Crankshaft oil seal

The crankshaft, like many other components of an internal combustion engine, has oil seals in the shape of a round cuff. Such elements protect the crankshaft-engine block assembly, seal the working environment from the environment, and prevent dust from entering. The oil seals have a special cross-section: the shaft is tightly wrapped around a plastic ring, which does not interfere with its rotation and ensures the tightness of the engine. A working oil seal lets through only 3-5 ml of oil per thousand kilometers.

Structure of a typical oil seal

Such parts operate under conditions of constant friction, humidity, and temperature changes, so oil seals are made of durable rubbers, silicone, and some polymers (for example, polyurethane). The main dimensions of the oil seal are its internal diameter, external diameter and height.

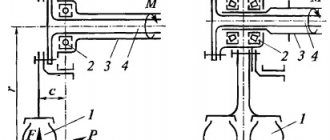

The main dimensions of the oil seals: D - outer diameter, d - inner diameter; B - oil seal height

Manufacturers, in order to save materials or reduce prices, produce crankshaft oil seals with sections of varying complexity. Let's consider their main types, namely:

- with a metal outer surface (option a);

- with a smooth surface (option b);

- with a corrugated surface (c);

- with hydrodynamic effect (d).

Types of oil seals

Model a seals will not provide the same degree of sealing as models b-d, but require less rubber for production and lower cost accordingly. A smooth oil seal (type b), even with sufficient density, will have cavities in the seat; such an assembly may “sweat”. Grooved grooves (like those of oil seal B) are crushed during installation and contribute to a tighter fit in the engine housing, this is an advantage over “bare” oil seals (a).

Special mention should be made of hydrodynamic seals (model d). They are more technologically advanced and efficient. The principle of their operation is as follows:

- special notches of small depth with the direction of rotation are applied to the inner plane;

- high crankshaft speeds swirl the oil in the area of the inner plane of the statically fixed oil seal, the oil flow hits the internal notches and receives the direction of movement from it;

- Such processes improve the efficiency of stuffing box units.

In order to further seal the oil seal-engine housing assembly, it is recommended to apply sealant to the outer surface of the oil seal before installation.

This is interesting: Technical characteristics of J20A

The crankshaft oil seal is installed at the points where the shaft exits the engine and is secured by pressure plates or adjacent engine components. The crankshaft has two oil seals: front and rear. The rear oil seal, as a rule, has a separate housing - a “flange”.

VAZ 2106 engine structure 1 – crankshaft pulley; 2 – generator drive belt; 3 – front crankshaft oil seal; 4 – camshaft drive chain; 5 – spring plate; 6 – guide sleeve; 7 – valve; 8 – internal spring; 9 – outer spring; 10 – lever spring; 11 – adjusting bolt; 12 – valve drive lever; 13 – camshaft; 14 – oil filler cap; 15 – cylinder head cover; 16 – spark plug; 17 – cylinder head; 18 – flywheel; 19 – rear crankshaft oil seal; 20 – oil pressure sensors; 21 – piston; 22 – oil level indicator; 23 – oil drain plug; 24 – connecting rod; 25 – oil pan; 26 – drive shaft of auxiliary units; 27 – crankshaft.

Crankshaft seal kit for VAZ 2106

Location

In most machines, oil seals are installed in several places depending on their purpose. As a rule, the engine itself provides two on the crankshaft

.

In modifications using a timing belt, they are also present on the shafts

coming out of the motor. In general, we can distinguish types of oil seals for:

- crankshaft - front and rear;

- oil pump;

- balancer

hub

seal stands out separately . This seal is much more massive and complex than others. The purpose of this part is to seal the hub gaps. Also, the body of such an oil seal has special additional edges that protect it from dirt.

Hub seal

Attention!

Oil seals cannot be repaired ; if worn, they are removed and discarded.

Replacement is usually required after 100 thousand km of car mileage. This is an average indicator depending on many factors. It's quite easy to see a problem coming. Some signs indicate this:

- Unpleasant sounds

of rotating parts. If the oil seal wears out, it hardens and may burst. As a result, the working oil flows out of its environment, entering the internal combustion chamber and other parts of the car. In this case, parts with a broken cap begin to come into contact more often, which can lead to rapid wear.

New and worn oil scrapers

- The appearance of oil on functional parts

where it should not be. For example, oil marks may be visible on the camshaft bed.

of oil seal for vehicle modification is very important Usually the manufacturer or seller knows the products well and can advise when choosing.

