Duty cycle

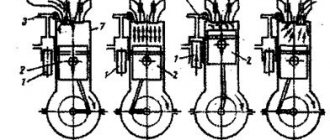

Depending on the number of strokes that make up the operating cycle, internal combustion engines are divided into two-stroke and four-stroke. Two-stroke engines are not used in modern cars; they are used only on motorcycles and as starters for tractor power units. The cycle of a four-stroke gasoline internal combustion engine includes the following strokes:

- Intake - the exhaust valve is closed, the intake valve is open, the piston moves downward, and the air-fuel mixture is sucked in.

- Compression - all valves are closed and the piston moves upward, compressing the air-fuel mixture.

- Working stroke - the valves remain closed; at the end of the previous stroke, a spark ignites the compressed mixture. The piston, under the influence of gas pressure from the burnt mixture, goes down, rotating the crankshaft.

- Exhaust - at the end of the previous stroke, the exhaust valve opens. The piston, pushed by the crankshaft, moves upward and displaces combustion products into the exhaust manifold.

The diesel cycle is different in that during intake only air is sucked in. Fuel is injected under pressure after air compression, and ignition occurs from contact of the diesel engine with air heated by compression.

Numbering

The cylinder numbering of an in-line engine starts with the one furthest from the gearbox. In other words, from the timing belt or chain side.

Sequence of work

On the crankshaft of an in-line 4-cylinder internal combustion engine, the cranks of the first and last cylinder are located at an angle of 180° to each other. And at an angle of 90° to the cranks of the middle cylinders. Therefore, to ensure the optimal angle of application of driving forces to the cranks of such a crankshaft, the order of operation of the cylinders is 1-3-4-2, as in VAZ and Moskvich internal combustion engines, or 1-2-4-3, as in GAZ engines.

Alternation of measures 1-3-4-2

It is impossible to guess the order of operation of the engine cylinders by external signs. You should read about this in the manufacturer's manuals. The easiest way to find out the operating order of the engine cylinders is in the repair manual for your car.

Multi-cylinder engine operation

During engine operation, its mechanisms are subject to significant gas pressure forces in the cylinder, inertial forces of unevenly moving parts of the crank mechanism, as well as centrifugal forces arising from the rotation of parts. These forces are not constant in magnitude and direction of their action, so they cause uneven operation of the engine.

When the engine operates unevenly, its mechanisms work with variable load, resulting in intense wear of parts. The uneven operation of a single-cylinder four-stroke engine is especially great.

To achieve uniform engine operation, either a heavy flywheel is installed on the crankshaft, or it is made multi-cylinder.

The flywheel accumulates energy during the power stroke and releases it during auxiliary strokes. But a heavy flywheel is used only for stationary engines, which, as a rule, operate in constant mode. Due to significant inertia, a heavy flywheel does not provide the acceleration required by a car engine, i.e. the ability of the engine to quickly develop and reduce speed. Therefore, in automobile engines, uniform operation is achieved not by increasing the weight of the flywheel, but by making the engine multi-cylinder. In a multi-cylinder engine, the power strokes alternate evenly in individual cylinders, as a result of which the inertia forces that arise in the crank mechanism during engine operation are largely balanced.

To ensure the greatest uniformity of operation of a multi-cylinder engine, it is necessary that the power strokes in different cylinders alternate at regular intervals and in a certain sequence. This sequence of repetition of the same strokes in different cylinders is called the firing order of the engine cylinders.

Rice. Table of alternating strokes of a four-cylinder four-stroke engine with the order of cylinder operation 1-2-4-3 (the numbers in the column “Position of the crankshaft cranks” indicate the serial numbers of the cylinders)

However, not every order ensures good engine performance. It is necessary that the next strokes of the power stroke follow in the cylinders that are most distant from one another. In this case, the load on the crankshaft main bearings will be distributed more evenly; In addition, exhaust gases from a cylinder in which exhaust has begun will not flow through the exhaust pipe into a cylinder in which exhaust has not yet ended.

