For owners of a VAZ 11183 car, the first “bells” that the Kalina steering rack is in danger of being repaired

, there will be knocks and extraneous sounds from the front suspension. It seems that the steering ends were replaced, the ball joints were changed, even the shock absorbers with support bearings were updated, but the knocking does not go away. So you'll definitely have to check it out and maybe start going through it. The Kalina steering rack repair technology is generally similar to all other front-wheel drive VAZs. The repair kit can be purchased from another model, as well as the rack, only the splined one may differ in length.

Removing the steering mechanism.

- From inside the cabin, unscrew the bolt securing the splined connection. It is located near the floor near the steering shaft. In the future, you won’t have to climb into the salon dirty, so we recommend performing this operation right away.

- We lift the car on a lift, remove the front wheels, knock out the steering tips from the steering knuckles.

- Unscrew the nuts securing the steering mechanism to the body. It is convenient to do this with a ratchet from under the wheel arches; you can remove the lockers if they are in the way, especially since you will have to get the steering mechanism through the fender.

- We remove the battery, as well as the platform on which it stands.

- We unscrew the top nut of the heat-reflecting plate; you will find it behind the intake manifold in front of the passenger seat. We bend the plate towards ourselves and get a space through which you can reach the rail.

- If it was not possible to remove the mechanism from the splined connection of the steering shaft, then you can pry it from the hood side by the body, swing it and then it will be easier to remove it. Disassembling the Kalina steering rack

- Unscrew the adjusting washer.

- We hit the steering rack body against a wooden block and remove the thrust bushing.

- Next, we take out the thrust bushing by hitting the Kalina steering rack body against a wooden block.

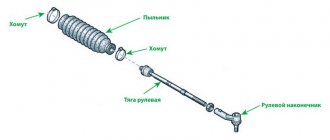

- Remove the boot and side plugs by cutting the plastic clamps.

- Again we hit the body against a wooden block until the drive shaft jumps out of the rack housing, after which the bar comes out of the body.

- Inside the case there is a plastic sleeve, which we take out with a screwdriver and insert a new one.

- We remove the old grease, wash it, blow out the rail and apply fresh lithol, especially lubricate the joints well.

- We tighten the adjusting washer according to the template in the instructions, but in practice we continue to tighten until the steering rack begins to move without play or jamming.

- We reassemble everything in the reverse order, after such repairs it will be necessary to set the toe angle of the wheels.

The steering of any car requires care and timely maintenance. If you make one mistake or inattention, it will affect the car's handling. This is not only and not so much comfort and ease of operation, but our safety and that of those around us. Therefore, if there are signs of inappropriate behavior of the car, you need to seek help. In most cases, this is what owners of cars with a complex and expensive design do, but if we have our own VAZ, then we can do it on our own. Kalina is an inexpensive, reliable and unpretentious car. Like any equipment, it needs care and timely maintenance of the steering system in general, and the steering rack in particular.

Diagnostics and signs of malfunction of the Kalina rack

Before you treat, you need to know what hurts. Before you start repairing the Kalina steering rack, you need to make sure that it is to blame for:

If these signs appear, most likely it is the rack that needs repair, but you can easily verify this - open the hood and pull the steering rod that comes from the rack. If it dangles in the rack housing, everything is clear and further diagnostics are pointless. We go to the store and buy a repair kit for the Kalina steering rack.

Tools and repair kits

To fully repair the steering rack, we will have to completely dismantle it and carry out inspection and defect detection. As a rule, all rubber and plastic parts of the rack will need to be replaced, so in order not to waste time, we’ll take care of the repair kit right away. It should include all rubber seals, anthers, two bearings - needle and ball, and a plastic bushing. This is an incomplete set.

To overhaul the rack, in addition to all of the above, it must also include the steering rack itself and the gear with the shaft. If your steering mechanism is in more or less decent condition, then a small set will be enough, but if you are not sure about this, then you will have to take a full set. But in any case it is cheaper than buying a new rack.

To work, we will need a regular set of tools plus several pullers, which it wouldn’t hurt to have for the future. This is a tie rod pin puller and a standard two-legged puller for pressing out bearings.

Removing the steering rack and disassembling it

Now that we are financially prepared to repair the rack, we should start removing it. To do this, we will clear the area in which the unit is located from dust and dirt, and provide access to the fastening of the rack and steering rods. We propose to carry out the work in this order:

We have the rack in our hands, all that remains is to wash it thoroughly, wipe it and clamp the crankcase in a vice through wooden blocks.

We remove the steering rods, having previously loosened the bolts. It is more convenient to do this with the rack removed, because when installing it back, installing the rods can cause additional trouble. We cut off the clamps securing them to the crankcase from the anthers and remove them, assessing the state of wear. It is better to replace them with new ones during assembly, even if they look decent. Rubber is rubber. After this, the central boot with corrugation will be removed. It is also better to replace it with a new one.