If it is impossible to find a product for a specific car model, you can take an alternative option, but the width of the unit should be slightly smaller. In addition, when choosing, you should pay attention to the presence

of anther and cutting on the working surface.

If they are not present, the service life of such a seal is no more than 30 thousand km. If you liked the article, give it a thumbs up

? “, leave comments and subscribe to our channel!

Selection and replacement of oil seals

One of the main features that distinguishes such parts is their cost: it is very low. But at the same time, replacing this car part is much more expensive compared to its cost.

It has its own characteristics and choice of seal. For normal operation, you should buy exactly the spare part for your car that is suitable for a specific model. In addition, it is not recommended to install domestically produced spare parts on foreign cars.

If you cannot find the required part for a specific vehicle model, then when choosing a new oil seal, it should have a smaller width than required - no problems with installation and use should arise. But a knot with a larger width will not work.

If you choose a model of such a part without cutting and a boot on the working surface, it will not last more than 30 thousand kilometers. The boot prevents dirt from penetrating into the oil seal; the thread ensures that excess oil is discharged back into the crankcase. In the absence of such additional devices, the service life of the oil seal is significantly reduced.

What is a seal in a car? Why is it needed and where is it located?

What is

a seal in a car? This is a special seal in the form of a ring (cap) that holds the technical oil necessary for the operation of the connections.

An example is an engine camshaft. Thanks to its rotation, the valves perform reciprocating movements. Under the temperature of the operating engine, the elements heat up and rub against each other strongly. The absence of an oil seal leads to rapid wear and tear of the main elements, and possibly the entire engine. Oil seals are made from heat-resistant materials. Factory parts have a special standard

for each type. When the seal rotates rapidly, the internal temperature of the seal increases. If it turns out to be of poor quality, the part can easily burn out.

What materials are oil seals made from?

Today, for the manufacture of oil seals, manufacturers use the following materials:

- Butadiene rubber (NBR)

is an average-cost material that can be used at temperatures from minus 40 to plus 120 ° C and has good resistance to most types of fuel and lubricant components.

Acrylate rubber (ACM)

– the cheapest material, suitable for use at temperatures from minus 30 to plus 150 ° C and usually used for the manufacture of hub seals.

Silicone (VMQ, MVG, ECOSIL)

- a fairly popular material that has a low cost, but has a number of disadvantages, including chemical instability to certain types of mineral oils.

Fluoroplastic/fluororubber (FRM, FKM)

- a widely used material from which oil seals are made for such elements of power plants as the camshaft, oil pump, crankshaft and much more. The main advantages of this material include resistance to most types of oils and chemical liquids, as well as excellent mechanical resistance. Its operating temperature range ranges from minus 40 to plus 180 °C.

- Teflon (PTFE)

is a material that is rapidly gaining popularity, which is facilitated by its high resistance to any chemically active liquids, the lowest friction index and the largest operating temperature range (from minus 40 to plus 220 ° C). Seals made from this material may have the highest cost, but provide minimal wear on the rotating elements of the motor.

Operating principle and device

The essence of such a sealing device is as follows: inside its body, where the spindle axis passes through it, there is a “box”, inside it there is a special packing - sealing material. It is pressed tightly against the spindle axis.

In this case, compression of the sealant material occurs, as a result of which it fits tightly on one side to the surface of the spindle and to the walls of its chamber on the other.

As a result, complete tightness is created, which does not allow the working environment to escape beyond its housing.

In mechanisms with a small diameter, the sealing material is pressed using a union nut, with a large diameter - using anchor bolts.

Operating principle and types of seals

Conventionally, the following tasks of seals can be distinguished:

- reducing the friction force of metal parts;

- protection against overheating and wear;

- preventing the entry of foreign substances into the working environment (for this purpose, there are special recesses on the surface of the products - anthers).

The principle of operation is the same for all, but the type and location depend on the drive and type of car. Let's look at each option in more detail:

- Main oil seals on front-wheel drive cars are installed in the cylinder block itself. Shields on these units are not provided for by their design. The oil seal holds in part due to the high pressure inside the crankcase. The seals press well against the surface of the rod and do not seal the assembly.

- Most rear-wheel drive cars are designed with a crankshaft shield, and an oil seal is installed in it on the front of the support bearing.

