Not a single internal combustion engine can function without proper cooling, and the VAZ 2107 engine is no exception in this sense. If problems occur in the cooling system, then overheating of the engine is a matter of a few minutes. Often the source of problems is the fan switch sensor. Fortunately, the car owner can easily replace it with his own hands. Let's try to figure out how this is done.

- Designs and principles of operation of sensors

Electromechanical sensor VAZ 2107 - Electronic sensor VAZ 2107

- Sensor location

- Sensor test sequence

- Operating procedure

Purpose of the VAZ 2107 fan switch sensor

It is easy to guess the purpose of the sensor from its name. This device is responsible for the timely activation of the fan blowing the main cooling radiator.

VAZ 2107 fan sensors have a monolithic body and small dimensions

Additional airflow is required when the antifreeze in the radiator heats up to a temperature above 90°C and the engine stops cooling normally. As a rule, this happens in the warm season when driving around the city or on country roads.

Instructions for removing and replacing the power supply with your own hands

To replace the DTOZH, you need to do the following:

- Open the hood and find the controller. Disconnect the terminals with wires from the battery.

- Antifreeze should be drained from the power unit cylinder block. The liquid is drained until its level is below the sensor installation location.

- Next, you will need to slide the protective cap on the connector and also disconnect the wire connected to the sensor.

- Using a 21mm wrench, you need to unscrew the device and pull it out of the seat. It is more convenient to use a spark plug wrench or socket for this purpose.

- Dismantle the device and replace it with a new one; further assembly is performed in the reverse order.

Designs and principles of operation of sensors

Over the years, various models of fan switching sensors were installed on VAZ 2107 cars. At first these were electromechanical sensors, then they were replaced by electronics. Let's take a closer look at each device.

Electromechanical sensor VAZ 2107

Inside the electromechanical sensor there is a small container with ceresite mixed with copper powder. Above this substance there is a flexible membrane with a pusher attached to it. And the pusher, in turn, is connected to the moving contact. This entire structure is housed in a steel case with thick walls (which are necessary to ensure more uniform heating of the sensor). On the outside of the housing there are threads and a pair of electrical contacts.

The operation of the VAZ 2107 electromechanical sensor is based on the expansion of ceresite under the influence of high temperature

The sensor operates on a simple principle: the volume of ceresite changes with increasing temperature. Ceresite, heating up under the influence of almost boiling antifreeze, expands and raises the membrane, which sets the pusher in motion. It reaches the moving contact and closes it, which causes the fan to turn on. When the temperature of the antifreeze drops due to additional airflow, the ceresite cools down, the membrane goes down, the contact opens and the fan turns off.

Electronic sensor VAZ 2107

The basis of the electronic sensor is a thermal resistor inserted into a massive steel housing. As in the previous case, the body has a thread that allows you to screw the sensor into the radiator, and a pair of contacts.

The main element of the VAZ 2107 electronic sensor is a thermistor

The operation of the electronic sensor is based on a change in the resistance of a resistor under the influence of high temperature. Changes in electrical resistance are monitored by a special circuit. And when the resistance reaches certain values, the circuit sends a signal to the contact system, they close and turn on the fan.

Sensor location

On almost all classic VAZ models, fan switching sensors are screwed directly into the cooling radiators. This is necessary so that most of the working surface of the sensor comes into contact with hot antifreeze. A special sealing gasket made of material resistant to high temperatures must be installed between the sensor and the radiator.

The red arrow indicates the VAZ 2107 fan sensor, the blue arrow indicates the O-ring under it

Since the VAZ 2107 fan sensor is screwed into the lower part of the main radiator, it is most convenient to change it from the inspection hole on which the car must be installed.

DIY replacement instructions

To replace the sensor, do the following:

- First, open the hood and disconnect the battery.

- Remove the coolant expansion tank cap and unscrew the cap from the radiator unit. This will prevent the formation of high pressure in the system.

- Next, place a container under the radiator assembly - the antifreeze will pour into it after removal. Turn off the tap and wait until the liquid drains.