Most likely, the picture you see will be unsightly - the dirt mixed with old grease has done its dirty work, so without despair, we tear the rail apart to the end. Unscrew the bearing cover, remove the spring and metal stop, plastic bushing and all seals. We tried to present this as clearly as possible in the photo.

Correct assembly of the steering rack

All removed parts must be washed and wiped, and those that are in the repair kit must be disposed of. If the rack itself does not look very tired, then you can not remove it, but simply wash it and coat it well right in the crankcase. The same applies to the gear shaft. If the bearing has even the slightest play, it should be replaced using a two-legged puller. A very important point. If you want the steering wheel to be level, you need to align the marks on the rack and the crankcase when assembling, as shown in the figure.

Hello, dear readers of the blog site

.

Today I bring to your attention a detailed photo report on such an event as replacing the Kalina steering rack

(steering rack 2110, 2112 of the new model).

Now it’s June 2014 and the odometer of my car shows almost 170 thousand km, and a year ago, at 144 thousand km, I did it and now drum rolls are coming from the steering mechanism again. I must say that repairing a steering rack is not a pleasant task, and I would like to get rid of the problem for a long time, which is why I decided to replace the entire steering rack of Kalina

.

Strictly speaking, replace

the whole mechanism, in my case, was not necessary.

It was necessary to replace only the rack

(the so-called

“rasp”

) and the plastic bushing in which the right end of this “rasp” moves, but I was unable to buy it separately, so I decided to replace the entire steering mechanism assembly. This is what the rack (“rasp”) looks like when fully extended to the right from the steering mechanism. As you can see, the right end of my Kalina's old steering rack was completely covered in rust.

The cause of knocking noises in the steering rack is a plastic bushing

, fixing the right end of the rail.

When the bushing stops tightly fitting the rack, the latter begins to dangle, making a drum roll on uneven surfaces. I think that after last year’s repair, the bushing on my Kalina became loose due to rust

that covered the right end of the steering rack. Last year, while repairing the steering mechanism, I replaced the bushing, cleaned the rack and lubricated it thoroughly, but after a couple of thousand kilometers the knocking in the rack began to return, and after another 5 thousand, the rack was already knocking no less than before the repair.

Disassembling the steering mechanism Lada Kalina 1117 2004 - 2013

Tools:

- Driver for socket attachment

- Knob attachment 10 mm

- Knob attachment 13 mm

- Tubular socket wrench 17 mm

- Octagon key 24 mm

- Hex key 6 mm

- Jack

- Side cutters

- Chisel

- Large hammer

- Medium flat screwdriver

- Circlip pliers

- Scraper

- Vise

- Mounting blade

- Electric drill

- Bearing puller

- Mandrel

- Beard

Parts and consumables:

- Wood block

- Pipe fastening nut

- Stop nut

- Drill 4 mm

- Gear shaft needle bearing

- Fiol-1 grease

- Roller Thrust Bearing Outer Race

- "Fast steel" or "Cold welding"

- Pipe section

1. In the cabin, unscrew the nut of the bolt securing the lower cardan joint to the steering gear shaft, as described here. Having removed the casing and unscrewing the fastening nuts with a 13mm wrench, remove the steering mechanism.

2. Using side cutters, we cut the clamps securing the steering gear cover and remove it.

3. Remove the steering rod support.

4. We insert the bit into the groove of the crankcase pipe mounting nut. We unscrew the nut, striking the beard (right-hand thread).

5. Remove the crankcase pipe.

6. Use a screwdriver to press out the two clamps of the bushing located inside the pipe.

7. We take out the bushing.

8. Remove the two rubber O-rings from the bushing.

9. The steering rack bushing has two clamps (shown by arrows).

10. If it is necessary to replace the nut, use circlip pliers to unscrew and remove the circlip. Remove the pipe securing nut.

11. Remove the rubber plug from the rack stop adjusting nut.

12. Using a scraper, remove the jammed metal in the locking areas of the stop adjusting nut.

13. Using a special 24mm wrench with an external octagonal head, unscrew the stop nut.

14. We take out the stop spring.

15. Using a screwdriver, remove the sealing ring.

16. By hitting the crankcase against a wooden block, we knock out the rack stop.

17. Using a screwdriver, remove the liner from the stop.

18. A rubber sealing ring is installed in the groove of the stop.

19. Remove the rubber ring from the crankcase that seals the hole for the steering mechanism on the front panel.

20. Remove the boot from the gear shaft.

21. Using a 6mm hexagon, unscrew the two screws securing the crankcase cover.

22. Remove the crankcase cover.

23. Remove the separator with the thrust bearing rollers.

24. Remove the sealing ring of the cover.

25. We remove the rack from the crankcase.

26. We press out the gear shaft by holding the shaft in a vice with soft metal jaw linings and pressing the crankcase upward with the mounting blade.