Many car enthusiasts often try to replace oil seals themselves, saving money. After reading various instructions on the forums, they take action. However, it is important to understand that each error is minus 50–70% of the oil seal life. If, with proper installation, it will last 200 thousand km, with a makeshift installation method, you should be prepared for wear after 70–100 thousand.

To replace the main oil seal on a front-wheel drive car yourself, you will need a number of actions:

- lift the car with a jack (or drive into the inspection hole);

- remove the engine protection and timing case;

- remove oil from the engine;

- remove the timing belt;

- remove the right front axle wheel;

- engage a lower gear;

- remove the pulley mount and remove the pulley itself;

- change up gear;

- set the piston of the first cylinder to TDC (marks will help for this);

- loosen the tension roller and remove the belt;

- unscrew the fastening of the clutch housing cover located at the bottom and remove it with the gasket (it is better to replace it before reassembling);

- disconnect the oil pump and oil receiver from the main bearing;

- remove the toothed pulley using 2 screwdrivers of equal size;

- unscrew the oil pump fastening bolts;

- separate the unit and remove the oil seal from it;

- lubricate the new product and install it in place;

- reassemble.

Guided by logic and accuracy, you can make the replacement yourself. However, if in doubt, you should contact a service station. It is important to buy only factory-made oil seals. Such elements are manufactured according to certain standards and serve the entire specified service life.

Oil seals - what are they and what are they for?

Oil seals are a special element used in a machine to seal the connections of various elements and rotating parts that operate on the reciprocating principle.

The main task of oil seals is to ensure complete sealing of the joints of moving and non-moving parts of the car, protecting them from various negative influences and preventing the leakage of lubricating fluid.

Oil seals are widely used in engines, transmission elements, steering, gearboxes, cooling and other systems, so it is not surprising that from time to time they require replacement.

Seal sizes

Although manufacturers may make seals to different standards and materials, they all have identical sizes and configurations. This means that oil seals for a specific part, but for different brands and models of cars, will have the same parameters in height, as well as outer and inner diameters.

Currently, most online stores selling oil seals offer customers interactive tables that allow them to select an original oil seal or its equivalent, based on parameters such as the make, model and year of manufacture of the car.

Operating principle of the oil seal

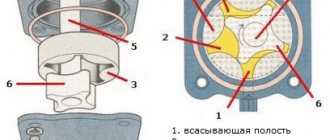

The stuffing box seal consists of the following elements:

- body made primarily of metal;

- packing - an elastic sealing material that is pressed tightly against the axle, preventing fluid leakage;

- a spring ring that improves the pressure of the seal seal against the moving shaft or guide.

To improve sealing and reduce friction, the packing has a complex shape. It includes beads, chamfers and flashes to improve efficiency. The figure below shows the design of an oil seal with a boot for a rotating shaft.

Oil seals - design features and technical solutions

An oil seal, or reinforced cuff, is a sealing device used in special equipment, cars, and special structures for complete sealing of rotating shafts and the articulation of parts operating on the principle of reciprocating motion (an example of the latter is cuffs at the junction of the power steering and steering rack). Both dynamically and statically, the products allow for separation and elimination of interpenetration of media:

- air and oil;

- water and air;

- coolants and air, etc.

Also, these seals prevent the penetration of acids, alkalis, and other aggressive media into the external environment and, if there are anthers, prevent dust and dirt from entering the engine components.

When designing models of reinforced cuffs, structures go through a long process of step-by-step development with the creation of a new or improvement of an existing polymer composite, with testing of the probe on a test bench and sea trials. It is the tests that allow us to draw final conclusions about the wear resistance of structures and obtain the necessary data for calculations. At the same time, the requirements for the performance characteristics of oil seals are constantly increasing. Thus, at present, some manufacturers provide a guarantee for 50 thousand hours of vehicle mileage (or 3 million km) without changing this seal, which seemed unattainable back in the 90s of the last century.

Today, designers offer a wide range of original solutions for improving reinforced cuffs for a particular unit. The key “points” at which work is being carried out are sealing along the rotation shaft and sealing along the seating area of the outer surface. Below are a number of these solutions.

Types and purpose of oil seals

Essentially, an oil seal is an O-ring. For its manufacture, fluorine rubber or silicone are used, which can withstand heat and temperature changes, and are also resistant to the negative effects of motor oil.