The most convenient operating orders for automobile engines are: for a four-cylinder engine - 1-2-4-3 and 1-3-4-2, for a six-cylinder engine - 1-5-3-6-2-4 and for an eight-cylinder engine - 1-5-4 —2—6—3—7—8.

The firing order of the cylinders is usually depicted in the form of a cycle sequence table.

Let's consider how a four-stroke four-cylinder engine operates with the cylinder operating order 1-2-4-3. Since the working cycle of a four-stroke engine is completed in two revolutions of the crankshaft (720°), and the number of working strokes occurring during this time is four, then for the correct alternation of working strokes, the crankshaft cranks are offset from one another by 180° (720°: 4), i.e. half a turn of the crankshaft, and are thus in the same plane.

During engine operation, the pistons in the first and fourth cylinders, during the first half-turn of the first revolution of the crankshaft, move from top dead center to bottom, the power stroke occurs in the first cylinder, and the intake stroke occurs in the fourth cylinder. In the second and third cylinders, the pistons move at this time to top dead center, in the second cylinder the compression stroke occurs, and in the third - the exhaust stroke.

During the second half-turn of the first revolution of the crankshaft, the pistons in the first and fourth cylinders move from bottom to top dead center, the first cylinder undergoes the exhaust stroke, and the fourth - the compression stroke. At this time, the pistons of the second and third cylinders move from top dead center to bottom, the power stroke occurs in the second cylinder, and the intake stroke occurs in the third.

During the first half-turn of the second revolution of the crankshaft, the pistons in the first and fourth cylinders move from top to bottom dead center, the intake stroke occurs in the first cylinder, and the power stroke occurs in the fourth. At this time, the pistons of the second and third cylinders move from bottom to top dead center; the exhaust stroke occurs in the second cylinder, and the compression stroke occurs in the third.

During the second half-turn of the second revolution of the crankshaft, the pistons in the first and fourth cylinders move from bottom to top dead center, the compression stroke occurs in the first cylinder, and the exhaust stroke occurs in the fourth. The pistons in the second and third cylinders move from top dead center to bottom; the intake stroke occurs in the second cylinder; the power stroke occurs in the third.

A four-cylinder four-stroke engine with a cylinder operating order of 1-3-4-2 differs from an engine with an operating order of 1-2-4-3 only in the design of the distribution mechanism, which determines a slightly different sequence of opening and closing valves and alternating strokes.

Both orders of cylinder operation, adopted for domestic four-stroke four-cylinder engines, are completely equivalent both in terms of uniformity and quality of engine operation. Six-cylinder engines, in which the cylinders are arranged in one row, are widely used in domestic cars. Such engines are called in-line engines, in contrast to engines whose cylinders are arranged in two rows at a certain angle to one another.

In a six-cylinder in-line engine, the crankshaft has six cranks. Since the working cycle of a four-stroke engine is completed in two revolutions of the crankshaft (720°), and the number of working strokes during this time is six, then for the correct alternation of working strokes, the crankshaft cranks are offset from one another by 120° (720°: 6), i.e., one third of the shaft revolution.

For single-row six-cylinder engines, the following crank arrangement is used: 1-6 - up, 2-5 - left, 3-4 - right, when viewed from the front end of the shaft.

When the crankshaft rotates, the pistons in a six-cylinder engine do not pass through their dead spots all at the same time, as in a four-cylinder engine, but only in pairs. Therefore, the strokes in all cylinders also do not begin and end simultaneously, but are shifted in one pair of cylinders relative to the other by 60°.

The overlap of strokes and the order of alternating power strokes in a six-cylinder four-stroke engine are shown in the table in the figure.