27. We remove the gear shaft with bearing from the crankcase.

28. Use a screwdriver to pry it off and remove the bushing retaining ring.

29. We take out the gear shaft bushing assembled with the support plate.

30. If it is necessary to replace the needle bearing, use a drill d=4 mm to drill two diametrically located holes in the crankcase so that they extend to the end of the outer ring of the needle bearing.

31. Through the drilled holes, using a rod of the appropriate diameter, we knock out the outer ring of the bearing from the crankcase.

32. Using a puller, we press the ball bearing of the gear shaft with the inner ring of the roller thrust bearing.

33. Use a puller to press the inner ring of the needle bearing off the shaft.

34. Using a screwdriver, pry and remove the gear shaft oil seal from the crankcase cover.

35. If it is necessary to replace the outer ring of a roller thrust bearing, use a scraper to remove the extruded metal in four places and remove the ring.

36. We generously lubricate the bearings, rack and gear teeth, and the plastic rack bushing with Fiol-1 grease.

37. We assemble the steering mechanism in the reverse order. We press the outer ring of the needle bearing into the crankcase using a mandrel of suitable diameter. To seal holes in the crankcase, you can use “fast steel” or “cold welding”.

38. We press the gear shaft with the ball bearing into the crankcase using a piece of pipe of a suitable diameter or a high head, applying force to the outer ring of the bearing. You can press the gear shaft into the crankcase, resting the outer ring of the bearing on the jaws of a vice. Then we put the crankcase on the bearing.

39. We press the crankcase with light blows of a hammer through a wooden block.

40. We press the gear shaft seal into the cover through a mandrel or head flush with the end of the cover.

41. We insert the rack into the steering gear housing. We install the pipe and turn the gear shaft so that the flat on it is located on the right side. We move the rack so that the steering rod support mounted on the rack is located in the middle of the pipe groove. We insert the rack stop, the stop spring and tighten the stop nut. It is recommended to replace the stop nut with a new one. Having adjusted the gap in the engagement of the gear with the rack, tighten the stop nut.

42. After tightening the nut, tighten it.

The article is missing:

- Photo of the instrument

- Photos of parts and consumables

- High-quality photos of repairs

- Repair descriptions

Source: https://wiki.zr.ru/161_Repair_Kalina

Diagnostics of the Kalina steering rack

So, dear readers, by replacing the bushing, repair the Kalina steering rack

It is only worth it if the right end of the rail is in perfect condition. If there is rust on it (as it was for me), then it will act as an abrasive and will “eat” the nylon bushing quite quickly. The right edge of the “rasp” should shine like a mirror, only then it will not break the sleeve.

Check the condition of the right edge of the rack

quite simple. To do this, you need to carefully cut off the plastic clamp that secures the long right boot, then remove this boot and, turning the steering wheel to the left, visually inspect the right end of the rack that has emerged from the body.

I advise you to carry out such a diagnosis

before removing the rack from the vehicle. And in general, if you are going to solve the problem with the rack yourself, then I sincerely wish you to remove and install it only once, because the process of installing the rack is quite complicated and can cause discomfort, especially if it needs to be repeated.

In the article about I already mentioned how to determine that a knock

comes precisely from

the Kalina steering rack

.

To do this, open the hood and give the steering rod a good tug with your hand

.

A serviceable steering rack bushing

will not allow the rods to move even a millimeter, but with a “broken” bushing, the rods will shake.

At the beginning of this video you can clearly see the play of the steering rack after a run of 164 t.km, and at the end - a new steering rack after a run of 3 t.km.

As you can see, there is no play on the new rack. If

On your Kalina,

the steering rods do not hang out

, which means

it is NOT the rack that is knocking

.

We repair the steering rack on Kalina

The serviceability of the steering system of any car is an important safety requirement on the road. Repair of the steering rack on Kalina must be carried out when any suspicious sounds occur. As practice shows, many car enthusiasts are calm about the fact that when turning the steering wheel there is a knocking or creaking noise, but this may indicate that the steering rack is knocking. Repairing the steering rack on Kalina is best done at a service station, but you can do it yourself.

