Purpose of the suspension

Trucks travel on a variety of roads. These include main asphalt highways, dirt roads, and off-road terrain with potholes and potholes. The general purpose of the suspension is to make movement in any conditions the least “traumatic” for the car, and for the people in it.

In particular, this car system helps:

- reduce vibration, especially if you have to drive on a difficult road;

- avoid strong tilting and rocking of the car when turning and braking;

- reduce sounds and noise associated with traffic;

- extend the safety and performance of truck parts;

- save fuel by more successfully passing difficult sections.

The suspension refers to the chassis of the car along with the wheels, which thanks to it are able to move independently of the body.

Truck suspension

There are several types of suspensions found on trucks. Each type of suspension has its own design features and operating characteristics. A suspension is a set of parts that attach the wheels of a car to the body. The mechanical assembly itself includes several elements. Due to the suspension elements, the level of vibration is reduced when the car crosses a road with uneven surfaces. Not only vibration damping, but also the level of noise damping from the outside that occurs when driving a car depends on the effectiveness of the suspension.

Main elements of the system

The suspension design includes the following parts:

- Components that provide elasticity. They can be metallic, such as springs or torsion bars, or non-metallic. Due to their elasticity, these components soften dynamic loads, absorb shocks and jolts that occur during movement, and ensure a smooth ride.

- Shock absorbers. The scheme of their operation is simple - these devices dampen vibrations created by elastic elements and prevent them from affecting the body and rocking it. They also provide good grip on the road. If the shock absorber fails, the wheels begin to “jump”.

- Guide parts. They are presented in the suspension by levers and rods. They connect the entire mechanism to the body and adjust the position of the wheels relative to it while driving in a straight line and when turning.

- Anti-roll bars. The main task of these components is to prevent the car from falling to one side when cornering.

- Wheel supports. Parts that take the load from the wheels and distribute it throughout the suspension.

- Fastening elements. These are bolts and hinges with which the suspension parts are connected to each other, and the suspension itself to the body.

Requirements for suspensions:

• optimal stiffness characteristic - the relationship between the normal (perpendicular to the supporting surface) load on the wheel and the deformation (deflection) of the suspension, measured as the normal movement of the wheel center relative to the body;

• optimal kinematics; the operation of the suspension guide device during vertical movements, roll or galloping (longitudinal angular vibrations) of the car body causes not only vertical movements of the wheels, but also lateral and angular movements both relative to the road and relative to the body; • optimal damping characteristics - damping vibrations of the wheels and car body that arise as a result of exposure mainly to road irregularities; may occur due to friction in some types of elastic elements and in the hinges of the suspension guide device; • minimum number of unsprung parts; these include wheels and tires, wheel brakes, steering knuckles, suspension struts, axles, etc.; • good contact of the wheel with the road; when a car drives over convex bumps (jumps) on the road surface at high speed due to insufficient rebound travel of the suspension or its large inertia, the wheel may come off the road;

• low noise and vibration levels; when operating a car, creaks occur due to suspension friction in metal hinges, rubber supports and elastic elements, and knocks occur in the hinges due to their wear and formation of gaps; • rational layout scheme.

MacPherson suspension

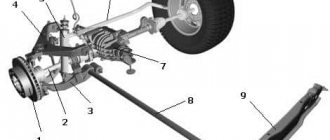

Truck suspension device:

a - dependent; b - independent pivot; c - independent, pinless; 1 — bracket; 2 — spring; 3 - clamp; 4 — front axle beam; 5 - earring; 6 - stepladder; 7 and 12 — levers; 8 - spring; 9 — kingpin; 10— steering knuckle; 11 — rotary stand; 13—subframe cross member.

How does independent suspension work?

Independent suspension elements

Types of truck suspensions

By type of connection in the wheel pair

According to this criterion, the classification includes dependent and independent suspensions. The first ones have been used for a long time, when there was no car yet. Dependent suspensions were then installed in carriages and horse-drawn vehicles. The peculiarity of this mechanism is the rigid connection between the wheels of the same axle, front or rear. As a result, their “behavior” while the car is moving is interdependent. This type of design is good for truck tractors and other heavy-duty vehicles that travel over rough terrain and off-road.

Independent suspensions have a device in which each wheel moves and reacts to bumps independently. If one of them hits a stone, it will move along with the surrounding parts. Meanwhile, the second wheel will retain traction. Both rear and front suspensions of this type perform better in passenger vehicles that are operated on smooth roads. This makes it more comfortable for passengers to be in the car. The independent design of trucks has a shorter service life, and its repair is more expensive.