- When these steps are completed, you will need to disconnect the wiring connector from the device. Next, using a 30mm wrench, you will need to unscrew the sensor and remove it from its seat. When dismantling, do not lose the steel seal, and before further installation it will be necessary to treat the installation site with sealant. It is important that the sealant itself is high-temperature - treating the seat with it will prevent leakage of consumables.

- When the device is installed, it is necessary to reinstall the plug on the radiator assembly. Further assembly is carried out in the reverse order - first you need to fill in the coolant, then connect the battery terminal.

- To diagnose the performance of the device, you need to start the power unit and warm it up to operating temperature so that the fan turns on.

Photo gallery “Changing the sensor ourselves”

Checking the functionality of the VAZ 2107 fan sensor

To check the serviceability of the fan switch sensor on a VAZ 2107, you will need the following things:

- container for boiling water;

- thermometer;

- household boiler;

- fan switch removed from the machine;

- household multimeter.

Sensor test sequence

The sequence for checking the sensor is as follows:

- Water is poured into the prepared container.

- The threaded part of the sensor is immersed in water, and its contacts are connected to the contacts of a multimeter configured to test electrical resistance.

- Now the thermometer and boiler are immersed in water.

- The boiler is turned on and the water begins to heat up. The heating temperature is monitored by a thermometer.

The VAZ 2107 sensor is immersed in a container of water and connected to a multimeter - When the water temperature reaches 95 degrees, the sensor resistance should disappear (this will be visible on the multimeter display).

- If at the above water temperature the resistance disappears, the fan switch sensor is considered to be working.

- If the sensor maintains resistance when heated above 95 degrees, it is faulty and must be replaced.

Video: checking the serviceability of the VAZ 2107 fan sensor

https://youtube.com/watch?v=FQ79qkRlLGs

Description of the coolant temperature controller

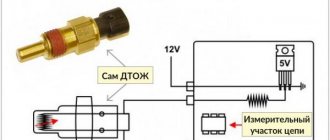

The temperature sensor is a resistor element that performs the function of transmitting and receiving data about the temperature of the consumable in the cooling system. As the temperature increases, the sensor's resistance changes, causing it to supply voltage to the instrument panel. The latter has an indicator that shows to what temperature the car’s power unit has warmed up. Where is DTOZH located? The device is located on the cylinder head, behind the fourth cylinder.

In injection machines, the DTOZh gives the ECU temperature readings, and the ECU turns on the fan itself, the fan switch on sensor, as a rule, is a power sensor, closes the contacts at a certain temperature - turns on the fan relay and is located mainly on the radiator (in a carburetor car), since the DTOZH is located on the engine.

Principle of operation

The principle of operation of DTOZH is the constant interaction of a magnetic field (constant) with the field of measuring devices. Voltage passes through all windings. The permanent magnet is connected to the indicator located in the dashboard. When the temperature changes, the resistance parameter of the device also changes, which leads to the oscillation of the needle.

Possible problems and methods for eliminating them

What malfunctions can occur in the operation of the device:

- The sensor has failed. This problem can be solved by replacing the controller with a functional one.

- The contact on the connector connecting the device to the on-board network is damaged. Also, the contacts may be oxidized. In case of such a malfunction, you can try to clean the contacts, but if their damage is very severe, then it is better to replace the connector.

- The device may stop working due to a damaged electrical circuit. It is necessary to diagnose the condition of the wiring with a tester; if the circuit is truly damaged, then the faulty section must be repaired or replaced.

Regulator diagnostics

To check functionality, you need to perform the following steps:

- First you need to warm up the power unit so that the temperature of the internal combustion engine increases to 90 degrees. After this, the engine can be turned off.

- Next, the ignition is activated and the car's capo opens.

- You need to disconnect the tip of the wire with the measuring device, and then short it to the motor housing.

- If, as a result of the actions performed, the sensor arrow on the control panel began to deviate to the right, entering the red zone, this indicates a breakdown of the controller. If the arrow does not move, then most likely there is an open circuit in the connection circuit.

The easiest way to check for an open circuit: on a working engine, remove the chip from the DTOZH, if everything is normal and there is no break in any circuit, then the fan will turn on at maximum speed (video shot by Dmitry Makarov).