Rice. Table of alternating strokes of a six-cylinder four-stroke engine with the operating order 1-5-3-6-2-4 (the numbers in the column “Position of the crankshaft cranks” indicate the serial numbers of the cylinders)

A special feature of two-stroke diesel engines is that their operating cycle is completed in one revolution of the crankshaft (360°). Therefore, the relative position of the crankshaft cranks has its own characteristics: in a four-cylinder engine, the cranks are shifted relative to each other by 90° (360°: 4), in a six-cylinder engine - by 60° (360°: 6).

Rice. Table of alternating strokes of a six-cylinder two-stroke diesel engine with the operating order 1—5—3—6—2—4 (the numbers in the column “Position of the crankshaft cranks” indicate the serial numbers of the cylinders)

The overlap of strokes and the order of alternation of working strokes in a two-stroke six-cylinder diesel engine are shown in the table in the figure.

Currently, eight-cylinder V-shaped engines are widely used in cars. The cylinders of these engines are arranged in two rows, most often at an angle of 90°. The crankshaft of such engines has four cranks, offset one relative to the other by 90°. Two connecting rods rest simultaneously on each crank journal.

In an eight-cylinder engine, eight power strokes are completed per working cycle (720°); their alternation, therefore, occurs through 90° (720°: 8). The order of operation of the cylinders and the alternation of strokes in an eight-cylinder engine are shown in the table in the figure.

Rice. Table of alternating strokes of an eight-cylinder engine with the order of cylinder operation 1—5—4—2—0—3—7—8 (the numbers in the column “Position of the crankshaft cranks” indicate the serial numbers of the cylinders)

In multi-cylinder engines, due to the continuous alternation of working strokes and their overlap with one another, a smoother and more uniform rotation of the crankshaft is ensured. Multi-cylinder engines operate more steadily, without the jolts and vibrations associated with single-cylinder engines.

Theory of internal combustion engine operation

The general principle of operation of engines running on gasoline or diesel fuel is known, perhaps, to everyone - fuel, burning in the cylinders, creates gas pressure that pushes the pistons, and then the force is converted into torque going to the wheels.

In order for the engine to operate evenly, fuel combustion does not occur in all cylinders at the same time, but in a certain order. The following are responsible for its compliance:

- gas distribution mechanism design;

- the angles between the cranks of the car crankshaft;

- cylinder arrangement - V-shaped or in-line;

- device of the ignition system for gasoline cars, and fuel injection pump for diesel cars.

Purpose of the cylinders

First of all, let's talk about what they are and what they are needed for. Simply put, it is the hole in the cylinder block through which the piston moves. Their presence is of great importance for the operation of the engine: all the most important processes of transformation and production of energy occur in the cylinders, and the energy, accordingly, sets the car in motion.

In fact, it combines two energies: fuel combustion and movement. It is worth noting that during operation the cylinders experience incredible loads associated with both high piston speed and high temperature. At the moment when fuel combustion occurs in them, a lot of energy is generated.

Principle of operation

Four cylinders can be made balanced without additional effort due to special balancing. If you remember, the usual order of operation of the cylinders.

1-3-4-2

Or

1-2-4-3

This allows you to reduce vibrations and use energy as efficiently as possible. The standard is that two pistons will be at the bottom, and two more at the top, ensuring uniform, jerk-free movement. This is achieved by placing each pair of cylinders in antiphase.

Cylinder sequence

The cylinders have numbers; in the documentation they are described in ABCD format, where instead of letters a digital designation is indicated. The numbering order starts from the timing chain or belt side - from the cylinder furthest from the gearbox. The one who wears number 1 is called the main one.

Important: if the cylinders operate in series, they should not be located next to each other. It is with this condition in mind that motor manufacturers have developed certain cycle order schemes.

The cylinders are equipped with valves through which gases enter and exit. The valves are controlled by a special device - a camshaft, on the surface of which special cams are located in a special way. It is their location that is responsible for the order of operation: the cam profile and its height affect the closing and opening moments, the size of the cross-section of the passage for gases, as well as how the valve will move depending on the current crankshaft angle.