By type of elastic elements

There are pendants:

- Spring. Such vibration damping mechanisms have been used since the beginning of automotive production. Springs are metal parts consisting of several plates or one sheet. The mentioned suspensions are wear-resistant and unpretentious to operating conditions. They are mainly installed on trucks and construction equipment equipped with two rear axles. This is a reliable solution when it is necessary to keep the body at a certain height. It ensures the safety of the truck.

- Spring. These suspensions protect the body from strong impacts and maintain the required ground clearance. This is achieved due to the elasticity of the springs, which can be cylindrical, barrel-shaped, or conical. Reinforced springs are more suitable for trucks. They can be equipped with the rear suspension. This part of the trucks is subject to particularly heavy weight. Repairing such a suspension is relatively cheap and can be carried out at almost any service station.

- Torsion bars. The structure of the entire mechanism includes rods that work for torsion. They contribute to the uniform distribution of loads that occur during driving when the wheels hit an uneven surface. Such suspensions can often be found on the chassis of SUVs. However, they are used quite rarely on cargo vehicles handling large consignments of goods due to expensive repairs.

- Pneumatic. These pendants differ from other types in that they operate on air or inert gas. It is pumped into special cylinders made of durable material. The pressure in them is adjusted depending on the conditions. This makes it possible to obtain the smoothest possible movement of trucks and fully control ground clearance. The disadvantage of pneumatic devices is the high initial cost. There are also difficulties in repairs. In particular, a damaged cylinder cannot be repaired; it only needs to be replaced. Such systems are mainly part of trucks, tractors, and buses. Pneumatic structures are rarely installed on passenger vehicles.

Purpose and design of car suspension

Rice. 127. Hydraulic shock absorber : I - eye; 2 - casing; 3, 4 — oil seals; 5 - bypass valve; 6, 15 - holes in the piston; 7 — recoil valve; 8, 11 — springs; 9 — intake valve: 10 — compression valve; 12, 13 - holes in the base; 14 - piston; 16 — body; 17 - cylinder; 18 — rod; 19 — hole in the rod guide.

The main parts of the shock absorber (Fig. 127) are housing 16, working cylinder 17, casing 2, piston 14 with rod 18, compression valve 10, recoil valve 7, bypass valve 5, inlet valve 9. The working cylinder is located inside the housing, from the bottom to the base is welded to it, and the top of the cylinder is closed with a rod guide. A piston connected to a rod moves inside the cylinder. The piston has two rows of holes arranged in circles. The holes 6 on the larger diameter are closed by a bypass plate valve 5, the holes on the smaller diameter 15 are blocked from below by the return valve plate 7. At the base of the cylinder there is one row of holes around the circumference, which are closed from above by the inlet valve 9. In the center of the base there is a compression valve 10.

The space between the cylinder and the piston is called the reserve cavity; together with the working cylinder, it is filled with liquid.

The outlet of the rod from the cylinder is sealed with a rubber seal 3. A seal 4 is installed between the seal race and the rod guide, sealing the reserve cavity.

Shock absorber operation. With a smooth compression stroke, the piston moves downwards, pressure is created under it, due to which the bypass valve 5 on the piston opens, and the liquid flows into the space above the piston. All the liquid from under the piston cannot flow into the space above the piston, since part of the volume above the piston is occupied by the rod. Therefore, part of the liquid flows through the slightly opening compression valve 10 into the reserve cavity.

With sudden compression, a large pressure is created under the piston, the compression valve opens by a large amount. The liquid flows through valve 5 into the space above the piston and through valve 10 into the reserve cavity.

During a smooth recoil stroke, pressure is created in the space above the piston. The liquid flows through holes 15 and slots in the recoil valve 7 into the space under the piston. At the same time, liquid enters the same space from the reserve cavity through the inlet valve 9.

With a sharp recoil stroke, the pressure above the piston increases quickly. The liquid, overcoming the force of the spring, opens valve 7 and passes into the space under the piston. At the same time, part of the liquid from the reserve cavity passes through the inlet valve 9 into the space under the piston.

In all cases, when liquid flows through the narrow holes of the valves, friction of the liquid is created against the walls of the holes and between its layers. Due to this friction, vibrations of the frame are damped. Friction generates heat, so a properly functioning shock absorber must be warm.

