the differentiating circuit, is transmitted to the input DD1.1, which is a one-shot device, which ultimately contributes to its switching. After this, the overdischarge of C1 begins, ending with switching the trigger. Ultimately, the one-shot device begins to respond to signals from the controller, generating rectangular signals at the first output.

As for the second one-shot DD1.2, its operating principle is similar - it allows you to reduce the signal duration by ten times at output 13. This component operates under load from the amplifier stage of transistors that open for the duration of the signal. As for the current passing through these elements, it is limited by resistors R6-R8, its indicator should be no more than 0.8 amperes.

This figure is not particularly large because:

- the signal itself lasts no more than one second;

- As a rule, the operation of this device for setting the ignition angle lasts no more than ten minutes; accordingly, overheating of the crystals is unlikely to occur in such a short time;

- Modern diodes are characterized by more optimal technical features compared to those used in stroboscope designs ten years ago.

Accordingly, the use of brighter diode elements will make it possible to largely reduce the load current as a result of an increase in the resistance value. This resistance increases across circuit components R6-R8.

Printed circuit board and assembly parts

Building your own strobe light is no problem. If you have a small budget, you can use inexpensive parts; if necessary, you can create a more modern device.

- On the above board, KD2999V is used as the diode element VD1, you can use another one, in this case it is important that the diode has a small forward voltage drop.

- Capacitor devices C2-C4 should be rated at 0.068 µF, and C1 is a high voltage component with a voltage of 400 volts.

- TM2 is a trigger with good noise immunity.

- Transistor components VT1 and VT2 must have high gain.

- Diode parts HL1-HL9 should have the highest brightness, while their dispersion angle should be minimal. LEDs must be installed on a separate board, and there must be three of them in one row.

What is a strobe

A stroboscope is a device for observing objects making rapid, periodically repeating movements. To do this, it illuminates a moving object with bright flashes of light, repeated with a frequency equal to the frequency of movement of this object. In this light, a moving object appears motionless. In a car engine, using a strobe light, you can determine the ignition timing angle. To do this, you need to synchronize the flashes with ignition pulses in the first cylinder, and direct the light to the TDC and ignition timing marks, illuminating the crankshaft pulley with a mark.

Factory-made stroboscopes usually have an inertia-free flash lamp as a light flash emitter, which allows you to adjust the ignition timing even in bright sunlight. However, it has a short service life and is not always on sale. Therefore, with the advent of LEDs with a luminous intensity of more than 2000 mcd, it became more convenient to use them when making a strobe light with your own hands. To convince us of the significant superiority of the luminous flux parameters of the new LEDs, let us recall that the AL307, with the same current consumption, has a luminous intensity of only 10–16 mcd. (diagram for video materials in the description under the video)

Materials

The strobe circuit proposed for making it yourself is simple and does not require complex settings. To make a simple strobe for adjusting the ignition timing with your own hands, you will need the following tools, parts and materials:

- Pocket flashlight with a large enough battery compartment.

- LEDs KIPD21P-K – 9 pcs.

- Chip K561TM2 (two two-stage D-triggers). Russian analogues: K176TM2, 564TM2; imported analogue – CD4013/HEF4013.

- Transistor KT315B – 2 pcs. (VT1, VT2); KT815A – 1 pc. (VT3).

- Trimmer resistor SPZ-196 or SP5-1 with a resistance of 33 kOhm.

- Fixed resistors 5.1 Ohm - 3 pcs., 3 kOhm - 1 pc., 15 kOhm - 1 pc., 20 kOhm - 2 pcs., 330 kOhm - 1 pc., with a power of at least 0.125 W.

- Diode KD213 or any other medium power with Urev. max not less than 16 V.

- Non-polar capacitors KM-5, K73-9 or others. C1 must have an operating voltage of at least 200 V, the rest not less than 16 V. 0.068 µF - 3 pcs., 47 pF - 1 pc.

- Any toggle switch to turn on the power of the device.

- 1 m of shielded wire (for example, antenna).

- 3 alligator clips.

- A small piece of foil PCB 1 mm thick.

- Stranded double insulated copper wire – 1.5 m.

- Glue gun.

- Soldering iron, solder, flux.