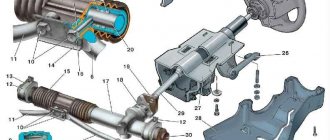

Steering mechanism: 1 – boot; 2, 20 – bolts; 3 – washer; 4 – oil seal; 5 – crankcase cover; 6, 17 – sealing rings; 7 – separator; 8 – drive gear with bearing; 9 – steering rack; 10 – left protective cap; 11 – rod support; 12 – bracket; 13 – plug; 14 – stop nut; 15 – stop spring; 16 – retaining ring; 18 – rack stop; 19 – stop liner; 21 – locking plate; 22 – cover plate; 23 – clamp; 24 – protective cover; 25 – right protective cap; 26 – steering gear housing

Design Features

The steering system of the Lada Kalina includes an electric power steering and a steering column that is adjustable in height and tilt. The steering mechanism is a steering rack with a variable transmission ratio. The rack engages with the engine crankcase through a gear having helical teeth, the pitch of which varies along the length of the rack. The figure shows the design of the Kalina steering rack.

The steering rack on Kalina is pressed against the gear by a spring. Friction is reduced by a plastic insert. The spring pressure is changed with an adjusting nut (the factory-set gap between the rack and the shaft is 0.1 mm). The second end of the rail rests against a plastic sleeve. Adjusting the gap helps eliminate knocking noises.

Replacing the Kalina steering mechanism assembly

So, dear readers, I will describe how I changed the Kalina steering rack

assembled. The day before, after calling a couple of stores, I found out that a regular original 4-turn rack would cost me 4 thousand rubles, and a version of a factory 3.1-turn rack would cost no less than 4,700 rubles. Heading to the store, I intended to buy a 3.1-turn rack, but on the sales floor I suddenly realized that the sporty ambience of the 3.1-turn rack was of no use to me, and the standard factory 4-turn rack suited me completely. In addition, I was also pleased with the opportunity to save money; in general, an original factory 4-turn rack was purchased, identical to that installed from the factory.

If anyone doesn’t know, then 4 revolutions is the number of revolutions of the steering wheel from the extreme right position to the extreme left and vice versa. My car is not equipped with an electric power steering, so with a 3.1-turn rack, turning the steering wheel would be somewhat more difficult than with a 4-turn rack. But with a 3.1-turn rack, the steering wheel becomes more sensitive, for example, less steering movement is required to avoid obstacles. We can say that the rack is 3.1 turns

more

suitable for drivers with a sporty driving style

.

Original steering mechanism

It’s not sold without tie rods, so I had to buy all this stuff as a set, although

I still need to replace

the tie rod ends The steering tips

on the new rack, by the way, differ from the “native” Kalinov ones, with which there are difficulties when adjusting the camber. The rail I bought was equipped with 10's lugs, which made me personally very happy. But this time I still won’t change the steering rods and ends; we’ll talk about this some other time.

When buying a new rack assembly, I prepared in advance to completely disassemble it and thoroughly lubricate it

, because

for some reason they save lubricant at AvtoVAZ

.

If you are not interested in additional lubrication of the rack, then you can skip this moment, otherwise I recommend that you disassemble the new rack

and lubricate it

in advance

, before removing the old rack from the car. For example, no matter how hard I tried, I couldn’t unscrew the stop nut on the new rack - the key failed, and I couldn’t go get another key, since by that time the car was already without a steering mechanism.

The tool that I used when replacing the Kalina steering rack

, described in more detail in the article about, you can look there, here I will only give a photo.

If you disassemble and lubricate the new steering mechanism

, then you will need

nylon ties

to secure the rubber boots of the rack.

The length of plastic ties should be at least 28-30 cm

.

Since the steering rods

I’m leaving the old ones for now, but I’ll put the new ones aside for now. To remove them from the new rail, I use a powerful wrench with a 15mm head and reinforced with a half-meter piece of steel pipe.

As you can see, the bushing

in the new factory rack it works almost “dry”.

On the side of the worm shaft the situation is somewhat better, but it wouldn’t hurt to add lubricant here too, especially from below, where the rack

stop presses

against the worm .

No matter how hard I tried, I could still unscrew the rack stop nut

I never succeeded.

The key that helped me out during last year's repairs, this time lost its position and began to bend at the junction with the octagon. Either the key had softened since last summer, or AvtoVAZ had tightened the nut too tightly, but I only managed to unscrew it half a turn. At the same time, the old steering rack

had already been removed from the car and options such as going for a new key or postponing repairs did not suit me.

In general, I tightened the nut to the maximum, loosened it 2 notches (as required by the instructions) and decided to lubricate the rack without completely disassembling it

.

Turning the worm shaft first in one direction and then in the other, I filled the rack with half a tube of lithol inside, so much so that it began to climb out of there. This is what happened.

Great! New steering rack for Kalina

It is prepared for use and can be installed on a car. The removal and installation process is described in detail in the article on, let’s repeat briefly. First of all, we remove the battery and the pad under it, disconnect the pad from the wires screwed to it, which are secured with a tricky clamp (pictured on the right).

It is advisable to clean the nuts securing the rack to the engine shield from dirt and spill it with “Vedashka” or kerosene in advance. This is a very important point!