Based on their location, there are 2 types of oil seals:

- Rear. Larger and more wear-resistant. If it was made with high quality, it can last a very long time - especially if the engine is properly cared for.

- Front. It differs from the front one in its smaller size and in that it wears out more intensively. Before you start replacing it, you should find out exactly which of the seals has failed.

Purpose of oil seals

The motor is equipped with a lubrication system that supplies oil to all working mechanisms. The peculiarity of the crankshaft is that its housing is brought out, so lubricant leaks at the exit points. It is at this point that the oil seal is installed, the diameter of which fully corresponds to the diameter of the crankshaft.

In vehicles with rear-wheel drive and longitudinally mounted engines, the seals are located in the crankshaft shield in front of the support bearing. In engines that do not have shields (front-wheel drive cars with longitudinally mounted engines and timing belts), the oil seals are installed in the cylinder block.

If the seal is faulty, lubricant leaks.

Purpose and principle of operation of the engine main oil seal

As already mentioned, lubricant is supplied to various friction pairs under pressure, and individual elements inside the engine are lubricated by splashing or gravity. One way or another, the main task is to minimize friction, remove wear products, and protect against mechanical damage and overheating.

In this case, the transmission of torque from the engine to other components is realized by removing the crankshaft from the internal combustion engine to connect to the flywheel. At the same time, there is a need to seal the hole under the shaft. For these purposes, a crankshaft oil seal is used.

This element is made of fluorine rubber or silicone, actually serving as an O-ring. The diameter of the main oil seal is equal to the diameter of the crankshaft. The oil seal material is heat-resistant and also resistant to engine oil. This avoids the risk of damage to the seal from excess heat that occurs as a result of friction.

Front-wheel drive cars, where the internal combustion engine has a transverse arrangement, and the gas distribution mechanism is often driven by a timing belt, the crankshaft oil seal is located in the BC due to the fact that shields on such power units are structurally absent. One way or another, in all cases, the purpose of the element is to prevent oil leakage from the engine cylinder block.

While the engine is running, the oil inside the crankcase is under a certain pressure. Thanks to this pressure, the seal is pressed against the parts and sealing surfaces. This allows you to reliably seal the engine against oil leakage at the installation site of the engine main oil seal.

Causes of oil seal leakage

The service life of the part ranges from 100 to 200 thousand kilometers, depending on the quality of the spare part itself and how carefully the car enthusiast takes care of the internal combustion engine. However, replacing the engine oil seal may be necessary much earlier.

Factors causing premature wear are:

- Engine overheating

. Despite the heat resistance, the manufacturing material has a temperature tolerance limit - and it is usually limited by the normal heating of the motor. When overheated, the seal begins to lose its properties, becomes brittle, deforms, and its tightness decreases. - Untimely replacement of engine oil

. The sediment formed during the operation of the internal combustion engine in the form of metal particles and contaminants from outside causes mechanical damage to the seal material. A small scratch eventually becomes a crack, causing lubricant to leak. The oil filter, on which the quality of the lubricant depends, should also be changed in a timely manner. - Long car downtime.

If the machine is not used for a long time and is even left in the cold, the oil seal dries out and cracks or loses its elasticity. - ICE malfunction

. The increased pressure of crankcase gases provokes the squeezing out of even the new oil seal and the formation of a gap between it and the crankshaft. - Crankshaft runout.

With a mileage of over 100 thousand km, the parts of the propulsion system wear out and become loose. The crankshaft begins to vibrate, a gap appears between it and the oil seal, and a tight fit becomes impossible. The seal itself becomes deformed as a result of wear.

Crankshaft oil seal leaking: causes of wear, breakdown

Symptoms of the problem: oil leak in the engine compartment, increased oil consumption. You can often see grease flowing onto the ground under a stationary machine. Of course, constantly topping it up does not solve the problem - you need to change the seals themselves.

There are several reasons why a leak forms:

- improper installation of gaskets, resulting in the formation of cracks on their working surfaces;

- oil flows when the engine overheats frequently, with high pressure in the crankcase (in winter, when ice plugs form);

- natural, physical wear and tear of the material;

- mechanical damage, resulting in leakage;

- low-quality material (typical for domestic products).

High-quality crankshaft seals are made of fluorine rubber FPM or silicone. Regular nitrile butadiene rubber quickly burns out, falls apart and leaks.

How to choose oil seals

The easiest way to make the right choice is to purchase original oil seals from an authorized dealer. In this case, the specialist will select a product that exactly matches the make and model of your car.