Malfunctions associated with the VAZ 2107 fan sensor

There are a number of the most common problems due to which the fan on the VAZ 2107 may not turn on at the right time, which will lead to engine overheating. Here they are:

- The fan switch sensor is burnt out. Most often this happens due to a sudden surge in voltage in the machine's electrical network, resulting from a short circuit. The electrical wiring on the VAZ 2107 has never been durable or reliable. Over time, it begins to crack and becomes completely unusable, which leads to a short circuit;

- The fuse for the fan has blown. There are situations when the fan sensor is working, but the fan still does not turn on. In this case, you need to look into the safety block located under the steering column of the car and find there the fuse responsible for the operation of the fan, remove it and inspect it. If it is melted and slightly blackened, the cause of the malfunction has been found.

Arrow 1 shows the location of the VAZ 2107 fan fuse. Arrow 2 shows the location of the fan relay

Unpleasant surprises from engine maintenance

Diagnostics and replacement of the oil pressure sensor

Hello. Today I want to talk about the coolant temperature sensor and the malfunctions associated with it. Picture from free access to the Internet.

DTOZH, Picture from free access to the Internet.

Brief information: The coolant temperature sensor (TES) is an important element of the electronic engine control system (ECM). The sensor is designed to measure engine temperature. Based on a signal from this sensor, the ECM, according to the program embedded in it, controls the fuel supply, adjusts the ignition angle, turns the engine cooling system fan on and off.

Structurally, the sensor is a thermistor that has a negative temperature coefficient, i.e., as the temperature increases, its resistance decreases. The thermistor itself is placed in a heat-conducting housing with a thread. A plastic connector with 2 thermistor leads is built into the case.

DTOZH design. Picture from free access to the Internet.

The sensor must have direct contact with the coolant.

Location of DTOZH. Picture from free access to the Internet.

In fact, this seemingly simple sensor can bring a lot of unpleasant moments to the car owner.

Symptoms of a malfunction of this sensor may be the following:

- jerking and jerking when the car is moving;

- increased fuel consumption (black carbon deposits on spark plugs);

- increased idle speed;

- poor starting when hot, and in some cases also when cold;

- engine overheating due to incorrect DTOZ values.

The most common reasons: a break inside the DTOZh or the wires leading to it. In this case, the engine malfunction lamp comes on, error: “Engine temperature sensor circuit malfunction.”

But there are also more insidious reasons: the DTOZh can give incorrect readings on the coolant temperature, that is, show a temperature lower than it actually is. For example, it can lower the temperature by 10-15 degrees. In this case, the fault lamp does not light up. The ECM does not send a signal to the engine cooling fan relay in time. The coolant level in the reservoir begins to rise, which can lead to engine overheating. In this case, only the indicator on the instrument panel can show the real temperature. In this case, you can remove the DTOZH, heat it separately in a kettle and measure with a tester how its resistance changes according to the table.

Table of resistance versus temperature. Picture from free access to the Internet.

But it’s better to buy a new one, since these sensors are inexpensive.

The next problem is poor starting on a cold engine. In this case, the error does not appear either. The temperature sensor, on the contrary, shows too high a temperature. For example, the outside temperature is -10 degrees, but the sensor shows +25 degrees. With such a difference, the engine may not start at all. It simply doesn't have enough fuel to start. Many times such cars were dragged on a cable. When you connect the scanner, everything becomes clear.

I hope the article will be useful to diagnosticians and car enthusiasts.

Sources

- zen.yandex.ru/media/zametki_avtodiagnosta/nepriiatnye-siurprizy-ot-dtoj-dvigatelia-5dc312b1e4fff000aed09f35

- osensorax.ru/klimat/datchik-temperatury-vaz-2107

- drive2.ru/l/495297553793810928/

- zapchasti.expert/datchiki/datchik-temperatury/datchik-temperatury-vaz-2107.html

- bumper.guru/klassicheskie-modeli-vaz/sistema-ohdazhdeniya/datchik-temperaturyi-ohlazhdayushhey-zhidkosti-vaz-2107-inzhektor.html