These nuts must be unscrewed

with great care

, without applying force, otherwise you can easily twist the pin welded to the body and then replacing the rack can become a big problem.

You will have to look for a suitable bolt, drill a hole in the body and insert the bolt from the inside. In general, be careful when unscrewing and tightening the four nuts that secure the steering gear to the body

!

Removing the locking plate

and with a powerful wrench with a 15mm head, unscrew

the steering rods

from the rack.

It’s good if by this point the penetrating lubricant has already done its job, because now it’s time to unscrew the steering rack from the engine shield

.

I remind you: you need to do this literally with two fingers

, without any extra effort. If it doesn’t work, then it’s better to clean the threads again, spray with WD-40 and wait a couple of minutes.

Unscrewing the steering gear

from the engine shield, go into the cabin and completely unscrew

the bolt

that tightens the flange of the elastic coupling of the steering shaft.

Flange

to loosen it

with something , then it will easily detach from the steering shaft. You can loosen it, for example, with a powerful screwdriver or a small pry bar.

Now, carefully move the steering mechanism

from the engine shield, trying to disconnect it from the steering shaft. If the flange tightening bolt is unscrewed and the flange is loosened, then this will happen easily and naturally.

Having disconnected the rack housing and slightly raised the left front wheel with a jack (it is not necessary to lift it off the ground), we remove the steering mechanism through the opening in the wheel arch. If you do this in the garage, then leave at least a meter of free space

to the left of the left front wheel.

Here it is - the original steering mechanism

, installed on the car at the plant in Togliatti.

We remove the fastening parts and move all this stuff to the new steering rack

.

New steering rack

ready for installation on the car.

Through the same opening in the left front wheel arch we place a new steering mechanism

into the engine compartment and install it in place. And here, dear readers, is where the fun begins. If you work together, then it will be easy for you to connect the rack with the steering shaft, but doing it alone is quite difficult, but I will now explain to you how to proceed in order to do everything quickly and keep your nerves in order.

Leaning against the steering gear

to the engine shield, lightly tighten the lower nuts securing the

steering rack

to the body. Do not tighten the upper part of the fasteners; let the body hang freely on the lower nuts.

To make the splined part of the worm shaft easier to connect with the steering shaft flange, I recommend that you lightly lubricate the connection point with some thick lubricant (for example, lithol), this way the parts will connect much more readily.

the steering rack removed

Kalina's steering column has free longitudinal movement. To make it easier to connect the elastic coupling flange with the rack shaft, I pulled the steering wheel towards me and it moved a couple of centimeters into the cabin.

Now, using a screwdriver, we combine the rack shaft and the flange of the elastic coupling of the steering shaft. Attention! The flange slot should be approximately in the middle of the ground part of the rack shaft.

This is the only way you will be able to fix the flange with a coupling bolt and not damage the thread of this bolt.

Don’t worry about the position of the steering wheel; it’s easier to move it later to the desired position than to try now to guess the correct position of the flange on the shaft. When the shaft engages the flange of the elastic coupling, turn them so that the groove on the shaft is vertical

.

As you can see, the rack shaft and coupling flange are at an angle to each other, which is why it is difficult to align them. We solve the problem this way: use a screwdriver or a small pry bar to tilt the flange, trying to align its axis with the axis of the rack shaft

. It all looks something like this:

When the coupling flange is on the same axis with the rack shaft, you can lightly hit the center of the steering wheel and the elastic coupling flange will slide onto the steering rack shaft.

.

Check. The shaft should fit into the flexible coupling flange clamp like this.

As soon as the Shaft is in place, return to the engine compartment and tighten the upper nuts securing the rack to the body. Attention! Be careful when tightening these nuts!

Don’t forget,

it’s better to under-tighten them than to over-tighten them!

If it was not possible to align the shaft with the flange the first time, then you need to try again and then everything will definitely work out. And here's another little tip: when you tighten these nuts, lubricate the protruding part of the threads of the studs with grease. Then the studs will not sour even after several years, and you can always unscrew the rail without tearing off the studs.

Now is the important moment

! If you now try to tighten the flange coupling bolt with a wrench, you can easily damage the threads on it, and this will certainly happen if the bolt does not fit into the recess on the shaft. This is exactly what happened to me, so I had to tighten the flange with a thinner bolt and nut and then go to the spare parts store. The ball joint mounting bolt from the classics turned out to be suitable; it cost 5 rubles, so I bought several in stock at once.

So, if you want to avoid this annoying nuisance, then make sure that there are no obstacles in the way of the coupling bolt. Firstly

When the flange is connected to the shaft, the notch of the steering shaft must be in the right place - where the pinch bolt will be located.