One of the camshaft options:

Crankshaft:

A standard 4-stroke cycle of a standard internal combustion engine takes 2 revolutions, or 720 degrees (360 and 360). The “cranks” located on the shaft are shifted by a certain angle so that the force from the engine pistons is constantly transmitted to the shaft. The mentioned angle is a value that depends on the engine model, its stroke rate, and the number of cylinders.

Let's look at the typical order for some engines.

Cylinder block

The block of working displacement chambers is made of cast iron. It features insert sleeves with a width of 7.5 millimeters. The top of the sleeves is sealed by clamping the collar of the element at the block and its head through an asbestos steel gasket. The seal at the bottom is made using two rubber rings.

Since 1970, in order to prevent the formation of cracks on engines, for middle cylinder blocks, on the tightening of the head bolts, counterbores were introduced into the holes and the bolts were increased in length. In blocks that do not have counterbores in the threads, short bolts with elongated bolts are used.

The chamber head is made of aluminum, valve seats and guides are inserted into it. The block and heads have asbestos-steel types of gaskets. Each block head is attached to the cylinder parts using 17 bolts. The operating order of the ZIL 130 cylinders is as follows: 1,5,4,2,6,3,7,8. In this case, their numbering is presented in the following form: the right working displacement chambers are designated by numbers 1, 2, 3 and 4, and the left ones - 5, 6, 7 and 8. The camshaft is installed in the block. A power unit with this arrangement of blocks is installed on ZIL-130, 131, 375 and 508.

What if you make 3, 5 or 6 “boilers”?

Well, what if we have, for example, 5 cylinders. In this case, it turns out that the angle between adjacent pistons will be 72°, and this does not contribute to balancing in any way, since the pistons will not be in antiphase. This will increase vibrations and shocks.

There are engine models with five cylinders, but they usually have additional shafts for stabilization, which complicates the design. Also, drivers often simply turn off the additional “pot”.

Sectional view of a five-cylinder engine

The three-cylinder engine works similarly.

Well, what about 6-cylinder ones? They are usually equipped with powerful and expensive cars. In general, they are similar to two three-cylinder engines combined. Accordingly, they have the same problems. Therefore, they are equipped with various shafts and balancers.

Six-cylinder engine with cylinder head removed

But the spread of engines with 6 cylinders is associated with the features of four-cylinder units. The fact is that 4 cylinders with a volume of over 2.5 liters become worse balanced and also turn out to be less efficient; additional parts are also needed for balancing. Therefore, it simply doesn’t make sense to go crazy if you can just add cylinders; anyway, the complexity of the motors will be the same.

A little about internal combustion engines

Knowledge about the structure and operation of a car will be a big plus for any car enthusiast. This is especially true for the engine - the most important element and heart of the iron horse. ICE has a lot of varieties - starting from the type of fuel and ending with small nuances unique to each car.

But the essence of the work is approximately the same:

Thanks to the sequential operation of the cylinders, the crankshaft is in constant motion, generating torque. The more cylinders, the easier and faster the crankshaft will rotate. So a diagram emerged, familiar even to schoolchildren who do not understand hardware - more cylinders - more powerful engine.

Inline 4-cylinder

There are two popular layouts of such internal combustion engines:

- in-line;

- Opposite.

The first means that the cylinders are arranged sequentially, in one row, and the engine pistons rotate a common crankshaft. Engines are often described by the abbreviation I4 or L4, you can also find the name Inline 4 and variations. Engineers place the cylinders both vertically and at some angle, depending on the engine design.

Example of a cylinder block:

This cylinder arrangement has become widespread in mass-produced car models, as well as in those vehicles where ease of maintenance and repair is important - SUVs, cars designed for taxi use, etc.