If you decide to buy an analogue, you need to consider several aspects of the choice:

- The product must be suitable in size, and it is allowed (although not recommended) to use oil seals whose width is slightly smaller than the original ones.

- The new oil seal must be designed for use in the same environment as the old product (for example, antifreeze or oil).

- The sealing device must be designed to operate in the temperature regime appropriate to the location where it is installed.

- The analogue must have a design corresponding to the original product (for example, have identical notches on the sealing ring, etc.).

Special attention should be paid to the presence of a boot or thread, where the first is designed to protect the part from dirt and dust, and the second is to act as a pump that dumps the oil back.

In addition to technical features, when choosing oil seals, you need to pay attention to the cost and manufacturer, giving preference to proven and popular brands and products of average market value. Otherwise, there is a high risk of running into low-quality products.

, which can not only quickly fail, but also lead to new troubles that promise large financial costs.

Important:

It is highly not recommended to use domestically produced oil seals on foreign cars, since the material and workmanship of such products still leaves much to be desired. But installing foreign-made oil seals on domestic cars is, on the contrary, recommended.

Brands of oil seals: which brands to give preference to

As mentioned above, when choosing oil seals for your car, it is better to give preference to trusted manufacturers that have been on the market for a long time and have positive reviews. These include brands such as

VAG, Goetze, Payen, Emmtec, SKF, KOS and Koyo

.

When choosing oil seals by size, it is customary to take into account three parameters:

- d – internal diameter;

- D – outer diameter;

- h – height / thickness.

The internal diameter of the oil seals can vary between 4-270 mm, the external diameter - between 7.8-310 mm, and the height - between 1.5-30 mm. However, there are seals that have unique product parameters that differ from the “standard” ones.

In the photo: parameters of crankshaft oil seals

The price of oil seals, depending on the size, country and brand of the manufacturer, as well as the destination, can range from 50-2500 thousand rubles. (22-1100 UAH). It is worth remembering that original oil seals are in most cases 30-60% more expensive than their analogues.

Thus, the cost of an original crankshaft rear oil seal for Renault (Dacia) Logan averages 1550-1600 rubles. (about 680 UAH), while its analogue can be purchased at a price of 650-700 rubles. (about 310 UAH).

Is it worth overpaying for a brand?

Considering the presence of a large number of analogues, many car owners have a completely logical question - do they need to overpay for the brand? The answer is yes, because larger manufacturers invest greater financial resources in developing and testing their products, which makes them much more reliable and durable. In addition, large “players” monitor their reputation, which, as is known, is one of the key factors influencing the number of product sales.

Another question is whether it is worth overpaying for original oil seals - it is not worth it, since today there are a huge number of analogue products on the market, the quality of workmanship and reliability of which is not only not inferior to the original ones, but even surpasses them.

How to replace crankshaft seals

Replacing crankshaft oil seals is a labor-intensive procedure and, accordingly, quite expensive, however, even with minimal experience, you can replace them yourself. For this you will need:

- Keys and screwdrivers;

- A special key designed to adjust the timing belt;

- Graphite lubricant or antifreeze;

- Container with motor oil;

- Heat-resistant sealant;

- Consumables (seals).

Before you begin the process of replacing oil seals, you need to turn off the power to the car (in other words, remove the terminals from the battery) and drain the engine oil. Next, we will consider the procedure for replacing the front and rear oil seals.

Replacing the front crankshaft oil seal

The process of replacing the front oil seal is performed in the following sequence:

- We dismantle the pulleys;

- Remove the timing belt protective cover (if equipped);

- Remove the toothed belt;

- Remove the drive toothed pulley;

- We dismantle the front oil seal and then replace it with a new product.

Let us immediately note that before installing the oil seal, engine oil is applied to its sealing edge, and sealant is applied to the upper, lower and beveled edges. It is also necessary to thoroughly clean the oil seal seat, otherwise there is a high risk of premature wear and, accordingly, replacement of the crankshaft.

Replacing the rear oil seal

The procedure for replacing the rear oil seal is somewhat more complicated and requires an inspection hole. Some craftsmen make do with a jack or, in the absence of one, with special supports, but this is extremely unsafe and we categorically do not recommend using this method. The process of dismantling and replacing the oil seal is carried out in the following sequence:

- Removing the gearbox;

- Removing the clutch;

- Removing the “old” oil seal;

- Installing a new product (do not forget about cleaning the seat).