And secondly

, push the steering wheel away from you so that it presses against the plastic trim of the steering column, it should look like this:

In this case, the flange will fit onto the steering gear shaft as much as possible:

Now you need to tighten the coupling bolt, but only by hand. There is NO NEED to tighten it with a wrench!

To avoid damaging the threads of the flange coupling bolt, it must be tightened by hand, without using a wrench.

If everything is done correctly, the bolt will tighten without problems. If something interferes, then you need to eliminate the cause, otherwise you will only damage the thread, and you still won’t be able to tighten the bolt.

Now that the bolt is tightened, but not yet tightening the flange, you need to push the steering wheel back towards you so that a gap will form under it again, otherwise the steering wheel will rub against the steering column cover with a squeak. So, with both hands, pull the steering wheel towards you, you can even pull it slightly.

Everything worked out? Great! Now you can tighten the coupling bolt with a spanner.

At the next stage, using a meter wrench with a 15mm head, we fasten the steering rods to the rack and do not forget to install a locking plate over the bolt heads.

Finally, here's the new steering rack.

installed on the car, which means that now is the time to check its condition by pulling its “whiskers” with your hand. The steering rods must remain motionless, no matter how you try to move them.

Then you can collect everything and put it in its place. We install the platform under the battery and screw the wires to it from below. We screw the thermal protection to the body, put the air duct in its place and tighten it with clamps. We install the battery, connect all the connectors, if for ease of operation you disconnected them.

The result of replacing the Kalina steering rack

Great! Now you just need to do a test drive. Take a marker with you to mark the highest point on the steering wheel when driving in a straight line. Returning to the repair site, we will move the steering wheel so that it faces straight.

So, sea trials. Having closed the garage, I pulled out onto the road and noticed that, out of habit, I was avoiding small bumps and politely slowing down in front of them. Having made a heroic effort on myself, I literally forced myself, without slowing down, to direct the car onto the side of the road covered with coarse gravel, and here was the long-awaited feeling of satisfaction: the roar had disappeared, the car went smoothly, methodically handling the unevenness with the suspension, but in the cabin it was practically inaudible .

I really hope that the well-lubricated and hermetically sealed new steering rack on my Kalina will last at least 3 years (for me it’s 75 thousand km), and after that I’ll definitely take it apart, wash it, lubricate it and replace the rubber covers, but only if The “rasp” will not rust.

Steering rack repair and diagnostics

The steering rack (steering gearbox) transmits force from the steering wheel to the wheels through rods.

The tie rod is one of the main parts of the steering system. There are three types of steering racks: Malfunctions associated with the steering rack can be indicated by knocking noises when turning, and the force required to turn the steering wheel also increases. It is quite difficult to check the condition of the steering rack due to its inaccessibility. To check the steering rack, you have to disassemble the entire steering mechanism.

How to put the steering wheel straight on Kalina?

After repairing or replacing the steering rack, it is not always possible to position the steering wheel so that it faces straight, so many car enthusiasts have a question: how can Kalina place the steering wheel straight?

Indeed, when the steering wheel is straight when driving in a straight line, it is not only pleasant, but also convenient. It's just easier to hold on to.

To then set the steering wheel straight

, first, while driving in a straight line, make a mark at the top point of the steering wheel, and when you arrive at the repair site, position the steering wheel so that this point is at the very top. Next, pull the central part of the steering wheel towards you, it will detach and end up in your hands.

The horn terminals must be disconnected, the central part of the steering wheel can be put aside.

Using a 24mm wrench, unscrew the nut securing the steering wheel to the steering shaft.

Don't forget to mark the position of the steering wheel relative to the shaft with a marker.

Now we take the steering wheel with both hands (at 9 and 3 o’clock) and, alternately shaking each hand towards and away from us, carefully remove the steering wheel from the splines of the steering shaft. As soon as the steering wheel is removed from the splines, turn it to the position you need (that is, put it straight) and put it back on the splines. Now, when driving straight, your steering wheel will also point straight.

My steering wheel was slightly skewed to the right, so I moved it one slot to the left, like this:

Is it necessary to do a wheel alignment when replacing the steering rack?

In conclusion, I would like to discuss with you this question, which is probably asked by everyone who is going to replace or repair the steering rack: is it necessary to adjust the wheel alignment after repairing or replacing the steering rack?

There is an opinion that this must be done; personally, I believe that

the wheel alignment angles

are NOT violated

during such repairs , and therefore

it is not necessary to adjust them

. When replacing a steering rack, as well as when repairing it, the suspension geometry does not change in any way; the steering rods are unscrewed from the rack and then screwed back, while all dimensions remain the same.

It’s another matter if, when replacing the steering rack, you also change the steering rods

assembled or at least

the steering ends

.