The cranks of cylinders 1 and 4 in the crankshaft design of an inline four-cylinder engine are located at an angle of 180 degrees, and at an angle of 90 to the cranks of cylinders 2 and 3. To create an optimal ratio of driving forces acting on the cranks, the engines act in the following sequences:

- system 1–2–4–3 – less popular;

- the main option is 1–3–4–2.

Among domestic cars, the operating procedure of a four-cylinder engine of the second type is used, for example, in the products of the VAZ concern, and the first is relevant for some ZMZ engines.

The operating procedure of a 4, 6, 8 cylinder engine - simple about the complex - DRIVE2

By and large, we, ordinary car enthusiasts, do not need to know the operating order of the engine cylinders. Well, it works and works. Yes, it’s hard to disagree with this. It is not necessary until you want to set the ignition yourself or start adjusting the valve clearances.

And it won’t be superfluous to know about the operating order of a car’s engine cylinders when you need to connect high-voltage wires to spark plugs, or high-pressure pipelines for a diesel engine. What if you decide to repair the cylinder head?

Well, you must admit, it would be funny to go to a car service center in order to correctly install the explosive wires. And how to go? If the engine troits.

What does the order of operation of the engine cylinders mean? ↑

The sequence with which strokes of the same name alternate in different cylinders is called the order of operation of the cylinders.

What determines the order of operation of the cylinders? There are several factors, namely:

— engine cylinder arrangement: single-row or V-shaped; — number of cylinders; — camshaft design;

- type and design of the crankshaft.

Engine duty cycle

The engine operating cycle consists of gas distribution phases. The sequence of these phases should be evenly distributed according to the force acting on the crankshaft. It is in this case that the engine runs smoothly.

A prerequisite is that the cylinders operating in series should not be located next to each other. For this purpose, engine manufacturers develop diagrams for the operating order of engine cylinders. But, in all schemes, the order of operation of the cylinders begins with the main cylinder No. 1.

The order of operation of the cylinders in different engines

For engines of the same type, but of different modifications, the operation of the cylinders may differ. For example, the ZMZ engine. The cylinder firing order of the 402 engine is 1-2-4-3, while the cylinder firing order of the 406 engine is 1-3-4-2.

If we delve deeper into the theory of engine operation, but so as not to get confused, we will see the following. The full operating cycle of a 4-stroke engine takes two revolutions of the crankshaft. In degrees this is equal to 720. For a 2-stroke engine it is 3600.

The shaft elbows are shifted to a certain angle so that the shaft is under constant force from the pistons. This angle directly depends on the number of cylinders and engine stroke.

— The order of operation of a 4-cylinder, single-row engine, the alternation of strokes occurs every 1800, but the order of operation of the cylinders can be 1-3-4-2 (VAZ) or 1-2-4-3 (GAZ).

— The operating order of a 6-cylinder in-line engine is 1-5-3-6-2-4 (the ignition interval is 1200).

— The operating order of the 8-cylinder V-engine is 1-5-4-8-6-3-7-2 (ignition interval 900).

— There is, for example, the order of operation of a 12-cylinder W-shaped engine: 1-3-5-2-4-6 are the left cylinder heads, and the right ones: 7-9-11-8-10-12

In order for you to understand this whole order of numbers, let's look at an example. The 8 cylinder ZIL engine has the following cylinder operating order: 1-5-4-2-6-3-7-8. The cranks are located at an angle of 900.

That is, if a working cycle occurs in cylinder 1, then through 90 degrees of crankshaft rotation, the working cycle occurs in cylinder 5, and sequentially 4-2-6-3-7-8. In our case, one crankshaft rotation is equal to 4 working strokes. The natural conclusion is that an 8-cylinder engine runs smoother and more evenly than a 6-cylinder engine.

Most likely, you will not need in-depth knowledge of the order of operation of the cylinders of your car's engine. But it is necessary to have a general idea about this. And if you decide to repair, for example, the cylinder head, then this knowledge will not be superfluous.