The assembly process occurs in reverse order.

Important:

When replacing oil seals, we carefully monitor the correct installation. There are often cases when the inner side of the oil seal bends, which subsequently leads to repeated leakage and repeated replacement of the oil seal. In addition, if there has been a bend, the use of even an unused product is not recommended, as this may result in the oil seal not fitting tightly to the seating area on the crankshaft.

Replacing the front engine oil seal

Before starting work, you should check the crankcase ventilation system for contamination and clean it if necessary. Otherwise, oil will ooze out even with a new oil seal.

Replacement is done as follows:

- The timing belt cover is removed.

- The fastening nuts of the generator belt are loosened, after which the belt is removed. It is most convenient to remove it first from the generator pulley, and then from the crankshaft pulley. Installation during assembly is carried out in the same sequence.

- The bolt securing the crankshaft pulley is loosened.

- The pulley is dismantled.

- The timing belt tension roller becomes loose.

- The crankshaft gear is dismantled. Removing it can be problematic - you need to use a special puller and/or treat the stuck part with a special liquid.

- The timing belt is removed.

- The old oil seal is removed.

- The seat is cleaned of contaminants - accumulated dust, sand, settled oil.

- A new oil seal is installed. Before planting, it is recommended to lubricate the part with oil or lithol. It is important to install it correctly - the slightest distortion or bend will cause a leak and cause the spare part to fail.

- Reassemble the mechanism in reverse order, taking into account the marks on the oil pump housing, gear or flywheel.

Sometimes it is possible to replace the engine oil seal without removing the cover. In this case, you will need a special puller, with which the part is carefully installed in the socket.

If the leak is not repaired in a timely manner, oil will begin to leak onto the elements of the engine system, causing them to fail. The timing belt mainly suffers - constant exposure to oil destroys its structure and can lead to breakage.

If the timing belt breaks, the valves may be bent - they will need to be completely replaced, plus the replacement of all consumables, some related parts, and the cost of repairs and lapping. In particularly advanced cases, repair of the piston system may be necessary.

Definition and features of the product

The oil seal is located where the crankshaft exits the engine and connects it to the flywheel. It is a seal made of a special heat-resistant material (thermorubber rubber, silicone, and so on). The main thing is that the material is absolutely inert to the temperature and chemical composition of the oil. The diameter of the oil seal is equal to the diameter of the shaft and may differ depending on the modification of the car.

The working oil, which helps all working elements function smoothly, does not leak out thanks to the main oil seal. In cases where the element is worn or broken, the following problems may occur:

- The used oil will enter the engine combustion chamber. As a result of the reaction under the influence of high temperatures, burnt oil residues will accumulate. This clogs the functional elements of the engine.

- A lack of working oil will negatively affect all metal parts of the assembly. The high friction force and high pressure during engine operation can gradually destroy even strong steel.

- On a front-wheel drive car, a high concentration of oil, when leaking through an inoperative oil seal, corrodes the timing belt. If it breaks, the valves may bend and the engine may break. Repairing an internal combustion engine costs hundreds of times more than one or two oil seals.

- In a rear-wheel drive car, oil can get into the junction of the engine and gearbox, which as a result can affect the operation of the clutch, and this is already dangerous for driving.

The main oil seal is replaced once every 150–200 thousand km. However, the indicator is absolutely individual. For example, if the oil is changed late or completely consumed, overheating in the components is possible. As a result, the elasticity of the seal deteriorates, and then it bursts and leaks the mixture. A competent driver always monitors each of the car’s components.

Signs of wear

Oil seals cannot be repaired. When parts fail, they must be replaced with new ones. At the same time, you should not save: the price of the oil seal is much lower than the estimated cost of replacing it.

The following signs indicate that the time for replacement is approaching:

- Extraneous sounds during operation of mechanisms. This indicates hardening or contamination of the stuffing box packing.

- The appearance of leaks at the interfaces of functional parts. This could be oil leaks on the engine walls, or antifreeze leaking from the cooling pump.

Delay in replacing oil seals leads to lubricant or coolant leakage. Through a damaged oil seal, dirt and sand can enter the bearings of the units, which will lead to serious damage requiring expensive repairs.

Causes of leakage

Oil leakage occurs due to the oil seal losing its original shape. This can happen for the following reasons.