Device design

The body of the strobe light will be a flashlight. The circuit is assembled by hanging installation. The finished circuit is filled with hot plastic from a glue gun, and after the filling has hardened, it is placed in the battery compartment of the flashlight. The power and signal cables are routed out through holes drilled in the housing. You need to solder clips to the ends of the power wires, indicating the polarity. Connect the antenna cable to the strobe input. Solder an alligator clip to the central core of the input cable. After connecting the strobe to the car engine, it will use it to send synchronization pulses from the high-voltage ignition wire to the input. To make this possible, it is enough to put it on the insulation of the high-voltage ignition wire of the first cylinder of the car engine. The synchronization pulse will go through the capacitance formed by the central core of the ignition wire and the clamp. That is, a simple homemade capacitive sensor will consist of an alligator clip placed on a high-voltage wire.

Device setup features

To use the device, it must be adjusted. The strobe light for tuning must be properly adjusted to provide the most accurate parameters. First of all, the tuning resistor R4 is adjusted, which allows you to set the desired visual effect. As you turn the control knob, you will notice that reducing the signal may result in insufficient illumination of the marks, and if the signal is increased, it will result in blur. Accordingly, during the first adjustment of the ignition timing with your own hands, you should correctly set the most optimal duration of the light flashes.

There is one more point that needs to be taken into account - the length of the cable that runs from the printed circuit board to the controller should be no more than half a meter. For the controller, you can use 10 cm of copper conductor, which should be soldered to the central core of the cable. When the connection is made, it is wound onto the insulated part of the high-voltage circuit in three turns.

To increase the level of noise immunity, the winding procedure is carried out as close as possible to the spark plug itself. If you don’t have copper, you can use an alligator clip - this component is soldered to the central core. In this case, the crocodile teeth must be slightly bent, otherwise it may damage the insulation.

Settings

The circuit contains a tuning resistor R4, by adjusting which you can achieve the desired visual effect. By rotating the knob, you can observe that a decrease in the current pulse leads to a lack of illumination of the marks, and an increase leads to blur. Therefore, during the first launch of the strobe, it is necessary to select the optimal duration of the flashes.

The length of the shielded wire from the printed circuit board to the sensor should not exceed 0.5 m. A 0.1 m copper conductor soldered to the central core of the shielded wire is suitable as a sensor. At the moment of connection, it is wound onto the insulation of the high-voltage wire of the first cylinder of the car, making 3 turns. To increase noise immunity, winding is carried out as close to the spark plug as possible. Instead of a copper conductor, you can take an alligator clip, which should also be soldered to the central core, and its teeth slightly bent inward so as not to damage the insulation.

Installation of UOZ with a strobe light

Now let's move on to the issue of adjusting the ignition angle using our own strobe. The procedure for setting the angle is relevant for both homemade and purchased devices. But before we consider the procedure for setting the ultrasound, we recommend that you familiarize yourself with the essence of the functioning of the stroboscopic effect (the author of the video about the principle of operation of the strobe and setting the ignition with its help on your own is the Samodelkin channel).

When you shine light on an object that is moving in the dark for a split second, you will notice that it appears to be frozen in place. Exactly where the outbreak occurred. For example, if you put a mark on a rotating disk and periodically illuminate it with flashes, at the very moment it appears, you will be able to notice the location of the mark. In this case, it is important that the flashes coincide in frequency with the rotation frequency of the disk or shaft.

Now let’s take a closer look at how the installed strobe light will allow you to adjust the ignition angle. Before making adjustments, two marks must be made in the engine compartment. The movable mark will be located on the crankshaft, in particular on the flywheel. The second mark - stationary - is installed on the body of the power unit.

After the marks are set, it is necessary to connect the controller (sensor). When the controller is connected, power is supplied to the self-assembled device. Next, the engine starts, it should operate at idle speed. If the marks coincide at the moment the light flashes appear, this indicates that the ignition angle is set correctly. If these marks do not match, then it will be necessary to adjust the ignition. The system is adjusted until the marks completely match.

Using the device

To set the advance angle (moment) with your own hands, use a device to illuminate the setting marks while the car engine is idling. One of them is located on the rotating parts of the car engine (on the crankshaft pulley or on the flywheel). The second mark is stationary, it is located either on the cover of the front part of the car’s cylinder block, or on the gearbox housing. If in the light of the device the movable mark appears to be opposite the stationary mark, the car’s ignition is normal and does not require adjustment of the timing (angle) of advance.

If the marks do not match, to adjust the timing, you need to change the position of the distributor accordingly. To delay the ignition timing, you need to turn the distributor in the direction of rotation of the slider, and to do it earlier, in the opposite direction. If sparking in your car is controlled by a microprocessor, look for a faulty sensor or entrust the solution to this problem to professionals.