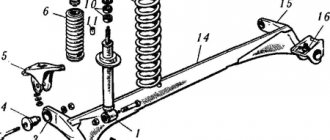

Rice. 128 Rear suspension of a three-axle vehicle : 1 - intermediate axle; 2, 3 — reaction rod brackets; 4, 8 - spring brackets; 5 — spring; 6.15 — suspension bracket; 7 - stepladder; 9 — rear axle; 10, 11, 14 reaction rods; 12 — balancer; 13 - axis.

The rear suspension (Fig. 128) of three-axle vehicles is dependent, spring, and balancer. The main parts of such a suspension are two inverted springs 5, two balancers, two axles 13 (on the Ural-4320 and ZIL-131 vehicles there is one common axle), two axle brackets, two rear suspension brackets, six reaction rods 10, 11, 14 , four rubber buffers.

Axle 13 is pressed into bracket 6, which is secured with studs to bracket 15, the latter is bolted to the frame spar. At the ends of the axles 13, on two bushings each, balancers 12 are installed. From axial displacements, the balancer is fixed with a split nut tightened with a bolt. The rubbing surfaces of the balancer are lubricated by oil poured through the top hole in the balancer cover, the oil is drained through the bottom hole, and the holes are closed with plugs. On the side of the bracket b, the balancer is sealed with an oil seal and rubber rings.

The spring in the middle part is attached to the balancer with two stepladders 7. The ends of the springs are installed freely in the brackets of the bridge beams.

Rubber buffers attached to the frame side members limit the upward travel of the axles and soften the impact of the beams on the frame.

Reaction rods serve to transmit pushing and braking forces from the bridge beams to the frame; they also receive reaction moments from the bridges that occur when starting or braking. Each bridge has three rods - one upper and two lower. The rod consists of a rod and two heads. On KamAZ-4310 and Ural-4320 vehicles, ball pins with liners and a spring are installed in the rod heads; the head is closed with a lid. To lubricate the rubbing surfaces of the hinge, there is a grease nipple in the head. On the ZIL-131 car, a ball pin and a clip with liners are installed in the head. The liner is made of woven tape impregnated with a special compound. The hinge is sealed with a rubber boot. During operation, the hinges of the reaction rods on this vehicle do not require lubrication.

The reaction rods are attached to the suspension brackets and axle arms.

With a balancer suspension, both axles form a common bogie, which can swing together with the springs on the axle and, in addition, due to the deflection of the springs, each axle can move independently, which ensures good adaptability of the wheels to road unevenness.

Suspension operation

It is necessary to carefully monitor the condition of this part of the truck. When moving, she experiences great impacts from the road. Because of this, some parts may lose their functionality. Then they need to be repaired or replaced.

You should inspect the entire mechanism before each flight to have an idea of its serviceability. It is also necessary to undergo preventive diagnostics, which can show problems that are not yet significant, but are fraught with more serious consequences. Eliminating them at the initial stage is always easier and less expensive.

Types of independent suspensions

McPherson

McPherson suspension is the most common front axle suspension on modern cars. The lower arm is connected to the hub via a ball joint. Depending on its configuration, longitudinal jet thrust can be used. A shock absorber strut with a spring is attached to the hub assembly, its upper support is fixed to the body.

Double wishbone front suspension

The transverse rod, attached to the body and connecting both levers, is a stabilizer that counteracts the roll of the car. The lower ball joint and shock absorber cup bearing allow the wheel to turn.

The rear suspension parts are made according to the same principle, the only difference is that the wheels cannot be turned. The lower arm has been replaced with longitudinal and transverse rods that secure the hub.

Pros:

- simplicity of design;

- compactness;

- reliability;

- inexpensive to manufacture and repair.

Minuses:

- average handling.

Double wishbone front suspension

More efficient and complex design. The upper mounting point of the hub is the second wishbone. A spring or torsion bar can be used as an elastic element. The rear suspension has a similar structure. This type of suspension design ensures better vehicle handling.

Air suspension

Air suspension

The role of springs in this suspension is performed by air cylinders with compressed air. With air suspension, it is possible to adjust the body height. It also improves ride quality. Used on luxury cars.

Hydraulic suspension

Adjusting the height and stiffness of the Lexus hydraulic suspension

Shock absorbers are connected to a single closed circuit with hydraulic fluid. The hydraulic suspension makes it possible to adjust the rigidity and ride height. If the car has control electronics, as well as adaptive suspension functions, it independently adapts to road and driving conditions.