- Freezing or drying out due to the car being left in the cold for a long time without moving.

- Wear on the interior. The service life of this part is approximately 100 – 150 thousand kilometers. Vibrations of the crankshaft during movement “break” the oil seal, changing its shape and disrupting the fit to the parts.

- Incorrect installation. Most often, this situation occurs when you replace a part yourself. For installation, service centers use special equipment or a light hammer, which is used to hammer the oil seal into place. Inexperienced craftsmen use a standard hammer during installation, deforming the part with strong blows.

- Untimely oil change. With prolonged use, dust and dirt accumulate in the lubricant, which scratch the seal and gradually destroy it.

- Engine malfunctions. The increased pressure of crankcase gases knocks the oil seal out of its proper place, and cracks form at the joints.

IMPORTANT. In an effort to save money, some car owners purchase cheap fake parts that fail prematurely. An original oil seal made of high-quality material can last up to 200 thousand km without replacement.

Omental tumors

There is such a thing as primary tumors of the omentum. They can be benign (cysts, dermoids, lipomas, angiomas, fibromas and others) and malignant (sarcomas, endotheliomas, cancer). Secondary formations manifest themselves as metastases from the stomach or intestines, as well as any other organ. In the terminal stage of the disease, the greater omentum is densely covered with altered lymph nodes and neoplasms. It takes the form of a wrinkled ridge and is easily identified by deep palpation of the abdominal wall. This phenomenon can cause intestinal obstruction.

Benign tumors of the omentum are quite rare. They do not cause discomfort to patients, so they can reach significant sizes. It is difficult to diagnose them: there are no specific symptoms, markers or any other indicators. Of the malignant tumors, sarcomas are the most common. They manifest themselves as intoxication syndrome, as well as stool retention and weight loss. These warning signs should prompt the doctor to think about cancer.

Selection rules

When choosing a seal yourself, it is recommended to give preference to the original or a high-quality analogue. Particular attention is paid to labeling, which every manufacturer necessarily supplies its products with:

- “VA” – for camshafts;

- “BASL” – for improved protection against dirt;

- “B1” – for uneven and worn surfaces;

- “B2” – with an additional metal ring for large diameters;

- “BA0F”, “B10F” – without a spring element;

- “DRL (RS)” – with a left notch on the inner surface;

- “DRW (RD)” – with a right notch on the inner surface;

- “D” – for limited pressure indicators (no more than 2 bar);

- “B” – for limited pressure indicators (no more than 10 bar);

- HD – for limited pressure indicators (no more than 100 bar);

- “RT” – with Teflon surface (PTFE);

- “UD” – with a universal profile;

- “U” – with the presence of the old profile.

The cost of the oil seal depends not only on the characteristics of the material used in production and the pricing policy of the company, but also on the production method. Profiles cut with a cutter are noticeably cheaper, but do not always correspond quite accurately to the specified parameters, so it is recommended to give preference to products produced using a matrix.

Tight omentum syndrome

Large diameter omentums appear due to the developing inflammatory process. Parts of the organ fuse with the peritoneum in various areas of the abdominal cavity and stretch it. Such adhesions can develop after surgery, with chronic inflammation of the genitourinary system.

Stretching of the omentum causes pain and disrupts the patency of the intestinal tube. Most often, patients complain of constant pain in the navel and above the womb after eating, as well as bloating and vomiting. A characteristic symptom of the disease is increased pain if the patient tries to bend back. The final diagnosis is made after ultrasound, computed tomography, and radiographs. The ideal option for diagnosis is laparoscopic surgery. If necessary, access can be expanded and adhesions removed.

Causes of leakage

First, let's look at the reasons why it leaks from under the crankshaft oil seal. Before looking for the location of the leak, you need to figure out which specific element has failed.

A car may have two oil seals:

- Front. This part is characterized by its small size and low service life. It usually breaks and leaks more often.

- Rear. Typically, the service life of this part is longer. As a rule, it corresponds to the service life of the vehicle as a whole. The rear oil seal is larger than the front one.

Leaking crankshaft oil seal

Below are the reasons why it is necessary to remove and replace the oil seal:

- Natural wear and tear. Car owners encounter this problem when their vehicle has driven more than 100 thousand km. Natural wear is caused by vibrations generated by the crankshaft, which contributes to the destruction of the internal component of the part. After all, the oil seal is tightly attached and adjacent to the shaft. Over the course of its service life, the device will break down and may lose its shape, causing it to move away from the surface of the assembly.