With a strobe light, setting the ignition on a carburetor engine is always much more convenient than “by ear”. But the price tags for such equipment sometimes “bite,” which pushes many motorists to alternative solutions to this issue, for example, by making a strobe light with their own hands.

Introduction

It's no secret that many problems that sometimes arise with a car can be corrected even by a novice car owner. Despite the apparent complexity of the mechanism, sometimes you can avoid another visit to the service center or the purchase of another unit for replacement. Anyone who wants to save money on purchasing a low-quality device can independently make, for example, a strobe light, which is designed for installing an ignition. Many beginners may be put off by the name, which seems too complicated and pretentious, but don’t rush to conclusions. To know how to make a strobe light for installing the ignition without purchasing an identical factory device, you should familiarize yourself with several proposed methods and stock up on all the necessary materials and tools. For those who are not confident in their abilities, it will be enough to go to a car store at least once and find out about the cost and quality of a production strobe light.

In fact, almost the majority of car owners resort to using conventional gas-discharge lamps to create this cunning device. True, such devices cannot be distinguished by long-term operation, especially since the cost of a lamp that once fails is not very different from the amount for which you can purchase a new strobe light. All this together can prompt a car enthusiast to create his own device. Let's look at the simplest and most accessible methods of creating a strobe.

"Advantages" of factory devices

Before you decide to purchase a standard factory strobe, you need to study in detail all its features and learn about the principle of operation. So, let’s first understand the scope of application of this device. A device called a strobe light allows the car owner to easily adjust the ignition. Having this device at hand can significantly speed up the entire setup process. Equipped with a lamp, the unit gives signals about the presence of a spark, so you can quickly and correctly set the required ignition timing.

It is impossible not to note the efficiency and accuracy of efficient factory instruments that can cope with this task in just a few minutes. However, despite such advantages, for some reason the vast majority of car enthusiasts try to create such a unit with their own hands, without rushing to buy a production version. Most likely, this aspect is due to the rather high cost of stroboscopes. The overwhelming majority of factory models are equipped with expensive gas-discharge lamps, the subsequent replacement of which becomes equal in price to purchasing a new device. Commercially available factory analogues are sold in the price range from 1000 to 6000 rubles (a simple Multitronics will cost the buyer 1000 rubles, Astro L5 at 1300, Focus F1 at 1700, and Focus F10 at 5600 rubles).

Answers to site visitor questions about setting up a strobe

Site visitor Yuri repeated the strobe light design and was pleased with its work. What stopped him from making a strobe based on super-bright LEDs was the price of LEDs. When setting up the strobe, Yuri had a number of questions, which I answered during correspondence. With the permission of Yuri, I decided to supplement this article with answers to questions from the correspondence that may be encountered by car enthusiasts who want to repeat the design of the presented strobe light.

| Question | Answer |

| Is it possible to replace the KU103V thyristor with the VT169G thyristor? | Yes, it can be replaced with VT169D or VT169G. Since the maximum anode-cathode voltage of the VT169 is not less than 400 V, the resistor R6 can be omitted; it is installed to protect the KU103V. |

| When the anode and cathode of the thyristor are bypassed, the lamp flashes, but when the transistor is opened and closed manually, the lamp does not react. | The thyristor or transistor is not properly soldered or is faulty. The resistor values do not match the diagram. To identify the cause, you need to disconnect all elements from the thyristor control electrode. In this case, the thyristor must be closed. If you connect it to the control electrode through a resistor according to the R7 circuit with a nominal value of 27 kOhm, then the thyristor should open. If it opens, then the transistor is to blame. If the thyristor does not open, then you can reduce the value of the resistor down to 1 kOhm; if you cannot open it in this way, then the thyristor is faulty. |

| The thyristor is working properly; when you touch the control electrode of the thyristor, the lamp flashes once, it turns out like a sensor. I don’t understand how the thyristor closes, perhaps it is locked by the potential of the control electrode? | The thyristor itself closes only when the anode-cathode voltage becomes less than a certain one for each type of thyristor. Therefore, when capacitor C6 is discharged, the thyristor will close itself. Resistor R8 performs the function of protecting the transistor from possible high-voltage pulses and at the same time prevents accidental opening of the thyristor from the same pulses. |