Sports independent suspensions

Helical suspension (coilovers)

Helical suspension, or coilovers, are shock-absorbing struts with the ability to adjust the stiffness directly on the car. Thanks to the threaded connection of the lower spring stop, you can adjust its height, as well as the amount of ground clearance.

Push-rod and pull-rod suspensions

These devices were developed for open-wheel racing cars. It is based on a two-lever design. The main feature is that the damping elements are located inside the body. The design of these types of suspension is very similar, the only difference is in the location of the load-bearing elements.

Difference between push-rod and pull-rod sports suspensions

Push-rod sports suspension: the load-bearing element - the pusher - works in compression.

Pull-rod sports suspension: the load-bearing element works in tension.

This design lowers the center of gravity and provides better vehicle stability. The pull-rod suspension has a lower center of gravity than the push-rod. However, in practice their overall effectiveness is approximately the same.

Why do you need suspension diagnostics?

Regular inspection and checking of the technical characteristics of the chassis is the key to the health of the car and its safety while driving. All suspension elements are under significant loads during movement. With an aggressive driving style and poor-quality road surfaces, these loads increase even more, which can cause wear on the structural elements of the suspension of even the most reliable car.

Periodic preventive diagnostics of the suspension helps to identify vulnerabilities and damage at the initial stage. This will allow you to replace worn parts in a timely manner, eliminating serious damage to the car and its subsequent expensive repairs. If you regularly perform suspension diagnostics, you will ensure your safety on the road and reduce the financial costs of repairing your car.

When do you need to do suspension diagnostics?

Experts recommend doing this procedure every 10...20 thousand kilometers, but at least once every 6 months. It is better to perform it before the winter period and with the onset of spring. This will help prepare the car for safe operation during difficult winter conditions, as well as eliminate the effects of exposure to low temperatures, sand-salt mixtures and anti-icing agents on suspension elements. It is also recommended to carry out diagnostic procedures before a long trip. This will reduce the likelihood that a fault will catch you by surprise along the way. In addition, chassis diagnostics are required when purchasing a used car.

Despite the age and mileage of the car, checking and diagnosing the suspension must be regular and mandatory. If you detect any extraneous noise or unusual behavior of the car while driving, you should diagnose its chassis.

There are a number of signs by which you can determine whether the suspension is faulty and the need for its diagnosis and maintenance. The main ones include extraneous noise from the suspension, the hum of its elements, knocking when overcoming bumps, play in the steering wheel, and a roll of the car body to one side. Further driving in a car with such characteristic signs of malfunction is dangerous, since the car poses a danger to other road users.

Stages of initial diagnosis

Suspension diagnostics consists of determining the reliability of all its structural elements. This process involves the following procedures:

- visual inspection of structural elements for mechanical damage;

- checking shock absorbers for leaks;

- monitoring the integrity and elasticity of springs;

- checking the functionality and absence of damage to the steering elements;

- inspection of the integrity of the CV joint boots, shock absorber, steering rods;

- monitoring the degree of wear of brake pads and brake discs.

Complex diagnostics, in addition to the listed procedures, involves checking the car on special stands and using special scanners.

Suspension operation

The work of the suspension is to convert the impact energy that occurs when a wheel hits an uneven road surface into the kinetic energy of the suspension elements. To absorb kinetic energy by converting it into potential energy, shock absorbers and springs are used. As a result, the force of impact on the car body is reduced, its swaying is reduced, the movement of the car becomes softer, and its directional stability improves.

Different car models have different suspension designs. For some it is more rigid, while for others, on the contrary, it is soft. Cars with rigid suspension have more informative and efficient control, but the driver and passengers feel less comfortable. The soft suspension is comfortable, but it has worse handling. To find the best option, engineers try to select a suspension design so that it is moderately stiff and at the same time comfortable for driving on roads with different surfaces.

Is it possible to perform suspension diagnostics without a service station?

There are several important factors that indicate the inappropriateness of conducting suspension diagnostics outside a service station:

- this requires certain experience, which professional mechanics have;

- you will need a lift, a set of special tools, and in some cases test vibration stands;

- due to ignorance or inexperience, a minor malfunction may not be identified, which can cause a serious breakdown or emergency on the road.

- Diagnostics of a car's chassis is not an expensive procedure, so you should not skimp on its implementation.