In this case, it is unlikely that you will be able to accurately adjust the length of the new steering rods, and therefore adjusting the

wheel alignment angles is simply

necessary

.

In this article we looked at the option of replacing a rack without tie rods and tips, and therefore the procedure for replacing Kalina tie rods

will be discussed in a separate article.

Replacing the Kalina steering rack. Results

So is it worth repairing the steering rack on Kalina?

(ten, twelve, etc.) or is it better to replace it right away? Let's summarize which option is better to choose and in which case.

- If the right end of the rack is covered with rust

, then it is useless to change only the bushing; the rasp itself must also be changed. If you come across a rack that is sold separately, then replace this rack and bushing. If you can’t buy a “rasp” separately from the body, then replace the entire steering mechanism assembly, it’s easier. - If the rack is clean, without traces of rust

, then feel free to change the bushing, stop and central protective cover (corrugation), and at the same time thoroughly lubricate the insides of the steering rack. With this kind of prevention you can save several thousand rubles, and how to perform this repair, read the article

That, my friends, is probably all! At the moment, I am satisfied with the repair of Kalina's steering rack (I've been driving with the new rack for a week), the results are exactly what I expected. I only hope that the effect will last for a long time, because I don’t plan to remove the rail again in the near future - this is a very dreary task.

Dear readers! I hope this material will help save your time and effort and I wish that the steering rack on your car will run for a very long time and never knock at all! See you soon in the next articles!

PS Today is January 29, 2015. Mileage 200 t.km. The steering rack is in order, there are no extraneous sounds.

Due to wear of individual parts or breakdown, repair of the Kalina steering rack may be required. A driver who closely monitors the technical condition of the vehicle will pay attention to the slightest malfunction. These include:

- knock;

- too tight;

- inability to change the position of the car's wheels in space.

If you quickly diagnose the problem, the repair will be quick and inexpensive.

Repair of electric power steering rack Lada Kalina: photo, video

Every Lada Kalina car owner will sooner or later be faced with the problem of steering rack failure and repair. Of course, experts and auto mechanics recommend changing this element, but not everyone can buy this element, so repair is the way out.

about repairing the steering rack on Lada Kalina:

The material will tell you how to repair the steering rack, give basic recommendations and assembly features.

Signs of a faulty steering rack

Steering rack repair kit

Before you begin repairing an element, you need to accurately determine that it is the steering rack on your car that has failed. For this, there are indirect and direct signs that will indicate the part. Of course, it is best to carry out diagnostics at a specialized car service center, but you can try with your own hands, for example, tighten the steering rack, but here you need to act carefully.

So, let's look at the main signs of a faulty steering rack:

All these signs are direct if the steering rack is faulty, which will be the first signs that the element needs to be diagnosed and repaired.

Causes of malfunction

General view of the steering

There are not many reasons for steering rack failure, but you need to know them. Timely maintenance, as well as diagnostics of the unit, can extend the life of the element.

Let's consider the main causes of steering rack malfunctions:

- Wear of elements that make up the rack.

- Damage due to an accident when the impact hit the wheel.

- Other reasons that caused the rack to start leaking.

All these reasons become the reason for repairing the steering unit.

Design characteristics

In order to repair the steering rack, you need to know its design and the elements that make up it. Let's look at the design diagram of the unit:

Steering rack diagram

Steering rack parts: 1 – rack bushing ring; 2 – rack support sleeve; 3 – steering gear housing; 4 – roller bearing; 5 – drive gear; 6 – ball bearing; 7 – retaining ring; 8 – protective washer; 9 – sealing ring; 10 – bearing nut; 11 – lock washer; 12 – boot; 13 – rack; 14 – protective cap; 15 – rack stop; 16 – sealing ring; 17 – retaining ring; 18 – stop nut; 19 – clamp; 20 – protective cover; 21 – inner tie rod end; 22 – connecting plate; 23 – locking plate; 24 – bolt securing the rod to the rack; A - mark on the boot; B - mark on the crankcase

What will be needed for repairs?

For restoration work related to the steering rack, a repair kit will be required. Usually, they cannot be found in specialized stores, and car enthusiasts, as a rule, go to the car market, where they can purchase a set of spare parts. In terms of price, this is much cheaper than buying a new rail.

The steering rack repair kit can be purchased either individually or as an assembly.

Repair kit for steering rack manufactured by Ricardo

2110-3403090-11 is the catalog number of a complete steering gear repair kit for the Lada Kalina. You can buy bushings and plastic inserts separately, but it is not recommended, since the quality of the products may be different, and accordingly, the wear on the left and right sides may differ.

Dismantling and disassembling the rack on Lada Kalina

When all the materials for repairing the steering rack have been collected and purchased, you can proceed directly to the repair operations.