| On the capacitor, I achieved a voltage of 400 V at a generation frequency of 200 kHz (I installed field-effect transistors as indicated in the article), but with a capacitance of C5 of 1 µF, the brightness of the flash was insignificant (IFK-120 lamp), and when C5 was increased to 10 µF, it became blinding. I understand that increasing the capacity will lead to its incomplete charge at high speeds, what capacity should I install? | Regarding the high voltage, it can be raised to at least a kilovolt by winding more turns of the secondary winding, and the brightness of the flash will increase accordingly. But the voltage value should not exceed the permissible value for the lamp. Therefore, it is better to wind more turns than to increase the capacity, and select the capacity based on the maximum speed that needs to be controlled. |

| According to the passport, the IFK-120 lamp has a rated voltage of 300±20 V, i.e. Isn’t it worth increasing the voltage above the existing 400 V? | It’s not worth it, as increased voltage can cause spontaneous flashes of the lamp. |

| From the characteristics of the BT169G thyristor - the unlocking control voltage is 0.5-0.8 V, i.e. when transistor VT3 is open, the circuit must ensure that the voltage at its collector relative to ground is less than 0.5 V so that the thyristor remains closed? | Yes. |

| When the transistor is closed, accordingly, the voltage on its collector and on the control electrode of the thyristor should exceed 0.5 V, but not more than 0.8 V so as not to burn the control junction of the thyristor? | Yes, in the circuit of the thyristor control electrode there is a resistor R7, which will limit the amount of current, thereby eliminating the possibility of increasing the voltage more than 0.8 V. |

| Does it matter which side the ferrite ring is placed on the high-voltage wire, or is that why VD10 is installed in the circuit? | It doesn't play, that's what the diode is for. |

| Does it make sense to replace VT10 with a field-effect transistor? | In this case, this is not necessary; field-effect transistors are afraid of static electricity and it is better not to use them unless necessary. |

| The changes that Yuri made when repeating the strobe circuit. | The EL1 ISSh-15 lamp was replaced with an IFK-120. I replaced transistors VT1 and VT2 type KT817B with field-effect ones IRFZ44N, VT3 type KT3102 with BC547. Thyristor KU103V on VT169G. Resistor R8 from 820 Ohm was increased to 2 kOhm, capacitor C5 was increased to 10 μF. |

Yuri's review of the work of a do-it-yourself strobe light: “The work of the strobe light has been tested on a car, it works perfectly, the flash brightness is excellent!!!”

The principle of creating the device

A strobe light for ignition adjustment is especially necessary for those who have a car with a carburetor. This is due to the peculiarities of the settings, since it is difficult to imagine correctly even in the mind, not to mention in reality, the ignition timing, which is present on contact distributors and all contactless distributors. It is simply impossible to cope in such a situation without a strobe light. Moreover, by using the services of this most precise device, you can adjust the ignition with extreme precision in just 7–8 minutes. This indicator, like other important elements of the car, must be given due attention, since without it the normal functioning of any vehicle is impossible. The need for such a product, the high cost of the factory version in the store and the availability of the necessary parts simply push a person to create his own strobe light.

List of required parts

Before you go to the store to purchase all the parts described below, you should carefully study all the materials and parts present in the garage; it is quite likely that most of them have been collecting dust on the shelves for a long time without any particular need. If you find most of the elements stored among waste materials for the manufacture of the device, the final cost of a finished and perfectly functioning strobe light will not exceed 100 rubles, which will save money for other needs. The first thing you need is a simple, cheap Chinese-made flashlight. It will be better if it is LED. If the available model turns out to be a lamp model, you will need to additionally purchase or remove all the required LEDs from the old flashlight.

In addition to the body, you will need electronic filling, the creation of which requires the following elements:

- transistor type KT315, which is probably stored in a discarded Soviet-style radio;

- thyristor KU112A, it can be found in the power supply of an old TV;

- capacitor designed for voltage 16 V;

- diode with low frequencies;

- relay for 12 V voltage, but you should choose a small part that can fit in the flashlight body;

- several "crocodiles";

- a coil of wires, 0.5 meters of which must be shielded;

- a small piece of copper wire.

Despite the wide variety of circuits created for the correct sequential assembly of the device, the newly minted creator of the strobe will in any case need such a supply of spare parts. In addition to having all the described parts, you need to arm yourself with a soldering iron; it will be better if the car owner has at least minimal skills in using it.