Good luck in learning the firing order of the cylinders in your car's engine. ©

crank mechanism

- The flywheel maintains the inertia of the crankshaft to move the pistons from the upper or lower extreme positions, as well as to rotate it more evenly.

- The crankshaft converts the linear movement of the pistons into rotation and transmits it through the clutch mechanism to the gearbox input shaft.

- The connecting rod transmits the force applied by the piston to the crankshaft.

- The piston pin creates a hinge connection between the connecting rod and the piston. Manufactured from alloyed high carbon steel with surface hardening. Essentially it is a thick-walled tube with a polished outer surface. There are two types: floating or fixed. The floaters move freely in the piston bosses and in the bushing pressed into the connecting rod head. The finger does not fall out of this design thanks to the locking rings installed in the grooves of the bosses. The fixed ones are held in the connecting rod head due to a shrink fit, and rotate freely in the bosses.

Examples of engine cylinder layout:

a — four-leaf V-shaped six-cylinder; b - four-stroke V-shaped eight-cylinder; c—four-stroke in-line four-cylinder; g - four-stroke in-line six-cylinder.

A single-cylinder four-stroke engine has significant uneven rotation of the crankshaft, which is caused by the fact that during two revolutions of the crankshaft, only one half-turn of the crankshaft rotates due to gas pressure, and three half-turns due to the energy accumulated by the flywheel. Moreover, during the power stroke, the rotation of the crankshaft is accelerated, and during the preparatory strokes it is slowed down, which causes increased engine vibration, which can only be partially reduced due to the significant moment of inertia of the flywheel.

Increasing the uniformity of engine operation can be achieved by increasing the number of cylinders, since this can increase the number of working strokes per revolution of the crankshaft.

4-cylinder boxer layout

In such a motor, the “pots” are placed in two rows at 180 degrees. This allows the power unit to be balanced and the center of gravity to be lower, and the crankshaft receives less load. Thanks to this, a motor of a similar layout, with the same weight, produces more power and speed.

The cylinders in these internal combustion engines operate according to an excellent scheme: the main one is 1-3-2-4, and the alternative is 1-4-2-3.

Here the pistons reach the so-called "top dead center", often abbreviated to TDC, on both sides simultaneously.

Model:

Interesting: there are cars with V-shaped units with 4 cylinders, but such examples on the market are relatively rare, the bulk are in-line and opposed.

Five-cylinder

These are units with 5 cylinders standing in a row. The relative displacement of the crankpins is 72 degrees. There are both two- and four-stroke samples; for the first (2 strokes), the standard order of optimal operation of the cylinder block for these engines is the activation sequence 1–2–4–3–5. This ensures uniform combustion of the fuel. These motors are widely used in marine technology.

On passenger cars, engineers report a different order for the operation of the “pots” of 5-cylinder typical engines - the 1-2-4-5-3 system.

Cylinder block:

What about now?

Contrary to popular belief, 8-cylinder engines are installed not only in luxury foreign cars, but also in ordinary tractors, trucks and construction equipment. As with weaker engines, the most balanced type is the in-line engine type. In other words, when all the cylinders are located in a row. They were used to equip the most expensive cars for a long time. This design was especially appreciated in America. However, the record holders here are the Germans, who highly value the balance and reliability of the in-line engine.

But even they, over time, had to switch to V-twin engines. The reason is simple and banal - the eight-cylinder Python simply did not fit in the standard engine compartment of modern cars.

ICE for 8 cylinders

Due to their dimensions, the engines are made in a V-shaped configuration.

Eight-cylinder internal combustion engine from Chevrolet:

Possible order of operation of an eight-cylinder engine of a modern car:

- option 1–5–4–2–6–3–7–8 – main;

- the principle 1–8–4–3–6–5–7–2 is another variation.