Before you begin, you need to completely clean the steering rack. This can be done manually, but it is best to use a steam mechanism under pressure, which will efficiently remove dirt and dust from all elements without damaging the parts.

Now, let's proceed to sequential operations to repair the steering rack:

- We place the brake shoes under the rear wheels and remove the handbrake.

We put the shoes under the wheels - Unscrew the bolt that secures the steering shaft.

Removing the coupling fixing bolt - Remove the cotter pins from the nuts securing the tie rods to the steering knuckle.

We remove the cotter pins using pliers - Unscrew the pin nuts and press them out.

If you can’t remove it by hand, you should use a pry bar and a hammer. Removing tie rod ends using a hammer and crowbar - Disconnect the EUR from the on-board network.

Disconnecting the EUR connector from the on-board network - We unscrew the fastenings of the rack housing to the car body.

Removing the steering rack mounts - Without dismantling the steering rods, we pull out the rack through the arch.

We dismantle the steering rack through the wheel arch - We unscrew the bolts securing the rods to the rack and dismantle them.

- Cut off the boot clamps.

Cut off the boot clamps using wire cutters - Unscrew the EUR mechanism and remove the cover. Most likely, the picture will not be the best, since dirt got into the boot and spread all over the rail.

- Unscrew the bearing cap and pull out the spring.

Removing the rack crankcase cover

Correct fault determination

- The right edge of the rack should shine, otherwise a steering rack repair kit is needed.

- The presence of even the slightest traces of rust, which will act as an abrasive material, is not allowed.

- You should check the integrity of the bushing: if it knocks or shows signs of wear, it needs to be replaced.

- It is necessary to carefully inspect all the fasteners: if places with loose clamps are found, tighten them.

You need to be very careful with the last factor. Excessive physical force will only do harm here. If you decide to diagnose and replace it yourself, you must use lubricant and a wrench. A heavily threaded bolt or nut simply requires the use of oil. In some cases, it can be moved 1-3 divisions, but do not despair. This is enough for a visual inspection.

If no signs of physical wear or rust are detected, you can return the nut to its place with your own hands. This will require a wrench and extreme concentration. Carefully pull the element to the desired level and fix it. There is 1 practical tip associated with the mentioned element: when driving intensively, you need to tighten the steering rack nut every 6 months.

There shouldn’t be any difficulties, because information on how to tighten the part is contained in the vehicle’s operating instructions.

How to fix a steering rack

Repairing a steering rack is not the easiest thing.

Removing and installing the rack is very labor-intensive; some difficult points must be mentioned in advance. This, for example, is where the rack attaches to the steering column. To repair the rack, you will need a steering rack repair kit 2110. The main task is to replace the rack stop and bushing, this will get rid of play and noise when overcoming small potholes.

For repairs we will need: the rack stop and bushing, the rack stop O-ring, the stop nut. You will also need a central corrugation; it is very likely that you will have to change it.

Before unscrewing, we wet the rack fastening studs with a wedge, otherwise they can be turned out. Always be aware of the dangers of twisting those studs! Otherwise you will have to drill through the engine compartment cover!

The inside of the rack may be rusty or extremely dirty; in this case, it needs to be washed with diesel fuel or gasoline.

When you assemble the rack, you will have to actively lubricate it, so it is better to buy lubricant in advance, preferably FIOL.

After removing the rail, you need to cut off the clamps; the clamp attaching to the body does not need to be removed, but we remove the other one with an elastic band. You can also remove the gasket, which is located at the point of contact between the rack and the hole in the engine shield.

Next you need to remove the anthers. Soak the stop nut in kerosene and remove the worm shaft. If this fails, you can try to lubricate everything inside without completely disassembling it.

After this, we begin to try to unscrew the stop nut, and you will need a good wrench. Next, we take out the spring, as well as the rubber band, turn it over with the hole down and hit it on some piece of wood to get the stop itself.

Next, we take out the old steering rack bushing. To do this, you need to bend the two protrusions and use a wire to pull the sleeve out of the body.

After you take out the rail, you need to wash it; the same diesel fuel will do for this. Also, it needs to be cleaned of grease and dirt.

To perfectly clean the rack, you can blow it out. In this case, you need to rotate the worm shaft. This will allow dirt to be blown out from the back.

After these procedures, everything needs to be lubricated and assembled. Lubricate the worm shaft by turning it.

It is necessary to generously lubricate the gear part, because... This is where the main friction lies. Next, we lubricate the ends of the rail; after lubricating it, check how it fits; only if this happens with some effort, it will stop making noise.

Next, remove the bushing from the rack and insert it into the housing, which has been lubricated in advance. Watch the locking tabs on the bushing.

You need to tighten the bolt that attaches the rods to the rack, position the body so that the bushing faces down, and place the rack on it.