To assemble this device, you need to connect all the parts in series with the existing wires and solder them securely. Through the rear hole in the flashlight, you will have to pass all the necessary wires that will ensure uninterrupted power supply to the strobe. If the selected flashlight model does not have a side hole, the car owner must make it himself. This is necessary in order to bring out a shielded wire, at the ends of which copper wire will be soldered to the central core. It is this element of the created device that will be a special signaling sensor.

Construction and details

The entire strobe circuit is assembled in a two-half plastic case measuring 4.5 × 7.5 × 16 cm. To allow light to escape from the flash lamp, a round hole is made in the end wall into which a lens in a mandrel is inserted.

This is not necessary; the window can be closed to protect it from dirt getting inside the strobe using any transparent material, such as organic glass. The lamp, to reduce light loss, is half wrapped in staniol foil.

All parts of the strobe, except for the lamp, are assembled on the printed circuit board shown in the photo.

Pulse transformer T1 has two windings. The primary winding is tapped from the middle. When winding, you need to measure the required length of wire with a diameter of 0.3-0.5 mm, fold it in half and wind 24 turns. Then connect the beginning of one winding to the end of the other, this will be the middle point. The secondary winding is wound with a wire with a diameter of 0.15-0.25 mm in the amount of 638 turns. To make a transformer, a ferrite core with a coil can be used from a step-down transformer of a non-repairable switching power supply AT or ATX computer, after first removing all the windings.

The T2 ignition pulse transformer is wound on a ferrite ring with a diameter of 15-20 mm with a permeability from 1000 to 3000 Nm. The primary winding is wound with 0.3 mm wire and has 4 turns. The secondary winding is wound with a wire with a diameter of 0.1 mm in silk insulation and a number of turns of 500. The large number of turns of the secondary winding was not taken by chance; at high engine speeds, capacitor C6 does not have time to fully charge and the ignition voltage decreases. Thanks to the reserve, sufficient voltage is provided for ignition. Before winding, the ferrite ring must be covered with insulating tape to prevent damage to the wire insulation. Before covering with insulation, it is necessary to grind off the sharp edges around the circumference of the ring with fine sandpaper. After winding, to avoid interturn breakdown of the insulation at high humidity, the transformer windings are impregnated with wax.

The inductive sensor coil is wound on a ferrite ring with a diameter of 40 mm with a permeability of 1000 to 3000 Nm. 35 turns of wire with a diameter of 0.8 mm are wound onto the ring evenly around the entire circumference. The top of the winding is covered with a layer of insulating tape.

The diameter of the ferrite ring was chosen based on the possibility of threading a high-voltage wire through the coil going to the car spark plug. But the practice of using a strobe has shown that it begins to work stably if you simply attach the coil to a high-voltage wire.

The strobe is connected to the battery using two alligator clips. For error-free connection, the crocodiles are marked with polarity.

Capacitors C5 and C6 type K73-17. The EL1 flash lamp type ISSH-15 is a low-power strobotron, its service life is more than 300 hours. It is specially designed for strobe lights.

Unlike the IFK-120, the ISSh-15 lamp has a longer life and can operate at higher frequencies. In the absence of ISSH-15, you can use IFK-120.

For ease of operation when setting the ignition timing in a car, a two-range analog tachometer with an extended scale is built into the strobe.

Operating principle of the device

So, after creating such an important device as a homemade car strobe light, you should understand the principle of its operation in order to seamlessly adjust the ignition angle in the future. A capacitor to which an electric current is applied is charged by a resistor. When the charge reaches the required level, the current is supplied by a resistor to the opened transistor. It is at this time that the relay begins to work, which is designed to create a circuit including a thyristor, diodes and a capacitor. The entire unit is a specialized divider through which the charge passes to the main contact of the thyristor. The opened control element entails the discharge of the capacitor, which is expressed through the lighting of the diodes. The flash of light that appears in the flashlight goes out. The main output of the transistor is connected through a thyristor and resistor to the central wire, as a result of which the transistor closes and the relay turns off.

The strobe for setting the ignition is signaled by a long glow of the diodes; this occurs due to a broken contact with a delay. After some time, the contact is de-energized and interrupted. The homemade device again assumes a state of inactivity, flashing at the moment the next impulse occurs. To achieve a brighter glow of the LEDs in the flashlight, you can use a capacitor with a larger capacity.

Ignition setting device made of LEDs

This device can be made using LEDs, but this strobe contains a specific microcircuit. It is launched through pulses that contain negative polarity. There are certain resistances in the structure of this type of circuit; they serve as limiters in order to reduce the amplitude of the incoming signal. In this case, the car battery will serve as the power source for the device itself.