This difference is imaginary and is due to a difference in the number of cylinders. In the USA, cylinder 1 is located in front in the direction of travel of the car, on the left, and in the European system - on the right. The cylinders are numbered in a checkerboard sequence, backwards and left to right, so both classifications represent essentially the same thing, as illustrated by the diagram:

The interval between fuel ignition is 90 degrees.

Operating procedure

This will be the most useful information for the average driver. The fact is that knowing the order of the heart of your car, you can easily adjust the valve clearance or start the ignition.

There is no point in describing the operating procedure of 8 cylinders of an in-line engine, since they are almost never found in passenger cars now. But V-shaped engines have a fairly precise sequence: 1 – 5 – 4 – 8 – 6 – 3 – 7 – 2. The operating cycle interval is 90 degrees (i.e., after 90 degrees of crankshaft rotation, after the first cylinder starts working, the next one starts working (in our case, the fifth one). This interval ensures very smooth engine operation. If you are the happy owner of the diesel giant ZiS, then the order of operation will be slightly different: 1 – 5 – 4 – 2 – 6 – 3 – 7 – 8. As you can see, in any case (this applies to all engines of any cylinder size), the engine’s working cycle begins with first cylinder.

It is worth remembering that the operation of an 8-cylinder V-engine differs from that of a 6-cylinder engine and is performed in an individual manner for each manufacturer. The diagram above is the most general, but not 100% suitable for every car. Even the type of engine modification plays a role.

It is clear that if it is necessary to calibrate the valve clearance, most owners will take their horses to a car service center. And not everyone will undertake to repair the BC head on their own. But if you are a true car fan, then you simply must work on your engine yourself at least once. And knowing how the engine works will greatly help you with this.

How to profitably exchange a used car

To guarantee the legality of the used car exchange service and its objective cost, the purchase and sale process should be carried out at a trusted auto center. Here the client will be offered:

- Diagnostics of the old model, on the basis of which its cost will be determined;

- Selection of cars for exchange, completely new or with a clean mileage history: all cars undergo forensic examination, therefore the car dealership will never sell a car with a “dark past”;

- Legal support of the transaction: the client enters into a notarized agreement and, if necessary, can use the credit services of the car dealership’s partner bank;

- Efficiency of the service: the client does not need to look for buyers for his vehicle; he does not need to settle issues with the traffic police or the bank. The listed functions are the task of the auto center.

Read here! Engine sump

Thus, with minimal documents, it is possible to buy an improved car within one to three days. The used car exchange service makes it possible to regularly change the owner’s vehicle fleet by purchasing its best models.

Possible causes of failure

During the operation of the internal combustion engine, various malfunctions are possible. To detect them, you should perform the following sequence of actions:

- First you need to start the car. The engine should idle. At this time, you should listen to what sounds are coming from the exhaust pipe. If you hear regular popping noises, then one of the cylinders is faulty. The cause may be faulty spark plugs and lack of spark. The malfunction can also be caused by a large amount of incoming air or insufficient compression in the cylinder.

- It is necessary to inspect the candles. If there is carbon deposits, moisture or oxidation, you need to clean it. Check the gap between the electrodes, which should be 0.8 - 0.9 mm.

- Replace all spark plugs, regardless of their appearance and vehicle mileage.

- If there are irregular emissions, you need to inspect the high-voltage wires. There should be no traces of oxidation on their tips, and the insulation should not be damaged. If defects are found, the wire should be replaced.

Wires connecting to the coil - The gas distributor cap should be inspected. There should be no soot or cracks on it. The carbon contact should be checked for damage and wear.

- The rotor needs to be inspected. It must be solid and have no signs of burnout. All parts with defects must be replaced.

- The pressure in the cylinders is allowed to be no lower than 1.1 MPa, and the compression difference should not exceed 0.1 MPa. If the indicators do not correspond, engine repair is necessary.

If after the above steps the problems remain, then you need to contact a service station to undergo a more accurate diagnosis of the VAZ 2109 engine and adjust the ignition system on the stand.