- Structural destruction as a result of prolonged parking of a vehicle on the street in winter. If the car is not used, the oil seal may dry out or harden due to prolonged exposure to negative temperatures. As a result of drying, the device will not be able to fit tightly to the crankshaft.

- New parts leak due to manufacturing defects. If the oil seal does not last long, the problem is the poor quality of the material used to develop it. To prevent such a problem, experts recommend not using parts from unknown manufacturers on cars.

- Errors made during installation. The problem occurs when the device is unevenly mounted on the crankshaft. When installing, the oil seal is driven into the seat using a hammer with gentle blows. But it is better to use a special installation tool, this will make the process easier and will not damage the device.

- Problems in the operation of the power unit. The appearance of defects in engine operation, such as an increase in crankcase gas pressure, can lead to leakage. Because of this, the oil seal is forced out. At the point where the part adheres to the crankshaft, a gap appears through which engine fluid escapes.

Visual instructions for replacing the device are provided by the KozTas channel.

How to determine the location of the leak

Our compatriots often confuse oil seal damage with oil filter failure.

Seeing traces of leaks, many car enthusiasts immediately change the oil seal without understanding the reason. As a result, there is no need to replace the oil filter. Before changing the device and eliminating traces of leakage, you need to decide which part has failed. If traces of oil appear in the rear part of the power unit, you should perform a visual diagnosis of the sump, as well as the transmission unit. Leakage can also occur in the gearbox, so drop some oil on the water. If the gearbox seal leaks, the lubricant will immediately spread across the surface of the water, and the fluid from the engine will remain on it in the form of a drop.

Signs of a leak include a lack of engine oil in the lubrication system. If you check the oil level and find that it is not enough, do not immediately add fluid. Check the motor for leaks, after which you can fix the problem.

Omental cyst

A cyst occurs due to obstruction of lymphatic vessels or as a result of the proliferation of an obliterated area of lymphoid tissue that is not connected to the general system. These cysts resemble thin round sacs filled with clear liquid. Their size can vary from five millimeters to several centimeters. The disease does not manifest itself in any way, but when the formation reaches a significant size, it can be felt through the anterior abdominal wall.

Treatment of this pathology is exclusively surgical. The cysts and the omental area are removed, preserving most of it. The prognosis for such patients is favorable.

Why does the oil seals squeeze out?

There is an opinion that the oil seals are squeezed out if the oil level in the engine is exceeded. Is it really?

Hello dear readers!

Surfing the Internet in search of an answer to the question: “why does the oil seals squeeze out?” you can come across many different opinions, but not all of them are true. Let's look at the main reasons why oil seals can be squeezed out (in the engine, gearbox, axles, etc.).

Popular myth

High oil level.

On many forums you can find such an opinion that if you pour oil into the engine, the oil pressure will increase and squeeze out the seals.

In reality, nothing like this will happen. If,

of course, your oil pump pressure reducing valve is working properly. If this valve is faulty, the pressure will be high (or low) and the oil level will be normal. Overfilling the oil, in turn, will not affect the squeezing out of the seals.

Why does the oil seals squeeze out?

Inappropriate seal.

A fairly common reason can be considered the installation of an oil seal of a different size. The fact is that prices for original oil seals can be unreasonably high, and analogues do not always match the size of the original oil seal. Thus, due to inattention, a smaller oil seal can be installed. Subsequently, during startup, such an oil seal may come out of its seat.

Axial play of shafts.

An equally popular reason for squeezing out oil seals is axial play of the shafts. For example, when the crankshaft half rings wear out, the shaft begins to move in the axial direction, thereby squeezing the oil seal out. It is treated by eliminating the axial play of the shafts.

Problem with the rings.

When the rings are stuck or the CPG is worn, the pressure of the crankcase gases increases. This can also be the cause of squeezing out the oil seals, but much more often it starts leaking from under the valve cover.

Problems with the crankcase ventilation system.

In most cases, the oil seals are squeezed out due to a clogged oil separator.

The main reason for clogged oil separator is the use of low-quality oil or untimely oil change.

On some cars there is a disease - the breather freezes. Axles and gearboxes also have a breather, which often becomes clogged, which leads to squeezing out the seals.

Thank you for your attention, like, have a nice day!

Source