Connecting the strobe light that sets the ignition is done using the following steps:

- you need to warm up the engine and leave it on;

- connect the handmade device to electricity;

- wind the sensor onto the cylinder wire;

- direct the light to a specific point located in the body;

- wrap the ignition housing until these marks come together;

- fix it in this state.

A homemade strobe for setting the ignition is not inferior in function to devices made at the factory. In this case, the main factor is to follow all manufacturing instructions and adhere to the diagram of the DIY device. Products made from scrap and simple materials may require little investment. Homemade strobes are fairly easy to repair if they become worn or broken.

The ignition installation device can be found in any specialized store; there are several types of them and they are quite common. However, the cost of this device often scares off vehicle owners, because it is not a cheap pleasure.

In the event of a malfunction or breakdown that occurs over time, replacing the worn part can be equal to the cost of the entire device itself. That is why car enthusiasts began to make strobe lights with their own hands. After all, to create it you will need parts that can be found in any store.

It is worth noting that a homemade device will cost several times less than a factory device. If you can’t make the device yourself, you can always find a craftsman who will do this work. Such specialists today work in almost every locality.

Making your own strobe light will save you a fair amount of money.

By applying electric current, the capacitor is charged through a resistor. After the charge reaches a certain level, the resistor will begin to supply current to the opening transistor. At this moment the relay is activated. This creates a circuit of thyristor, diode and capacitor. This system acts as a divider, through which the charge reaches the control contact of the thyristor. Then it opens, the capacitor discharges the stored energy into the diodes. Eventually they burst into flames. Through a thyristor and a resistor, the main output of the transistor is connected to the main wire. The transistor then turns off and the relay turns off.

In this case, the glow time of the diodes becomes longer, since there is a delay in breaking the contact. But in the end, the contact is interrupted and the thyristor is de-energized. The device goes into a quiet position until the next impulse. To make the LEDs glow brighter, you need to use a capacitor with a larger capacitance.

Creating a strobe light on a chip

The simplest strobe for installing the ignition is to create a device that is based on the DD1 microcircuit, which is a single-vibrator. Several diodes are connected to this microcircuit, which help protect it from possible errors that occur during connection. Before the next pulse hits the microcircuit, it is in its usual quiet state. The system is equipped with two different pins, with the first having a low level, which is opposed by a high inverse pin. Accordingly, the connected capacitor is connected with a plus to the inverse terminal, due to which it is charged. A pulse passing through the entire microcircuit “hooks” a trigger, behind which a charged capacitor is connected to operation. The entire process takes place directly through the resistor. The soldered-in DD1 chip responds to the electric current supplied to it, displaying the energy through the glow of LEDs.

Principle of operation

The strobe circuit is powered by a car battery. At the moment the switch SA1 is closed, the trigger DD1 goes to its original state. In this case, a high potential appears at the inverse outputs (2, 12), and a low potential appears at the direct outputs (1, 13). Capacitors C3, C4 are charged through the corresponding resistors.

The pulse from the sensor, having passed through the differentiating circuit, arrives at the clock input of the first monovibrator DD1.1, which leads to its switching. Recharging of C3 begins, which after 15 ms ends with the next trigger switching. Thus, the one-shot device reacts to pulses from the sensor, generating rectangular pulses at the output (1). The duration of the output pulses from DD1.1 is determined by the ratings of R3 and C3.

The second one-shot DD1.2 works similarly to the first, reducing the duration of the pulses at the output (13) by 10 times (to approximately 1.5 ms). The load for DD1.2 is an amplifier cascade of transistors that open for the duration of the pulse. The pulse current through the LEDs is limited exclusively by resistors R6-R8 and in this case reaches a value of 0.8 A.

Do not be afraid of such a large current value. Firstly, its pulse does not exceed 1 ms, with a duty cycle in operating mode of at least 15. Secondly, modern LEDs have much better technical characteristics compared to their predecessors from 2000, when this circuit first came into practical use. Then it was necessary to look for LEDs with a luminous intensity of 2000 mcd. Now a white LED (light-emitting diode) type C512A-5 mm from Cree with a dispersion angle of 25° is capable of delivering 18,000 mcd at a constant current of 20 mA. Therefore, the use of ultra-bright LEDs will significantly reduce the load current by increasing the resistance R6-R8. Thirdly, the time of using a strobe usually does not exceed 5-10 minutes, which does not cause overheating of the emitting diode crystals.